Download - Mammoet BV

Download - Mammoet BV Download - Mammoet BV

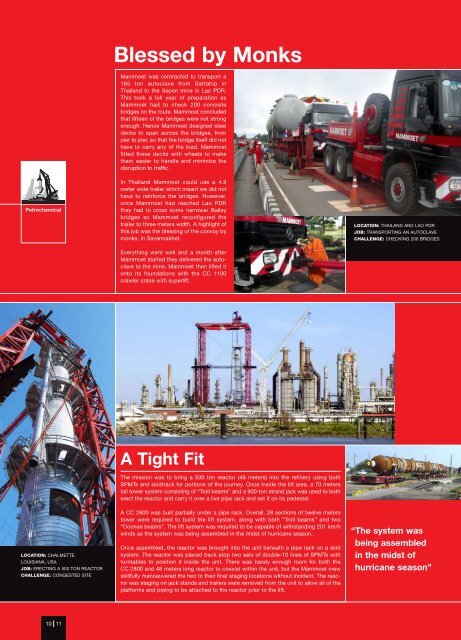

Petrochemical LOCATION: CHALMETTE, LOUISIANA, USA JOB: ERECTING A 500 TON REACTOR CHALLENGE: CONGESTED SITE 10 11 Blessed by Monks Mammoet was contracted to transport a 165 ton autoclave from Sattahip in Thailand to the Sepon mine in Lao PDR. This took a full year of preparation as Mammoet had to check 200 concrete bridges on the route. Mammoet concluded that fifteen of the bridges were not strong enough. Hence Mammoet designed steel decks to span across the bridges, from pier to pier, so that the bridge itself did not have to carry any of the load. Mammoet fitted these decks with wheels to make them easier to handle and minimize the disruption to traffic. In Thailand Mammoet could use a 4.9 meter wide trailer which meant we did not have to reinforce the bridges. However, once Mammoet had reached Lao PDR they had to cross some narrower Bailey bridges so Mammoet reconfigured the trailer to three meters width. A highlight of this job was the blessing of the convoy by monks, in Savannakhet. Everything went well and a month after Mammoet started they delivered the autoclave to the mine. Mammoet then lifted it onto its foundations with the CC 1100 crawler crane with superlift. A Tight Fit The mission was to bring a 500 ton reactor (48 meters) into the refinery using both SPMTs and skidtrack for portions of the journey. Once inside the lift area, a 70 meters tall tower system consisting of “Troll beams” and a 900-ton strand jack was used to both erect the reactor and carry it over a live pipe rack and set it on its pedestal. A CC 2800 was built partially under a pipe rack. Overall, 28 sections of twelve meters tower were required to build the lift system, along with both “Troll beams” and two “Oconee beams”. The lift system was required to be capable of withstanding 201 km/h winds as the system was being assembled in the midst of hurricane season. Once assembled, the reactor was brought into the unit beneath a pipe rack on a skid system. The reactor was placed back atop two sets of double-10 lines of SPMTs with turntables to position it inside the unit. There was barely enough room for both the CC 2800 and 48 meters long reactor to coexist within the unit, but the Mammoet crew skillfully manoeuvered the two to their final staging locations without incident. The reactor was staging on jack stands and trailers were removed from the unit to allow all of the platforms and piping to be attached to the reactor prior to the lift. LOCATION: THAILAND AND LAO PDR JOB: TRANSPORTING AN AUTOCLAVE CHALLENGE: CHECKING 200 BRIDGES “ The system was being assembled in the midst of hurricane season”

“The coordination of necessary details” Saudi Kayan Project For Mammoet Dubai, the prestigious Saudi Kayan Project in Jubail Industrial City kicked off with the delivery of two 1,147 ton reactors to the plant, followed by a 1,595 ton wash tower with a length of 100 meters and another 38 smaller items. We transported the process equipment from the King Fahd Industrial Port to the Saudi Kayan site over a distance of roughly seventeen kilometers. Mammoet later installed the two reactors and the wash tower using an MSG-80, while the other items were installed by the client. LOCATION: JUBAIL INDUSTRIAL CITY JOB: HEAVY TRANSPORT From Italy to the USA Mammoet was awarded a turnkey contract to transport two 1,000 ton reactors from the fabricator in Italy to Tuscaloosa, Alabama, USA. Some of the challenges included the coordination of necessary details with all of the various parties involved and finding a long enough berth in Houston where the cargo could be transferred from the roro ship onto a barge. The barge transported the reactors to Tuscaloosa where they were unloaded and placed into storage. Petrochemical “ The transport of 41 pieces from the King Fahd Industrial Port” LOCATION: ITALY AND THE USA JOB: TRANSPORTING TWO 1,000 TON REACTORS CHALLENGE: COORDINATION OF DETAILS WITH ALL PARTIES INVOLVED

- Page 1 and 2: 8Petrochemical page 6 Power page 16

- Page 3 and 4: LOCATION: THE HAGUE, THE NETHERLAND

- Page 5 and 6: “We are confidently looking towar

- Page 7 and 8: LOCATION: SINGAPORE JOB: INSTALLING

- Page 9: Offloading, Transporting and Positi

- Page 13 and 14: Record for Mammoet Dubai Turnaround

- Page 15 and 16: SHE-Q “Improving the translations

- Page 17 and 18: “This required the Moscow ring ro

- Page 19 and 20: Photographs courtesy of Robert de H

- Page 21 and 22: Nacelle Changeout Mammoet originall

- Page 23 and 24: Challenge: Organize a special progr

- Page 25 and 26: day one has been to save the client

- Page 27 and 28: ups and mega load-outs Angel Platfo

- Page 29 and 30: Skidding 5% Downhill A Chinese yard

- Page 31 and 32: Mammoet LTM 1200 (1:50) √ Limited

- Page 33 and 34: Dubai Metro Project LOCATION: SALT

- Page 35 and 36: “We combined the SPMTs with a gan

- Page 37 and 38: not to become a shipowner, apart fr

- Page 39 and 40: ������ �����

Petrochemical<br />

LOCATION: CHALMETTE,<br />

LOUISIANA, USA<br />

JOB: ERECTING A 500 TON REACTOR<br />

CHALLENGE: CONGESTED SITE<br />

10 11<br />

Blessed by Monks<br />

<strong>Mammoet</strong> was contracted to transport a<br />

165 ton autoclave from Sattahip in<br />

Thailand to the Sepon mine in Lao PDR.<br />

This took a full year of preparation as<br />

<strong>Mammoet</strong> had to check 200 concrete<br />

bridges on the route. <strong>Mammoet</strong> concluded<br />

that fifteen of the bridges were not strong<br />

enough. Hence <strong>Mammoet</strong> designed steel<br />

decks to span across the bridges, from<br />

pier to pier, so that the bridge itself did not<br />

have to carry any of the load. <strong>Mammoet</strong><br />

fitted these decks with wheels to make<br />

them easier to handle and minimize the<br />

disruption to traffic.<br />

In Thailand <strong>Mammoet</strong> could use a 4.9<br />

meter wide trailer which meant we did not<br />

have to reinforce the bridges. However,<br />

once <strong>Mammoet</strong> had reached Lao PDR<br />

they had to cross some narrower Bailey<br />

bridges so <strong>Mammoet</strong> reconfigured the<br />

trailer to three meters width. A highlight of<br />

this job was the blessing of the convoy by<br />

monks, in Savannakhet.<br />

Everything went well and a month after<br />

<strong>Mammoet</strong> started they delivered the autoclave<br />

to the mine. <strong>Mammoet</strong> then lifted it<br />

onto its foundations with the CC 1100<br />

crawler crane with superlift.<br />

A Tight Fit<br />

The mission was to bring a 500 ton reactor (48 meters) into the refinery using both<br />

SPMTs and skidtrack for portions of the journey. Once inside the lift area, a 70 meters<br />

tall tower system consisting of “Troll beams” and a 900-ton strand jack was used to both<br />

erect the reactor and carry it over a live pipe rack and set it on its pedestal.<br />

A CC 2800 was built partially under a pipe rack. Overall, 28 sections of twelve meters<br />

tower were required to build the lift system, along with both “Troll beams” and two<br />

“Oconee beams”. The lift system was required to be capable of withstanding 201 km/h<br />

winds as the system was being assembled in the midst of hurricane season.<br />

Once assembled, the reactor was brought into the unit beneath a pipe rack on a skid<br />

system. The reactor was placed back atop two sets of double-10 lines of SPMTs with<br />

turntables to position it inside the unit. There was barely enough room for both the<br />

CC 2800 and 48 meters long reactor to coexist within the unit, but the <strong>Mammoet</strong> crew<br />

skillfully manoeuvered the two to their final staging locations without incident. The reactor<br />

was staging on jack stands and trailers were removed from the unit to allow all of the<br />

platforms and piping to be attached to the reactor prior to the lift.<br />

LOCATION: THAILAND AND LAO PDR<br />

JOB: TRANSPORTING AN AUTOCLAVE<br />

CHALLENGE: CHECKING 200 BRIDGES<br />

“ The system was<br />

being assembled<br />

in the midst of<br />

hurricane season”