INNOVATORS Gold Award - New Orleans City Business

INNOVATORS Gold Award - New Orleans City Business

INNOVATORS Gold Award - New Orleans City Business

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INNOVATOR<br />

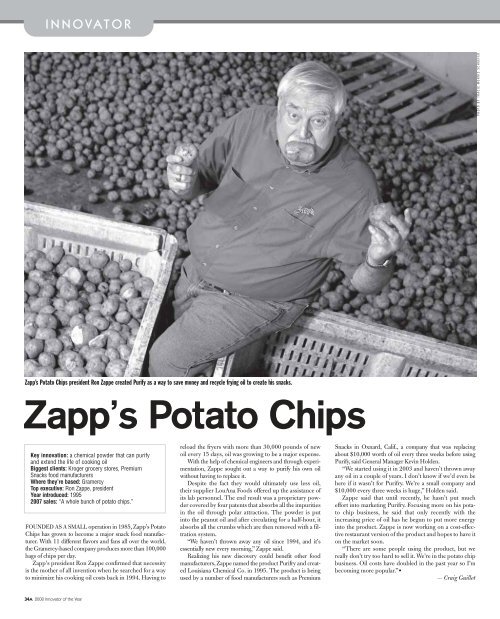

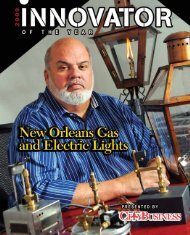

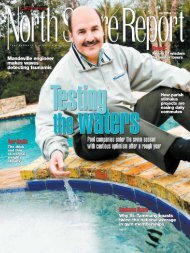

PHOTO BY TRACIE MORRIS SCHAEFER<br />

Zapp’s Potato Chips president Ron Zappe created Purify as a way to save money and recycle frying oil to create his snacks.<br />

Zapp’s Potato Chips<br />

Key innovation: a chemical powder that can purify<br />

and extend the life of cooking oil<br />

Biggest clients: Kroger grocery stores, Premium<br />

Snacks food manufacturers<br />

Where they’re based: Gramercy<br />

Top executive: Ron Zappe, president<br />

Year introduced: 1995<br />

2007 sales: “A whole bunch of potato chips.”<br />

FOUNDED AS A SMALL operation in 1985, Zapp’s Potato<br />

Chips has grown to become a major snack food manufacturer.<br />

With 11 different flavors and fans all over the world,<br />

the Gramercy-based company produces more than 100,000<br />

bags of chips per day.<br />

Zapp’s president Ron Zappe confirmed that necessity<br />

is the mother of all invention when he searched for a way<br />

to minimize his cooking oil costs back in 1994. Having to<br />

reload the fryers with more than 30,000 pounds of new<br />

oil every 15 days, oil was growing to be a major expense.<br />

With the help of chemical engineers and through experimentation,<br />

Zappe sought out a way to purify his own oil<br />

without having to replace it.<br />

Despite the fact they would ultimately use less oil,<br />

their supplier LouAna Foods offered up the assistance of<br />

its lab personnel. The end result was a proprietary powder<br />

covered by four patents that absorbs all the impurities<br />

in the oil through polar attraction. The powder is put<br />

into the peanut oil and after circulating for a half-hour, it<br />

absorbs all the crumbs which are then removed with a filtration<br />

system.<br />

“We haven’t thrown away any oil since 1994, and it’s<br />

essentially new every morning,” Zappe said.<br />

Realizing his new discovery could benefit other food<br />

manufacturers, Zappe named the product Purifry and created<br />

Louisiana Chemical Co. in 1995. The product is being<br />

used by a number of food manufacturers such as Premium<br />

Snacks in Oxnard, Calif., a company that was replacing<br />

about $10,000 worth of oil every three weeks before using<br />

Purify, said General Manager Kevin Holden.<br />

“We started using it in 2003 and haven’t thrown away<br />

any oil in a couple of years. I don’t know if we’d even be<br />

here if it wasn’t for Purifry. We’re a small company and<br />

$10,000 every three weeks is huge,” Holden said.<br />

Zappe said that until recently, he hasn’t put much<br />

effort into marketing Purifry. Focusing more on his potato<br />

chip business, he said that only recently with the<br />

increasing price of oil has he begun to put more energy<br />

into the product. Zappe is now working on a cost-effective<br />

restaurant version of the product and hopes to have it<br />

on the market soon.<br />

“There are some people using the product, but we<br />

really don’t try too hard to sell it. We’re in the potato chip<br />

business. Oil costs have doubled in the past year so I’m<br />

becoming more popular.”•<br />

— Craig Guillot<br />

34A 2008 Innovator of the Year