MARIC CONTROL VALVES - Premier Valves

MARIC CONTROL VALVES - Premier Valves

MARIC CONTROL VALVES - Premier Valves

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

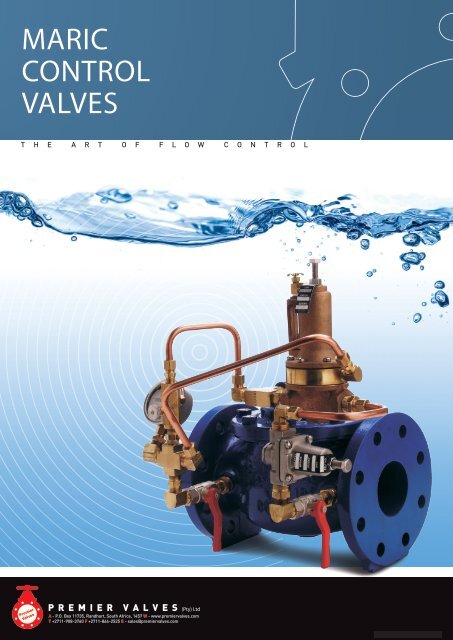

<strong>MARIC</strong><br />

Control <strong>Valves</strong><br />

<strong>CONTROL</strong><br />

<strong>VALVES</strong><br />

t h e a r t o f f l o w c o n t r o l<br />

PREMIER <strong>VALVES</strong> (Pty) Ltd<br />

A - P.O. Box 11735, Randhart, South Africa, 1457 W - www.premiervalves.com<br />

T +2711-908-3760 F +2711-864-2525 E - sales@premiervalves.com<br />

A P.O. Box 11735, Randhart, South Africa, 1457 W www.premiervalves.com<br />

T +2711-908-3760 F +2711-864-2525 E sales@premiervalves.com<br />

<strong>CONTROL</strong> <strong>VALVES</strong><br />

1<br />

Registered <strong>Premier</strong> franchisees

<strong>MARIC</strong> FLOW <strong>CONTROL</strong> <strong>VALVES</strong><br />

Product Range<br />

Maric Flow Control Australia is an Australian owned<br />

engineering firm situated in Adelaide, South Australia.<br />

Established in 1963 the company has experienced rapid growth<br />

in recent years with approximately 40% of its production going<br />

to overseas distributors.<br />

The company manufactures Maric flow control valves which<br />

maintain a constant pre-set flow rate of water, over a wide<br />

pressure range. For flow rate sensitive pumps, filters, pump ·<br />

glands and water distribution systems, the installation of these<br />

valves can offer many benefits and valuable protection. The<br />

technology is based on a precision moulded rubber control<br />

ring in the valves body, with an orifice diameter that varies in<br />

response to the pressure differential applied to it. The greater<br />

the pressure, the smaller the orifice, and vice versa, thereby<br />

maintaining a constant flow.<br />

PRODUCT RANGE<br />

B.S.P. SCREWED<br />

Available in: Brass, Chrome, UPVC & Stainless steel.<br />

Select desired flow rate from "available flow rates" on back page.<br />

Flow control Check valves available in limited configurations.<br />

Available in FF MF FM - First letter denotes inlet<br />

Flow rates available are from 0.4 litres/minute up to the maximum listed below.<br />

Body Sizes<br />

(mm):<br />

Max. Flow<br />

UMinute:<br />

WAFER TYPE<br />

¼ 10 15 20 25 32 40 50<br />

9 9 23 54 114 233 233 342<br />

For mounting between flanged pipe fittings.<br />

(Table "0" as standard. Other specs to order)<br />

Available in: Brass, UPVC, Gunmetal & Stainless Steel.<br />

Wafers are supplied with an o'ring in each face for sealing.<br />

Standard Wafer 0.0. is located by flange bolts. Full flange wafers made to order.<br />

Flow rates available are from 0.4 litres/minute up to the maximum listed below.<br />

Body Sizes<br />

(mm):<br />

Max. Flow<br />

L/Minute:<br />

INSERT TYPE<br />

25 32 40 50 65 80 100 150 200 250 300<br />

233 233 233 342 456 699 1279 2320 4427 6058 8854<br />

Inserts are out of sight and protected from unauthorised interference.<br />

Available in: Brass, UPVC & Stainless Steel<br />

Plain insert - various applications including press fitting into OEM's equipment & tapware etc.<br />

The high quality of all Maric valves is maintained through the<br />

use of a quality assurance program based on IS09001 , and<br />

is audited by SAl Global, (a division of Standards Australia).<br />

This allows the company to be both quality assured and hold a<br />

current WaterMark License.<br />

The valves are reliable, compact, self-cleaning and are<br />

maintenance free throughout the life of the valve. Flow rate<br />

increases generally one half to one percent per year. Therefore<br />

depending on the accuracy required by the installation, valve life<br />

can be up to 20 years.<br />

Flanged & Special inserts - for numerous applications including water meter flow control. Suitable for 15 to 50 mm water meters.<br />

Flow rates available are from 0.4 litres/minute upwards Specific dimensions and flow rates are available on application.<br />

A P.O. Box 11735, Randhart, South Africa, 1457 W www.premiervalves.com<br />

T +2711-908-3760 F +2711-864-2525 E sales@premiervalves.com

WHEN ORDERING THESE <strong>VALVES</strong>, PLEASE BE SURE TO<br />

SPECIFY:-<br />

• Body size<br />

• Thread configuration for screwed valves or Wafer type<br />

• Body material<br />

• Pressure differential range - if other than Precision<br />

• Flow Rate<br />

Performance Graph: Typical of PRECISION valves irrespective of body size or flow rate<br />

Rated Flow<br />

Flow Rate<br />

(as a percentage<br />

of rated flow)<br />

Control Rubber Options<br />

140%<br />

120%<br />

100%<br />

80%<br />

60%<br />

Maric Name Abbreviation Control<br />

Rubber<br />

0<br />

100<br />

200<br />

300<br />

400<br />

500<br />

600<br />

STANDARD SPECIFICATIONS<br />

Pressure Differential Range: 140 - 1000 kPa<br />

Flow Rate Accuracy: + / - 10%<br />

Temperature Range: 0- 60°C (50aC for UPVC)<br />

Available flow rates: litres/minute<br />

.4 / .45 / .5 / .55 / .63 / .7 / .8 / .9 / 1.0 / 1.1 / 1.2 / 1.3 / 1.5 / 1.6/<br />

1.8 / 2.0 / 2.3 / 2.5 / 2.8 /3.2 / 3.5 / 4.0 / 4.5 / 5.0 / 5.5 / 6.3 17.0 /<br />

8.0 / 9.0 / 10 / 11 / 12 / 13 / 15 / 16 / 18 / 20 / 23 / 25 / 28 / 32 / 36 /<br />

41 / 45 / 49 / 54 / 59 / 66 / 73 / 82 / 91 / 102 / 114 / 125 / 138 / 150 /<br />

162 / 180 / 199 / 216 /233/ up to 8854 11m<br />

700<br />

800<br />

900<br />

1000<br />

1100<br />

Pressure Differential Range Flow Rate<br />

Accuracy<br />

Pressure<br />

Differential<br />

(across valve in kPa)<br />

Max<br />

Temperature<br />

PRECISION (standard) "P" Nitrile 140 -1000 kPa 20 -150 psi +/-10% 60°C<br />

Low Pressure "LP" Nitrile 40 - 300 kPa 6 - 40 psi +/-20% 60°C<br />

High Pressure (1) "N6" Nitrile 140 -1500 kPa 20 - 220 psi +/-20% 60°C<br />

High Pressure (2) "N7" Nitrile 170 - 2000 kPa 25 - 290 psi +/-20% 60°C<br />

EPDM & Viton control rubbers are available for harsh environments and/or higher temperature applications.<br />

Understanding Headloss or Pressure Differential (P.O.) across valve.<br />

QUESTION: What will the headloss across the Maric valve be?<br />

ANSWER: At least 140 kPa, or, between 140 and 1000 kPa if the<br />

system is designed and operating correctly. This is because the<br />

function of our PRECISION range of valves is to control the flow<br />

when Pressure Differential across the valve is within this range.<br />

Therefore, to achieve full rated flow (accurate to within ±10 %),<br />

the installation must provide for inlet to be at least 140 kPa<br />

above outlet pressure.<br />

<strong>MARIC</strong> FLOW <strong>CONTROL</strong> <strong>VALVES</strong><br />

A P.O. Box 11735, Randhart, South Africa, 1457 W www.premiervalves.com<br />

T +2711-908-3760 F +2711-864-2525 E sales@premiervalves.com<br />

How to Order<br />

TO CALCULATE HEADLOSS: Assume valve is controlling flow<br />

as required. Determine what pressure will be at inlet and<br />

what pressure will be at outlet. The Pressure Differential will<br />

then simply be the difference between inlet and outlet above.<br />

Should this work out to be less than 140 or greater than 1000<br />

kPa, then this PRECISION valve will not provide full flow and<br />

the installation will either require altering, or the use of Low<br />

Pressure valves (40 - 300 kPa) or High Pressure valves (140 to<br />

1500 kPa or 170 to 2000 kPa).

<strong>MARIC</strong> FLOW <strong>CONTROL</strong> <strong>VALVES</strong><br />

Benefits Of Using Maric Flow Control <strong>Valves</strong><br />

MINING: CENTRIFUGAL PUMPS<br />

• Maximise gland packing life through carefully controlled<br />

gland-water flow<br />

• Minimise dilution of slurry<br />

• Ensure availability of gland-water to all glands on a common<br />

gland-water line<br />

• Save valuable water supplies<br />

• Also used in fire fighting equipment, safety showers & dust<br />

suppression<br />

Common Valve Attributes: Often stainless steel screwed,<br />

15 - 25mm, flow control check valves fitted with EPDM control<br />

rubbers.<br />

Environment: Harsh, exposed to extreme pressure,<br />

temperature and corrosion.<br />

WATER AUTHORITIES<br />

• Encourage payment of overdue water bills<br />

• Improve mains distribution pressure<br />

• Extend water meter life<br />

• Enable agreed maximum flow to consumers tanks.<br />

• Enable economical distribution to sparsely populated areas<br />

• Enforce water restriction<br />

• Reduce infrastructure costs<br />

Small connections: Brass water meter and tail inserts, and<br />

brass BSP screwed valves for 0.4 to 60 Ipm<br />

Larger connections: BSP Screwed Brass 15 - 50mm, M&F<br />

or F&M also PVC and Gunmetal wafer type 40-150mm for<br />

20 - 2000 Ipm<br />

Environment: Usually potable water at ambient temp.<br />

WATER TREATMENT<br />

• Prevent media loss during back-flushing<br />

• Protect delicate filters from excessive flow rates<br />

• Enable controlled flow rate of sampling water to analysing<br />

equipment<br />

• Ensure 100% bacteria kill in ultraviolet water sterilisation<br />

Common Valve Attributes: 6mm - 50mm F&F PVC Screwed,<br />

and 40 - 200mm UPVC Wafers in Precision type<br />

Environment: Water quality and PH varies, hence UPVC<br />

material. Usually ambient temperature<br />

A P.O. Box 11735, Randhart, South Africa, 1457 W www.premiervalves.com<br />

T +2711-908-3760 F +2711-864-2525 E sales@premiervalves.com

CENTRIFUGAL PUMP PROTECTION<br />

Extend pump life by:<br />

• Keeping pump on its curve by limiting maximum flow rate<br />

• Prevent up-thrust damage (common on high draw-down<br />

submersibles)<br />

• Prevent cavitation damage<br />

• Prevent over-pumping beyond the supply capacity<br />

• Maximise gland packing life through carefully controlled<br />

gland-water flow<br />

Common Valve Attributes: 25 - 50mm F&F Brass and Stainless<br />

steel, screwed and 25-200mm wafer type in Brass, Gunmetal,<br />

PVC or Stainless steel<br />

Environment: Good to saline conditions, ambient temp.<br />

Often High Pressures<br />

OTHER INDUSTRIAL APPLICATIONS<br />

• Vacuum Pumps "Liquid Ring" - operator convenience,<br />

prevent overheating and overloading<br />

• Fire-fighting - guarantee pressu re and flow to all hydrants,<br />

control flow of water and foaming agent to ensure correct<br />

dose ratio<br />

• Dust Suppression - minimise dust and erosion<br />

• Distilleries - ensure correct cooling of condensers<br />

• Safety showers & eye-wash equipment - ensure safe<br />

operation<br />

Common Valve Attributes: Brass, Chrome and Stainless steel,<br />

screwed or wafer type<br />

Environment: Water quality, PH and temperatures vary, may<br />

require the use EPDM or viton control rubbers<br />

DOMESTIC/COMMERCIAL<br />

• Showers water conservation and energy savings<br />

• Drinking fountains controlled stream<br />

• Toilet cisterns - Prevent "continuous flush" operation if fill<br />

rate is too fast<br />

• Water hammer prevention<br />

Common Valve Attributes: Brass and Chrome plated, 15mm<br />

BSP screwed M&F or F&M, 4.5, 7, 9, or 11 Ipm with Kwyflo<br />

control rubbers for quiet operation<br />

Environment: Potable water up to 600 Celsius<br />

<strong>MARIC</strong> FLOW <strong>CONTROL</strong> <strong>VALVES</strong><br />

Benefits Of Using Maric Flow Control <strong>Valves</strong><br />

A P.O. Box 11735, Randhart, South Africa, 1457 W www.premiervalves.com<br />

T +2711-908-3760 F +2711-864-2525 E sales@premiervalves.com

t h e a r t o f f l o w c o n t r o l<br />

PREMIER <strong>VALVES</strong> (Pty) Ltd<br />

P.O. Box 11735, Randhart, South Africa, 1457<br />

sales@premiervalves.com<br />

T +2711-908-3760 F +2711-864-2525<br />

www.premiervalves.com<br />

DISTRIBUTOR’S DETAILS<br />

Design: www.infiltratemedia.co.za