Kingscote Streets Upgrades - Kangaroo Island Council

Kingscote Streets Upgrades - Kangaroo Island Council

Kingscote Streets Upgrades - Kangaroo Island Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

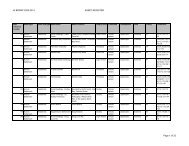

Table 3.4 Quality Testing Requirements for Earthworks<br />

Item Test Type Minimum Testing Frequency<br />

Type A & B Fill Material Grading One test per 1,000 tonne<br />

Plasticity Index<br />

One test per 1,000 tonne<br />

Linear Shrinkage<br />

One test per 1,000 tonne<br />

Weighted Plasticity Index One test per 1,000 tonne<br />

Bulk Fill under Pavements Field Dry Density 1 per 500 m 2 or min of 3 per lot<br />

Maximum Dry Density 1 per material type<br />

Bulk Fill under reserves Field Dry Density 1 per 1000 m 3 or min of 3 per lot<br />

Maximum Dry Density 1 per material type<br />

Trench Fill under pavements Field Dry Density 1 per 50 lineal metres per layer<br />

Maximum Dry Density 1 per material type<br />

Trench Fill under reserves Field Dry Density 1 per 100 lineal metres per layer<br />

Maximum Dry Density 1 per material type<br />

Trenches for water reticulation and sewer construction shall be backfilled and tested in accordance<br />

with SA Water requirements.<br />

If no rate of testing is provided, testing rates shall be in accordance with AS 3798 – Guidelines on<br />

Earthworks for Commercial and Residential Developments.<br />

The following test procedures shall be used for Quality testing:<br />

Table 3.5<br />

Test Type<br />

Test Procedures for Earthworks<br />

Test Procedure<br />

Sampling of materials TSA Test Procedure - TP 226<br />

Preparation of samples AS 1289.1<br />

Atterberg Limits AS 1289 3.1.2 ,3.2.1, 3.3.1 & 3.4.1<br />

Particle Distribution AS 1289 C6.2<br />

Linear Shrinkage AS 1289.3.4.1<br />

Maximum Dry Density AS 1289.5.2.1<br />

Optimum Moisture Content AS 1289.2.1.1 & AS 1289.2.1.4<br />

Field Density<br />

AS 1289.5.8.1 (Nuclear Method)<br />

Dry Density Ratio TSA Test Procedure - TP 320<br />

Note:<br />

• Dry Density Ratio shall be calculated to the nearest 0.1%.<br />

• Density measurements shall be made to the nearest 0.01 tonne/m 3 .<br />

• Test location co-ordinates shall be measured to the nearest 100 mm.<br />

3.4.4.1 Materials Being Used in the Works<br />

Where in the opinion of the Superintendent the material being used in the Works differs from the<br />

specified material, the Superintendent may order a sample to be taken and retested. If the material<br />

does not comply with the specification the cost of sampling and testing shall be borne by the<br />

Contractor and, in addition, the work which incorporates the material shall be liable to be rejected at<br />

the Superintendent’s discretion.<br />

Ref No. 20120236SA1 <strong>Kingscote</strong> <strong>Streets</strong> <strong>Upgrades</strong> Technical Specification 11