RF 100 VARIABLE HELIX SoLId CARBIdE End MILLS - Guhring, Inc.

RF 100 VARIABLE HELIX SoLId CARBIdE End MILLS - Guhring, Inc.

RF 100 VARIABLE HELIX SoLId CARBIdE End MILLS - Guhring, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

∡χ<br />

∡γ<br />

∡ χ ≠ ∡ γ<br />

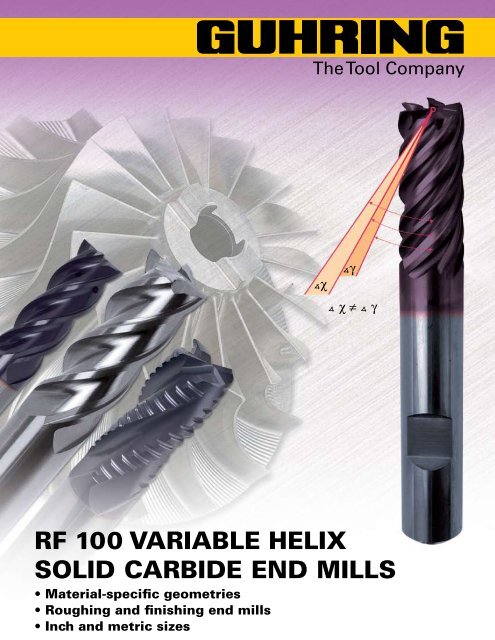

<strong>RF</strong> <strong>100</strong> <strong>VARIABLE</strong> <strong>HELIX</strong><br />

Solid Carbide <strong>End</strong> Mills<br />

• Material-specific geometries<br />

• Roughing and finishing end mills<br />

• <strong>Inc</strong>h and metric sizes

At <strong>Guhring</strong>, our mission is to provide customers with the means to take cost out of machining<br />

production components by improving machine process times and product quality.<br />

<strong>Guhring</strong>, <strong>Inc</strong>. is a subsidiary of Guehring oHG, headquartered in Albstadt, Germany. Globally,<br />

Guehring employs over 4,500 people. The Brookfield, WI manufacturing plant and corporate<br />

headquarters employs more than 250 people. Additional resources include our warehouse in<br />

Huntington Beach, CA, and a manufacturing facility in Detroit, MI.<br />

In order to better serve our customers’ needs, <strong>Guhring</strong> offers a full range of special tool design/<br />

manufacturing capabilities in our USA manufacturing plants. Our engineers can take blueprint<br />

part concepts and design specialized tools in high speed steel, carbide and even PCD which<br />

combine multiple manufacturing operations and reduce production costs. <strong>Guhring</strong> has the<br />

capability to manufacture special drill, reamer, end mill and countersink tools; solid or coolant fed.<br />

<strong>Guhring</strong> also offers a full reconditioning service that can recondition special and standard<br />

drill points, end mills and reamers to their original specifications. In addition, <strong>Guhring</strong>’s<br />

reconditioning service can provide tool modifications such as end mill corner radius and<br />

chamfers quickly and accurately.<br />

Our coatings division offers superior PVD coatings for cutting tools and wear parts. <strong>Guhring</strong><br />

offers traditional TiN, TiCN and TiAlN coatings, as well as high performance proprietary coatings<br />

such as FIREX ® , MolyGlide ® , Super-A TM , nano-FIREX ® and new nano-A TM coating. With coating<br />

chambers in both Wisconsin and Michigan, <strong>Guhring</strong> can provide quick turnaround and competitive<br />

pricing on all types of parts, even beyond cutting tools.<br />

2

<strong>RF</strong> <strong>100</strong> Variable Helix <strong>End</strong> Mill QUICK-FINDER - <strong>End</strong> Mill selection guide<br />

Slot-Milling<br />

Roughing<br />

Finishing<br />

Material<br />

Workpiece<br />

Conditions<br />

1 x d<br />

0.3 - 0.8 x d<br />

< 0.1 x d<br />

Good machining<br />

<strong>RF</strong> <strong>100</strong> A<br />

<strong>RF</strong> <strong>100</strong> A<br />

conditions<br />

(e.g. # 3077) page 21<br />

(e.g. # 3077) page 21<br />

<strong>RF</strong> <strong>100</strong> S/F<br />

Wrought Aluminum Alloys<br />

< 3% Si.<br />

Poor machining<br />

conditions<br />

<strong>RF</strong> <strong>100</strong> A<br />

(e.g. # 3077) page 21<br />

<strong>RF</strong> <strong>100</strong> A<br />

(e.g. # 3077) page 21<br />

(e.g. # 3115) page 23<br />

Good machining<br />

<strong>RF</strong> <strong>100</strong> F<br />

<strong>RF</strong> <strong>100</strong> F<br />

Aluminium<br />

> 3% - 12% Si<br />

Steel & Alloys < 30 HRC<br />

conditions<br />

Poor machining<br />

(e.g. # 3078) page 13<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

(e.g. # 3078) page 13<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> S/F<br />

(e.g.. # 3115) page 23<br />

Cast Iron < 200 HB 30<br />

conditions<br />

(e.g. # 3081) page 17<br />

(e.g. # 3081) page 17<br />

Good machining<br />

<strong>RF</strong> <strong>100</strong> U<br />

<strong>RF</strong> <strong>100</strong> U<br />

Steel & Alloys<br />

30-38 HRC<br />

Cast Iron > 200 HB 30<br />

Hardened Steel<br />

< 54 HRC<br />

conditions<br />

Poor machining<br />

conditions<br />

(e.g. # 3113) page 7<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

(e.g. # 3082) page 11<br />

(e.g. # 3114) page 8<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

(e.g. # 3082) page 11<br />

<strong>RF</strong> <strong>100</strong> S/F<br />

(e.g.. # 3115) page 23<br />

Good machining<br />

<strong>RF</strong> <strong>100</strong> VA<br />

<strong>RF</strong> <strong>100</strong> VA<br />

Stainless Steels<br />

conditions<br />

Poor machining<br />

(e.g. # 3080) page 15<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

(e.g. # 3080) page 15<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> S/F<br />

(e.g. # 3631) page 23<br />

conditions<br />

(e.g. # 3081) page 17<br />

(e.g. # 3081) page 17<br />

Good machining<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

Titanium & Nickel Alloys<br />

conditions<br />

Poor machining<br />

(e.g. # 3876) page 19<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

(e.g. # 3876) page 19<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

<strong>RF</strong> <strong>100</strong> S/F<br />

(e.g.. # 3115) page 23<br />

conditions<br />

(e.g. # 3082) page 11<br />

(e.g. # 3082) page 11<br />

Poor machining conditions = low horsepower, small machine taper, long reach,<br />

non-stable setup, or difficult chip removal<br />

3

<strong>Guhring</strong> No. Index<br />

Index<br />

<strong>Guhring</strong> no. Description Surface<br />

Finish<br />

3077 <strong>RF</strong> <strong>100</strong> A standard length variable helix end mills for aluminum Bright 21<br />

3078 <strong>RF</strong> <strong>100</strong> F standard length variable helix end mills for materials < 30 HRC FIREX ® 13<br />

3079 <strong>RF</strong> <strong>100</strong> U standard length variable helix end mills, corner radius, for materials < 54 HRC FIREX ® 9<br />

3080 <strong>RF</strong> <strong>100</strong> VA standard length variable helix end mills for stainless steels nano-A TM 15<br />

3081 <strong>RF</strong> <strong>100</strong> VA/NF standard length variable helix roughing-finishing end mills for stainless steels nano-A TM 17<br />

3082 <strong>RF</strong> <strong>100</strong> U/HF standard length variable helix roughing-finishing end mills, for materials < 54 HRC FIREX ® 11<br />

3099 <strong>RF</strong> <strong>100</strong> U stub length variable helix end mills for materials < 54 HRC FIREX ® 7<br />

3<strong>100</strong> <strong>RF</strong> <strong>100</strong> U standard length variable helix end mills for materials < 54 HRC FIREX ® 8<br />

3113 <strong>RF</strong> <strong>100</strong> U stub length variable helix end mills for materials < 54 HRC FIREX ® 7<br />

3114 <strong>RF</strong> <strong>100</strong> U standard length variable helix end mills for materials < 54 HRC FIREX ® 8<br />

3115 <strong>RF</strong> <strong>100</strong> SF standard length 6-flute variable helix end mills for materials < 54 HRC FIREX ® 23<br />

3202 <strong>RF</strong> <strong>100</strong> A standard length variable helix end mills for aluminum, metric Bright 21<br />

3366 <strong>RF</strong> <strong>100</strong> F standard length variable helix end mills, coolant through, for materials < 30 HRC, metric FIREX ® 13<br />

3627 <strong>RF</strong> <strong>100</strong> U long length variable helix end mills for materials < 54 HRC, metric FIREX ® 9<br />

3629 <strong>RF</strong> <strong>100</strong> F standard length variable helix end mills for materials < 30 HRC, metric FIREX ® 13<br />

3631 <strong>RF</strong> <strong>100</strong> SF standard length 6-flute variable helix end mills for materials < 54 HRC, metric FIREX ® 23<br />

3731 <strong>RF</strong> <strong>100</strong> U stub length variable helix end mills for materials < 54 HRC, metric FIREX ® 7<br />

3732 <strong>RF</strong> <strong>100</strong> U standard length variable helix end mills for materials < 54 HRC, metric FIREX ® 8<br />

3736 <strong>RF</strong> <strong>100</strong> U standard length variable helix end mills for materials < 54 HRC, metric FIREX ® 8<br />

3876 <strong>RF</strong> <strong>100</strong> Ti standard length variable helix end mills, corner radius, for titanium alloys Super-A TM 19<br />

Page<br />

<strong>RF</strong>-LINE<br />

Standard<br />

Tooth<br />

profile<br />

Shank style<br />

Helix<br />

angle<br />

Tool illustration Tool material Surface finish Diameter range Series Page<br />

<strong>RF</strong> <strong>100</strong> U variable helix end mills for materials < 54 HRC<br />

center cutting<br />

fract. N HA 35°/38°<br />

Solid<br />

carbide<br />

3/16 - 1” 3113 7<br />

fract. N HB 35°/38°<br />

Solid<br />

carbide<br />

3/8 - 1” 3099 7<br />

metric N HB 35°/38°<br />

Solid<br />

carbide<br />

6.00 - 20.00 3731 7<br />

fract. N HA 35°/38°<br />

Solid<br />

carbide<br />

3/16 - 1” 3114 8<br />

fract. N HB 35°/38°<br />

Solid<br />

carbide<br />

3/8 - 1” 3<strong>100</strong> 8<br />

metric N HA 35°/38°<br />

Solid<br />

carbide<br />

4.00 - 25.00 3736 8<br />

metric N HB 35°/38°<br />

Solid<br />

carbide<br />

4.00 - 25.00 3732 8<br />

fract. N HA/HB 35°/38°<br />

r<br />

Solid<br />

carbide<br />

1/4 - 1” 3079 9<br />

metric N HA 35°/38°<br />

Solid<br />

carbide<br />

10.00 - 25.00 3627 9<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

4

<strong>RF</strong>-LINE<br />

Standard<br />

Tooth<br />

profile<br />

Shank style<br />

Helix<br />

angle<br />

Tool illustration Tool material Surface finish Diameter range Series Page<br />

<strong>RF</strong> <strong>100</strong> U/HF variable helix roughing-finishing end mills for materials < 54 HRC<br />

fine truncated profile, center cutting<br />

fract. HF HA/HB 30°/32°<br />

Solid<br />

carbide<br />

1/4 - 1” 3082 11<br />

Index<br />

<strong>RF</strong> <strong>100</strong> F variable helix end mills for materials < 30 HRC<br />

center cutting<br />

fract. NH HA/HB 40°/42°<br />

Solid<br />

carbide<br />

3/16 - 1” 3078 13<br />

metric NH HA 40°/42°<br />

Solid<br />

carbide<br />

4.00 - 20.00 3629 13<br />

metric NH HB 40°/42°<br />

<strong>RF</strong> <strong>100</strong> VA variable helix end mills for stainless steel<br />

center cutting<br />

fract. N HA/HB 36°/38°<br />

Solid<br />

carbide<br />

Solid<br />

carbide<br />

6.00 - 20.00 3366 13<br />

3/16 - 1” 3080 15<br />

<strong>RF</strong> <strong>100</strong> VA/NF variable helix roughing finishing end mills for stainless steel<br />

coarse truncated profile, center cutting<br />

fract. NF HA/HB 36°/38°<br />

<strong>RF</strong> <strong>100</strong> Ti variable helix end mills for titanium and nickel alloys<br />

corner radius, center cutting<br />

r<br />

fract. N HA/HB 35°/38°<br />

Solid<br />

carbide<br />

Solid<br />

carbide<br />

1/4 - 1” 3081 17<br />

1/4 - 1” 3876 19<br />

<strong>RF</strong> <strong>100</strong> A variable helix end mills for aluminum and cast aluminum < 22 HRC<br />

center cutting<br />

fract. W HA/HB 40°/42°<br />

Solid<br />

carbide<br />

3/16 - 1” 3077 21<br />

metric W HA 40°/42°<br />

<strong>RF</strong> <strong>100</strong> SF 6-flute variable end mills for materials < 54 HRC<br />

center cutting<br />

Solid<br />

carbide<br />

4.00 - 20.00 3202 21<br />

fract. NH HA<br />

44°/45°<br />

46°<br />

Solid<br />

carbide<br />

5/16 - 1” 3115 23<br />

metric NH HA<br />

44°/45°<br />

46°<br />

Solid<br />

carbide<br />

8.00 - 25.00 3631 23<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

5

<strong>RF</strong>-LINE<br />

Variable helix end mills <strong>RF</strong> <strong>100</strong> U for materials < 54 HRC<br />

<strong>RF</strong>-LINE<br />

<strong>Guhring</strong> has developed the <strong>RF</strong> <strong>100</strong> end mill with variable<br />

helix angle primarily to prevent chattering and the so-called<br />

corkscrew effect (as found when withdrawing tools having<br />

a large helix angle).<br />

The <strong>RF</strong> <strong>100</strong> U is a universal design for a wide range of materials<br />

and applications. This design is an excellent choice for job<br />

shops and manufacturers who mill a variety of materials.<br />

The variable helix angle also offers the following additional<br />

advantages:<br />

• up to 60% higher in feed rates<br />

• longer tool life<br />

• increased drilling depths<br />

• vibration-free machining<br />

• suitable for roughing and finishing<br />

• increased surface finish quality<br />

• reduced cutter wandering<br />

Micro edge<br />

protection<br />

for longer<br />

tool life<br />

Ff in [N] Ff in [N]<br />

400<br />

300<br />

200<br />

38°<br />

<strong>100</strong><br />

0<br />

35°<br />

400 <strong>RF</strong> <strong>100</strong><br />

300<br />

200<br />

<strong>100</strong><br />

0<br />

standard 4-flute<br />

0 0,5 1,0 1,5 2,0<br />

Linear milling section [mm]<br />

35°<br />

38°<br />

A cutting force comparison between a conventional type N and a <strong>RF</strong> <strong>100</strong><br />

variable helix end mill clearly shows the <strong>RF</strong> <strong>100</strong> end mill’s quieter and more<br />

stable machining characteristics.<br />

Material<br />

Application ranges<br />

H<br />

<br />

Hardness<br />

<strong>RF</strong> <strong>100</strong> U<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

< 30 HRC<br />

30-38 HRC<br />

< 25 HRC<br />

> 25 HRC<br />

< Si 3%<br />

Si 3%-12%<br />

< 30 HRC<br />

30-38 HRC<br />

< 200 HB 30<br />

> 200 HB 30<br />

< 32 HRC<br />

32-50 HRC<br />

< 54 HRC<br />

<strong>RF</strong> <strong>100</strong> VA<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> A<br />

<strong>RF</strong> <strong>100</strong> F<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> SF<br />

optimal suitability limited suitability hard machining<br />

H<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

6<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> U (universal) variable helix end mills for materials < 54 HRC<br />

Stub length<br />

Series 3113 3099<br />

Standard <strong>Guhring</strong> std.<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type N N<br />

d 2<br />

shank tolerance h6 h6<br />

Helix angle 35°/38° 35°/38°<br />

d 1<br />

tolerance h10 h10<br />

Techn. data page 25 25<br />

Series 3731<br />

Standard DIN 6527 K<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

N<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 35°/38°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 25<br />

d2<br />

d1<br />

d2<br />

d1<br />

<strong>RF</strong>-LINE<br />

l 2<br />

l 2<br />

l 1<br />

l 1<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

fract. fract. fract. fract. flutes no.<br />

3/16 3/16 2 3/8 4 4.760 l<br />

1/4 1/4 2 1/2 4 6.350 l<br />

5/16 5/16 2 1/2 4 7.940 l<br />

3/8 3/8 2 5/8 4 9.520 l m<br />

1/2 1/2 2 1/2 5/8 4 12.700 l m<br />

5/8 5/8 3 3/4 4 15.870 l m<br />

3/4 3/4 3 1 4 19.050 l m<br />

1 1 3 1 4 25.400 l m<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

mm mm mm mm flutes no.<br />

6.000 6.000 54.00 10.00 4 6.000 m<br />

8.000 8.000 58.00 12.00 4 8.000 m<br />

10.000 10.000 66.00 14.00 4 10.000 m<br />

12.000 12.000 73.00 16.00 4 12.000 m<br />

14.000 14.000 75.00 18.00 4 14.000 m<br />

16.000 16.000 82.00 22.00 4 16.000 m<br />

18.000 18.000 84.00 24.00 4 18.000 m<br />

20.000 20.000 92.00 26.00 4 20.000 m<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

7

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> U (universal) variable helix end mills for materials < 54 HRC<br />

Standard length<br />

Series 3114 3<strong>100</strong><br />

Standard <strong>Guhring</strong> std.<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type N N<br />

d 2<br />

shank tolerance h6 h6<br />

Helix angle 35°/38° 35°/38°<br />

d 1<br />

tolerance h10 h10<br />

Techn. data page 25 25<br />

Series 3736 3732<br />

Standard DIN 6527 L<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type N N<br />

d 2<br />

shank tolerance h6 h6<br />

Helix angle 35°/38° 35°/38°<br />

d 1<br />

tolerance h10 h10<br />

Techn. data page 25 25<br />

<strong>RF</strong>-LINE<br />

d2<br />

d1<br />

d2<br />

d1<br />

l 2<br />

l 2<br />

l 1<br />

l 1<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

fract. fract. fract. fract. flutes no.<br />

3/16 3/16 2 5/8 4 4.760 l<br />

1/4 1/4 2 1/2 3/4 4 6.350 l<br />

5/16 5/16 2 1/2 13/16 4 7.940 l<br />

3/8 3/8 2 1/2 1 4 9.520 l m<br />

7/16 7/16 2 3/4 1 4 11.110 l<br />

1/2 1/2 3 1 4 12.700 l m<br />

5/8 5/8 3 1/2 1 1/4 4 15.870 l m<br />

3/4 3/4 4 1 1/2 4 19.050 l m<br />

1 1 4 1 1/2 4 25.400 l m<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

mm mm mm mm flutes no.<br />

4.000 6.000 57.00 11.00 4 4.000 l m<br />

5.000 6.000 57.00 13.00 4 5.000 l m<br />

6.000 6.000 57.00 13.00 4 6.000 l m<br />

8.000 8.000 63.00 19.00 4 8.000 l m<br />

10.000 10.000 72.00 22.00 4 10.000 l m<br />

12.000 12.000 83.00 26.00 4 12.000 l m<br />

14.000 14.000 83.00 26.00 4 14.000 l m<br />

16.000 16.000 92.00 32.00 4 16.000 l m<br />

18.000 18.000 92.00 32.00 4 18.000 m m<br />

20.000 20.000 104.00 38.00 4 20.000 l m<br />

25.000 25.000 121.00 45.00 4 25.000 l m<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

8<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> U (universal) variable helix end mills for materials < 54 HRC<br />

Standard length with corner radius<br />

Series 3079<br />

Standard <strong>Guhring</strong> std.<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

N<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 35°/38°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 25<br />

Long length<br />

Series 3627<br />

Standard <strong>Guhring</strong> std.<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

N<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 35°/38°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 25<br />

All tools come with<br />

NAS-Style corner radius<br />

<strong>RF</strong>-LINE<br />

Diameter 1/2“ to 1“ with flatted shank<br />

r<br />

d2<br />

d1<br />

d2<br />

d1<br />

l 2<br />

l 2<br />

l 1<br />

l 1<br />

d1=d2 l1 l2 r no. Order<br />

Availability<br />

fract. fract. fract. fract. flutes no.<br />

1/4 2 1/2 3/4 0.015 4 6.352 l<br />

1/4 2 1/2 3/4 0.031 4 6.354 l<br />

5/16 2 1/2 13/16 0.031 4 7.944 l<br />

3/8 2 1/2 1 0.031 4 9.524 l<br />

7/16 2 3/4 1 1/4 0.031 4 11.114 l<br />

1/2 3 1/2 1 1/4 0.031 4 12.704 l<br />

1/2 3 1/2 1 1/4 0.040 4 12.705 l<br />

1/2 3 1/2 1 1/4 0.062 4 12.706 l<br />

1/2 3 1/2 1 1/4 0.090 4 12.707 l<br />

5/8 3 1/2 1 1/4 0.031 4 15.874 l<br />

5/8 3 1/2 1 1/4 0.062 4 15.876 l<br />

3/4 4 1 1/2 0.062 4 19.056 l<br />

3/4 4 1 1/2 0.090 4 19.057 l<br />

3/4 4 1 1/2 0.125 4 19.059 l<br />

1 4 1 1/2 0.062 4 25.406 l<br />

1 4 1 1/2 0.090 4 25.407 l<br />

1 4 1 1/2 0.125 4 25.409 l<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

mm mm mm mm flutes no.<br />

10.000 10.000 <strong>100</strong>.00 40.00 4 10.000 m<br />

12.000 12.000 150.00 45.00 4 12.000 m<br />

14.000 14.000 150.00 45.00 4 14.000 m<br />

16.000 16.000 150.00 65.00 4 16.000 m<br />

18.000 18.000 150.00 65.00 4 18.000 m<br />

20.000 20.000 150.00 65.00 4 20.000 m<br />

25.000 25.000 150.00 75.00 4 25.000 m<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

9

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> U/HF variable helix roughing /<br />

finishing end mills for materials < 54 HRC<br />

Based on our standard <strong>RF</strong> <strong>100</strong> end mills, we have developed<br />

a new series of variable-helix end mills with a completely<br />

new designed roughing profile.<br />

The result is a drastic increase in tool life compared to conventional<br />

knuckle-type geometries and an improvement<br />

in surface finish-quality of the workpiece, so that in many<br />

applications finishing operations are unnecessary.<br />

<strong>RF</strong>-LINE<br />

Surface finish quailty<br />

of 2-3 µm, requires no<br />

additional finishing<br />

operation in many cases<br />

• up to 60% higher in feed rates<br />

• vibration-free machining<br />

• increased surface finish quality (Ra = 2-3 µm)<br />

• small easy removable chips<br />

• less cutting pressure<br />

• vastly reduced horsepower consumption<br />

Ff in [N] Ff in [N]<br />

400<br />

300<br />

200<br />

<strong>100</strong><br />

0<br />

38°<br />

400<br />

300<br />

200<br />

<strong>100</strong><br />

0<br />

standard 4-flute<br />

35°<br />

<strong>RF</strong> <strong>100</strong><br />

0 0,5 1,0 1,5 2,0<br />

Linear milling section [mm]<br />

30°<br />

32°<br />

Material<br />

Application ranges<br />

H<br />

Hardness<br />

< 30 HRC<br />

30-38 HRC<br />

< 25 HRC<br />

> 25 HRC<br />

< Si 3%<br />

Si 3%-12%<br />

< 30 HRC<br />

30-38 HRC<br />

< 200 HB 30<br />

> 200 HB 30<br />

< 32 HRC<br />

32-50 HRC<br />

< 54 HRC<br />

<br />

<strong>RF</strong> <strong>100</strong> U<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

<strong>RF</strong> <strong>100</strong> VA<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

Micro edge<br />

protection<br />

for longer<br />

tool life<br />

<strong>RF</strong> <strong>100</strong> A<br />

<strong>RF</strong> <strong>100</strong> F<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> SF<br />

optimal suitability limited suitability hard machining<br />

H<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

10<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> U/HF (universal) variable helix end mills with roughing-finishing profile<br />

Standard length, fine truncated profile<br />

Series 3082<br />

Standard<br />

<strong>Guhring</strong> std.<br />

Tool material<br />

Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

HF (new)<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 30°/32°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 26<br />

NEW: Fine truncated profile<br />

<strong>RF</strong>-LINE<br />

1/2“ Ø and up with flatted shank<br />

NF HF<br />

d2<br />

d1<br />

l 2<br />

l 1<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

fract. fract. fract. fract. flutes no.<br />

1/4 1/4 2 1/2 3/4 4 6.350 l<br />

5/16 5/16 2 1/2 13/16 4 7.940 l<br />

3/8 3/8 2 1/2 1 4 9.520 l<br />

1/2 1/2 3 1/2 1 1/4 4 12.700 l<br />

5/8 5/8 3 1/2 1 1/4 4 15.870 l<br />

3/4 3/4 4 1 1/2 4 19.050 l<br />

1 1 4 1 1/2 4 25.400 l<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

11

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> F variable helix end mills for freecutting<br />

materials < 30 HRC<br />

We have developed the <strong>RF</strong> <strong>100</strong> end mill with variable spiral<br />

angle primarily to prevent chattering and the so-called<br />

corkscrew effect (as found when withdrawing tools having<br />

a large spiral angle)<br />

Milling cutters with internal coolant delivery offer a considerably<br />

longer tool life and higher feed rates compared<br />

to conventional tools. <strong>Guhring</strong> has designed the milling<br />

cutter’s radial coolant exit at an angle of 64º, offering considerable<br />

protection to the sensitive cutting edge corner.<br />

This coolant exit design also helps to prevent any built-up<br />

edge.<br />

<strong>RF</strong>-LINE<br />

Therefore, <strong>Guhring</strong>‘s <strong>RF</strong> <strong>100</strong> F variable helix end mills offer<br />

the following advantages:<br />

• up to 60% higher in feed rates<br />

• longer tool life<br />

• vibration-free machining<br />

• suitable for roughing and finishing<br />

• increased surface finish quality<br />

Micro edge<br />

protection<br />

for longer<br />

tool life<br />

Standard<br />

milling<br />

IC<br />

milling<br />

25 50 75 <strong>100</strong> 125<br />

Tool life in m<br />

Milling cutters with internal cooling achieve a 2/3 longer tool life in comparison<br />

with conventional milling cutters.<br />

40°<br />

42°<br />

Material<br />

Application ranges<br />

H<br />

Hardness<br />

< 30 HRC<br />

30-38 HRC<br />

< 25 HRC<br />

> 25 HRC<br />

< Si 3%<br />

Si 3%-12%<br />

< 30 HRC<br />

30-38 HRC<br />

< 200 HB 30<br />

> 200 HB 30<br />

< 32 HRC<br />

32-50 HRC<br />

< 54 HRC<br />

<strong>RF</strong> <strong>100</strong> U<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

<strong>RF</strong> <strong>100</strong> VA<br />

Optimal chip evacuation thanks<br />

to 64º radial coolant exit.<br />

<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> A<br />

<strong>RF</strong> <strong>100</strong> F<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> SF<br />

optimal suitability limited suitability hard machining<br />

H<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

12<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> F variable helix end mills for free-cutting materials < 30 HRC<br />

Standard length<br />

Series 3078<br />

Standard <strong>Guhring</strong> std.<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

NH<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 40°/42°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 27<br />

Series 3629 3366<br />

Standard DIN 6527 L<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type NH NH<br />

d 2<br />

shank tolerance h6 h6<br />

Helix angle 40°/42° 40°/42°<br />

d 1<br />

tolerance h10 h10<br />

Techn. data page 27 27<br />

d2<br />

d1<br />

d2<br />

d1<br />

<strong>RF</strong>-LINE<br />

Diameter 1/2“ to 1“ with flatted shank<br />

l 2<br />

l 2<br />

l 1<br />

l 1<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

fract. fract. fract. fract. flutes no.<br />

3/16 3/16 2 5/8 4 4.760 l<br />

1/4 1/4 2 1/2 3/4 4 6.350 l<br />

5/16 5/16 2 1/2 13/16 4 7.940 l<br />

3/8 3/8 2 1/2 1 4 9.520 l<br />

1/2 1/2 3 1/2 1 1/4 4 12.700 l<br />

5/8 5/8 3 1/2 1 1/4 4 15.870 l<br />

3/4 3/4 4 1 1/2 4 19.050 l<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

mm mm mm mm flutes no.<br />

4.000 6.000 57.00 11.00 4 4.000 m<br />

5.000 6.000 57.00 13.00 4 5.000 m<br />

6.000 6.000 57.00 13.00 4 6.000 m m<br />

8.000 8.000 63.00 19.00 4 8.000 m m<br />

10.000 10.000 72.00 22.00 4 10.000 m m<br />

12.000 12.000 83.00 26.00 4 12.000 m m<br />

16.000 16.000 92.00 32.00 4 16.000 m m<br />

20.000 20.000 104.00 38.00 4 20.000 m m<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

13

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> VA variable helix end mills<br />

for stainless steels<br />

Milling stainless steel presents some unique challenges.<br />

<strong>Guhring</strong> developed the <strong>RF</strong> <strong>100</strong> VA style variable helix end<br />

mill to have greater tool life and performance in stainless<br />

steels.<br />

<strong>RF</strong> <strong>100</strong> VA style end mills feature <strong>Guhring</strong>‘s newest highperformance<br />

coating, nano-A TM . This micro-layer coating<br />

has the superior heat and wear resistance that is needed<br />

when milling stainless steels.<br />

<strong>RF</strong>-LINE<br />

This end mill design also allows these benefits:<br />

• up to 60% higher feed rates<br />

• longer tool life<br />

• increased drilling depths<br />

• vibration-free machining<br />

• suitable for roughing and finishing<br />

• increased surface finish quality<br />

• reduced cutter wandering<br />

400<br />

standard 4-flute<br />

Micro edge<br />

protection<br />

for longer<br />

tool life<br />

Ff in [N] Ff in [N]<br />

300<br />

200<br />

<strong>100</strong><br />

0<br />

400<br />

300<br />

200<br />

<strong>100</strong><br />

<strong>RF</strong> <strong>100</strong><br />

0<br />

0 0,5 1,0 1,5 2,0<br />

Linear milling section [mm]<br />

A cutting force comparion between a conventiona type N and a <strong>RF</strong> <strong>100</strong><br />

variable helix end mill clearly shows the <strong>RF</strong> <strong>100</strong> end mill’s quieter and<br />

more stable machining characteristics<br />

Application ranges<br />

36°<br />

38°<br />

Material<br />

H<br />

Hardness<br />

< 30 HRC<br />

30-38 HRC<br />

< 25 HRC<br />

> 25 HRC<br />

< Si 3%<br />

Si 3%-12%<br />

< 30 HRC<br />

30-38 HRC<br />

< 200 HB 30<br />

> 200 HB 30<br />

< 32 HRC<br />

32-50 HRC<br />

< 54 HRC<br />

<strong>RF</strong> <strong>100</strong> U<br />

<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

<strong>RF</strong> <strong>100</strong> VA<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> A<br />

<strong>RF</strong> <strong>100</strong> F<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> SF<br />

optimal suitability limited suitability hard machining<br />

H<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

14<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> VA variable helix end mills for stainless steels<br />

Standard length<br />

Series 3080<br />

Standard<br />

<strong>Guhring</strong> std.<br />

Tool material<br />

Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

N<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 36°/38°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 28<br />

d2<br />

d1<br />

<strong>RF</strong>-LINE<br />

Diameter 1/2“ to 1“ with flatted shank<br />

l 2<br />

l 1<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

fract. fract. fract. fract. flutes no.<br />

3/16 3/16 2 5/8 4 4.760 l<br />

1/4 1/4 2 1/2 3/4 4 6.350 l<br />

5/16 5/16 2 1/2 13/16 4 7.940 l<br />

3/8 3/8 2 1/2 1 4 9.520 l<br />

1/2 1/2 3 1/2 1 1/4 4 12.700 l<br />

5/8 5/8 3 1/2 1 1/4 4 15.870 l<br />

3/4 3/4 4 1 1/2 4 19.050 l<br />

1 1 4 1 1/2 4 25.400 l<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

15

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> VA/NF variable helix roughing /<br />

finishing end mills for stainless steels<br />

<strong>RF</strong>-LINE<br />

Based on our standard <strong>RF</strong> <strong>100</strong> end mills, we have developed<br />

a new series of variable-helix end mills with a completely<br />

new designed roughing profile for stainless steel.<br />

The result is a drastic increase in tool life compared to conventional<br />

knuckle-type geometries and an improvement in<br />

surface finish-quality of the workpiece, so that in many applications<br />

finishing operations are unnecessary.<br />

<strong>RF</strong> <strong>100</strong> VA style end mills feature <strong>Guhring</strong>‘s newest highperformance<br />

coating, nano-A TM . This micro-layer coating<br />

has the superior heat and wear resistance that is needed<br />

when milling stainless steels.<br />

This end mill design also allows these benefits:<br />

• up to 60% higher in feed rates<br />

• vibration-free machining<br />

• increased surface finish quality<br />

• small easy removable chips<br />

• less cutting preasure<br />

• vastly reduced horsepower consumption<br />

Surface finish quailty<br />

of 2-3 µm, requires no<br />

additional finishing<br />

operation in many cases<br />

Ff in [N] Ff in [N]<br />

400<br />

300<br />

200<br />

38°<br />

<strong>100</strong><br />

0<br />

standard 4-flute<br />

35°<br />

400 <strong>RF</strong> <strong>100</strong><br />

300<br />

200<br />

<strong>100</strong><br />

0<br />

0 0,5 1,0 1,5 2,0<br />

Linear Linear milling milling section section [mm] [mm]<br />

36°<br />

38°<br />

Material<br />

Application ranges<br />

H<br />

Hardness<br />

< 30 HRC<br />

30-38 HRC<br />

< 25 HRC<br />

> 25 HRC<br />

< Si 3%<br />

Si 3%-12%<br />

< 30 HRC<br />

30-38 HRC<br />

< 200 HB 30<br />

> 200 HB 30<br />

< 32 HRC<br />

32-50 HRC<br />

< 54 HRC<br />

<strong>RF</strong> <strong>100</strong> U<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

Micro edge<br />

protection<br />

for longer<br />

tool life<br />

<br />

<strong>RF</strong> <strong>100</strong> VA<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> A<br />

<strong>RF</strong> <strong>100</strong> F<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> SF<br />

optimal suitability limited suitability hard machining<br />

H<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

16<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> VA/NF variable helix end mills with roughing / finishing profile for stainless steel<br />

Standard length, coarse truncated profile<br />

Series 3081<br />

Standard<br />

<strong>Guhring</strong> std.<br />

Tool material<br />

Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

NF (new)<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 36°/ 38°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 29<br />

NEW: Coarse truncated profile<br />

<strong>RF</strong>-LINE<br />

1/2“ Ø and up with flatted shank<br />

NF<br />

d2<br />

d1<br />

l 2<br />

l 1<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

mm mm mm mm flutes no.<br />

1/4 1/4 2 1/2 3/4 4 6.350 l<br />

5/16 5/16 2 1/2 13/16 4 7.940 l<br />

3/8 3/8 2 1/2 1 4 9.520 l<br />

1/2 1/2 3 1/2 1 1/4 4 12.700 l<br />

5/8 5/8 3 1/2 1 1/4 4 15.870 l<br />

3/4 3/4 4 1 1/2 4 19.050 l<br />

1 1 4 1 1/2 5 25.400 l<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

17

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> Ti variable helix end mills<br />

for titanium and nickel alloys<br />

We have developed the <strong>RF</strong> <strong>100</strong> end mill with variable spiral<br />

angle primarily to prevent chattering and the so-called<br />

corkscrew effect (as found when withdrawing tools having<br />

a large spiral angle)<br />

The <strong>RF</strong> <strong>100</strong> Ti is especially designed for titanium and other<br />

aerospace alloys, and has a totally new corner radius design<br />

for increased tool life and highest metal removal rates.<br />

The special features of <strong>Guhring</strong>’s milling cutters with<br />

corner radius are:<br />

• outside diameter and the radius is ground in one pass<br />

• radius point geometry with constant helix-radius<br />

correction<br />

<strong>RF</strong>-LINE<br />

High wear protection thanks to radius geometry with constant rake angle<br />

and continuous spiral.<br />

Seamless radius area provides high form and contour accuracy.<br />

Application ranges<br />

35°<br />

38°<br />

Material<br />

H<br />

Hardness<br />

< 30 HRC<br />

30-38 HRC<br />

< 25 HRC<br />

> 25 HRC<br />

< Si 3%<br />

Si 3%-12%<br />

< 30 HRC<br />

30-38 HRC<br />

< 200 HB 30<br />

> 200 HB 30<br />

< 32 HRC<br />

32-50 HRC<br />

< 54 HRC<br />

<strong>RF</strong> <strong>100</strong> U<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

<strong>RF</strong> <strong>100</strong> VA<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> A<br />

<br />

<strong>RF</strong> <strong>100</strong> F<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> SF<br />

optimal suitability limited suitability hard machining<br />

H<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

18<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> Ti variable helix end mills for titanium and nickel alloys<br />

Standard length with corner radius<br />

Series 3876<br />

Standard<br />

<strong>Guhring</strong> std.<br />

Tool material<br />

Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

N<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 35°/38°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 30<br />

All tools come with<br />

NAS-style corner radius<br />

<strong>RF</strong>-LINE<br />

Diameter 1/2“ to 1“ with flatted shank<br />

r<br />

d2<br />

d1<br />

l 2<br />

l 1<br />

d1=d2 l1 l2 r no. Order<br />

Availability<br />

fract. fract. fract. fract.<br />

flutes no.<br />

1/4 2 1/2 3/4 0.015 4 6.352 l<br />

1/4 2 1/2 3/4 0.031 4 6.354 l<br />

5/16 2 1/2 13/16 0.031 4 7.944 l<br />

3/8 2 1/2 1 0.031 4 9,524 l<br />

7/16 2 3/4 1 1/4 0.031 4 11.114 l<br />

1/2 3 1/2 1 1/4 0.031 4 12.704 l<br />

1/2 3 1/2 1 1/4 0.040 4 12.705 l<br />

1/2 3 1/2 1 1/4 0.062 4 12.706 l<br />

1/2 3 1/2 1 1/4 0.090 4 12.707 l<br />

5/8 3 1/2 1 1/4 0.031 4 15.874 l<br />

5/8 3 1/2 1 1/4 0.062 4 15.876 l<br />

3/4 4 1 1/2 0.062 4 19.056 l<br />

3/4 4 1 1/2 0.090 4 19.057 l<br />

3/4 4 1 1/2 0.125 4 19.059 l<br />

1 4 1 1/2 0.062 4 25.406 l<br />

1 4 1 1/2 0.090 4 25.407 l<br />

1 4 1 1/2 0.125 4 25.409 l<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

19

<strong>RF</strong>-LINE<br />

<strong>Guhring</strong> variable helix end mills <strong>RF</strong> <strong>100</strong> A<br />

for aluminum and cast aluminum<br />

The <strong>RF</strong> <strong>100</strong> A style variable helix end mill is designed specifically<br />

for milling aluminum and aluminum alloys. Higher<br />

helix and cutting edge rake angles are well-suited for<br />

aluminum milling applications, and provide optimum tool<br />

life and performance.<br />

<strong>Guhring</strong>‘s <strong>RF</strong> <strong>100</strong> A variable helix end mills offer the<br />

following advantages:<br />

• up to 60% higher in feed rates<br />

• longer tool life<br />

• vibration-free machining<br />

• suitable for roughing and finishing<br />

• increased surface finish quality<br />

<strong>RF</strong>-LINE<br />

Type W<br />

Micro edge<br />

protection<br />

for longer<br />

tool life<br />

10 µm 10 µm<br />

Peak-to-valley height Ra = 0.81 μm<br />

<strong>RF</strong> <strong>100</strong> end mill<br />

Rt = 5.8 μm<br />

35°<br />

Peak-to-valley height Ra = 0.26 μm<br />

Rt = 1.8 μm<br />

38°<br />

Surface finish quality comparison between a conventional end mill type<br />

N and a <strong>RF</strong> <strong>100</strong> end mill clearly shows the <strong>RF</strong> <strong>100</strong> end mill’s quieter and<br />

more stable machining characteristics.<br />

Application ranges<br />

40°<br />

42°<br />

Material<br />

Hardness<br />

< 30 HRC<br />

30-38 HRC<br />

< 25 HRC<br />

> 25 HRC<br />

< Si 3%<br />

Si 3%-12%<br />

< 30 HRC<br />

30-38 HRC<br />

< 200 HB 30<br />

> 200 HB 30<br />

< 32 HRC<br />

32-50 HRC<br />

H<br />

< 54 HRC<br />

<strong>RF</strong> <strong>100</strong> U<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

<strong>RF</strong> <strong>100</strong> VA<br />

<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> A<br />

<strong>RF</strong> <strong>100</strong> F<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> SF<br />

optimal suitability limited suitability hard machining<br />

H<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

20<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> A variable helix end mills for aluminum and cast aluminum < 22 HRC<br />

Standard length<br />

Series 3077<br />

Standard <strong>Guhring</strong> std.<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

W<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 40°/42°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 31<br />

Series 3202<br />

Standard DIN 6527 L<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

W<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 40°/42°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 31<br />

d2<br />

d1<br />

d2<br />

d1<br />

<strong>RF</strong>-LINE<br />

Diameter 1/2“ to 1“ with flatted shank<br />

l 2<br />

l 2<br />

l 1<br />

l 1<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

fract. fract. fract. fract. flutes no.<br />

3/16 3/16 2 5/8 4 4.760 l<br />

1/4 1/4 2 1/2 3/4 4 6.350 l<br />

5/16 5/16 2 1/2 13/16 4 7.940 l<br />

3/8 3/8 2 1/2 1 4 9.520 l<br />

1/2 1/2 3 1/2 1 1/4 4 12.700 l<br />

5/8 5/8 3 1/2 1 1/4 4 15.870 l<br />

3/4 3/4 4 1 1/2 4 19.050 l<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

mm mm mm mm flutes no.<br />

4.000 6.000 57.00 11.00 4 4.000 m<br />

5.000 6.000 57.00 13.00 4 5.000 m<br />

6.000 6.000 57.00 13.00 4 6.000 m<br />

8.000 8.000 63.00 19.00 4 8.000 m<br />

10.000 10.000 72.00 22.00 4 10.000 m<br />

12.000 12.000 83.00 26.00 4 12.000 m<br />

16.000 16.000 92.00 32.00 4 16.000 m<br />

20.000 20.000 104.00 38.00 4 20.000 m<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

21

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> SF ”Super Finish“:<br />

the versatile variable helix end mill<br />

<strong>RF</strong>-LINE<br />

optimized web thinning<br />

and flute profile<br />

44°<br />

45°<br />

46°<br />

20<br />

18<br />

Standweg L f<br />

[m]<br />

16<br />

14<br />

12<br />

10<br />

8<br />

Micro edge<br />

protection<br />

for longer<br />

tool life<br />

6<br />

4<br />

2<br />

0<br />

Based on our 4-fluted <strong>RF</strong> <strong>100</strong> U end mill, <strong>RF</strong> <strong>100</strong> SF<br />

possesses a larger, more rigid core paired with 6 cutting<br />

edges. As well as fine finishing, the application range also<br />

includes semi-roughing operations, i.e. feed widths (ae) up<br />

to 0.3 x d.<br />

Thanks to its special geometry, <strong>RF</strong> <strong>100</strong> SF<br />

offers the following advantages:<br />

• high form accuracy<br />

• vibration-free<br />

• optimized flute profile<br />

• high feed rates possible<br />

• optimal surface finish quality<br />

• improved tool life<br />

Gühring <strong>RF</strong> <strong>100</strong><br />

Tool life Lf [m]<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

<strong>Guhring</strong> <strong>RF</strong> <strong>100</strong><br />

Tool-Ø: 20 mm<br />

Coating: FIREX<br />

Cutting depth: 30 mm<br />

Feed: DOC = 30 mm/ae = 4mm<br />

Feed rate: 7,800 mm/tooth<br />

Tool life: 15 m<br />

Competition<br />

Tool life comparison:<br />

In finishing operations in 42CrMo4<strong>RF</strong>, <strong>RF</strong> <strong>100</strong> SF achieves a 7-fold tool life<br />

increase in comparison with conventional end mills.<br />

Material<br />

Hardness<br />

< 30 HRC<br />

30-38 HRC<br />

Werkzeug-Ø: 20 mm<br />

Beschichtung: FIRE<br />

Schnitttiefe: 30 mm<br />

Zustellung: a p<br />

= 30 mm/a e<br />

= 4 mm<br />

Vorschub: 7.800 mm/Z<br />

Standweg: 15 m<br />

Application ranges<br />

< 25 HRC<br />

> 25 HRC<br />

< Si 3%<br />

Si 3%-12%<br />

< 30 HRC<br />

30-38 HRC<br />

Tool-Ø: 20 mm<br />

Coating: TiAlN<br />

Cutting depth: 10 mm<br />

Feed: DOC = 30 mm/ae = 4mm<br />

Feed rate: 2,250 mm/tooth<br />

Tool life: 15 m<br />

< 200 HB 30<br />

> 200 HB 30<br />

< 32 HRC<br />

32-50 HRC<br />

H<br />

< 54 HRC<br />

<strong>RF</strong> <strong>100</strong> U<br />

<strong>RF</strong> <strong>100</strong> U/HF<br />

<strong>RF</strong> <strong>100</strong> VA<br />

<strong>RF</strong> <strong>100</strong> VA/NF<br />

<strong>RF</strong> <strong>100</strong> A<br />

<strong>RF</strong> <strong>100</strong> F<br />

<br />

<strong>RF</strong> <strong>100</strong> Ti<br />

<strong>RF</strong> <strong>100</strong> SF<br />

optimal suitability limited suitability hard machining<br />

H<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

22<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700

<strong>RF</strong>-LINE<br />

<strong>RF</strong> <strong>100</strong> SF 6-flute variable helix end mills for materials < 54 HRC<br />

Standard length<br />

Series 3115<br />

Standard <strong>Guhring</strong> std.<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

NH<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 44°/45°/46°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 32<br />

Series 3631<br />

Standard DIN 6527 L<br />

Tool material Solid carbide<br />

Surface finish<br />

Application<br />

Type<br />

NH<br />

d 2<br />

shank tolerance<br />

h6<br />

Helix angle 44°/45°/46°<br />

d 1<br />

tolerance<br />

h10<br />

Techn. data page 32<br />

d2<br />

d1<br />

d2<br />

d1<br />

<strong>RF</strong>-LINE<br />

l 2<br />

l 2<br />

l 1<br />

l 1<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

fract. fract. fract. fract. flutes no.<br />

5/16 5/16 2 1/2 13/16 6 7.940 l<br />

3/8 3/8 2 1/2 1 6 9.520 l<br />

1/2 1/2 3 1 6 12.700 l<br />

5/8 5/8 3 1/2 1 1/4 6 15.870 l<br />

3/4 3/4 4 1 1/2 6 19.050 l<br />

1 1 4 1 1/2 6 25.400 l<br />

d1 d2 l1 l2 no. Order<br />

Availability<br />

mm mm mm mm flutes no.<br />

8.000 8.000 63.00 19.00 6 8.000 m<br />

10.000 10.000 72.00 22.00 6 10.000 m<br />

12.000 12.000 83.00 26.00 6 12.000 m<br />

16.000 16.000 92.00 32.00 6 16.000 m<br />

20.000 20.000 104.00 38.00 6 20.000 m<br />

25.000 25.000 121.00 45.00 6 25.000 m<br />

All <strong>RF</strong> <strong>100</strong> end mills feature a corner chamfer for cutting edge protection.<br />

Please see the Technical Section of this brochure for details on the chamfer.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

When ordering: EDP no. = Series + Order no., example: 3867 12.700<br />

23

Technical section

<strong>RF</strong> <strong>100</strong> U <strong>End</strong> Mill Feeds and Speeds<br />

and Hardened Steel - Series 3079, 3099,<br />

3<strong>100</strong>, 3113, 3114, 3627, 3731, 3732, 3736<br />

Values based on FIREX ® coated end mill<br />

Adjustment for Axial DOC (Depth of Cut):<br />

2 x Cutter Dia. IPT 50% Ramp cut reduce IPT by 30%<br />

Drilling reduce IPT 50%<br />

Type of Cut<br />

Calculations based on the following.<br />

Radial Width of Cut<br />

(WOC)<br />

Axial Depth of Cut<br />

(DOC)<br />

Slot 1 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Rough .3 to .8 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Finish .1 to .2 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Material<br />

Color<br />

Code<br />

Hardness<br />

Type of<br />

Cut<br />

Speed<br />

Feed (inches per tooth) by tool diameter<br />

SFM 1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 1.0”<br />

Free Machining & Low Carbon Steels<br />

<strong>100</strong>6, <strong>100</strong>8, 1015, 1018, 1020, 1022, 1025, 1117, 1140, 1141,<br />

11L08, 11L14, 1213, 12L13, 12L14, 1215, 1330<br />

Less Than<br />

28 HRc<br />

Slot 425 .0006 .0011 .0020 .0026 .0031 .0036 .0055<br />

Rough 475 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 600 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

Medium & High Carbon Steel, Alloy Steel<br />

& easy-to-machine Tool Steel<br />

1030, 1035, 1040, 1045, 1050, 1052, 1055, 1060, 1085, 1095,<br />

1541, 1551, 9255, 2515, 3135, 3415, 4130, 4137, 4140, 4150,<br />

4320, 4340, 4520, 5015, 5115, 5120, 5132, 5140, 5155, 6150,<br />

8620, 9262, 9840, 52<strong>100</strong>, O1, O2, O6, S2, W1 to W310<br />

Less than<br />

38 HRc<br />

Slot 375 .0006 .0011 .0020 .0026 .0031 .0036 .0055<br />

Rough 450 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 550 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

Tool Steels & Die Steels<br />

O7, M1, M2, M3, M4, M7, T1, T2, T4, T5, T8, T15, A2, A3, A6,<br />

A7, H10, H11, H12, H13, H19, H21, L3, L6, L7, P2, P20, S1,<br />

S5, S7, 52<strong>100</strong>, A 128, D2, D3, D4, D5, D7<br />

Less than<br />

38 HRc<br />

Slot 350 .0006 .0012 .0019 .0024 .0028 .0033 .0051<br />

Rough 425 .0008 .0015 .0024 .0030 .0035 .0041 .0064<br />

Finish 500 .0009 .0018 .0029 .0036 .0042 .0050 .0077<br />

Hardened Steels<br />

Carbon and Alloy Steels, Tool & Die Steels<br />

40 HRc to<br />

54 HRc<br />

54 HRc to<br />

60 HRc<br />

Slot 150 .0004 .0010 .0014 .0019 .0023 .0027 .0039<br />

Rough 175 .0005 .0013 .0018 .0024 .0029 .0034 .0049<br />

Finish 200 .0006 .0015 .0021 .0029 .0035 .0041 .0059<br />

Slot<br />

Rough<br />

Finish<br />

Stainless Steel<br />

Easy to Machine - 416, 410, 430, 302, 303<br />

Less than<br />

28 HRc<br />

Slot 180 .0006 .0011 .0015 .0020 .0024 .0030 .0040<br />

Rough 250 .0008 .0014 .0019 .0025 .0030 .0038 .0050<br />

Finish 450 .0009 .0017 .0023 .0030 .0036 .0045 .0060<br />

Stainless Steel<br />

Moderately Difficult - 304, 316, Invar, Kovar<br />

Less than<br />

28 HRc<br />

Slot 180 .0006 .0012 .0015 .0020 .0024 .0030 .0040<br />

Rough 200 .0008 .0015 .0019 .0025 .0030 .0038 .0050<br />

Finish 400 .0009 .0018 .0023 .0030 .0036 .0045 .0060<br />

Stainless Steel<br />

Difficult to Machine - 316L, 17-4 PH, 15-5 PH, 13-8 PH<br />

Less than<br />

38 HRc<br />

Slot 150 .0005 .0009 .0013 .0018 .0022 .0028 .0038<br />

Rough 180 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 350 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

High-Temperature Alloys<br />

Nimonic, <strong>Inc</strong>onel, Monel, Hastelloy<br />

Less than<br />

38 HRc<br />

Slot 75 .0002 .0005 .0010 .0012 .0015 .0016 .0022<br />

Rough <strong>100</strong> .0003 .0006 .0013 .0015 .0019 .0020 .0028<br />

Finish 130 .0003 .0008 .0015 .0018 .0023 .0024 .0033<br />

Titanium Alloys<br />

6AI-4V, 5AI-2.5 Sn, 6AI-2Sn-4Zr-6Mo, 3Ai-8V-6Cr4Mo-4Zr,<br />

10V-2Fe-3Ai, 13V-11Cr-3Ai<br />

Less than<br />

38 HRc<br />

Slot 150 .0002 .0005 .0010 .0012 .0015 .0016 .0022<br />

Rough 200 .0003 .0006 .0013 .0015 .0019 .0020 .0028<br />

Finish 350 .0003 .0008 .0015 .0018 .0023 .0024 .0033<br />

Cast Iron - Gray CG<br />

ASTM A48, CLASS 20, 25, 30, 35, SAE J431C, GRADES<br />

G1800, G3000, G3500, GG 10, 15, 20, 25, 30, 35, 40<br />

Cast Iron - Ductile & Malleable CGI<br />

60-40-18, 65-45-12, D4018, D4512, D5506, 32510, 35108,<br />

M3210, M4504, M5503, 250, 300, 350, 400, 450<br />

Less than<br />

32 HRc<br />

Less than<br />

32 HRc<br />

Slot 600 .0006 .0011 .0020 .0026 .0031 .0036 .0055<br />

Rough 675 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 800 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

Slot 500 .0006 .0011 .0020 .0026 .0031 .0036 .0055<br />

Rough 575 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 650 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

TECHNICAL<br />

SECTION<br />

Aluminum<br />

Alloys - 2024, 6061, 7075, Wrought<br />

Less than<br />

150 HB30<br />

Slot<br />

Rough<br />

Finish<br />

Aluminum<br />

High Silicon - A380, A390, Castings<br />

Less than<br />

180 HB30<br />

Slot<br />

Rough<br />

Finish<br />

Magnesium Alloys<br />

Less than<br />

180 HB30<br />

Slot<br />

Rough<br />

Finish<br />

Non-ferrous<br />

Copper Alloys, Brass, Bronze<br />

Less than<br />

120 HB30<br />

Slot<br />

Rough<br />

Finish<br />

These feeds and speeds are recommendations for initial setup. In actual use, depending on the machining environment and<br />

workpiece material, significantly higher speeds and feeds may be achievable. Tools with bold feed column no. are preferred choice.<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

25

<strong>RF</strong> <strong>100</strong> U-HF - <strong>End</strong> Mill Feeds and Speeds<br />

- Series 3082<br />

Values based on FIREX ® coated end mill<br />

Adjustment for Axial DOC (Depth of Cut):<br />

2 x Cutter Dia. IPT 50% Ramp cut reduce IPT by 30%<br />

Drilling reduce IPT 50%<br />

Type of Cut<br />

Calculations based on the following.<br />

Radial Width of Cut<br />

(WOC)<br />

Axial Depth of Cut<br />

(DOC)<br />

Slot 1 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Rough .3 to .8 x Cutter Dia. .5 to 1.5 x Cutter Dia.<br />

Semi-Finish .1 to .2 x Cutter Dia. .5 to 2.0 x Cutter Dia.<br />

Material<br />

Free Machining & Low Carbon Steels<br />

<strong>100</strong>6, <strong>100</strong>8, 1015, 1018, 1020, 1022, 1025, 1117, 1140, 1141,<br />

11L08, 11L14, 1213, 12L13, 12L14, 1215, 1330<br />

Medium & High Carbon Steel, Alloy Steel<br />

& easy-to-machine Tool Steel<br />

1030, 1035, 1040, 1045, 1050, 1052, 1055, 1060, 1085, 1095,<br />

1541, 1551, 9255, 2515, 3135, 3415, 4130, 4137, 4140, 4150,<br />

4320, 4340, 4520, 5015, 5115, 5120, 5132, 5140, 5155, 6150,<br />

8620, 9262, 9840, 52<strong>100</strong>, O1, O2, O6, S2, W1 to W310<br />

Color<br />

Code<br />

Hardness Type of Cut<br />

Less Than<br />

28 HRc<br />

Less than<br />

38 HRc<br />

Speed<br />

Feed (inches per tooth) by tool diameter<br />

SFM 1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 1.0”<br />

Slot 380 .0005 .0010 .0018 .0023 .0028 .0032 .0050<br />

Rough 420 .0007 .0012 .0023 .0029 .0035 .0041 .0062<br />

Semi-Finish 540 .0008 .0015 .0027 .0035 .0042 .0049 .0074<br />

Slot 330 .0005 .0010 .0018 .0023 .0028 .0032 .0050<br />

Rough 400 .0007 .0012 .0023 .0029 .0035 .0041 .0062<br />

Semi-Finish 500 .0008 .0015 .0027 .0035 .0042 .0049 .0074<br />

TECHNICAL<br />

SECTION<br />

Tool Steels & Die Steels<br />

O7, M1, M2, M3, M4, M7, T1, T2, T4, T5, T8, T15, A2, A3, A6,<br />

A7, H10, H11, H12, H13, H19, H21, L3, L6, L7, P2, P20, S1,<br />

S5, S7, 52<strong>100</strong>, A 128, D2, D3, D4, D5, D7<br />

Hardened Steels<br />

Carbon and Alloy Steels, Tool & Die Steels<br />

Stainless Steel<br />

Easy to Machine - 416, 410, 430, 302, 303<br />

Stainless Steel<br />

Moderately Difficult - 304, 316, Invar, Kovar<br />

Stainless Steel<br />

Difficult to Machine - 316L, 17-4 PH, 15-5 PH, 13-8 PH<br />

High-Temperature Alloys<br />

Nimonic, <strong>Inc</strong>onel, Monel, Hastelloy<br />

Titanium Alloys<br />

6AI-4V, 5AI-2.5 Sn, 6AI-2Sn-4Zr-6Mo, 3Ai-8V-6Cr4Mo-4Zr,<br />

10V-2Fe-3Ai, 13V-11Cr-3Ai<br />

Cast Iron - Gray CG<br />

ASTM A48, CLASS 20, 25, 30, 35, SAE J431C, GRADES<br />

G1800, G3000, G3500, GG 10, 15, 20, 25, 30, 35, 40<br />

Cast Iron - Ductile & Malleable CGI<br />

60-40-18, 65-45-12, D4018, D4512, D5506, 32510, 35108,<br />

M3210, M4504, M5503, 250, 300, 350, 400, 450<br />

Aluminum<br />

Alloys - 2024, 6061, 7075, Wrought<br />

Aluminum<br />

High Silicon - A380, A390, Castings<br />

Magnesium Alloys<br />

Non-ferrous<br />

Copper Alloys, Brass, Bronze<br />

Less than<br />

38 HRc<br />

40 HRc to<br />

54 HRc<br />

54 HRc to<br />

60 HRc<br />

Less than<br />

28 HRc<br />

Less than<br />

28 HRc<br />

Less than<br />

38 HRc<br />

Less than<br />

38 HRc<br />

Less than<br />

38 HRc<br />

Less than<br />

32 HRc<br />

Less than<br />

32 HRc<br />

Slot 310 .0005 .0011 .0017 .0022 .0025 .0030 .0046<br />

Rough 380 .0007 .0014 .0021 .0027 .0032 .0037 .0057<br />

Semi-Finish 450 .0008 .0016 .0026 .0032 .0038 .0045 .0069<br />

Slot 130 .0004 .0009 .0013 .0017 .0021 .0024 .0035<br />

Rough 150 .0005 .0011 .0016 .0021 .0026 .0030 .0044<br />

Semi-Finish 180 .0005 .0014 .0019 .0026 .0031 .0036 .0053<br />

Slot<br />

Rough<br />

Semi-Finish<br />

Slot 160 .0005 .0010 .0014 .0018 .0022 .0027 .0036<br />

Rough 225 .0007 .0012 .0017 .0023 .0027 .0034 .0045<br />

Semi-Finish 400 .0008 .0015 .0020 .0027 .0032 .0041 .0054<br />

Slot 160 .0005 .0011 .0014 .0018 .0022 .0027 .0036<br />

Rough 180 .0007 .0014 .0017 .0023 .0027 .0034 .0045<br />

Semi-Finish 360 .0008 .0016 .0020 .0027 .0032 .0041 .0054<br />

Slot 135 .0005 .0008 .0012 .0016 .0020 .0025 .0034<br />

Rough 160 .0007 .0012 .0023 .0029 .0035 .0041 .0062<br />

Semi-Finish 320 .0008 .0015 .0027 .0035 .0042 .0049 .0074<br />

Slot 65 .0002 .0005 .0009 .0011 .0014 .0014 .0020<br />

Rough 90 .0002 .0006 .0011 .0014 .0017 .0018 .0025<br />

Semi-Finish 115 .0003 .0007 .0014 .0016 .0020 .0022 .0030<br />

Slot 135 .0002 .0005 .0009 .0011 .0014 .0014 .0020<br />

Rough 180 .0002 .0006 .0011 .0014 .0017 .0018 .0025<br />

Semi-Finish 315 .0003 .0007 .0014 .0016 .0020 .0022 .0030<br />

Slot 540 .0005 .0010 .0018 .0023 .0028 .0032 .0050<br />

Rough 600 .0007 .0012 .0023 .0029 .0035 .0041 .0062<br />

Semi-Finish 720 .0008 .0015 .0027 .0035 .0042 .0049 .0074<br />

Slot 450 .0005 .0010 .0018 .0023 .0028 .0032 .0050<br />

Rough 500 .0007 .0012 .0023 .0029 .0035 .0041 .0062<br />

Semi-Finish 585 .0008 .0015 .0027 .0035 .0042 .0049 .0074<br />

Slot<br />

Less than<br />

Rough<br />

150 HB30<br />

Semi-Finish<br />

Slot<br />

Less than<br />

Rough<br />

180 HB30<br />

Semi-Finish<br />

Slot<br />

Less than<br />

Rough<br />

180 HB30<br />

Semi-Finish<br />

Slot<br />

Less than<br />

Rough<br />

120 HB30<br />

Semi-Finish<br />

These feeds and speeds are recommendations for initial setup. In actual use, depending on the machining environment and<br />

workpiece material, significantly higher speeds and feeds may be achievable. Tools with bold feed column no. are preferred choice.<br />

bright Super-A FIREX ® nano-A l stocked in USA m stocked internationally<br />

26

<strong>RF</strong> <strong>100</strong> F <strong>End</strong> Mill Feeds and Speeds<br />

Series 3078, 3366, 3629<br />

Values based on FIREX ® coated end mill<br />

Adjustment for Axial DOC (Depth of Cut):<br />

2 x Cutter Dia. IPT 50% Ramp cut reduce IPT by 30%<br />

Drilling reduce IPT 50%<br />

Type of Cut<br />

Calculations based on the following.<br />

Radial Width of Cut<br />

(WOC)<br />

Axial Depth of Cut<br />

(DOC)<br />

Slot 1 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Rough .3 to .8 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Finish .1 to .2 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Material<br />

Color<br />

Code<br />

Hardness<br />

Type of<br />

Cut<br />

Speed<br />

Feed (inches per tooth) by tool diameter<br />

SFM 1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 1.0”<br />

Free Machining & Low Carbon Steels<br />

<strong>100</strong>6, <strong>100</strong>8, 1015, 1018, 1020, 1022, 1025, 1117, 1140, 1141,<br />

11L08, 11L14, 1213, 12L13, 12L14, 1215, 1330<br />

Medium & High Carbon Steel, Alloy Steel<br />

& easy-to-machine Tool Steel<br />

1030, 1035, 1040, 1045, 1050, 1052, 1055, 1060, 1085, 1095,<br />

1541, 1551, 9255, 2515, 3135, 3415, 4130, 4137, 4140, 4150,<br />

4320, 4340, 4520, 5015, 5115, 5120, 5132, 5140, 5155, 6150,<br />

8620, 9262, 9840, 52<strong>100</strong>, O1, O2, O6, S2, W1 to W310<br />

Less Than<br />

28 HRc<br />

Less than<br />

38 HRc<br />

Slot 425 .0006 .0011 .0020 .0026 .0031 .0036 .0055<br />

Rough 475 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 600 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

Slot 375 .0006 .0011 .0020 .0026 .0031 .0036 .0055<br />

Rough 450 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 550 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

Tool Steels & Die Steels<br />

O7, M1, M2, M3, M4, M7, T1, T2, T4, T5, T8, T15, A2, A3, A6,<br />

A7, H10, H11, H12, H13, H19, H21, L3, L6, L7, P2, P20, S1,<br />

S5, S7, 52<strong>100</strong>, A 128, D2, D3, D4, D5, D7<br />

Hardened Steels<br />

Carbon and Alloy Steels, Tool & Die Steels<br />

Stainless Steel<br />

Easy to Machine - 416, 410, 430, 302, 303<br />

Stainless Steel<br />

Moderately Difficult - 304, 316, Invar, Kovar<br />

Stainless Steel<br />

Difficult to Machine - 316L, 17-4 PH, 15-5 PH, 13-8 PH<br />

High-Temperature Alloys<br />

Nimonic, <strong>Inc</strong>onel, Monel, Hastelloy<br />

Titanium Alloys<br />

6AI-4V, 5AI-2.5 Sn, 6AI-2Sn-4Zr-6Mo, 3Ai-8V-6Cr4Mo-4Zr,<br />

10V-2Fe-3Ai, 13V-11Cr-3Ai<br />

Cast Iron - Gray CG<br />

ASTM A48, CLASS 20, 25, 30, 35, SAE J431C, GRADES<br />

G1800, G3000, G3500, GG 10, 15, 20, 25, 30, 35, 40<br />

Cast Iron - Ductile & Malleable CGI<br />

60-40-18, 65-45-12, D4018, D4512, D5506, 32510, 35108,<br />

M3210, M4504, M5503, 250, 300, 350, 400, 450<br />

Aluminum<br />

Alloys - 2024, 6061, 7075, Wrought<br />

Aluminum<br />

High Silicon - A380, A390, Castings<br />

Magnesium Alloys<br />

Non-ferrous<br />

Copper Alloys, Brass, Bronze<br />

Less than<br />

38 HRc<br />

40 HRc to<br />

54 HRc<br />

54 HRc to<br />

60 HRc<br />

Less than<br />

28 HRc<br />

Less than<br />

28 HRc<br />

Less than<br />

38 HRc<br />

Less than<br />

38 HRc<br />

Less than<br />

38 HRc<br />

Less than<br />

32 HRc<br />

Less than<br />

32 HRc<br />

Less than<br />

150 HB30<br />

Less than<br />

180 HB30<br />

Less than<br />

180 HB30<br />

Less than<br />

120 HB30<br />

These feeds and speeds are recommendations for initial setup. In actual use, depending on the machining environment and<br />

workpiece material, significantly higher speeds and feeds may be achievable. Tools with bold feed column no. are preferred choice.<br />

Slot 350 .0006 .0012 .0019 .0024 .0028 .0033 .0051<br />

Rough 425 .0008 .0015 .0024 .0030 .0035 .0041 .0064<br />

Finish 500 .0009 .0018 .0029 .0036 .0042 .0050 .0077<br />

Slot<br />

Rough<br />

Finish<br />

Slot<br />

Rough<br />

Finish<br />

Slot 180 .0006 .0011 .0015 .0020 .0024 .0030 .0040<br />

Rough 250 .0008 .0014 .0019 .0025 .0030 .0038 .0050<br />

Finish 450 .0009 .0017 .0023 .0030 .0036 .0045 .0060<br />

Slot 180 .0006 .0012 .0015 .0020 .0024 .0030 .0040<br />

Rough 200 .0008 .0015 .0019 .0025 .0030 .0038 .0050<br />

Finish 400 .0009 .0018 .0023 .0030 .0036 .0045 .0060<br />

Slot 150 .0005 .0009 .0013 .0018 .0022 .0028 .0038<br />

Rough 180 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 350 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

Slot 75 .0002 .0005 .0010 .0012 .0015 .0016 .0022<br />

Rough <strong>100</strong> .0003 .0006 .0013 .0015 .0019 .0020 .0028<br />

Finish 130 .0003 .0008 .0015 .0018 .0023 .0024 .0033<br />

Slot 150 .0002 .0005 .0010 .0012 .0015 .0016 .0022<br />

Rough 200 .0003 .0006 .0013 .0015 .0019 .0020 .0028<br />

Finish 350 .0003 .0008 .0015 .0018 .0023 .0024 .0033<br />

Slot 600 .0006 .0011 .0020 .0026 .0031 .0036 .0055<br />

Rough 675 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 800 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

Slot 500 .0006 .0011 .0020 .0026 .0031 .0036 .0055<br />

Rough 575 .0008 .0014 .0025 .0033 .0039 .0045 .0069<br />

Finish 650 .0009 .0017 .0030 .0039 .0047 .0054 .0083<br />

Slot<br />

Rough<br />

Finish<br />

Slot<br />

Rough<br />

Finish<br />

Slot<br />

Rough<br />

Finish<br />

Slot<br />

Rough<br />

Finish<br />

TECHNICAL<br />

SECTION<br />

general purpose alloyed/unalloyed steels high tensile steels stainless steels cast materials Ti and Ni alloys Al and Al-alloys<br />

27

<strong>RF</strong> <strong>100</strong> VA <strong>End</strong> Mill Feeds and Speeds<br />

Series 3080<br />

Values based on FIREX ® coated end mill<br />

Adjustment for Axial DOC (Depth of Cut):<br />

2 x Cutter Dia. IPT 50% Ramp cut reduce IPT by 30%<br />

Drilling reduce IPT 50%<br />

Type of Cut<br />

Calculations based on the following.<br />

Radial Width of Cut<br />

(WOC)<br />

Axial Depth of Cut<br />

(DOC)<br />

Slot 1 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Rough .3 to .8 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Finish .1 to .2 x Cutter Dia. .5 to 1.0 x Cutter Dia.<br />

Material<br />

Color<br />

Code<br />

Hardness<br />

Type of<br />

Cut<br />

Speed<br />

Feed (inches per tooth) by tool diameter<br />

SFM 1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 1.0”<br />