INNOVATORS Gold Award - New Orleans City Business

INNOVATORS Gold Award - New Orleans City Business

INNOVATORS Gold Award - New Orleans City Business

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ON THE BRINK<br />

Green Door Construction<br />

Key innovation: The only company in the city to use<br />

aerated autoclaved concrete, a pre-fabricated concrete<br />

block that is lighter, more fireproof and a better insulator<br />

than common concrete.<br />

Biggest client: Samuel Green Charter School — and his<br />

parents’ Uptown home<br />

Where they’re based: <strong>New</strong> <strong>Orleans</strong><br />

Top executive: Patrick Ibert<br />

Year introduced: 2006<br />

2007 sales: $600,000<br />

AMERICANS HAVE become aware of the necessity to be<br />

more energy efficient, and in most cases consumers are<br />

more mindful about what they drive, where they shop<br />

and what they buy.<br />

Patrick Ibert of Green Door Construction has taken<br />

this philosophy and applied it to the materials he uses in<br />

his construction business.<br />

“We are the only contractor in the city that uses aerated<br />

autoclaved concrete for building projects,” Ibert said.<br />

“It is a pre-fabricated concrete block that is lighter than<br />

common concrete, more fireproof and a better insulator.”<br />

Ibert said the AAC blocks are manufactured from lime,<br />

sand or mine tailings,along with cement,gypsum,an aeration<br />

agent and water. The concoction is poured into a cast, which<br />

produces a solid block that is interlocking and stackable.<br />

“The blocks are a product of Europe,” Ibert said.<br />

“They have unbelievable versatility and are so easy to use.”<br />

Ibert said the blocks can be sawed, drilled, nailed and<br />

routered using normal woodworking tools. The blocks do<br />

a better job of dampening noise than standard concrete<br />

and are much more environmentally friendly, he said.<br />

“They are manufactured from readily available natural<br />

resources,” Ibert said. “The materials are nontoxic and<br />

not a source of indoor air pollution. Less jobsite waste is<br />

created, and the product is completely recyclable.”<br />

Ibert has used the AAC blocks to help Samuel Green<br />

Charter in <strong>New</strong> <strong>Orleans</strong> build three outdoor classrooms,<br />

as well as its edible schoolyard. His biggest client as of<br />

late, however, is within the family.<br />

“I’m rebuilding my parent’s ancestral home in the<br />

Garden District, which burned to the ground during<br />

Hurricane Katrina,” Ibert said. “The project calls for a<br />

complete retrofit of the 100-year-old home to make it<br />

more energy efficient while keeping the historic aspects<br />

of the home intact. A person’s home is their single greatest<br />

asset, and our goal is to make our construction functional<br />

and aesthetically pleasing.”<br />

Ibert said the new home will be more energy efficient<br />

and should hold up better to the elements. The new<br />

home will include solar panels for self-sustaining energy<br />

and will be pest-, fire- and mold-resistant.<br />

“I hope it will be the perfect home for the <strong>New</strong> <strong>Orleans</strong><br />

climate.”•<br />

— Robin Shannon<br />

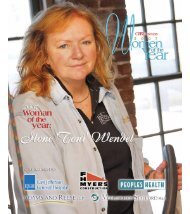

PHOTO BY FRANK AYMAMI<br />

Patrick Ibert has used his aerated autoclaved concrete blocks for Samuel Green Charter School’s three outdoor classrooms and in renovating his parents’ Garden District home.<br />

<strong>New</strong> <strong>Orleans</strong> <strong>City</strong><strong>Business</strong> 53A