Andex rotary rakes - ACI Distributors

Andex rotary rakes - ACI Distributors

Andex rotary rakes - ACI Distributors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

323(S)-353-383-393-423(T)-433-463<br />

633-653-703-773-783-843-1503<br />

<strong>Andex</strong><br />

<strong>rotary</strong> <strong>rakes</strong>

<strong>Andex</strong> 323(S)-353-393-423T-433<br />

Compact design,<br />

low maintenance<br />

Vicon offers the smaller user a choice<br />

of five models designed for use on<br />

lower horsepower tractors, whilst<br />

delivering similar raking performance<br />

to its higher specification machines.<br />

With the option of pivoting and fixed<br />

three point linkage mounting and also<br />

a trailed version, there is a model to<br />

suit all needs, from lowland farmer,<br />

to the user looking for clean raking<br />

performance even when working on<br />

steep hillsides.<br />

<strong>Andex</strong> ‘compact’ rotor head<br />

The rotor head is grease lubricated within a<br />

fully enclosed housing, including a<br />

maintenance free cam track and cam followers.<br />

The rotor shaft, tine arms and pinion shaft<br />

are all mounted on two bearings for maximum<br />

strength and long service life.<br />

Large acreage with low hp tractors<br />

Attached to a linkage mounted drawbar, the<br />

<strong>Andex</strong> 423T can be easily operated by low<br />

horse power tractors. The machine can be<br />

raised up to a height of 50 cm conveniently<br />

from the tractor driver’s seat.<br />

Fully enclosed & grease lubricated rotor head<br />

Compact design for easy maintenance

<strong>Andex</strong> 353 with 3.5 m working width, 10 detachable tine arms<br />

fitted with 3 double tines each, fast and effective raking action<br />

<strong>Andex</strong> 393<br />

Gauge wheel<br />

<strong>Andex</strong> 423T

<strong>Andex</strong> 383-423-463<br />

Built-in reliability<br />

4 double tines<br />

per arm<br />

<strong>Andex</strong> 383<br />

1. Pinion with ball bearings at either side<br />

2. Constantly lubricated steel guide rollers<br />

3. Crown wheel with large radially<br />

mounted ball bearing<br />

4. 400 mm diameter shallow angle cam<br />

track<br />

5. Tine control arm housings made from<br />

aluminium die casting<br />

6. Tine arms pivot on low friction ball<br />

bearings<br />

Crown wheel and pinion assembly<br />

running in an oilbath gear case<br />

completely eliminates wear compared<br />

to open manually greased designs

Advanced tine control system<br />

The <strong>Andex</strong> 383, 423 and 463 offer the intensive<br />

farmer and contractor a drive system designed<br />

for long term reliability: The crown wheel and<br />

pinion assembly are running in a fully enclosed<br />

oilbath ensuring permanent and 100% reliable<br />

lubrication. The crown wheel is located by a<br />

massive radial ball bearing which gives<br />

exceptional support and ensures consistent<br />

engagement of gear teeth without influence<br />

from outside forces.<br />

A large diameter shallow profile cam track<br />

ensures that the cam follower rollers are<br />

smoothly guided throughout the entire cycle.<br />

Each tine control arm pivots on a pair of<br />

sealed ball bearings mounted in a rugged<br />

aluminium housing. Wear is virtually eliminated<br />

and the frictional loads imposed on the cam<br />

assembly during raking of heavy first cut crops<br />

is also dramatically reduced.<br />

Exceptional raking performance<br />

With up to 13 double tangential tine arms<br />

and four double tines per arm Vicon <strong>Andex</strong><br />

<strong>rakes</strong> are equipped for maximum raking<br />

performance.<br />

The high tine frequency ensures clean raking<br />

performance even at reduced rpm and high<br />

forward speed. Infinitely variable cam track<br />

adjustment allows fine tuning to obtain optimum<br />

raking and swath formation according to crop<br />

conditions.<br />

Perfect ground following<br />

Users requiring maximum smoothness in<br />

operation at higher forward speeds can upgrade<br />

the wide standard axle to a fixed or castoring<br />

tandem axle (fixed version is fitted as standard<br />

on <strong>Andex</strong> 463). A guide wheel can also be<br />

fitted under the headstock to allow accurate<br />

following of ground contours independent of<br />

the tractor linkage.<br />

Standard Hydrolift height adjustment<br />

For maximum operating convenience<br />

<strong>Andex</strong> 423 and 463 are fitted as standard<br />

with a hydraulic height adjusting facility<br />

(Hydrolift): from the tractor seat you can quickly<br />

set the tine height to match the length of<br />

stubble or different ground conditions.<br />

On <strong>Andex</strong> 383 rotor height is adjusted using<br />

a crank handle.<br />

Double tangential tine arm positioning<br />

Quick and simple folding for transport<br />

For road transport the rotor guard frames are<br />

folded up close to the main frame where they<br />

automatically lock into position. An assistor<br />

spring linked to the swath deflector reduces<br />

the effort required.<br />

Infinitely variable cam track adjustment<br />

Pivoting 3pt headstock<br />

Hydrolift height adjustment<br />

<strong>Andex</strong> 463 in tranport position

<strong>Andex</strong> 653<br />

<strong>Andex</strong> 653<br />

Side delivery <strong>rakes</strong><br />

50 cm ground clearance<br />

<strong>Andex</strong> 653<br />

Exceptional versatility makes the <strong>Andex</strong> 653<br />

ideal for farmers who want to replace a single<br />

rotor rake with a big twin rotor machine.<br />

These <strong>rakes</strong> meet all your requirements,<br />

whether you need an 11 m wide double swath<br />

to be collected by a high performance forage<br />

harvester or small night windrows for hay crops.<br />

Trailed by a drawbar linkage, the <strong>Andex</strong> 653<br />

can be hitched to small tractors from 29 kW<br />

(40 HP) onwards.<br />

For the gearbox design see page 2.<br />

Ground clearance in large crops<br />

With 50 cm lifting height, swaths can be driven<br />

over with no problem at all. Rotors are lifted<br />

using only a single acting valve.<br />

Easy conversion from working to<br />

transport configuration<br />

There’s no need to remove tine arms: moving<br />

the <strong>Andex</strong> 653 to transport position only<br />

requires a simple operation on the control unit.<br />

The swath deflector will automatically fold<br />

clear and transport width is only 2.85 m.<br />

<strong>Andex</strong> ‘compact’ rotor head<br />

The rotor head is grease lubricated within a<br />

fully enclosed housing, including a<br />

maintenance free cam track and cam followers.<br />

The rotor shaft, tine arms and pinion shaft<br />

are all mounted on two bearings for maximum<br />

strength and long service life.<br />

Fully enclosed & grease<br />

lubricated rotor head

<strong>Andex</strong> 653<br />

<strong>Andex</strong> 653:<br />

formation of<br />

one double swath<br />

<strong>Andex</strong> 653:<br />

formation of two<br />

single swaths<br />

Rotors with perfect ground following ability<br />

A flexible link frame between the main frame and rotors gives optimum ground<br />

following. The TerraLink ground following system allows the machine to follow<br />

nearly any kind of contours, preventing the tines from digging into the ground or<br />

leaving crop in the field.<br />

The rake is moved from transport to working position and back hydraulically,<br />

while the swath curtain is folding automatically. No need for the driver to leave<br />

the tractor when arriving/leaving a field.<br />

TerraLink system<br />

TerraLink offers 4-fold advantages:<br />

The TerraLink system offers clear advantages<br />

over pivoting linkage systems:<br />

• maintenance free system - no pivots or joints<br />

to wear out<br />

• automatic rotor suspension ensuring smooth<br />

operation<br />

• in-built pressure bias on front wheels<br />

prevents lifting and tine bounce<br />

• optimum ground following for clean raking at<br />

high forward speeds

<strong>Andex</strong> 773<br />

Side delivery <strong>rakes</strong><br />

QUATTRO<br />

<strong>Andex</strong> 773: designed for professional<br />

large acreage users<br />

The new side delivery <strong>Andex</strong> 773 with<br />

controlled steering facility is fitted with 2x12<br />

double tangential tine arms which can collect<br />

double swath. Adjustable cam tracks permit<br />

the best possible swath formation at any time.<br />

Exceptional manoeuverability and a generous<br />

amount of ground clearance with lifted rotors<br />

contribute to the superb performance of this<br />

rake.<br />

For the gearbox design see page 4.

<strong>Andex</strong> 633-703<br />

Centre swath <strong>rakes</strong><br />

<strong>Andex</strong> 703 with TerraLink system<br />

<strong>Andex</strong> 633 and 703, the new centre<br />

swath rake with ‘TerraLink’ system<br />

On the <strong>Andex</strong> 633 and 703 Vicon present the<br />

‘TerraLink’ ground following system (optional<br />

on <strong>Andex</strong> 633). A unique combination of four<br />

wheel undercarriage and specially designed<br />

rotor suspension ensures a superb raking<br />

action even at high forward speed.<br />

For the gearbox design see page 2.<br />

QUATTRO<br />

Rotors with perfect ground following ability<br />

A flexible link frame between the main frame and rotors combined with<br />

the Quattro four wheel undercarriage gives optimum ground following.<br />

The TerraLink Quattro system controls the rotor in 3 dimensions for<br />

perfect ground following. The active steering device on the main frame<br />

in combination with the 90° pivoting headstock ensures excellent track<br />

following and maximum manoeuvrability in all circumstances.<br />

TerraLink offers 4-fold advantages:<br />

The TerraLink system offers clear advantages over pivoting linkage systems:<br />

• maintenance free system - no pivots or joints to wear out<br />

• automatic rotor suspension ensuring smooth operation<br />

• in-built pressure bias on front wheels prevents lifting and tine bounce<br />

• Quattro ground following four wheel undercarriage for clean raking at<br />

high forward speeds<br />

TerraLink Quattro system<br />

Flexible link

<strong>Andex</strong> 783-843<br />

Centre swath <strong>rakes</strong><br />

QUATTRO<br />

<strong>Andex</strong> 783-843<br />

With adjustable working widths of 7.0 to 7.8 m<br />

and 7.6 to 8.4 m. These heavy duty contractor<br />

specification <strong>rakes</strong> provide the swath formation<br />

capability to keep harvesting operations<br />

running at their optimum output.<br />

At the heart of both models is a heavy-duty<br />

rotor head system. Proven to perform year in,<br />

year out in heavy first cut crops, they are<br />

superbly engineered, with the crown wheel and<br />

pinion assembly running in a fully enclosed<br />

oil bath, giving maintenance free, 100%<br />

continuous lubrication. The crown wheel is<br />

located by a massive radial bearing which<br />

offers exceptional support for further added<br />

reliability.<br />

A large diameter shallow profile cam track,<br />

ensures a smooth path for the cam follower<br />

rollers throughout the entire cycle. Each<br />

tangentially mounted tine arm pivots on a pair<br />

of sealed ball bearings mounted in a rugged<br />

aluminium housing. Wear is eliminated and the<br />

frictional loads imposed on the cam assembly<br />

during raking of heavy first cut crops are<br />

dramatically reduced.<br />

With its cleverly designed steering system,<br />

sharp turns up to 90° can be made. As soon<br />

as the rotors are lifted clear of the crop the<br />

driver can concentrate on making the shortest<br />

turn.<br />

Vicon sets new standards<br />

The rear carrier frame with controlled steering<br />

facility gives this rake excellent track following<br />

characteristics, allowing tight turns on<br />

headlands and loss free swathing even in<br />

awkwardly shaped fields. Even if the rotors<br />

are lifted on a steep slope, the steering system<br />

reliably counteracts any deviation.<br />

The ability to make sharp turns up to 90°<br />

and the cross stabilizer in the headstock are<br />

unique Vicon features.

Perfect ground following with TerraLink Quattro<br />

1. Pinion with ball bearings at either side<br />

2. Constantly lubricated steel guide rollers<br />

3. Crown wheel with large radially mounted<br />

ball bearing<br />

4. 400 mm diameter shallow angle cam track<br />

5. Tine control arm housings made from<br />

aluminium die casting<br />

6. Tine arms pivot on low friction ball bearings<br />

Crown wheel and<br />

pinion assembly<br />

running in an oilbath<br />

gear case completely<br />

eliminates wear<br />

compared to open<br />

manually greased<br />

designs

<strong>Andex</strong> 1503<br />

4-rotor rake<br />

Huge raking performance<br />

56 tine arms = 280 tines! Four rotors, each<br />

fitted with 15 tine arms and five tines per arm,<br />

ensure unbeatable raking quality in all<br />

conditions.<br />

Work rates of up to 17 hectares per hour mean<br />

that silage can be left to wilt for longer and<br />

the potential of your harvesting machines<br />

can be increased by up to 35%.<br />

Quickly matched to changing<br />

conditions<br />

Raking width can be continuously varied on<br />

the move between 11 m and 15 m. Raking<br />

width can be matched to the density of crop<br />

to obtain an evenly shaped and equally wide<br />

swath over the full length.<br />

This unique adjustment facility permits the<br />

operator to react instantly to any new<br />

situation. You can independently steer an<br />

outside rotor around an obstacle such as a<br />

pole or tree without having to change travel<br />

direction with the complete machine.<br />

Optimum ground pressure at all times<br />

Hydraulic ground pressure control means<br />

constant and adjustable pressure on the<br />

rotors regardless of their position on the<br />

carrier frame. Whatever the ground speed or<br />

selected working width, sward is handled<br />

with utmost care and raking quality is superb<br />

both in terms of output and swath formation<br />

- ensuring the smoothest possible flow of<br />

crop into the following machine.<br />

Free mobililty in three planes combined with<br />

six steered twin wheels per rotor give each<br />

rake head perfect ground following ability for<br />

the cleanest possible raking performance.<br />

B<strong>rakes</strong> and tyres<br />

A choice of tyre sizes (550/45 R22.5) not<br />

only ensures gentle treatment of the ground,<br />

but also makes for excellent stability both in<br />

the field and on the road.<br />

Hydraulic or pneumatic b<strong>rakes</strong> permit road<br />

speeds up to 50 km/h, so it takes minimum<br />

time to move the machine from one field to<br />

another.

A superbly manoeuverable unit<br />

The 2-pt headstock allows a turning angle<br />

up to 90° and the steered wheel axles<br />

ensure these Vicon <strong>rakes</strong> have unequalled<br />

manoeuverability. Despite a total length of 9 m,<br />

even narrow gateways or approach lanes to<br />

fields are easily negotiated.<br />

Super quick change-over<br />

With its clever folding mechanism the total<br />

height remains below 4 m - despite a rotor<br />

diameter of 3.8 m! And there’s no need to<br />

remove tine arms for road transport, conversion<br />

from transport to operating position is<br />

conveniently controlled from the tractor<br />

driver’s seat.<br />

Steerable road wheels<br />

Main carriage wheels are hydraulically<br />

steerable from the AutoForm controlbox,<br />

allowing extra manoevrability when entering<br />

narrow gateways or when working across<br />

side slopes. Wheels automatically return to<br />

the straight ahead position at the touch of the<br />

controlbox joystick.<br />

Electric height adjustment of rotors<br />

Each rotor can independently be set for height<br />

using the in-cab control system (option).<br />

Excellent clearance for headland turns<br />

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx<br />

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx<br />

AutoForm<br />

The operator-friendly AutoForm control<br />

box gives fully automatic or manual control<br />

of the rake. All major functions, e.g. lifting<br />

for headland turns or folding & unfolding<br />

the unit into transport or operating position,<br />

are activated by simply pressing one switch.<br />

Programmable delay between lifting and<br />

lowering of each pair of rotors keeps the<br />

operator’s workload to a minimum.

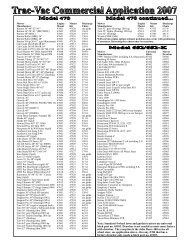

Technical specifications<br />

<strong>Andex</strong> 393<br />

<strong>Andex</strong> 653<br />

<strong>Andex</strong> 323S<br />

<strong>Andex</strong> 323S 323 353 383 393 423 423T<br />

Dimensions and weights<br />

Working width (m) 3.20 (10’6”) 3.20 (10’6”) 3.50 (11’6”) 3.80 (12’6”) 3.90 (12’8”) 4.20 (13’9”) 4.20 (13’9”)<br />

Transport width (m) 1.20 (3’11”) 1.58 (5’2”) 1.73 (5’7”) 1.62 (5’4”) 1.75 (5’8”) 1.74 (5’8”) 2.10 (6’10”)<br />

Transport length - - - - - - -<br />

Transport height - - - - - - -<br />

Weight (kg) 300 320 420 540 460 610 540<br />

(665 lbs) (665 lbs) (928 lbs) (1186 lbs) (1014 lbs) (1344 lbs) (1190 lbs)<br />

Swath width (m)<br />

Hitching system<br />

Fixed 3-pt headstock (cat.) 1/2 - - - - - -<br />

Pivoting 3-pt headstock (cat.) - 1/2 1/2 1/2 1/2 2 -<br />

Lower links (2-pt.) - - - - - - -<br />

Linkage drawbar - - - - - - •<br />

Gauge wheel 16° o o o o o o o<br />

Rotors/Tine arms/Tines<br />

Rotor diameter (m) 2.60 (8’6”) 2.60 (8’6”) 2.80 (9’2”) 3.05 (10’0”) 3.05 (10’0”) 3.35 (10’11”) 3.35 (10’10”)<br />

Swath delivery left left left left left left left<br />

Number of rotors 1 1 1 1 1 1 1<br />

Number of arms per rotor 9 9 10 11 11 12 11<br />

Number of double tines per arm 3 3 3 4 4 4 4<br />

Continuous cam track adjustment - - - • - • -<br />

Detachable tangential • • • • • • •<br />

Double tangential tine arms - - • • • • •<br />

Height adjustment rack rail rack rail mech. mech. mech. hydr. mech.<br />

Wheels and axles<br />

Tyre (rotors) 15x6.00-6 6PR 15x6.00-6 6PR 16x6.00-6 6PR 16x6.50-8 6PR 16x6.50-8 6PR 16x6.50-8 6PR 18x6.50-6 6PR<br />

Fixed tandem axle - o o o o o •<br />

Pivoting tandem axle - - - - - o -<br />

Standard tyres (carrying frame) - - - - - - -<br />

Optional tyres (carrying frame) - - - - - - -<br />

Further optional equipment<br />

Carrier arm compensating system - o o • o • -<br />

Locking catch for slopes - - o • o • -<br />

Safety accessories<br />

Warning panels o o o o o o o<br />

Road lights o o o o o o o<br />

• = standard o = optional - = not available<br />

<strong>Andex</strong> 353<br />

<strong>Andex</strong> 423T<br />

<strong>Andex</strong> 433<br />

<strong>Andex</strong> 423 <strong>Andex</strong> 463<br />

<strong>Andex</strong> 383

<strong>Andex</strong> 633<br />

<strong>Andex</strong> 773<br />

<strong>Andex</strong> 703<br />

<strong>Andex</strong> 843 <strong>Andex</strong> 1503<br />

433 463 633 653 703 773 783 843 1503<br />

4.30 (15’) 4.60 (15’1”) 6.30 (20’8”) 6.50 (21’4”) 7.00 (23’)/ 7.70 (25’3”)/ 7.00 (23”)/ 7.60 (24’9”)/ 9,50 (31’16”)/<br />

7.50 (24’8”) 8.40 (27’6”) 7.80 (25’8”) 8.40 (27’6”) 15,00 (49’20”)<br />

2.00 (6’9”) 2.14 (7’0”) 2.82 (9’3”) 2.85 (9’4”) 2.85 (9’4”) 2.82 (9’3”) 2.82 (9’3”) 2.82 (9’3”) 3.00 (9’10”)<br />

- - 5.47 (18’10”) 6.90 (22’8”) 5.77 (19’1”) 8.34 (27’3”) 5.77 (19’1”) 6.07 (20’2”) 9.20 (30’18”)<br />

- - 4.06 (13’4”) - 3.45 (11’6”)/ 3.20 (10’6”)/ 3.45 (11’3”)/ 3.30 (10’10”)/ 3.45 (11’4”)/<br />

4.15 (13’11”) 3.99 (13’1”) 4.15 (18’6”) 3.99 (13’1”) 3.99 (13’1”)<br />

500 660 1330 1150 1500 1990 1650 1700 5600<br />

(1115 lbs) (1463 lbs) (2932 lbs) (2530 lbs) (3345 lbs) (4740 lbs) (3650 lbs) (3750 lbs) (12.300 lbs)<br />

1.30 (4’3”) 1.30 (4’3”) 1.30-1.80 1.30-2.00 1.40-2.50<br />

(4’3”-5’10”) (4’3”-6’9”) (4’7”-8’2”)<br />

- - - - - - - - -<br />

1/2 2 - - - - - - -<br />

- - 1/2 - 1/2 1/2 1/2 1/2 2<br />

- - - • - - - - -<br />

o o - o - - - - -<br />

3.35 (10’10”) 3.65 (11’10”) 3.00 (9’10”) 2.70 (11’11”) 3.35 (10’10”) 3.45 (11’4”)/ 3.35 (10’10”) 3.65 (8’10”) 3.80 (12’6”)<br />

3.65 (11’10”)<br />

left left centre 1-2x left centre 1-2x left centre centre centre<br />

1 1 2 2 2 2 2 2 4<br />

12 13 2x11 2x11 11 2x12 2x11 2x12 13/15<br />

4 4 3 3/4 4 4 4 4 5<br />

- • - - - • • • •<br />

• • - - o • • • •<br />

• • • • • • • • •<br />

mech. hydr. mech. mech. mech. mech. mech. mech. mech. •/elec. o<br />

16x8.50-8 4PR 16x6.50-8 6PR 16x6.50-8 6PR 18x8.50-8 4PR 16x6.50-6 6PR 16x6.50-8 6PR 16x6.50-8 6PR 16x6.50-8 6PR 16x8x6.50-8 6PR<br />

o • o • TerraLink TerraLink TerraLink TerraLink TerraLink<br />

- o o - Quattro Quattro Quattro Quattro Quattro<br />

- - 10.0/80-12 - 10.0/80-12 10.0/80-12 10.0/75-15.3 10.0/75-15.3 19.0/45-17<br />

- - 10.0/75-15.3 - 10.0/75-15.3 10.0/75-15.3 - - 500/50-17<br />

o • - - - - - - -<br />

o • - - - - - - -<br />

o o • • • • • • •<br />

o o • • • • • • •<br />

This documentation is not binding. Availability of models, specifications and optional equipment may differ from country to country. Please consult your local dealer.<br />

Specifications and design are subject to change without notice. Printed in Holland. © Kverneland Group<br />

Vital parts<br />

The Kverneland Group regards the sale of each machine as the start of a long-term and<br />

valuable relationship. To support the relationship, we provide the vital high quality spare parts<br />

and an efficient spare parts service.<br />

Our parts are designed to ensure reliability, safety and an optimal performance of the machines.<br />

The quality lies in the innovative construction work and in the production processes at our<br />

production sites. The spare parts are available in close proximity to you; at our dealership in<br />

your area as well as at our distribution centres. We maintain high availability of spare parts to<br />

ensure minimum operational disruption at your end.<br />

You can depend on the Kverneland Group to offer a premium service. It’s vital for us!<br />

This documentation is not binding. Availability of models, specifications and optional equipment may differ from country to country. Please consult your local dealer.<br />

Specifications and design are subject to change without notice. Printed in Holland. © Kverneland Group

Kverneland Group is the largest<br />

specialised producer and<br />

distributor of farming implements<br />

in the world. The Group is a<br />

family of strong brands enabling<br />

us to provide both the farmer<br />

and dealer with a unique and<br />

complete range of high quality<br />

products for soil preparation,<br />

grass harvesting, seeding,<br />

spreading, spraying, potato<br />

cultivation and grape harvesting.<br />

www.kvernelandgroup.com<br />

A full range of<br />

forage harvesting<br />

equipment<br />

Vicon offers you a full range of<br />

forage harvesting equipment:<br />

drum and disc mowers and mower<br />

conditioners, tedders, <strong>rakes</strong>,<br />

fixed and variable chamber round<br />

balers, big square balers, bale<br />

wrappers, fertiliser spreaders<br />

and maize choppers.<br />

All Vicon machines are protected by a<br />

Duracoat powder paint coating.<br />

The result is a sealed extremely hard<br />

wearing and attractive finish.<br />

Kverneland Group UK Ltd<br />

Walkers Lane, Lea Green, St. Helens<br />

Merseyside WA9 4 AF<br />

Tel 01744 853 200, Fax 01744 853 400<br />

Kverneland Ireland Ltd<br />

Hebron Industrial Estate<br />

Kilkenny<br />

Tel 056 51597, Fax 056 62207<br />

Kverneland Group<br />

Global Product Area Grass<br />

P.O. Box 1000<br />

2150 BA Nieuw-Vennep<br />

The Netherlands<br />

F 1525-GB