EPSILON - Chiller

EPSILON - Chiller

EPSILON - Chiller

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNICAL CATALOGUE<br />

<strong>EPSILON</strong><br />

4,3÷25 kW<br />

AIR BLUE<br />

a i r c o n d i t i o n i n g<br />

Water chiller<br />

<strong>EPSILON</strong><br />

Reversible heat pump<br />

<strong>EPSILON</strong>/HP<br />

Water chiller with storage tank and pumps<br />

<strong>EPSILON</strong>/ST<br />

Condensing unit<br />

<strong>EPSILON</strong>/LE<br />

Cod. 202480C02<br />

Water chiller<br />

Air / Water<br />

Axial fans and<br />

Rotary vane type or scroll<br />

compressors<br />

1370

INDEX<br />

R407C<br />

Technical characteristics pag. 4<br />

Technical data standard unit pag. 6<br />

Electrical data standard unit pag. 7<br />

Cooling capacity standard unit pag. 8<br />

Heating capacity standard unit pag. 9<br />

Cooling capacity Epsilon/LE pag. 10<br />

Heating capacity Epsilon/HP/LE pag. 11<br />

Operating limits pag. 12<br />

Fouling factor corrections pag. 13<br />

Sound level pag. 14<br />

Overall dimensions pag. 15<br />

Dimensions and operating weight of the most frequently-used layouts pag. 21<br />

Installations recommendations pag. 23

TECHNICAL CHARACTERISTICS<br />

<strong>EPSILON</strong><br />

Air-cooled liquid chillers with rotating type compressor for sizes 5 to 7 and hermetic scroll compressor for sizes 8.5 to 25; plate type<br />

evaporator:<br />

UNIT FRAME<br />

Self supporting frame with removable panels constructed from galvanized sheet steel with RAL 5014 powder paint baked at 180°C<br />

to provide a durable weatherproof finish.<br />

COMPRESSORS<br />

Single phase rotating type (models 5-7), internal thermal protection and crankcase heater, assembled on rubber vibration mounts<br />

(size 7 only).<br />

Hermetic scroll compressor (models 8.5 to 25), internal thermal protection and crankcase heater, assembled on rubber vibration<br />

mounts.The models with three phase power supply are equipped with a safety device (phase sequence relay) to prevent the<br />

rotation in inverse sense of the compressor. Condenser Composed of a high efficiency finned coil manufactured from mechanically<br />

expanded copper tubes and aluminium fins. The coil with special fins and crossgrooved tubes allows high ambient temperature<br />

operation. The finned coil is protected by a metal grille which is installed as standard.<br />

CONDENSER FANS<br />

Axial fans directly coupled to 6 pole motors with internal Klixon overload protection. Motor protection category is IP 54.<br />

The fan is equipped with a safety grille to UNI EN 294.<br />

ELETTROFANS<br />

Del type assiale, studiati per ottimizzare l’efficienza e ridurre l’emissione sonora, direttamente accoppiati a motore elettrico a 6<br />

poli, con protezione termica (klixon interno). Il grado di protezione del motore è IP 54. Il ventilatore include la griglia di protezione<br />

antinfortunistica secondo UNI EN 294.<br />

EVAPORATOR<br />

Brazed plate type in 316 AISI stainless steel. Thermal insulation of evaporator is provided by closed cell expanded material.<br />

The evaporator is equipped with a low water temperature probe for freeze protection and is equipped as standard with a mechanical<br />

flow switch.<br />

The use of plate type heat exchangers provides:<br />

• An improved COP/EER;<br />

• A reduced refrigerant charge;<br />

• A reduced unit weight and dimension;<br />

• A reduction in maintenance.<br />

REFRIGERANT CIRCUIT<br />

Comprising: charge connection on liquid and suction line, liquid sight-glass, filter/dryer, thermostatic expansion valve with external<br />

pressure equalisation, high and low pressure switches and relief valve.<br />

ELECTRICAL PANEL<br />

The electrical panel includes:<br />

• Main switch;<br />

• Fuses to protect auxiliary and power circuit;<br />

• Compressor contactor;<br />

• Pump contactor/relay (ST version);<br />

• The microprocessor (Eliwell) controls the following functions on all units:<br />

- Water temperature regulation, with entering water temperature control;<br />

- Freeze protection;<br />

- Compressor time intervals;<br />

- Alarm signalling;<br />

- Alarm reset;<br />

- Common alarm contact for remote signalling;<br />

- Digital input for remote ON-OFF;<br />

• Potential free contacts for compressor operating status;<br />

• Contatto puliti di allarme generale<br />

• Display presentation of the following information:<br />

- Entering and leaving water temperature;<br />

- Condensing temperature;<br />

- Programmed temperature set-point and differential;<br />

- Alarm descriptions with code;<br />

- Compressor and pump hours run meter.<br />

Electrical power supply [V/f/Hz]: 230/1/50±5% for sizes 5 e 07, and 400/3+N~/50 ±5% or sizes from 8.5 to 25.<br />

CONTROLS AND SAFETY DEVICES<br />

• Chilled water temperature probe (at evaporator inlet);<br />

• Reeze protection probe at the outlet of each evaporator (with automatic reset managed by controller; after a preset number of trips<br />

the control stops the unit);<br />

• Safety high pressure switch (with automatic reset managed by controller; after a preset number of trips the control stops the unit);<br />

4

• Low pressure switch (with automatic reset managed by controller; after a preset number of trips the control stops the unit);<br />

• Mechanical flow switch, supplied on all units as kit;<br />

• Condensing pressure control by fan speed regulator for low ambient temperature operation.<br />

TESTING<br />

The units are subjected to a dry run in the factory and supplied complete with oil and refrigerant.<br />

VERSIONS<br />

<strong>EPSILON</strong>/HP: REVERSE CYCLE HEAT PUMP<br />

In addition to the components of standard unit, includes:<br />

4-way reversing valve, liquid receiver, non return valve, second thermostatic valve. Microprocessor enabled for summer/winter<br />

changeover and automatic defrosting, digital input for remote summer/winter changeover.<br />

<strong>EPSILON</strong>/LE: CONDENSING UNIT<br />

As regards to the standard unit, this model is not equipped with an evaporator and thermostatic valve.<br />

The unit is supplied without refrigerant fluid charge.<br />

The unit is in any case equipped with microprocessor controller managed by an external thermostat.<br />

<strong>EPSILON</strong>/LE/HP: HEAT PUMP CONDENSING UNIT<br />

In addition to the components of version Epsilon/LE, this unit includes:<br />

4-way reversing valve, liquid receiver, non return valve, second thermostatic valve.<br />

The solenoid valve on the liquid line is supplied as standard. Suction and discharge valves on the suction and liquid line, a solenoid<br />

valve on the liquid line and a non return valve can be supplied as an option.<br />

The unit is supplied without refrigerant fluid charge.<br />

The unit is in any case equipped with microprocessor controller managed by an external thermostat for summer/ winter changeover<br />

from digital input and automatic defrost cycle with a temperature probe.<br />

HYDRAULIC MODULE OPTIONS<br />

<strong>EPSILON</strong>/ST 1PS: UNIT WITH STORAGE TANK AND PUMP<br />

In addition to the components of standard version, this unit includes:<br />

insulated storage tank, circulating pump with rgulating gate valve, expansion tank (standard only on HP version),bleed valve, unload<br />

valve for hydraulic circuit emptying, water side relief valve (the value is set at 3 bar,corresponding to the maximum permissible<br />

working pressure.<br />

ACCESSORIES<br />

REFRIGERANT CIRCUIT ACCESSORIES<br />

• High and low pressure gauges;<br />

• Liquid receiver (standard on versions HP);<br />

• Compressor suction and discharge valves;<br />

• Liquid line valve ;<br />

• Liquid line solenoid valve.<br />

HYDRAULIC CIRCUIT ACCESSORIES<br />

• Anti-freeze evaporator heater;<br />

• Anti-freeze kit (ST1 PS version) with anti-freeze evaporator heater, heater on the hydraulic circuit and pump,immerged heater in<br />

the storage tank;<br />

• Expansion tank (only version ST 1PS, standard for HP version);<br />

• Automatic filling device (only version ST 1PS).<br />

ELECTRICAL ACCESSORIES<br />

• Serial interface RS485;<br />

• Remote user terminal panel (in addition to the standard terminal);<br />

• Summer/winter changeover from digital input;<br />

• Remote on/off from digital input.<br />

VARIOUS ACCESSORIES<br />

• Rubber anti-vibration mounts;<br />

• Condenser Copper/Copper coil;<br />

• Condenser Copper/Copper tinned coils;<br />

• Pre-painted aluminium condenser coil;<br />

• Condensing coil with anticorrosion treatment with polyurethane based coating. The product provides durableresistance to corrosion<br />

in coastal environments, rural or industrial areas;<br />

• Condensate drain pan (only versions HP and HP/LE);<br />

• Metal grille to protect the finned coil;<br />

• Finish in “RAL” colour other than standard.<br />

5

TECHNICAL DATA STANDARD UNIT<br />

UNIT SIZE 5 7 8.5 10 12.5 15 20 25<br />

COOLING (*)<br />

Nominal capacity kW 4,63 6,38 8,13 10,1 12,3 14,5 19,1 25,6<br />

Evaporator water fl ow l/h 797 1095 1397 1727 2099 2495 3285 4397<br />

Basic version pressure drop kPa 34,1 36,4 28,8 35,9 36,6 32,9 49,8 43,8<br />

HEATING (**)<br />

Nominal capacity kW 4,9 7,0 9,2 11,3 13,4 16,4 19,9 28,5<br />

COMPRESSORS<br />

type<br />

rotary<br />

vane type<br />

scroll<br />

Quantity n 1 1 1 1 1 1 1 1<br />

Refrigerant circuits n 1 1 1 1 1 1 1 1<br />

Power consumption<br />

cooling (*)<br />

kW 1,70 2,25 2,94 3,3 4,1 4,9 6,2 8,7<br />

Power consumption<br />

heating (**)<br />

kW 1,3 2,1 3,1 3,6 4,4 5,1 6,4 8,9<br />

Capacity steps % 100/0 100/0 100/0 100/0 100/0 100/0 100/0 100/0<br />

FANS type axial<br />

Air fl ow m3/h 3100 2800 2800 5800 5800 5200 8300 7800<br />

VERSION ST 1PS<br />

External available pressure kPa 77 71 74 149 136 125 117 90<br />

Tank capacity l 40 40 40 60 60 60 75 75<br />

BASIC UNIT SIZES AND WEIGHTS<br />

Length mm 1121 1121 1121 1221 1221 1221 1521 1521<br />

Width mm 418 418 418 538 538 538 660 660<br />

Height mm 1102 1102 1102 1102 1102 1102 1102 1102<br />

Operating weigh kg 92 104 120 153 157 164 190 236<br />

(*) ambient air temperature 35°C; evaporator inlet/outlet water temperature 12-7 °C<br />

(**) ambient air temperature 8°C BS, 70 UR; condenser inlet/outlet water temperature 40-45 °C<br />

6

ELECTRICAL DATA STANDARD UNIT<br />

ELECTRIC<br />

CHARACTERISTICS<br />

5 7 8.5 10 12.5 15 20 25<br />

Maximum absorbed power (1)<br />

kW<br />

2,00<br />

(2,30)<br />

2,80<br />

(3,10)<br />

4,40<br />

(4,70)<br />

5,30<br />

(5,60)<br />

6,40<br />

(6,70)<br />

7,50<br />

(7,80)<br />

8,60<br />

(9,10)<br />

12,60<br />

(13,10)<br />

Maximum starting current<br />

A<br />

41,60<br />

(43,00)<br />

67,60<br />

(69,00)<br />

37,60<br />

(39,00)<br />

46,60<br />

(48,00)<br />

57,60<br />

(59,00)<br />

70,60<br />

(72,00)<br />

99,80<br />

(101,80)<br />

121,80<br />

(123,80)<br />

Full load current (2)<br />

A<br />

10,90<br />

(12,30)<br />

15,90<br />

(17,30)<br />

11,90<br />

(13,30)<br />

12,90<br />

(14,30)<br />

15,10<br />

(16,50)<br />

16,10<br />

(17,50)<br />

18,80<br />

(20,80)<br />

26,80<br />

(28,80)<br />

Fan motor nominal power n x kW 1 x 0,14 1 x 0,14 1 x 0,14 1 x 0,36 1 x 0,36 1 x 0,36 1 x 0,40 1 x 0,40<br />

Fan motor nominal absorbed<br />

current<br />

n x A 1 x 0,60 1 x 0,60 1 x 0,60 1 x 1,60 1 x 1,60 1 x 1,60 1 x 1,80 1 x 1,80<br />

Pump motor nominal power n x kW 1 x 0,30 1 x 0,30 1 x 0,30 1 x 0,30 1 x 0,30 1 x 0,30 1 x 0,45 1 x 0,45<br />

Pump motor nominal current n x A 1 x 1,36 1 x 1,36 1 x 1,36 1 x 1,36 1 x 1,36 1 x 1,36 1 x 2,04 1 x 2,04<br />

Power supply V/ph/Hz 230/1~/50 230/1~/50 400/3N~/50 400/3N~/50 400/3N~/50 400/3N~/50 400/3N~/50 400/3N~/50<br />

±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5%<br />

Control power supply V/ph/Hz 230/1~/50 230/1~/50 230/1~/50 230/1~/50 230/1~/50 230/1~/50 230/1~/50 230/1~/50<br />

(1) mains power supply to allow unit operation<br />

(2) maximum current before safety cut-outs stop the unit. This value is never exceeded and must be used to size the electrical<br />

supply cables and relevant safety devices (refer to electrical wiring diagram supplied with the unit).<br />

Values in brackets refer to ST version units (units with storage tank and pumps or units with exclusively pumps)<br />

7

COOLING CAPACITY STANDARD UNIT<br />

MODEL<br />

5<br />

7<br />

8.5<br />

10<br />

12.5<br />

15<br />

20<br />

25<br />

To<br />

Ambient air temperature [°C]<br />

[°C]<br />

25 30 35 40 45<br />

kWf kWe kWf kWe kWf kWe kWf kWe kWf kWe<br />

5 4,93 1,38 4,65 1,52 4,36 1,66 4,05 1,80 3,74 1,94<br />

6 5,07 1,40 4,79 1,54 4,49 1,68 4,18 1,82 3,86 1,96<br />

7 5,21 1,41 4,92 1,55 4,63 1,70 4,32 1,84 3,99 1,99<br />

8 5,35 1,42 5,06 1,57 4,76 1,72 4,45 1,87 - -<br />

9 5,49 1,44 5,20 1,59 4,90 1,74 4,58 1,89 - -<br />

10 5,63 1,45 5,34 1,61 5,04 1,76 4,72 1,91 - -<br />

5 6,77 1,84 6,40 2,02 6,00 2,20 5,58 2,38 5,11 2,57<br />

6 6,97 1,86 6,60 2,04 6,19 2,23 5,76 2,41 5,32 2,59<br />

7 7,17 1,88 6,79 2,07 6,38 2,25 5,95 2,44 5,49 2,63<br />

8 7,38 1,91 6,99 2,09 6,57 2,28 6,13 2,47 - -<br />

9 7,58 1,93 7,19 2,12 6,76 2,31 6,32 2,50 - -<br />

10 7,78 1,95 7,38 2,15 6,95 2,34 6,50 2,53 - -<br />

5 8,73 2,31 8,15 2,57 7,60 2,88 7,08 3,22 6,59 3,62<br />

6 9,02 2,33 8,43 2,60 7,86 2,91 7,33 3,26 6,82 3,66<br />

7 9,31 2,36 8,71 2,63 8,13 2,94 7,58 3,29 7,06 3,70<br />

8 9,61 2,39 8,97 2,67 8,41 2,97 7,84 3,33 - -<br />

9 9,92 2,41 9,29 2,69 8,69 3,01 8,11 3,36 - -<br />

10 10,2 2,4 9,60 2,72 8,98 3,04 8,39 3,40 - -<br />

5 10,8 2,6 10,1 2,9 9,40 3,24 8,75 3,63 8,13 4,09<br />

6 11,2 2,6 10,4 2,9 9,71 3,27 9,05 3,66 8,43 4,11<br />

7 11,6 2,6 10,8 2,9 10,1 3,3 9,38 3,68 8,75 4,13<br />

8 11,9 2,7 11,2 3,0 10,4 3,3 9,73 3,71 - -<br />

9 12,4 2,7 11,6 3,0 10,8 3,3 10,1 3,7 - -<br />

10 12,8 2,7 12,0 3,0 11,2 3,3 10,5 3,8 - -<br />

5 13,2 3,2 12,3 3,6 11,5 4,0 10,7 4,5 9,97 5,05<br />

6 13,6 3,2 12,7 3,6 11,9 4,0 11,1 4,5 10,3 5,1<br />

7 14,1 3,3 13,1 3,6 12,3 4,1 11,5 4,6 10,7 5,1<br />

8 14,5 3,3 13,6 3,7 12,7 4,1 11,9 4,6 - -<br />

9 15,0 3,3 14,0 3,7 13,1 4,1 12,3 4,6 - -<br />

10 15,5 3,3 14,5 3,7 13,6 4,2 12,7 4,7 - -<br />

5 15,7 3,8 14,6 4,3 13,6 4,8 12,6 5,4 11,7 6,0<br />

6 16,2 3,9 15,1 4,3 14,1 4,8 13,1 5,4 12,1 6,1<br />

7 16,7 3,9 15,6 4,4 14,5 4,9 13,5 5,5 12,6 6,2<br />

8 17,2 3,9 16,1 4,4 15,0 4,9 14,0 5,5 - -<br />

9 17,8 4,0 16,6 4,5 15,5 5,0 14,4 5,6 - -<br />

10 18,3 4,0 17,1 4,5 16,0 5,0 14,9 5,7 - -<br />

5 20,1 4,9 19,1 5,4 18,0 6,0 16,8 6,7 15,5 7,4<br />

6 20,8 4,9 19,7 5,5 18,6 6,1 17,4 6,7 16,1 7,4<br />

7 21,5 5,0 20,4 5,5 19,1 6,2 17,9 6,8 16,6 7,5<br />

8 22,2 5,1 21,0 5,6 19,8 6,2 18,5 6,9 - -<br />

9 22,9 5,1 21,7 5,7 20,4 6,3 19,1 7,0 - -<br />

10 23,6 5,2 22,4 5,8 21,0 6,4 19,7 7,1 - -<br />

5 27,3 6,7 25,8 7,5 24,1 8,4 22,3 9,4 20,4 10,6<br />

6 28,1 6,8 26,6 7,6 24,9 8,5 23,0 9,6 21,1 10,7<br />

7 29,0 6,9 27,4 7,7 25,6 8,7 23,7 9,7 21,7 10,8<br />

8 29,9 7,0 28,2 7,9 26,3 8,8 24,4 9,8 - -<br />

9 30,8 7,1 29,0 8,0 27,2 8,9 25,2 9,9 - -<br />

10 31,7 7,2 29,9 8,1 27,9 9,0 25,8 10,1 - -<br />

kWf : cooling capacity [kW]<br />

kWe : compressors power input [kW]<br />

T0 : evaporator water outlet temperature [°C]<br />

8

HEATING CAPACITY STANDARD UNIT<br />

Ta RH Condenser water inlet / outlet temperature [°C]<br />

MODEL<br />

5<br />

7<br />

8.5<br />

10<br />

12.5<br />

15<br />

20<br />

25<br />

[°C] %<br />

30/35 35/40 40/45 45/50<br />

kWt kWe kWt kWe kWt kWe kWt kWe<br />

-10 95 3,5 1,1 3,4 1,2 - - - -<br />

-5 90 3,6 1,1 4,1 1,2 4,0 1,3 - -<br />

0 90 4,3 1,1 4,1 1,2 4,0 1,3 3,9 1,4<br />

5 80 4,9 1,1 4,7 1,2 4,6 1,3 4,5 1,4<br />

8 70 5,2 1,1 5,1 1,2 4,9 1,3 4,8 1,4<br />

10 70 5,5 1,1 5,3 1,2 5,2 1,4 5,1 1,5<br />

-10 95 5,0 1,7 4,8 1,9 - - - -<br />

-5 90 5,1 1,7 4,9 1,9 4,7 2,0 - -<br />

0 90 6,0 1,7 5,9 1,9 5,7 2,0 5,5 2,2<br />

5 80 6,9 1,8 6,7 1,9 6,5 2,1 6,3 2,2<br />

8 70 7,3 1,8 7,2 1,9 7,0 2,1 6,8 2,2<br />

10 70 7,7 1,8 7,6 1,9 7,4 2,1 7,2 2,3<br />

-10 95 6,4 2,4 6,4 2,7 - - - -<br />

-5 90 7,1 2,4 7,1 2,7 7,3 3,1 - -<br />

0 90 7,9 2,5 7,9 2,8 8,0 3,1 8,2 3,5<br />

5 80 8,7 2,5 8,7 2,8 8,8 3,1 8,9 3,5<br />

8 70 9,1 2,5 9,1 2,8 9,2 3,1 9,3 3,5<br />

10 70 9,5 2,5 9,5 2,8 9,5 3,2 9,7 3,5<br />

-10 95 7,7 2,8 8,6 3,1 - - - -<br />

-5 90 8,7 2,8 8,6 3,1 8,7 3,5 - -<br />

0 90 9,8 2,8 9,7 3,2 9,7 3,5 9,8 4,0<br />

5 80 10,9 2,8 10,8 3,2 10,7 3,6 10,7 4,0<br />

8 70 11,5 2,9 11,4 3,2 11,3 3,6 11,3 4,0<br />

10 70 12,1 2,9 11,9 3,2 11,8 3,6 11,8 4,0<br />

-10 95 9,2 3,3 9,3 3,8 - - - -<br />

-5 90 10,3 3,4 10,3 3,8 10,5 4,3 - -<br />

0 90 11,6 3,4 11,5 3,9 11,6 4,4 11,8 4,9<br />

5 80 12,9 3,5 12,8 3,9 12,8 4,4 12,9 5,0<br />

8 70 13,6 3,5 13,4 3,9 13,4 4,4 13,5 5,0<br />

10 70 14,2 3,5 14,1 4,0 14,0 4,4 14,0 5,0<br />

-10 95 11,4 3,8 11,4 4,3 - - - -<br />

-5 90 12,7 3,9 12,7 4,4 12,8 4,9 - -<br />

0 90 14,3 3,9 14,2 4,4 14,3 5,0 14,5 5,7<br />

5 80 15,8 4,0 15,6 4,5 15,6 5,1 15,8 5,7<br />

8 70 16,6 4,0 16,4 4,5 16,4 5,1 16,5 5,8<br />

10 70 17,3 4,0 17,1 4,5 17,1 5,1 17,2 5,8<br />

-10 95 13,0 4,7 13,1 5,2 - - - -<br />

-5 90 14,8 4,8 14,9 5,3 15,0 5,9 - -<br />

0 90 16,9 4,9 17,0 5,5 17,0 6,1 17,1 6,8<br />

5 80 18,9 5,0 18,9 5,6 18,9 6,3 18,9 7,0<br />

8 70 20,0 5,1 20,0 5,7 19,9 6,4 19,9 7,1<br />

10 70 20,9 5,2 20,9 5,8 20,8 6,4 20,8 7,2<br />

-10 95 18,6 6,0 18,8 6,7 - - - -<br />

-5 90 21,1 6,2 21,3 6,9 21,6 7,9 - -<br />

0 90 24,0 6,4 24,2 7,2 24,4 8,2 24,7 9,3<br />

5 80 26,7 6,7 26,8 7,6 27,0 8,6 27,2 9,7<br />

8 70 28,3 7,0 28,4 7,9 28,5 8,9 28,6 10,0<br />

10 70 29,5 7,2 29,6 8,1 29,6 9,1 29,7 10,3<br />

kWt : heating capacity [kW]<br />

kWe : compressors power input [kW]<br />

Ta : evaporator inlet air temperature dry bulb [°C]<br />

RH : evaporator inlet air relative humidity [%]<br />

9

COOLING CAPACITY <strong>EPSILON</strong>/LE<br />

MODEL<br />

5<br />

7<br />

8.5<br />

10<br />

12.5<br />

15<br />

20<br />

25<br />

Tev<br />

Ambient air temperature [°C]<br />

[°C]<br />

25 30 35 40 45<br />

kWf kWe kWf kWe kWf kWe kWf kWe kWf kWe<br />

0 4,7 1,4 4,5 1,5 4,2 1,6 3,8 1,8 3,5 1,9<br />

2,5 5,1 1,4 4,8 1,5 4,5 1,7 4,2 1,8 3,8 2,0<br />

5 5,5 1,4 5,2 1,6 4,8 1,7 4,5 1,9 4,2 2,0<br />

7,5 5,8 1,5 5,5 1,6 5,2 1,8 4,9 1,9 - -<br />

10 6,2 1,5 5,9 1,7 5,6 1,8 5,2 2,0 - -<br />

0 6,6 1,8 6,2 2,0 5,8 2,2 5,4 2,3 4,9 2,5<br />

2,5 7,1 1,9 6,7 2,1 6,3 2,2 5,8 2,4 5,4 2,6<br />

5 7,6 1,9 7,2 2,1 6,8 2,3 6,3 2,5 5,8 2,7<br />

7,5 8,2 2,0 7,7 2,2 7,3 2,4 6,8 2,6 - -<br />

10 8,7 2,1 8,2 2,3 7,8 2,5 7,3 2,7 - -<br />

0 8,4 2,3 7,8 2,5 7,3 2,9 6,7 3,2 6,3 3,6<br />

2,5 9,2 2,3 8,5 2,6 7,9 2,9 7,4 3,3 6,8 3,7<br />

5 9,9 2,4 9,3 2,7 8,6 3,0 8,0 3,4 7,5 3,8<br />

7,5 10,8 2,5 10,1 2,8 9,4 3,1 8,8 3,5 - -<br />

10 11,7 2,6 11,0 2,9 10,2 3,2 9,6 3,6 - -<br />

0 10,7 2,6 9,9 2,9 9,2 3,2 8,5 3,6 7,9 4,1<br />

2,5 11,7 2,7 10,9 2,9 10,1 3,3 9,4 3,7 8,7 4,1<br />

5 12,8 2,7 11,9 3,0 11,1 3,3 10,3 3,7 9,6 4,2<br />

7,5 13,9 2,7 13,0 3,0 12,1 3,4 11,3 3,8 - -<br />

10 15,2 2,8 14,2 3,1 13,3 3,5 12,4 3,9 - -<br />

0 13,4 3,2 12,4 3,6 11,5 4,0 10,7 4,5 9,9 5,1<br />

2,5 14,5 3,3 13,5 3,7 12,6 4,1 11,7 4,6 10,9 5,1<br />

5 15,8 3,4 14,8 3,7 13,8 4,2 12,8 4,7 11,9 5,2<br />

7,5 17,2 3,5 16,1 3,8 15,0 4,3 14,0 4,8 - -<br />

10 18,7 3,5 17,5 3,9 16,4 4,4 15,3 4,9 - -<br />

0 15,8 3,8 14,7 4,3 13,6 4,8 12,6 5,3 11,6 6,0<br />

2,5 17,1 3,9 15,9 4,4 14,8 4,9 13,7 5,5 12,7 6,2<br />

5 18,6 4,1 17,3 4,5 16,1 5,1 14,9 5,7 13,8 6,3<br />

7,5 20,1 4,2 18,8 4,7 17,5 5,2 16,3 5,8 - -<br />

10 21,7 4,3 20,3 4,8 19,0 5,4 17,7 6,0 - -<br />

0 17,4 4,6 16,4 5,1 15,5 5,7 14,4 6,3 13,3 7,0<br />

2,5 19,0 4,8 17,9 5,3 16,9 5,9 15,8 6,5 14,5 7,2<br />

5 20,6 4,9 19,5 5,5 18,4 6,0 17,1 6,7 15,8 7,4<br />

7,5 22,3 5,1 21,1 5,6 19,9 6,2 18,6 6,9 - -<br />

10 24,1 5,3 22,9 5,8 21,5 6,4 20,0 7,1 - -<br />

0 23,8 6,4 22,5 7,1 21,0 8,0 19,4 9,0 17,7 10,0<br />

2,5 25,9 6,6 24,4 7,4 22,8 8,2 21,1 9,2 19,3 10,3<br />

5 28,0 6,8 26,4 7,6 24,7 8,5 22,8 9,5 20,9 10,7<br />

7,5 30,2 7,1 28,5 7,9 26,6 8,8 24,6 9,8 - -<br />

10 32,5 7,4 30,6 8,2 28,6 9,1 26,5 10,2 - -<br />

kWf : cooling capacity [kW]<br />

kWe : compressors power input [kW]<br />

Tev: evaporating temperature [°C]<br />

10

HEATING CAPACITY <strong>EPSILON</strong>/HP/LE<br />

MODEL<br />

5<br />

7<br />

8.5<br />

10<br />

12.5<br />

15<br />

20<br />

25<br />

Ta RH Condensing temperature [°C]<br />

[°C] %<br />

40 45 50 55 62<br />

kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe<br />

-10 95 3,1 1,2 - - - - - - - -<br />

-5 90 3,3 1,2 3,2 1,3 - - - - - -<br />

0 90 4,0 1,3 3,9 1,4 3,7 1,5 - - - -<br />

5 80 4,6 1,3 4,5 1,4 4,3 1,5 4,2 1,6 - -<br />

8 70 4,9 1,3 4,8 1,4 4,7 1,5 4,5 1,6 4,3 1,8<br />

10 70 5,2 1,3 5,1 1,4 4,9 1,5 4,8 1,7 4,6 1,8<br />

-10 95 4,8 1,7 - - - - - - - -<br />

-5 90 5,1 1,7 4,9 1,9 - - - - - -<br />

0 90 6,1 1,7 5,9 1,9 5,7 2,0 - - - -<br />

5 80 6,9 1,7 6,8 1,9 6,6 2,0 6,4 2,2 - -<br />

8 70 7,4 1,7 7,2 1,9 7,0 2,1 6,8 2,2 6,5 2,5<br />

10 70 7,8 1,8 7,6 1,9 7,4 2,1 7,2 2,3 6,9 2,5<br />

-10 95 6,4 2,4 - - - - - - - -<br />

-5 90 7,2 2,4 7,2 2,7 - - - - - -<br />

0 90 8,0 2,4 8,0 2,7 8,1 3,0 - - - -<br />

5 80 8,8 2,4 8,8 2,7 8,8 3,0 8,9 3,4 - -<br />

8 70 9,3 2,4 9,2 2,7 9,2 3,1 9,3 3,4 9,6 4,0<br />

10 70 9,7 2,4 9,6 2,7 9,6 3,1 9,7 3,4 9,9 4,0<br />

-10 95 7,7 2,8 - - - - - - - -<br />

-5 90 8,6 2,8 8,6 3,2 - - - - - -<br />

0 90 9,8 2,8 9,7 3,2 9,6 3,6 - - - -<br />

5 80 10,9 2,8 10,7 3,2 10,6 3,6 10,7 4,0 - -<br />

8 70 11,5 2,8 11,3 3,2 11,3 3,6 11,3 4,0 11,5 4,7<br />

10 70 12,1 2,8 11,9 3,2 11,8 3,6 11,8 4,0 11,9 4,7<br />

-10 95 9,2 3,4 - - - - - - - -<br />

-5 90 10,3 3,4 10,3 3,8 - - - - - -<br />

0 90 11,6 3,4 11,5 3,8 11,6 4,4 - - - -<br />

5 80 12,9 3,4 12,8 3,9 12,7 4,4 12,8 4,9 - -<br />

8 70 13,6 3,4 13,5 3,9 13,4 4,4 13,4 4,9 13,7 5,8<br />

10 70 14,3 3,4 14,1 3,9 14,0 4,4 14,0 4,9 14,2 5,8<br />

-10 95 11,5 3,8 - - - - - - - -<br />

-5 90 12,8 3,8 12,8 4,3 - - - - - -<br />

0 90 14,5 3,9 14,3 4,4 14,3 4,9 - - - -<br />

5 80 16,0 3,9 15,8 4,4 15,7 5,0 15,8 5,6 - -<br />

8 70 16,9 3,9 16,6 4,4 16,5 5,0 16,6 5,6 16,9 6,6<br />

10 70 17,7 3,9 17,4 4,4 17,3 5,0 17,2 5,6 17,5 6,7<br />

-10 95 12,9 4,9 - - - - - - - -<br />

-5 90 14,8 5,0 14,9 5,6 - - - - - -<br />

0 90 16,9 5,0 17,0 5,6 17,0 6,3 - - - -<br />

5 80 18,9 5,0 18,9 5,6 18,9 6,3 18,9 7,0 - -<br />

8 70 20,1 5,0 20,0 5,6 20,0 6,3 19,9 7,0 19,8 8,2<br />

10 70 21,0 5,0 20,9 5,6 20,8 6,3 20,8 7,0 20,7 8,2<br />

-10 95 18,6 6,2 - - - - - - - -<br />

-5 90 21,2 6,2 21,4 7,0 - - - - - -<br />

0 90 24,2 6,2 24,3 7,0 24,5 7,9 - - - -<br />

5 80 26,9 6,2 26,9 7,0 27,0 7,9 27,2 8,9 - -<br />

8 70 28,5 6,2 28,6 7,0 28,6 7,9 28,6 8,9 28,7 10,6<br />

10 70 29,9 6,2 29,8 7,0 29,8 7,9 29,8 8,9 29,8 10,6<br />

kWt: heating capacity [kW]<br />

kWe: compressors power input [kW]<br />

Ta: evaporator inlet air temperature dry bulb [°C]<br />

11

OPERATING LIMITS<br />

Temperatura di uscita acqua utenza [°C]<br />

O ultet user water temperature [°C ]<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

-5<br />

7<br />

Raffreddamento<br />

Cooling<br />

Con utilizzo di glicole etilenico<br />

With ethilene glycol<br />

-10<br />

-15 -10 -5 0 5 10 15 20 25 30 35 40 45 50<br />

Temperatura aria esterna [°C]<br />

Ambient temperature[°C]<br />

55<br />

Temperatura di uscita acqua utenza [°C]<br />

O ultet user water temperature [°C ]<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

Riscaldamento<br />

Heating<br />

20<br />

-20 -15 -10 -5 0 5 10 15 20 25 30<br />

Temperatura aria esterna [°C]<br />

Ambient temperature[°C]<br />

IL SALTO TERMICO DELL’ACQUA PER TUTTE LE VERSIONI DEVE ESSERE COMPRESO TRA: min:4 °C max: 7°C<br />

WATER THERMAL DIFFERENCE FOR ALL VERSIONS MUST BE:<br />

12

FOULING FACTOR CORRECTIONS<br />

f1-f2: capacity correction factors<br />

Fouling factors (m° C/W) Evaporator Recovery Condenser<br />

f1 fp1 f2 fp2<br />

0 Scambiatore pulito 1 1 1 1<br />

0,44 x 10 -4 0,98 0,99 0,99 1,03<br />

0,88 x 10 -4 0,96 0,99 0,98 1,04<br />

1,76 x 10 -4 0,93 0,98 0,95 1,06<br />

fp1-fp2: compressor power input correction factors<br />

Unit performances reported in the tables are given for the condition of clean exchanger (fouling factor = 1), For different fouling factor<br />

values, unit performances should be corrected with the correction factors shown above.<br />

13

SOUND LEVEL<br />

STANDARD UNIT<br />

MODEL<br />

Octave bands [Hz]<br />

Total<br />

63 [dB] 125 [dB] 250 [dB] 500 [dB] 1000 [dB] 2000 [dB] 4000 [dB] 8000 [dB] dB(A)<br />

Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp<br />

5 71 56 73 58 71 56 70 55 66 50 62 46 57 42 48 33 71,0 56,0<br />

7 72 56 74 58 71 56 71 56 66 51 62 47 58 42 49 33 72,0 57,0<br />

8.5 72 57 74 59 72 57 71 56 67 51 63 47 58 43 49 34 72,0 57,0<br />

10 80 65 81 66 76 61 75 60 73 58 67 52 62 47 55 40 77,0 62,0<br />

12.5 81 66 81 66 77 62 75 60 73 58 67 52 63 48 55 40 77,0 62,0<br />

15 81 66 81 66 77 62 76 60 73 58 68 53 63 48 55 40 78,0 63,0<br />

20 79 64 81 66 79 64 79 63 74 58 69 54 65 50 56 41 79,0 64,0<br />

25 79 64 81 66 79 64 79 63 74 59 70 54 66 50 56 41 80,0 64,0<br />

Lw: sound power values in free field conditions are calculated in accordance with ISO 3746.<br />

Lp: sound pressure values measured at 1 meter from the unit in free field conditions in compliance with ISO 3746.<br />

VALUES OF THEORETICAL NOISE ATTENUATION<br />

IN FUNCTION OF FREE FIELD DISTANCE<br />

Distance (m) 1 2 3 4 5 6 7 8 9 10<br />

Attenuation (dB) 0 6 9,5 12 14 15,5 17 18 19 20<br />

14

OVERALL DIMENSIONS<br />

MOD. 5-7-8.5<br />

Ep<br />

C 50<br />

457<br />

Rc<br />

C<br />

Mf<br />

*<br />

1102<br />

Es<br />

Rp<br />

225 877<br />

A<br />

Uin<br />

Uout<br />

763 269 70<br />

76<br />

Pm<br />

* St<br />

Pu *<br />

1102<br />

15<br />

B<br />

Uin<br />

226 177<br />

Cdh *<br />

222 880<br />

81 1021<br />

1117<br />

403 15<br />

15<br />

1102<br />

1121,2<br />

418<br />

1117<br />

400<br />

400<br />

400<br />

N°4 ANTIVIBRANTI IN GOMMA<br />

(OPZIONALI)<br />

400<br />

N°4 RUBBER ANTIVIBRATION<br />

ISOLATORS (OPTIONAL)<br />

30<br />

FLUSSO ARIA CONDENSAZIONE<br />

CONDENSING AIR FLOW<br />

<br />

40<br />

Ep<br />

QUADRO ELETTRICO<br />

ELECTRICAL PANEL<br />

Es<br />

INGRESSO ALIMENTAZIONE ELETTRICA<br />

ELECTRICAL SUPPLY INLET<br />

Cdh<br />

SCARICO CONDENSA VERS. HP<br />

CONDENSATE DRAIN HP VERSION<br />

Ø22<br />

Rc<br />

CONNESSIONI REFRIGERANTE<br />

REFRIGERANT CONNECTIONS<br />

St<br />

SERBATOIO DI ACCUMULO<br />

STORAGE TANK<br />

Rp<br />

PANNELLO ASPORTABILE<br />

REMOVABLE PANEL<br />

Pu<br />

POMPA<br />

PUMP<br />

Uin<br />

INGRESSO ACQUA UTILIZZO<br />

USER WATER INLET<br />

Mf<br />

FILTRI METALLICI<br />

METALLIC FILTER<br />

Uout<br />

USCITA ACQUA UTILIZZO<br />

USER WATER OUTLET<br />

Pm<br />

GRIGLIE DI PROTEZIONE<br />

PROTECTIVE METAL MESH<br />

SPAZI DI INSTALLAZIONE<br />

CLEARANCES<br />

* OPTIONAL<br />

15

OVERALL DIMENSIONS<br />

MOD. 5-7-8.5<br />

50 300 50<br />

G1<br />

G4<br />

IMPRONTA A TERRA/FOOTPRINT<br />

G2<br />

G3<br />

25 350 25<br />

400<br />

12 1076 12<br />

1100<br />

Fh<br />

G..<br />

FORI DI FISSAGGIO<br />

FIXING HOLES<br />

PUNTI DI APPOGGIO ANTIVIBRANTI<br />

VIBRATION DAMPER FOOT HOLDS<br />

Ø12<br />

16

OVERALL DIMENSIONS<br />

MOD. 10-12.5-15<br />

Ep<br />

557<br />

C<br />

1102<br />

Es<br />

Rp<br />

C 50<br />

230 872<br />

A<br />

Uin<br />

Uout<br />

763 269 70<br />

Rc<br />

Mf<br />

*<br />

Pm<br />

74<br />

* St<br />

Pu *<br />

1202<br />

1217<br />

1221<br />

15<br />

20<br />

312 191<br />

503 15<br />

538<br />

B<br />

Uin<br />

222<br />

81<br />

Cdh *<br />

980<br />

1121<br />

400<br />

400<br />

400<br />

N°4 ANTIVIBRANTI IN GOMMA<br />

(OPZIONALI)<br />

400<br />

N°4 RUBBER ANTIVIBRATION<br />

ISOLATORS (OPTIONAL)<br />

30<br />

FLUSSO ARIA CONDENSAZIONE<br />

CONDENSING AIR FLOW<br />

<br />

40<br />

Ep<br />

Es<br />

QUADRO ELETTRICO<br />

ELECTRICAL PANEL<br />

INGRESSO ALIMENTAZIONE ELETTRICA<br />

ELECTRICAL SUPPLY INLET<br />

Cdh<br />

SCARICO CONDENSA VERS. HP<br />

CONDENSATE DRAIN HP VERSION<br />

Ø22<br />

Rc<br />

CONNESSIONI REFRIGERANTE<br />

REFRIGERANT CONNECTIONS<br />

St<br />

SERBATOIO DI ACCUMULO<br />

STORAGE TANK<br />

Rp<br />

PANNELLO ASPORTABILE<br />

REMOVABLE PANEL<br />

Pu<br />

POMPA<br />

PUMP<br />

Uin<br />

INGRESSO ACQUA UTILIZZO<br />

USER WATER INLET<br />

Mf<br />

FILTRI METALLICI<br />

METALLIC FILTER<br />

Uout<br />

USCITA ACQUA UTILIZZO<br />

USER WATER OUTLET<br />

Pm<br />

GRIGLIE DI PROTEZIONE<br />

PROTECTIVE METAL MESH<br />

SPAZI DI INSTALLAZIONE<br />

CLEARANCES * OPTIONAL<br />

17

OVERALL DIMENSIONS<br />

MOD. 10-12.5-15<br />

50 400 50<br />

G1<br />

G2<br />

IMPRONTA A TERRA/FOOTPRINT<br />

G4<br />

G3<br />

12 1476 12<br />

25 450 25<br />

500<br />

1500<br />

Fh<br />

G..<br />

FORI DI FISSAGGIO<br />

FIXING HOLES<br />

PUNTI DI APPOGGIO ANTIVIBRANTI<br />

VIBRATION DAMPER FOOT HOLDS<br />

Ø12<br />

18

OVERALL DIMENSIONS<br />

MOD. 20-25<br />

557<br />

Ep<br />

C<br />

50<br />

Uin<br />

B<br />

C<br />

Rc<br />

Mf<br />

*<br />

1102<br />

Es<br />

Rp<br />

925 177<br />

A<br />

Uin<br />

Uout<br />

566 466 70<br />

Pm<br />

*<br />

St<br />

Pu *<br />

20 314 189<br />

Cdh *<br />

222<br />

1280<br />

1502 15<br />

20 503<br />

137,5<br />

81<br />

1421<br />

1521<br />

660,5<br />

74<br />

400<br />

400<br />

400<br />

400<br />

N°4 ANTIVIBRANTI IN GOMMA<br />

(OPZIONALI)<br />

N°4 RUBBER ANTIVIBRATION<br />

ISOLATORS (OPTIONAL)<br />

FLUSSO ARIA CONDENSAZIONE<br />

CONDENSING AIR FLOW<br />

Ep<br />

QUADRO ELETTRICO<br />

ELECTRICAL PANEL<br />

Es<br />

INGRESSO ALIMENTAZIONE ELETTRICA<br />

ELECTRICAL SUPPLY INLET<br />

Cdh<br />

SCARICO CONDENSA VERS. HP<br />

CONDENSATE DRAIN HP VERSION<br />

Ø22<br />

Rc<br />

CONNESSIONI REFRIGERANTE<br />

REFRIGERANT CONNECTIONS<br />

St<br />

SERBATOIO DI ACCUMULO<br />

STORAGE TANK<br />

Rp<br />

PANNELLO ASPORTABILE<br />

REMOVABLE PANEL<br />

Pu<br />

POMPA<br />

PUMP<br />

Uin<br />

INGRESSO ACQUA UTILIZZO<br />

USER WATER INLET<br />

Mf<br />

FILTRI METALLICI<br />

METALLIC FILTER<br />

Uout<br />

USCITA ACQUA UTILIZZO<br />

USER WATER OUTLET<br />

Pm<br />

GRIGLIE DI PROTEZIONE<br />

PROTECTIVE METAL MESH<br />

SPAZI DI INSTALLAZIONE<br />

CLEARANCES * OPTIONAL<br />

19

OVERALL DIMENSIONS<br />

MOD. 20-25<br />

50 400 50<br />

G1<br />

G2<br />

IMPRONTA A TERRA/FOOTPRINT<br />

G4<br />

G3<br />

12 1476 12<br />

25 450 25<br />

500<br />

1500<br />

Fh<br />

G..<br />

FORI DI FISSAGGIO<br />

FIXING HOLES<br />

PUNTI DI APPOGGIO ANTIVIBRANTI<br />

VIBRATION DAMPER FOOT HOLDS<br />

Ø12<br />

20

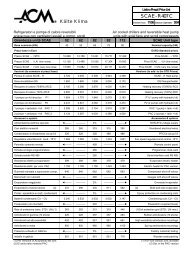

DIMENSIONS AND OPERATING WEIGHT<br />

OF THE MOST FREQUENTLY-USED LAYOUTS<br />

MODEL Version Hydraulic<br />

module<br />

Sound level Length (mm) Depth (mm) Height (mm)<br />

Operating<br />

weight (kg)<br />

5 CH - b 1.121 418 1.102 88<br />

5 HP - b 1.121 418 1.102 92<br />

5 HP 1PS b 1.121 418 1.102 161<br />

5 LE/HP - b 1.121 418 1.102 87<br />

7 CH - b 1.121 418 1.102 100<br />

7 HP - b 1.121 418 1.102 104<br />

7 HP 1PS b 1.121 418 1.102 173<br />

7 LE/HP - b 1.121 418 1.102 98<br />

8.5 CH - b 1.121 418 1.102 114<br />

8.5 HP - b 1.121 418 1.102 120<br />

8.5 HP 1PS b 1.121 418 1.102 188<br />

8.5 LE/HP - b 1.121 418 1.102 114<br />

10 CH - b 1.221 538 1.102 139<br />

10 HP - b 1.221 538 1.102 153<br />

10 HP 1PS b 1.221 538 1.102 248<br />

10 LE/HP - b 1.221 538 1.102 145<br />

12.5 CH - b 1.221 538 1.102 140<br />

12.5 HP - b 1.221 538 1.102 157<br />

12.5 HP 1PS b 1.221 538 1.102 253<br />

12.5 LE/HP - b 1.221 538 1.102 148<br />

15 CH - b 1.221 538 1.102 148<br />

15 HP - b 1.221 538 1.102 164<br />

15 HP 1PS b 1.221 538 1.102 259<br />

15 LE/HP - b 1.221 538 1.102 155<br />

20 CH - b 1.521 661 1.102 174<br />

20 HP - b 1.521 661 1.102 190<br />

20 HP 1PS b 1.521 661 1.102 304<br />

20 LE/HP - b 1.521 661 1.102 172<br />

25 CH - b 1.521 661 1.102 221<br />

25 HP - b 1.521 661 1.102 236<br />

25 HP 1PS b 1.521 661 1.102 350<br />

25 LE/HP - b 1.521 661 1.102 215<br />

CH: water chiller<br />

HP: heat pump<br />

LE: condensing<br />

2PS: 2 pumps + storage tank<br />

1PS: pump + storage tank<br />

b: base<br />

SLN: super low noise<br />

21

INSTALLATIONS RECOMMENDATIONS<br />

LOCATION<br />

- Strictly allow clearances as indicated in the catalogue.<br />

- Locate the unit in order to be compatible with environmental requirements (sound level, integrationinto the site, etc.).<br />

ELECTRICAL CONNECTIONS<br />

- Check the wiring diagram enclosed with the unit, in which are always present all the instructions necessary to the electrical<br />

connections.<br />

- Supply the unit at least 12 hours before start-up, in order to turn crankcase heaters on. Do notdisconnect electrical supply during<br />

temporary stop periods (i.e. weekends).<br />

- Before opening the main switch, stop the unit by acting on the suitable running switches or, if lacking, on the remote control.<br />

- Before servicing the inner components, disconnect electrical supply by opening the main switch.<br />

- The electric supply line must be equipped with an automatic circuit breaker (to be provided by theinstaller.<br />

HYDRAULIC CONNECTIONS<br />

- Carefully vent the system, with pump turned off, by acting on the vent valves. This procedure is fundamental: little air bubbles can<br />

freeze the evaporator causing the general failure of thesystem.<br />

- Drain the system during seasonal stops (wintertime) or use proper mixtures with low freezing point. Incase of temporary stop<br />

periods an electric heater should be installed on the evaporator and hydraulic circuit.<br />

- Install the hydraulic circuit including all the components indicated in the recommended hydraulic circuitdiagrams (expansion<br />

vessel, flow switch, strainer, storage tank, vent valves, shut off valves, flexibleconnections, etc.).<br />

- Connect the flow switch, which is furnished on all units, not fitted. Follow the instructions enclosed with the units.<br />

START UP AND MAINTENANCE OPERATIONS<br />

- Strictly follow what reported in use and maintenance manual. All these operations must be carried on by trained personnel only.<br />

23

BLUE BOX Conditioning<br />

AIR BLUE Air Conditioning<br />

BLUE FROST Refrigeration<br />

are trademarks of<br />

BLUE BOX GROUP<br />

BLUE BOX GROUP s.r.l.<br />

Via E. Mattei, 20<br />

35028 Piove di Sacco PD Italy<br />

Tel. +39.049.9716300<br />

Fax. +39.049.9704105<br />

www.blueboxgroup.it<br />

info@blueboxgroup.it<br />

The technical data may be changed without notice.<br />

202480C02 - Issue 07.05<br />

ISO 9001 - Cert. N.0201