Kingscote Streets Upgrades - Kangaroo Island Council

Kingscote Streets Upgrades - Kangaroo Island Council

Kingscote Streets Upgrades - Kangaroo Island Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

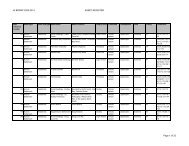

The application temperatures for primes, primer-binder and binders shall comply with the following<br />

table.<br />

Table 7.2<br />

Application Temperatures for primes, primer-binders and binders<br />

Product<br />

Spraying Temp<br />

Min (⁰C) Uncut<br />

Re-heating Temp<br />

Max (⁰C) Uncut<br />

Spraying Temp<br />

Min (⁰C) Cut<br />

Re-heating Temp<br />

Max (⁰C) Cut<br />

Light Prime 15 30 na na<br />

Medium Prime 40 60 na na<br />

Primer Binder 95 120 na na<br />

C170 175 185 Resultant 185<br />

C320 175 185 Resultant 185<br />

PMB 190 200 185 190<br />

Crumb Rubber 190 200 190 200<br />

Multigrade 175 185 Resultant 185<br />

Emulsion<br />

Manufacturer’s<br />

recommendation<br />

90 na na<br />

Note:<br />

For cut C170, C320 and Multigrade the binder shall be heated to 185⁰C, additive and/or cutter added and then<br />

sprayed at the resultant temperature.<br />

Volume correction factors for converting bituminous binders from 15⁰C to elevated temperatures<br />

shall be in accordance with DTEI Master Specification Part 226 Appendix 1 and Appendix 2.<br />

7.4.12 Operation of the Sprayer<br />

The application of primer, primer binder, and binder shall be by mechanical sprayer. Hand spraying<br />

will only be permitted when the use of a mechanical sprayer is not practicable.<br />

All sections of road 8 m or less in width and with the same application rate shall be sprayed in one<br />

pass. Where part width spraying is used, the Contractor shall submit in the Quality Plan details of<br />

how they intend to ensure uniform application of binder across the joint.<br />

The spraying for each run of the sprayer shall commence on a protective strip of heavy paper laid<br />

across, and held securely to, the pavement surface beforehand. The sprayer shall ensure that the<br />

road speed for correct application is attained at the commencement of spraying. The sprayer shall<br />

maintain a constant road speed throughout the length of each sprayer run.<br />

Where the spray seal design includes a double/ double seal, both courses the seal shall be laid on<br />

the same day.<br />

7.4.13 Spreading and Rolling Aggregate<br />

Spreading of aggregate shall proceed as close as practical after spraying of the binder has<br />

commenced and shall be completed within five minutes of spraying.<br />

The Contractor shall uniformly spread the specified nominal size aggregate at the target application<br />

rate uniformly over the sprayed surface by means of suitable mechanical spreading equipment.<br />

Sufficient loaded trucks of aggregate shall be at the site to provide full cover for the area sprayed.<br />

The method to determine the actual aggregate spread rate shall be detailed in the Quality Plan.<br />

Rolling shall commence immediately after aggregate spreading has commenced. Sufficient rollers<br />

shall be supplied to ensure that total area sprayed receives the minimum coverage (roller hours)<br />

derived from the following table and to cover the full width to be sealed with one pass. Adequate<br />

time must be allowed at the end of the day’s work to ensure that the last materials spread receive<br />

adequate rolling.<br />

Ref No. 20120236SA1 <strong>Kingscote</strong> <strong>Streets</strong> <strong>Upgrades</strong> Technical Specification 34