Chapter 12 Physical Vapor Deposition (PVD)

Chapter 12 Physical Vapor Deposition (PVD)

Chapter 12 Physical Vapor Deposition (PVD)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

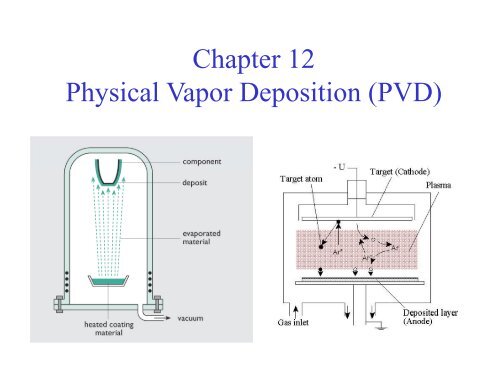

<strong>Chapter</strong> <strong>12</strong><br />

<strong>Physical</strong> <strong>Vapor</strong> <strong>Deposition</strong> (<strong>PVD</strong>)

<strong>PVD</strong> methods:<br />

Evaporation – condensation of metal vapor in<br />

high vacuum to deposit a thin film on a wafer; unable to<br />

cover severe topology (poor step coverage) which is<br />

beneficial when doing lift-off patterning; also hard to<br />

deposit alloys due to possible difference in melting<br />

points.<br />

Sputtering - use of plasma and acceleration of<br />

ions towards a target; material “sputtered” from the<br />

target and deposited on the wafer; extensively used in Si<br />

technology; moderate step coverage.

Evaporation Process:<br />

*Chamber under high vacuum (low pressure and long mfp)<br />

*metal pieces placed in crucible (charge) and heated to T m<br />

*substrates placed above the crucible, and<br />

*metal deposits on the substrates.<br />

Not shown in picture is a shutter that would be<br />

opened when the evaporation rate reaches a certain<br />

rate indicating pure metal deposition.<br />

View factor associated with deposition (like RTP);<br />

deposition rate depends on location of wafer in<br />

chamber (above crucible will have ↑ dep rate).<br />

For better uniformity and step coverage, planetary<br />

sample holders are rotated during deposition and<br />

samples are heated.<br />

<strong>Deposition</strong> rate monitored with quartz crystal<br />

(oscillates at a resonance frequency that shifts when<br />

additional mass is deposited on the crystal).<br />

Figure <strong>12</strong>.1 A simple diffusion-pumped<br />

evaporator showing vacuum plumbing and<br />

the location of the charge-containing<br />

crucible and the wafers.

For reasonable deposition<br />

rates, the vapor pressure<br />

must be ∼ 10 mTorr. This<br />

makes it nearly impossible<br />

ibl<br />

to evaporate some<br />

materials (refractory<br />

metals: Ta, W, Mo, Ti)<br />

Figure <strong>12</strong>.2 <strong>Vapor</strong> pressure curves for some commonly<br />

evaporated materials (data adapted from Alcock et al.).

<strong>Deposition</strong> rate depends on position of wafer<br />

View factor, k depends on R, Θ, Φ<br />

Wafers directly above the crucible will be coated more heavily than<br />

wafers off to the side. Wafers can all be mounted on the surface of a<br />

sphere (planetary) for more uniform deposition.<br />

Figure <strong>12</strong>.3 The geometry of deposition for a wafer (A) in an arbitrary<br />

position and (B) on the surface of a sphere.

Step Coverage<br />

If the substrate surface is not<br />

planar, the long mfp in<br />

evaporation means that<br />

evaporated material will follow<br />

a straight line; some areas are<br />

“shadowed”<br />

AR = step height<br />

step diameter<br />

Helps to rotate and heat the<br />

substrates.<br />

Planetary holders rotate<br />

simultaneously around two<br />

axes.<br />

Figure <strong>12</strong>.5 (A) Time evolution of the evaporative<br />

coating of a feature with aspect ratio of 1.0, with<br />

little surface atom mobility (i.e., low substrate<br />

temperature) and no rotation. (B) Final profile of<br />

deposition on rotated and heated substrates.

Evaporator systems: crucible heating techniques<br />

Resistively Heated<br />

Figure <strong>12</strong>.7 Resistive evaporator sources. (A) Simple sources including heating<br />

the charge itself and using a coil of refractory metal heater coil and a charge rod.<br />

(B) More standard thermal sources including a dimpled boat in resistive media.

Evaporator systems: crucible heating techniques<br />

Inductively Heated<br />

Figure <strong>12</strong>.8 Example of an inductively heated crucible used to create moderately<br />

charged temperatures.

Evaporator systems: crucible heating techniques<br />

Electron beam<br />

Heat of vaporization is<br />

supplied by the impact<br />

of an electron beam<br />

focused on the charge<br />

and melts a region of the<br />

material to be<br />

evaporated;<br />

Adv: possible to coevaporate<br />

materials with<br />

dual targets,<br />

Disadv: more expensive<br />

than resistance heated<br />

systems, substrates may<br />

have radiation damage<br />

Figure <strong>12</strong>.9 Electron beam evaporative sources. (A) A simple low flux<br />

source using a hot wire electron source and a thin movable rod. (B) A<br />

popular p source using a 2707 source arc in which the beam can be rastered<br />

across the surface of the charge. The magnet must be much larger than<br />

shown to achieve the full 270° of arc.

Evaporation<br />

Advantages: Simple process, relatively<br />

inexpensive, high purity films can be<br />

deposited.<br />

Disadvantages: difficult to evaporate alloys<br />

due to different melting points, “line of<br />

sight” deposition results in poor surface<br />

coverage unless there is rotation ti of fthe<br />

samples; deposition of refractory materials<br />

is a problem due to high temperatures<br />

required.<br />

Figure <strong>12</strong>.10 A commercial evaporator. Inset<br />

shows a planetary (photographs courtesy of<br />

CHA Industries).

Evaporation of Alloys<br />

Figure <strong>12</strong>.11 Methods for evaporating multicomponent films include (A)<br />

single-source evaporation, (B) multisource simultaneous evaporation, and (C)<br />

multisource sequential evaporation.

Sputtering:<br />

Bombard the target (cathode) with energetic ions, usually Ar + , in a<br />

plasma. Target material, not the wafers, must be placed on the electrode<br />

with maximum ion flux.<br />

*Chamber base pressure - high<br />

vacuum,<br />

*Argon flows into chamber<br />

raising pressure to mTorr range,<br />

*power supplied to electrodes,<br />

*target material deposits on the<br />

wafers.<br />

Allows deposition of refractory<br />

metals, alloys, dielectrics if an RF<br />

system is used.<br />

Figure <strong>12</strong>.<strong>12</strong> Chamber for a simple parallel-plateplate<br />

sputtering system.

Basic steps in sputter deposition:<br />

1) plasma generation – glow discharge formed when inert gas<br />

becomes ionized by an E-field; an electron accelerated towards<br />

anode, ionizes Ar atoms upon collision<br />

2) ion bombardment – Ar + impacts the target with high energies and<br />

transfer their momentum to the target material; these collisions<br />

disrupt the atomic surface causing target atoms, ions, and electrons to<br />

be ejected<br />

3) sputtered atom transport – sputtered atoms, ions, are influenced<br />

by collisions they undergo during transport to the film (determined<br />

by background pressure); sputtered particles will lose their energy as<br />

number of collisions increases so important to control the pressure<br />

4) film growth - sputtered material leaves the target and deposits on<br />

surrounding surfaces. The rate of diffusion is dependent upon the<br />

substrate material and Temp. Growth proceeds by diffusion and form<br />

nuclei, linuclei ligrow and eventually form islands; il islands il grow<br />

together until a continuous film is formed.

When an energetic ion strikes the surface of a material --<br />

1) Ions with low energies may bounce of the surface<br />

2) Ions may adsorb to the surface, giving up its energy to<br />

phonons (heat)<br />

3) Ion penetrates t into material, depositing energy deep into the<br />

substrate<br />

Figure <strong>12</strong>.13 Possible outcomes for an ion<br />

incident on the surface of a wafer.

Sputter Yield (S)<br />

Determines rate of sputter deposition<br />

S = # target atoms ejected/number of<br />

ions incident<br />

Depends on:<br />

•Target material<br />

•Mass of bombarding ions<br />

•Energy of bombarding ions<br />

Each target material has a threshold<br />

energy (below that energy no<br />

sputtering occurs), typically 10-30 eV.<br />

Figure <strong>12</strong>.14 Sputter yield as a function of ion<br />

energy for normal incidence id argon ions for a<br />

variety of materials (after Anderson and Bay,<br />

reprinted by permission).

S versus Ion atomic number<br />

Figure <strong>12</strong>.15 Sputter yield as a function of the bombarding ion<br />

atomic number for 45-keV ions incident on silver, copper, and<br />

tantalum targets (after Wehner, reprinted by permission, AIP).

Magnetron Sputtering – a magnetic field applied at right angles to<br />

the E-field; causes e- to follow spiral paths, increases probability of<br />

ionizing a gas atom, increases ionization efficiency, confines<br />

plasma resulting in a higher deposition rate; also able to form<br />

plasma at lower chamber pressures<br />

Figure <strong>12</strong>.17 Planar and cylindrical magnetron sputtering systems T: target; P:<br />

plasma; SM: solenoid; M: magnet; E: electric field; B: magnetic field (after<br />

Wasa and Hayakawa, reprinted by permission, Noyes Publications).

Fig. <strong>12</strong>.18 in text, p. 340 shows cross section of a planar magnetron<br />

target using permanent magnets to supply the field<br />

The region of the target beneath the ringshaped<br />

volume where the plasma density is<br />

highest is sputtered the most rapidly and this<br />

target erosion is called the race-track<br />

Target showing erosion in the race-track<br />

From: Fundamentals of High Power Impulse<br />

Magnetron Sputtering, dissertation by Johan Böhlmark<br />

Figure <strong>12</strong>.18 Detailed cross section of a<br />

rectangular planar magnetron target using<br />

permanent magnets to supply the field (after<br />

Wasa and Hayakawa, reprinted by<br />

permission, Noyes Publications).

Film morphology<br />

Zone model (Zones 1, 2, 3, T) indicates the films final<br />

characteristics based on the substrate temperature and ion energy;<br />

T-region is characterized by very small grains<br />

Zone1-low T, low ion energy<br />

yields amorphous, porous<br />

materials; Raise T or lower P<br />

moves to T-zone<br />

Zone2-Increase T and/or<br />

increase ion energy will<br />

increase grain size - tall<br />

columnar grains<br />

Zone3-Increase T, film has<br />

large 3-D grains– surface may<br />

be rough and hazy<br />

Figure <strong>12</strong>.21 The three-zone model of film deposition as proposed by<br />

Movchan and Demchishin (after Thornton, reprinted by permission, AIP).

Step Coverage<br />

Application of substrate heat will dramatically improve the step<br />

coverage due to surface diffusion; High AR can be a problem<br />

otherwise.<br />

Figure <strong>12</strong>.22 Cross section of the time evolution of the typical<br />

step coverage for unheated sputter deposition in a high aspect<br />

ratio contact.

Can improve step coverage by collimated sputtering or<br />

application of a bias to the wafer.<br />

Figure <strong>12</strong>.24 In collimated sputtering a<br />

disposable collimator is placed close to the<br />

wafers to increase directionality.<br />

Figure <strong>12</strong>.26 In bias sputtering, the ions<br />

incident on the surface of the wafer<br />

redistribute the deposited film to improve<br />

step coverage.

Ionized Metal Plasma (IMP) sputter deposition – ejected<br />

atoms pass through a second plasma; IMP process produces<br />

near-vertical deposition.<br />

Figure <strong>12</strong>.25 The Endura system by Applied Materials uses a number of <strong>PVD</strong> or CVD chambers<br />

fed by a central robot. For conventional and IMP sputtering, targets are hinged to open upward. Two<br />

open chambers are shown, along with the load lock (from Applied Materials).

Reactive sputtering: use of reactive gases (O 2 , CH 4 , NH 3 , N 2 ) rather<br />

than inert gases to sputter oxides, carbide, nitrides.<br />

Example below is for TiN<br />

Figure <strong>12</strong>.28 Resistivity and composition of reactively sputtered TiN as a function of the N 2<br />

flow in the sputtering chamber (after Tsai, Fair, and Hodul, reprinted by permission, The<br />

Electrochemical Society, and Molarius and Orpana, reprinted by permission, Kluwer<br />

Academic Publishing).

Figure <strong>12</strong>.29 Cross section electron micrograph of a<br />

moderately high aspect ratio contact that has been sputterdeposited<br />

with TiN (after Kohlhase, Mändl, and Pamler,<br />

reprinted by permission, AIP).

A thin film deposited on a substrate can be either in tensile stress or<br />

compressive stress; if stress is too large, film may peel away from<br />

the surface; implications in reliability.<br />

Figure <strong>12</strong>.30 The change in wafer deflection may be used to<br />

measure the stress in a deposited layer. This is typically measured<br />

using a reflected laser beam.

Sputtering<br />

Advantages: Moderately ygood step coverage; ;preferred<br />

technique for deposition of alloys, can sputter a wide variety of<br />

materials<br />

Disadvantages: may have some Argon incorporation in the film;<br />

could have some damage to substrate although not as much as in<br />

e-beam evaporation