Kingscote Streets Upgrades - Kangaroo Island Council

Kingscote Streets Upgrades - Kangaroo Island Council

Kingscote Streets Upgrades - Kangaroo Island Council

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Once an area or lot has been proof rolled and accepted by the Superintendent, any damage to the<br />

subgrade due to weather or the Contractor’s activities shall be the responsibility of the Contractor.<br />

No further payment will be made for the repair of soft spots as a result of such damage.<br />

5.1.5 Protection of the Subgrade<br />

Immediately following approval of the subgrade the Contractor shall commence construction of the<br />

pavement to protect the subgrade from moisture from inclement weather and/or construction traffic.<br />

5.1.6 Subgrade Remediation<br />

Where directed by the Superintendent, the Contractor shall carry out remedial works to the affected<br />

areas as directed by the Superintendent:<br />

In confined areas where movement is detected, the Contractor shall remove the suspect subgrade<br />

to the depth nominated by the Superintendent and replace and compact with quarry waste<br />

(PM3/55), screened quarry rubble (PM2/20) or stockpiled pavement material as directed.<br />

In larger areas, the Contractor shall remove the suspect subgrade to the depth nominated by the<br />

Superintendent and backfill using rock ballast (RB65/RB100) rolled to provide a tight, compact<br />

working platform, to enable construction of the pavement layers as specified elsewhere.<br />

5.2 Quality Requirements – Subgrade Preparation<br />

5.2.1 Inspections<br />

The following Hold Points are required during the subgrade preparation:<br />

H-SG1<br />

5.2.2 Quality Testing<br />

Approval and proof roll prior of the subgrade, prior to commencing pavement<br />

construction.<br />

The Contractor shall undertake testing of the subgrade at the following minimum frequency:<br />

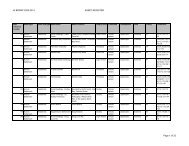

Table 5.1<br />

Quality Testing Requirements for Subgrade Preparation<br />

Item Test type Minimum Testing Frequency<br />

Subgrade Field Dry Density 1 per 300 m 2 or min of 3<br />

Maximum Dry Density<br />

Optimum Moisture Content<br />

1 per material type<br />

1 per material type<br />

Level of finished Subgrade Verification Survey 20 m Chainages<br />

The following test procedures shall be as detailed in the granular pavement section of this<br />

specification.<br />

5.2.3 Tolerances<br />

Construction tolerances on each finished granular pavement layer are as follows:<br />

Table 5.2<br />

Item<br />

Finished level of subgrade<br />

Field Dry Density<br />

Field Moisture content<br />

Tolerances on Subgrade Preparation<br />

Tolerance<br />

As detailed in the pavement design<br />

Not Applicable<br />

-10% + 3% of specified moisture<br />

Ref No. 20120236SA1 <strong>Kingscote</strong> <strong>Streets</strong> <strong>Upgrades</strong> Technical Specification 23