Kingscote Streets Upgrades - Kangaroo Island Council

Kingscote Streets Upgrades - Kangaroo Island Council

Kingscote Streets Upgrades - Kangaroo Island Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mechanical spreading equipment shall be used to spread aggregate and capable of achieving a<br />

uniform spread rate. Spreading equipment shall be calibrated as detailed in the quantity<br />

requirements of this specification.<br />

Rollers shall be pneumatic tyred multi-wheel rollers with a minimum mass of 7 tonnes, smooth tyres<br />

and a minimum tyre pressure of 690 kPa. Rollers must be capable of achieving effective<br />

incorporation of aggregate into the binder without breakdown or crushing of the cover aggregate.<br />

7.4.9 Pavement Temperature and Weather Conditions<br />

The Contractor shall measure and record pavement temperatures at regular intervals during the<br />

works using appropriate equipment and measurement procedures.<br />

Spraying of primers, primer binders and binders should only be undertaken if the pavement<br />

temperature has been at or above the temperature shown in the following table and does not fall<br />

below the recommended minimum pavement temperature during the period of spraying.<br />

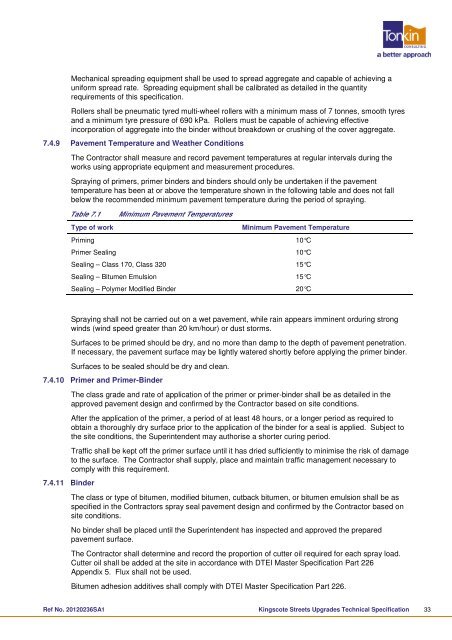

Table 7.1<br />

Type of work<br />

Minimum Pavement Temperatures<br />

Minimum Pavement Temperature<br />

Priming 10°C<br />

Primer Sealing 10°C<br />

Sealing – Class 170, Class 320 15°C<br />

Sealing – Bitumen Emulsion 15°C<br />

Sealing – Polymer Modified Binder 20°C<br />

Spraying shall not be carried out on a wet pavement, while rain appears imminent orduring strong<br />

winds (wind speed greater than 20 km/hour) or dust storms.<br />

Surfaces to be primed should be dry, and no more than damp to the depth of pavement penetration.<br />

If necessary, the pavement surface may be lightly watered shortly before applying the primer binder.<br />

Surfaces to be sealed should be dry and clean.<br />

7.4.10 Primer and Primer-Binder<br />

7.4.11 Binder<br />

The class grade and rate of application of the primer or primer-binder shall be as detailed in the<br />

approved pavement design and confirmed by the Contractor based on site conditions.<br />

After the application of the primer, a period of at least 48 hours, or a longer period as required to<br />

obtain a thoroughly dry surface prior to the application of the binder for a seal is applied. Subject to<br />

the site conditions, the Superintendent may authorise a shorter curing period.<br />

Traffic shall be kept off the primer surface until it has dried sufficiently to minimise the risk of damage<br />

to the surface. The Contractor shall supply, place and maintain traffic management necessary to<br />

comply with this requirement.<br />

The class or type of bitumen, modified bitumen, cutback bitumen, or bitumen emulsion shall be as<br />

specified in the Contractors spray seal pavement design and confirmed by the Contractor based on<br />

site conditions.<br />

No binder shall be placed until the Superintendent has inspected and approved the prepared<br />

pavement surface.<br />

The Contractor shall determine and record the proportion of cutter oil required for each spray load.<br />

Cutter oil shall be added at the site in accordance with DTEI Master Specification Part 226<br />

Appendix 5. Flux shall not be used.<br />

Bitumen adhesion additives shall comply with DTEI Master Specification Part 226.<br />

Ref No. 20120236SA1 <strong>Kingscote</strong> <strong>Streets</strong> <strong>Upgrades</strong> Technical Specification 33