Company Magazine for the Odfjell Group - March 2005

Company Magazine for the Odfjell Group - March 2005

Company Magazine for the Odfjell Group - March 2005

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

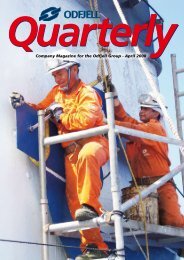

Quality Section<br />

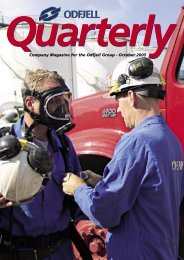

Safety initiatives in Rotterdam<br />

QHSE-MATTERS DO MATTER<br />

By Toon Ruizendaal, QHSE Manager OTR<br />

<strong>Odfjell</strong> Terminals<br />

(Rotterdam) B.V.<br />

has put in a lot of<br />

resources to fur<strong>the</strong>r<br />

enhance<br />

safety, as part of<br />

<strong>the</strong> overall rehabilitation<br />

of <strong>the</strong><br />

terminal. The<br />

summary below<br />

outlines <strong>the</strong> most<br />

important safety initiatives taken or<br />

still in progress at <strong>the</strong> terminal:<br />

• In 2003 we appointed a full-time<br />

safety supervisor, who makes<br />

inspection rounds on <strong>the</strong> entire<br />

terminal twice a day.<br />

• Since February 2004 we publish a<br />

monthly QHSE newsletter on our<br />

local intranet, in<strong>for</strong>ming all our staff<br />

and contractors about QHSE-matters.<br />

• We have since April 2004 conducted<br />

frequent “communication meetings<br />

involving all operational staff,<br />

focussing on quality and safety.<br />

• In 2004 we completed a revision of<br />

<strong>the</strong> emergency organisation,<br />

including training of <strong>the</strong> staff.<br />

• We have initialised several projects<br />

increasing <strong>the</strong> safety standards on<br />

<strong>the</strong> terminal, ei<strong>the</strong>r completed or in<br />

progress:<br />

• Fall protection at truck/rail loading<br />

areas and jetties.<br />

• Renovation of <strong>the</strong> fixed foam and<br />

sprinkler installations at several<br />

jetties.<br />

• During <strong>2005</strong> we will move PID’s<br />

central control room to a more safe<br />

distance from <strong>the</strong> distillation plant.<br />

• In 2004, we appointed five manipulation<br />

co-ordinators to organise<br />

unloading and transfers. These are<br />

working in shifts 24/7 to fur<strong>the</strong>r<br />

improve <strong>the</strong> control of operational<br />

execution.<br />

• Since third quarter of 2004 we are<br />

reviewing all operational procedures,<br />

including training of <strong>the</strong> staff<br />

involved. This work is expected to be<br />

completed by mid <strong>2005</strong>.<br />

• As from <strong>the</strong> first quarter of <strong>2005</strong> we<br />

will offer comprehensive mandatory<br />

induction training <strong>for</strong> all contractors,<br />

as part of our ef<strong>for</strong>ts to enhance contractor<br />

safety at <strong>the</strong> terminal.<br />

• During third quarter of 2004 we<br />

commenced cleaning and de-bottlenecking<br />

of <strong>the</strong> firewater network<br />

and pumps, to be completed by mid<br />

<strong>2005</strong>.<br />

• We are doing a Hazard and<br />

Operability study (HAZOP) of all<br />

“old” vapour recovery systems<br />

(from Q4 2004 - <strong>2005</strong>).<br />

• We are at <strong>the</strong> moment reorganising<br />

<strong>the</strong> Working Permit Department and<br />

<strong>the</strong> related procedures.<br />

• We have launched a PR campaign on<br />

safety and quality issues, to increase<br />

<strong>the</strong> general safety-awareness and to<br />

achieve a continuous upgrade of <strong>the</strong><br />

safety culture <strong>for</strong> all staff.<br />

It goes without saying that <strong>the</strong>se initiatives<br />

require a lot of ef<strong>for</strong>t as well as<br />

substantial investments, and we still<br />

have quite a way to go. The complex<br />

terminal infrastructure at OTR, and <strong>the</strong><br />

necessity to maintain our ongoing<br />

business, means that work is going on<br />

"everywhere on <strong>the</strong> terminal", hence<br />

making any upgrade quite a challenge.<br />

However, this process is necessary to<br />

keep such a large and busy terminal to<br />

<strong>the</strong> highest safety standards.<br />

26 ODFJELL Quarterly <strong>March</strong> <strong>2005</strong>