Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Master Pump Minimum Flow Control Valves<br />

When a motor or turbine-driven boiler feedwater discharge<br />

flow. some of the energy generated from the pumping action is<br />

converted to heat. if the pump discharge flow falls below a set<br />

minimum level there is a rapid increase in both temperature and<br />

pressure within the pump. This increase can cause mechanical<br />

pump damage due to caviattion or excessive pressures. To guard<br />

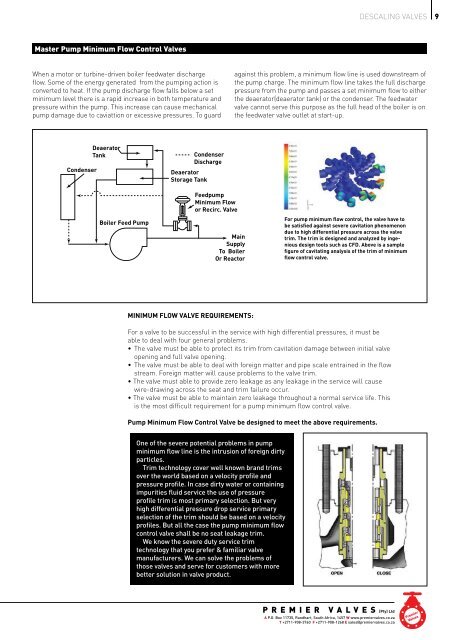

condenser<br />

deaerator<br />

tank<br />

Boiler Feed Pump<br />

condenser<br />

discharge<br />

deaerator<br />

storage tank<br />

Feedpump<br />

Minimum Flow<br />

or recirc. Valve<br />

Main<br />

supply<br />

to Boiler<br />

Or reactor<br />

MiniMuM FlOW ValVe requireMents:<br />

against this problem, a minimum flow line is used downstream of<br />

the pump charge. The minimum flow line takes the full discharge<br />

pressure from the pump and passes a set minimum flow to either<br />

the deaerator(deaerator tank) or the condenser. The feedwater<br />

valve cannot serve this purpose as the full head of the boiler is on<br />

the feedwater valve outlet at start-up.<br />

For a valve to be successful in the service with high differential pressures, it must be<br />

able to deal with four general problems.<br />

• The valve must be able to protect its trim from cavitation damage between initial valve<br />

opening and full valve opening.<br />

• The valve must be able to deal with foreign matter and pipe scale entrained in the flow<br />

stream. Foreign matter will cause problems to the valve trim.<br />

• The valve must able to provide zero leakage as any leakage in the service will cause<br />

wire-drawing across the seat and trim failure occur.<br />

• The valve must be able to maintain zero leakage throughout a normal service life. This<br />

is the most difficult requirement for a pump minimum flow control valve.<br />

Pump Minimum Flow control Valve be designed to meet the above requirements.<br />

One of the severe potential problems in pump<br />

minimum flow line is the intrusion of foreign dirty<br />

particles.<br />

Trim technology cover well known brand trims<br />

over the world based on a velocity profile and<br />

pressure profile. In case dirty water or containing<br />

impurities fluid service the use of pressure<br />

profile trim is most primary selection. But very<br />

high differential pressure drop service primary<br />

selection of the trim should be based on a velocity<br />

profiles. But all the case the pump minimum flow<br />

control valve shall be no seat leakage trim.<br />

We know the severe duty service trim<br />

technology that you prefer & familiar valve<br />

manufacturers. We can solve the problems of<br />

those valves and serve for customers with more<br />

better solution in valve product.<br />

<strong>Descaling</strong> <strong>ValVes</strong><br />

For pump minimum flow control, the valve have to<br />

be satisfied against severe cavitation phenomenon<br />

due to high differential pressure across the valve<br />

trim. the trim is designed and analyzed by ingenious<br />

design tools such as cFd. above is a sample<br />

figure of cavitating analysis of the trim of minimum<br />

flow control valve.<br />

9