View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

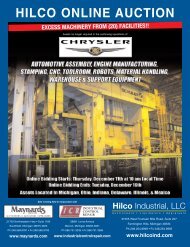

FOR IMMEDIATE SALE!<br />

(2) Complete Engine Manufacturing Lines<br />

for 2.7L & 3.5L V6 Engines<br />

Offered as a Turn-Key Facility with Certain<br />

Worldwide IPR Manufacturing Rights<br />

Includes Real Estate With a Land Area of 109 Acres & Building Area of 1.869 Million Sq. Ft.<br />

Hilco Real Estate<br />

Hilco Industrial, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

www.hilcoind.com

Located at Kenosha Engine Plant, Kenosha, WI USA<br />

Old Carco Liquidation Trust owner of the assets formerly owned by Chrysler LLC<br />

Kenosha Engine Plant<br />

This is a complete engine manufacturing facility including real estate that is<br />

being offered with certain worldwide IPR manufacturing rights.<br />

This facility is located on 109 acres with multiple buildings consisting of over<br />

1.89 million square feet.<br />

Announcement of Sale<br />

Hilco Industrial, LLC, is pleased to announce that they have been appointed<br />

by Old Carco Liquidation Trust, owner of the assets formely owned by<br />

Chrysler LLC, to offer for sale the entire manufacturing assets, land and<br />

buildings, as a Turn-Key Facility with certain Worldwide IPR Manufacturing<br />

Rights, the Kenosha Engine Plant, Kenosha, WI, USA. This facility produces<br />

(2) complete, gasoline V-6 engines with 2.7L & 3.5L displacement.<br />

All manufacturing component lines for the 5 C’s, engine assembly, support equipment and building services are included in this<br />

once-in-a-lifetime opportunity.<br />

Method of Sale<br />

These opportunities are available for IMMEDIATE inspection, negotiation, or sale contract through a private negotiated sale. These lines are<br />

offered strictly subject to prior sale regardless of your status within the sales process. All assets sold as is, where is, without any warranties<br />

expressed or implied.<br />

Location of Facility<br />

The Kenosha Engine Plant, Kenosha, Wisconsin, is located just north of the Illinois border, lying equal distance between Chicago, IL and<br />

Miwaukee, WI, on Lake Michigan. The facility is located a few miles from the main interstate highway I-94 which is one of the main manufacturing<br />

corridors in the USA. The closest International Airports are Chicago O’Hare (ORD) & Milwaukee’s Mitchell Airport (MKE). We will<br />

be more than happy to assist clients from country’s requiring visas with the application process.<br />

Line Capacities<br />

• 2.7L ENGINE LINE: Displacement/Power: 2.7L; 6-Cylinder, Aluminum, Gasoline/Petrol; 24-Valve, DOHC, dVVT, Electronic Throttle;<br />

Capacity of 95 Engines Per Hour; Year of Installation: 1996<br />

• 3.5L ENGINE LINE: Displacement/Power: 3.5L; 6-Cylinder, Aluminum, Gasoline/Petrol; 24-Valve, SOHC, Electronic Throttle;<br />

Capacity of 60 Engines Per Hour; Year of Installation: 2002<br />

History of Facility<br />

The Kenosha Engine Plant has a long history of car manufacturing which takes it back to the start of the car industry in the United States.<br />

The plant was established in 1902 manufacturing bicycles. The plant was then converted into one of the nation’s first auto plants. As the<br />

car industry developed in the USA the Kenosha plant was associated with such famous names as Nash, Kelvinator, Hudson, American<br />

Motors, Chrysler, and Daimler Benz. While Chrysler was under the ownership of Daimler-Benz a complete new engine plant was designed<br />

and built from the ground up producing the 3.5L V-6 High Output Engine in 2002. This plant has been designed and maintained to the<br />

highest of International Standards.<br />

Inspection<br />

(Although obtained from sources deemed reliable, the liquidator makes no warranty or guarantee to the accuracy of the information herein contained.)<br />

We invite your immediate inspection of this facility strictly by prior appointment. Only your personal inspection can truly verify the<br />

magnitude and scope of this opportunity.<br />

Terms & Conditions<br />

All items will be sold “as is, where is” without any warranties, expressed or implied. Although obtained from sources<br />

deemed reliable, the Auctioneer makes no warranty or guarantee to the accuracy of the information herein contained.<br />

Buyers are encouraged to thoroughly inspect the items. This brochure is subject to additions and deletions.<br />

For More Information or for an<br />

Inspection Appointment,<br />

Please Contact the<br />

USA Office of:<br />

Hilco Industrial, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Phone: +1.248.254.9999 or Email: kep@hilcoind.com

3.5L ENGINE LINE (Line is fully automated with Liebherr Gantry Loading Systems)<br />

Displacement/Power: 3.5L • 6-Cylinder, Aluminum, Gasoline/Petrol • 24-Valve, SOHC, Electronic Throttle • Capacity: 60 Engines Per Hour • Year Installation: 2002<br />

3.5L Engine Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4<br />

3.5L Cylinder Block Line<br />

Grob, Nagel, Durr, Gilman . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5<br />

3.5L Cylinder Head Line<br />

Lamb, Durr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6<br />

3.5L Connecting Rod Line<br />

Alfing, Gardner, Nagel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7<br />

3.5L Crankshaft Line<br />

Landis, Heller, Impco, Schenck, Etxe-Tar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8<br />

3.5L Camshaft Line<br />

Landis, Impco, Phillips, Etxe-Tar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10<br />

2.7L ENGINE LINE (Line is fully automated with Liebherr Gantry Loading Systems)<br />

Displacement/Power: 2.7L • 6-Cylinder, Aluminum, Gasoline/Petrol • 24-Valve, DOHC, dVVT, Electronic Throttle • Capacity: 95 Engines Per Hour • Year Installation: 1996<br />

2.7L Engine Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12<br />

2.7L Cylinder Block Line<br />

Giddings & Lewis, Ingersoll, Micromatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13<br />

2.7L Cylinder Head Line<br />

Giddings & Lewis, Ingersoll, Gilman . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14<br />

2.7L Crankshaft Line<br />

Landis, Heller, Ingersoll, Schenck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16<br />

2.7L Camshaft Line<br />

Landis, Impco, Marposs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18<br />

2.7L Connecting Rod Line<br />

Excello, Mattison, Nagel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20<br />

REAL ESTATE<br />

Real Estate Available<br />

Office Space of 590,000+ Sq. Ft. & Manufacturing Related of 1,300,000+ Sq. Ft. . . . . . . page 21

3.5L ENGINE LINE PG 4<br />

3.5L SOHC 24-VALVE 60° V6 ENGINE<br />

Developed in the early 1990’s with volume production in 1993. Vehicle Usages included the Dodge<br />

Intrepid, Chrysler 300, Dodge Charger, Dodge Magnum, Eagle Vision, Chrysler Pacifica, Chrysler<br />

Concorde, Plymouth Prowler, Dodge Journey.<br />

Technical attributes based on 2010MY 3.5L -SOHC engine used in the Chrysler 300 vehicle:<br />

•The Chrysler 300 is a North-South engine application.<br />

•Engine dress components are not included in base engine as shipped from engine assembly plant.<br />

•Example: Machines, belt, mounts, and air induction components.<br />

Basic Dimensions<br />

Displacement<br />

Bore Diameter<br />

Stroke<br />

3518 cc<br />

96 mm<br />

81 mm<br />

Bore/Stroke Ratio 1.19<br />

Bore Spacing<br />

Block Length<br />

Block Height<br />

Rod Length<br />

Piston Height<br />

113.3 mm<br />

409.6 mm<br />

229.3 mm<br />

151 mm<br />

Compression Ratio 9.8:1<br />

38.14 mm<br />

Firing Order 1-2-3-4-5-6<br />

Oil Type 10W-30<br />

Leading Bank<br />

Bank Offset<br />

Right<br />

43 mm<br />

Performance<br />

• Peak Power<br />

250 Hp (186 kW) @ 6400 RPM<br />

• Peak Torque<br />

250 Lb-Ft (339 Nm) @ 3800 RPM<br />

• Ratings based on J1349 JUN1995<br />

• (c/o -not re-rated to August ‘04 standard)<br />

• Exhaust Back Pressure<br />

14 in.Hg @ 1490 lbm/hr flow -steady state<br />

• Fuel Shut-Off<br />

6450 RPM<br />

• Fuel Consumption<br />

1600 RPM 2.4 bar = 316 BSFC<br />

(g/kW-hr) w/EGR<br />

2000 RPM 2.0 Bar = 353 BSFC<br />

(g/kW-hr) W/EGR<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

3.5L CYLINDER BLOCK LINE<br />

OP# Manufacturer No. of Stations Machine Type OP Description<br />

310 Grob 11 Transfer Line Machining operations<br />

320 Grob 18 Transfer Line Machining operations<br />

330 Grob 22 Transfer Line Machining operations<br />

340 Grob 18 Transfer Line Machining operations<br />

350 Grob 22 Transfer Line Machining operations<br />

360 Durr Washing Machine Wash block<br />

10 Gillman Assembly Transfer Line Assembly operations<br />

20 Grob 22 Transfer Line Machining operations<br />

30 Grob 17 Transfer Line Machining operations<br />

40 Grob 28 Transfer Line Machining operations<br />

50 Nagel Honing Machine Hone cylinder bores<br />

60 Durr Washing Machine Final wash<br />

70 Gillman Assembly Transfer Line Assembly operations<br />

3.5L ENGINE LINE PG 5<br />

GILLMAN ASSEMBLY TRANSFER LINE (OP 70)<br />

GROB BLOCK MACHINING TRANSFER LINE<br />

DURR BLOCK WASHING MACHINE CENTRI-SPRAY WASHING MACHINE NAGEL BLOCK CYLINDER BORE HONING MACHINE (OP 50)<br />

GROB BLOCK MACHINING TRANSFER LINE GROB BLOCK MACHINING TRANSFER LINE DURR BLOCK WASHING MACHINE<br />

For more information, please visit us on the web at www.hilcoind.com

3.5L ENGINE LINE PG 6<br />

3.5L CYLINDER HEAD LINE<br />

OP Manufacturer Stations Machine Type OP Description<br />

310 Lamb 33 Transfer Line Machining operations<br />

320 Lamb 28 Transfer Line Machining operations<br />

330 Lamb 18 Transfer Line Machining operations<br />

340 Lamb 26 Transfer Line Machining operations<br />

350 Lamb 27 Transfer Line Machining operations<br />

10 Durr Washing Machine Wash head<br />

20 Lamb 19 Transfer Line Machining operations<br />

30 Lamb 29 Transfer Line Machining operations<br />

40 ABB Robot Deburring operation<br />

50 Durr Washing Machine Final wash<br />

60 Lamb Assembly Machine Assembly operation<br />

LAMB CYLINDER HEAD ASSEMBLY LINE ABB ROBOTIC DEBURRING STATION (OP 40) DURR CYLINDER HEAD WASHING MACHINE<br />

LAMB CYLINDER HEAD ASSEMBLY LINE LAMB CYLINDER HEAD TEST & ASSEMBLY MACHINE ZEISS CYLINDER HEAD CMM INSPECTION MACHINE<br />

LAMB CYLINDER HEAD MACHINING TRANSFER LINE<br />

DURR CYLINDER HEAD WASHING MACHINE<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

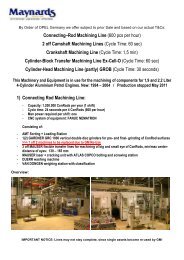

3.5L CONNECTING ROD LINE<br />

OP# Manufacturer Model Machine Type OP Description<br />

310 Landis Gardner GRC-1000 Double Disc Grinder Rough grind con-rod flat<br />

320 Alfing Transfer Line Machining operations<br />

10 Alfing Transfer Line Laser etch & crack con-rod<br />

20 Landis Gardner GRC-1000 Double Disc Grinder Finish grind con-rod flat<br />

30 Alfing Transfer Line Machining operations<br />

40 Alfing Transfer Line Drill Oil Hole<br />

3.5L ENGINE LINE PG 7<br />

50 Nagel 6PV-T Honing Machine Hone small & big bores<br />

60 Centri-Spray Washing Machine Wash con-rod<br />

70 Liebherr Transport & Sorting System Transport & sort con-rods<br />

ALFING CON-ROD CRACKER (OP 10)<br />

ALFING CON-ROD MACHINING TRANSFER LINE<br />

ALFING CON-ROD MACHINING TRANSFER LINE<br />

NAGEL MODEL 6PV-T CON-ROD BORE HONING MACHINE (OP 50)<br />

CENTRI-SPRAY CON-ROD WASHING MACHINE (OP 60)<br />

CON-ROD SORTING & ASSEMBLY MACHINE<br />

CON-ROD ASSEMBLY MACHINE GARDNER GRC-100 DOUBLE DISC GRINDER (OP 310) GARDNER GRC-100 DOUBLE DISC GRINDER (OP 20)<br />

For more information, please visit us on the web at www.hilcoind.com

3.5L ENGINE LINE PG 8<br />

3.5L CRANKSHAFT LINE<br />

OP# Manufacturer Model Machine Type Control OP Description<br />

10 Schenck Turner Transfer Line CAB 750 Mill to length, mass center<br />

20A Heller DRZ 20/2/800 Turn Broach Num Rough post & flange<br />

20B Heller DRZ 20/2/800 Turn Broach Num Rough post & flange<br />

20C Heller DRZ 20/2/800 Turn Broach Num Rough post & flange<br />

30A Heller RFK 20/2/800 External Crank Mill Num Rough pins<br />

30B Heller RFK 20/2/800 External Crank Mill Num Rough pins<br />

30C Heller RFK 20/2/800 External Crank Mill Num Rough pins<br />

40A Heller DRZ 20/2/800 Turn Broach Num Semi Finish Mains<br />

40B Heller DRZ 20/2/800 Turn Broach Num Semi Finish Mains<br />

50A Heller RFK 20/1/800 External Crank Mill Num Semi Finish Pins<br />

50B Heller RFK 20/1/800 External Crank Mill Num Semi Finish Pins<br />

60 ICMS Fillet Rolling Machine Deep Fillet Roll Pins & Mains<br />

70 ETXE-TAR Transfer Line Modicon PLC Drill Oil Holes<br />

80 ETXE-TAR Transfer Line Modicon PLC Machine Flange Holes & Post<br />

90A Landis 5SE Multi Wheel Grinder System 6400 Finish grind 4 Mains, 1 seal<br />

90B Landis 5SE Multi Wheel Grinder System 6400 Finish grind 4 Mains, 1 seal<br />

100 Landis 4SE Plunge Grinder System 6400 Finish grind 3 post end dias.<br />

103 Marposs In Line Inspection Station E9066 Inspect<br />

110A Landis 3L Orbital CBN Crankpin Grinder System 6400 Finish grind 6 pins<br />

110B Landis 3L Orbital CBN Crankpin Grinder System 6400 Finish grind 6 pins<br />

110C Landis 3L Orbital CBN Crankpin Grinder System 6400 Finish grind 6 pins<br />

110D Landis 3L Orbital CBN Crankpin Grinder System 6400 Finish grind 6 pins<br />

110E Landis 3L Orbital CBN Crankpin Grinder System 6400 Finish grind 6 pins<br />

Off line QPAC QJ0 471 Crank Repair Polisher Repair Lapping<br />

120A Landis 3LB CBN Main Bearing Grinder System 6400 Finish grind 2 thrustwalls & 1 pilot<br />

120B Landis 3LB CBN Main Bearing Grinder System 6400 Finish grind 2 thrustwalls & 1 pilot<br />

120C Landis 3LB CBN Main Bearing Grinder System 6400 Finish grind 2 thrustwalls & 1 pilot<br />

123 Marposs In Line Inspection Machine Inspect<br />

130A Marposs In Line Inspection Machine Inspect<br />

130B ABB IRB6400 Robot Debur & Chamfer Oil holes<br />

140 Schenck Balancer Transfer Line CAB750 Measure mass distribution<br />

140 Schenck Balance Gage CAB750 Off Line Balance<br />

150 Impco 1640 XT Micro Finishing System Micro-rough, micro finish<br />

160 Marposs Final Gage E9066 Final Inspection<br />

170 Centri-Spray Washing Machine Wash crankshaft<br />

Adcole 1200-2 Inspection Machine Off Line Balance<br />

LK G80C CMM Renishaw PH 10M Probe<br />

Willis RD1100 Radial Drill<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

ADCOLE 1200-2 CRANKSHAFT<br />

INSPECTION MACHINE LK CMM CRANKSHAFT INSPECTION MACHINE SCHENCK END FACE & MASS CENTER MACHINING LINE (OP 10)<br />

3.5L ENGINE LINE PG 9<br />

(1 OF 5) HELLER DRZ 20/2/800 TURN<br />

TURN BROACHES (OP 20 & OP 40)<br />

(1 OF 5) HELLER RFK 20/2/800 TURN<br />

TURN BROACHES (OP 30 & OP 50)<br />

INGERSOLL CM SYSTEMS FILLET ROLLING MACHINE<br />

ETXE-TAR OIL HOLE DRILLING TRANSFER LINE (OP 70)<br />

ETXE-TAR OIL HOLE DRILL & TAP TRANSFER LINE (OP 80)<br />

(1 OF 2) LANDIS 5SE MULTI-WHEEL<br />

MAIN BEARING GRINDERS (OP 90)<br />

(1 OF 5) LANDIS 3L ORBITAL CBN PIN<br />

CHASER GRINDERS ( OP 100) (1 OF 2) ABB ROBOTIC CHAMFERING STATION (OP 130)<br />

(1 OF 3) LANDIS 3LB CBN MAIN BEARING GRINDERS (OP 120)<br />

SCHENCK CRANKSHAFT FINAL BALANCING LINE (OP 140) MARPOSS FINAL INSPECTION GAGE STATION (OP 160) CENTRI SPRAY CRANKSHAFT WASHING MACHINE (OP 170)<br />

For more information, please visit us on the web at www.hilcoind.com

3.5L ENGINE LINE PG 10<br />

3.5L CAMSHAFT LINE<br />

OP# Manufacturer Model Capacity Machine Type Control OP Description<br />

310 ETXE-TAR Transfer Line Modicon HMI Mill to length, center drill<br />

320A Federal Mogul Tri-Way Turning Machine Turn flange & seal, journal dias<br />

320B Federal Mogul Tri-Way Turning Machine Turn flange & seal, journal dias<br />

330 AA Phillips EM-2530-03 Cam Lobe Milling Machine Rough eccentric milling of lobes<br />

330 BA Phillips EM-2530-03 Cam Lobe Milling Machine Rough eccentric milling of lobes<br />

330 AB Phillips EM-2530-03 Cam Lobe Milling Machine Rough eccentric milling of lobes<br />

330 BB Phillips EM-2530-03 Cam Lobe Milling Machine Rough eccentric milling of lobes<br />

335<br />

A&B<br />

Adcole 911-24 24" Inspection Machine Inspect camshaft<br />

340 A Inductoheat Twin Spindle Scanners Harden lobes<br />

340 B Inductoheat Twin Spindle Scanners Harden lobes<br />

350 A Impco Straightening Press Straighten camshaft<br />

350 B Impco Straightening Press Straighten camshaft<br />

360A Landis 5SE Multi Wheel Grinder System 6400 Grind main bearings<br />

360 B Landis 5SE Multi Wheel Grinder System 6400 Grind main bearings<br />

370 AA Landis 3L 250 X 680 CBN Cam Lobe Grinder System 6400 Grind all cam lobes<br />

370 AB Landis 3L 250 X 680 CBN Cam Lobe Grinder System 6400 Grind all cam lobes<br />

370 AC Landis 3L 250 X 680 CBN Cam Lobe Grinder System 6400 Grind all cam lobes<br />

370 BA Landis 3L 250 X 680 CBN Cam Lobe Grinder System 6400 Grind all cam lobes<br />

370 BB Landis 3L 250 X 680 CBN Cam Lobe Grinder System 6400 Grind all cam lobes<br />

370 BC Landis 3L 250 X 680 CBN Cam Lobe Grinder System 6400 Grind all cam lobes<br />

380 A Impco 1540XT WS Micro Finishing Machine Micro finish, 4 mains, 9 lobes<br />

380 B Impco 1540XT WS Micro Finishing Machine Micro finish, 4 mains, 9 lobes<br />

390 A Marposs M110 Final Gage E9096 Inspect camshaft<br />

390 B Marposs M110 Final Gage E9096 Camshaft lobe profile final inspec.<br />

400 Centri-Spray Washer Wash camshaft<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

(1 OF 2) ADCOLE 911 CAMSHAFT<br />

MEASURING MACHINE (OP 335) EXTE-TAR END PREP TRANSFER LINE (OP 130) (1 OF 2) TRI-WAY END TURNING MACHINE (OP 320)<br />

3.5L ENGINE LINE PG 11<br />

(1 OF 4) PHILLIPS EM-2530-03 CAM<br />

LOBE MILLING MACHINES (OP 330)<br />

(1 OF 2) INDUCTOHEAT TWIN SPINDLE<br />

INDUCTION SCANNERS (OP 340) (1 OF 2) IMPCO STRAIGHTENING PRESSES (OP 350)<br />

(1 OF 2) LANDIS 5SE MULTI-WHEEL<br />

MAIN BEARING GRINDER (OP 360) (1 OF 6) LANDIS 3L CBN CAM LOBE GRINDER (OP 370) (1 OF 6) LANDIS 3L CBN CAM LOBE GRINDER (OP 370)<br />

(1 OF 6) LANDIS 3L CBN CAM LOBE GRINDER (OP 370)<br />

(1 OF 2) IMPCO 1540XT CAMSHAFT<br />

MICRO FINISHING MACHINE (OP 380)<br />

(1 OF 2) MARPOSS M110 FINAL<br />

CAMSHAFT GAGE STATIONS (OP 390)<br />

For More Information or an Inspection Appointment,<br />

Please Contact the USA Office of:<br />

Hilco Industrial, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Phone: +1.248.254.9999 or Email: kep@hilcoind.com<br />

CENTRI-SPRAY CAMSHAFT WASHING MACHINE (OP 400)<br />

For more information, please visit us on the web at www.hilcoind.com

2.7L DOHC 24-VALVE 60° V6 ENGINE<br />

Developed in the mid 1990’s with volume production 1998 MY. Vehicle usages included the Dodge<br />

Intrepid, Chrysler 300, Dodge Charger, Dodge Magnum, Eagle Vision, Chrysler Pacifica, Chrysler<br />

Concorde, Dodge Journey, Dodge Stratus, Chrysler Cirrus, Chrysler Sebring.<br />

Technical attributes based on 2010MY 2.7L -DOHC engine used in the Dodge Charger vehicle:<br />

•The Dodge Charger is a North-South engine application.<br />

•Engine dress components are not included in base engine as shipped from engine assembly plant.<br />

•Example: Machines, belt, mounts, and air induction components.<br />

Basic Dimensions<br />

Displacement<br />

Bore Diameter<br />

Stroke<br />

2736 cc<br />

86 mm<br />

78.5 mm<br />

Bore/Stroke Ratio 1.1<br />

Bore Spacing<br />

104 mm<br />

2.7L ENGINE LINE PG 12<br />

Block Length<br />

447 mm<br />

Block Height<br />

210 mm<br />

Rod Length<br />

139.75 mm<br />

Piston Height<br />

31.2 mm<br />

Compression Ratio 9.9:1<br />

Firing Order 1-2-3-4-5-6<br />

Oil Type 5W-20<br />

Leading Bank<br />

Right<br />

Bank Offset<br />

37.3 mm<br />

Performance<br />

• Peak Power<br />

178 Hp (133 kW) @ 5500 RPM<br />

• Peak Torque<br />

190 Lb-Ft (258 Nm) @ 4000 RPM<br />

• Ratings based on J1349 AUG2004<br />

• Exhaust Back Pressure<br />

7 in.Hg @ 1270 lbm/hr total flow -transient<br />

• Fuel Shut-Off<br />

6464 RPM<br />

• Fuel Consumption<br />

1600 RPM 2.4 bar = 353 BSFC<br />

(g/kW-hr) w/EGR<br />

2000 RPM 2.0 Bar = 386 BSFC<br />

(g/kW-hr) W/EGR<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

2.7L CYLINDER BLOCK LINE<br />

OP# Manufacturer No of Stations Machine Type OP Description<br />

310 Giddings & Lewis 32 Transfer Line Rough Mill<br />

320 Giddings & Lewis 27 Transfer Line Rough Mill, Drill Cylinder Bore<br />

330 Giddings & Lewis 22 Transfer Line Drill Block Deck<br />

340 Giddings & Lewis 25 Transfer Line Drill, Tap Bearing Cap Mounting Holes<br />

350 Giddings & Lewis Carousel Washer Primary Block Washer<br />

10 Giddings & Lewis 26 Assembly Bearing Cap Assembly and Leak Test<br />

20 Giddings & Lewis 15 Transfer Line Drill Oil Pan Mounting Holes<br />

30 Giddings & Lewis 20 Lift and Carry Underbank Drill<br />

40 Giddings & Lewis 20 Transfer Line Drill Ends<br />

50A & B Giddings & Lewis 8 each Transfer Line Crank Bore<br />

60A & B Giddings & Lewis 15 each Transfer Line Finish Cylinder Bore/Banks<br />

70 Giddings & Lewis 23 Transfer Line Bore Block Deck Dowels<br />

80 Micromatic 36 Transfer Line Hone and Microsize Cylinder Bores<br />

90 Giddings & Lewis Carousel Washer Final Block Washer<br />

100 Giddings & Lewis 30 Transfer Line Cup Plug Assembly/Leak Test<br />

COOLANT FILTRATION GALLERY GIDDING & LEWIS BLOCK MACHINING TRANSFER LINE GIDDING & LEWIS BLOCK MACHINING TRANSFER LINE<br />

2.7L ENGINE LINE PG 13<br />

GIDDING & LEWIS BLOCK MACHINING TRANSFER LINE GIDDING & LEWIS BLOCK MACHINING TRANSFER LINE MICROMATIC BLOCK HONING LINE (OP 80)<br />

BLOCK LEAK<br />

TESTING<br />

STATIONS GIDDINGS & LEWIS BLOCK MACHNING TRANSFER LINE SHEFFIELD CORDAX BLOCK INSPECTION CMM<br />

For more information, please visit us on the web at www.hilcoind.com

2.7L CYLINDER HEAD LINE<br />

OP# Manufacturer No of Stations Machine Type OP Description<br />

LEFT HAND<br />

310LH Giddings & Lewis 14 Transfer Line Rough Mill, Drill and Bore<br />

320LH Giddings & Lewis 20 Transfer Line Drill, Ream, Chamfer, Tap, Bore<br />

330LH Giddings & Lewis 22 Transfer Line Mill, Drill, Chamfer, Tap<br />

340LH Giddings & Lewis 28 Transfer Line Drill, Chamfer, Tap, Ream<br />

350LH Giddings & Lewis 18 Transfer Line Drill, Rough Bore, Chamfer, Gage<br />

360LH Giddings & Lewis 18 Transfer Line Drill, Rough Bore, Chamfer, Gage<br />

370LH Giddings & Lewis Carousel Washer Primary Head Washer<br />

10LH Giddings & Lewis 18 Transfer Line Assemble Valve Seat Inserts and Guides<br />

20LH Giddings & Lewis 9 Transfer Line Blow-Off and Assemble Bearing Caps<br />

2.7L ENGINE LINE PG 14<br />

30LH Giddings & Lewis 15 Transfer Line Finish Valve Seats, Ream G. Holes<br />

40LH Giddings & Lewis 23 Transfer Line Semi-Finish, Finish Mill<br />

50LH Giddings & Lewis Carousel Washer Final Head Washer<br />

60LH Giddings & Lewis 22 Transfer Line Cup Plug Assembly, Leak Tests<br />

70LH Giddings & Lewis N/A Off-Line Off Line Dunk Test<br />

RIGHT HAND<br />

310RH Giddings & Lewis 14 Transfer Line Rough Mill, Drill and Bore<br />

320RH Giddings & Lewis 20 Transfer Line Drill, Ream, Chamfer, Tap, Bore<br />

330RH Giddings & Lewis 22 Transfer Line Mill, Drill, Chamfer, Tap<br />

340RH Giddings & Lewis 28 Transfer Line Drill, Chamfer, Tap, Ream<br />

350RH Giddings & Lewis 18 Transfer Line Drill, Rough Bore, Chamfer, Gage<br />

360RH Giddings & Lewis 18 Transfer Line Drill, Rough Bore, Chamfer, Gage<br />

370RH Giddings & Lewis Carousel Washer Primary Head Washer<br />

10RH Giddings & Lewis 18 Transfer Line Assemble Valve Seat Inserts and Guides<br />

20RH Giddings & Lewis 9 Transfer Line Blow-Off and Assemble Bearing Caps<br />

30RH Giddings & Lewis 15 Transfer Line Finish Valve Seats, Ream G. Holes<br />

40RH Giddings & Lewis 23 Transfer Line Semi-Finish, Finish Mill<br />

50RH Giddings & Lewis Carousel Washer Final Head Washer<br />

60RH Giddings & Lewis 22 Transfer Line Cup Plug Assembly, Leak Tests<br />

70RH Giddings & Lewis N/A Off-Line Off Line Dunk Test<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

GIDDINGS & LEWIS CYLINDER HEAD TRANSFER LINE GIDDINGS & LEWIS CYLINDER HEAD TRANSFER LINE STATION ZEISS CENTRAMAX HEAD CMM INSPECTION<br />

SHEFFIELD PROGAGE H25 HEAD CMM INSPECTION GIDDINGS & LEWIS CYLINDER HEAD TRANSFER LINE GIDDINGS & LEWIS CYLINDER HEAD TRANSFER LINE<br />

BE OFF-LINE HEAD WASHER<br />

INGERSOLL RAND HEAD<br />

WASHING MACHINE<br />

GIDDINGS & LEWIS CYLINDER HEAD TRANSFER LINE<br />

2.7L ENGINE LINE PG 15<br />

GIDDINGS & LEWIS CYLINDER HEAD TRANSFER LINE<br />

GIDDINGS & LEWIS CYLINDER HEAD TRANSFER LINE<br />

GIDDINGS & LEWIS CYLINDER HEAD TRANSFER LINE<br />

GIDDINGS & LEWIS CYLINDER HEAD ASSEMBLY STATION<br />

CENTRAL COOLANT SYSTEM FILTRATION GALLERY<br />

GIDDINGS & LEWIS CYLINDER<br />

HEAD TRANSFER LINE STATION<br />

For more information, please visit us on the web at www.hilcoind.com

2.7L CRANKSHAFT LINE<br />

2.7L ENGINE LINE PG 16<br />

OP# Manufacturer Model Machine Type Control OP Description<br />

10 ICMS Transfer Line Ends prep, qualifies Length<br />

20A ICMS Broaching Machine<br />

20B ICMS Broaching Machine<br />

20C ICMS Broaching Machine<br />

30A Heller RFK 200/800/2 Twin Head Crankmill UniPro CNC 90 Rough mill pins & cheek cwts.<br />

30B Heller RFK 200/800/2 Twin Head Crankmill UniPro CNC 90 Rough mill pins & cheek cwts.<br />

30C Heller RFK 200/800/2 Twin Head Crankmill UniPro CNC 90 Rough mill pins & cheek cwts.<br />

40A ICMS Broaching Machine Finish turn all mains & top cwts.<br />

40B ICMS Broaching Machine Finish turn all mains & top cwts.<br />

50A Heller RFK 200/800/2 Twin Head Crankmill UniPro CNC 90 Finish Mill Pins & Ucuts<br />

50B Heller RFK 200/800/2 Twin Head Crankmill UniPro CNC 90 Finish Mill Pins & Ucuts<br />

60 ICMS Deep Fillet Roll Crank Fillet Roll Pins & Mains<br />

70A Kreuger Oil Hole Drill Trans Line Servo Drive Drill Oil Holes in Pins & Mains<br />

70B Kreuger Oil Hole Drill Trans Line Drill Oil Holes in Pins & Mains<br />

80A ICMS Thrust Face Transfer M/C Indramat Turn Thrust Face<br />

80B ICMS Thrust Face Transfer M/C Turn Thrust Face<br />

85 Marposs M110 Modular In-Line Gage E9066<br />

90 Kreuger Transfer Line Drill & Tap Flange & Post<br />

100A Landis 5RE Multi Wheel Grinder System 3200 Finish Grind 4 Main Journals<br />

100B Landis 5RE Multi Wheel Grinder System 3200 Finish Grind 4 Main Journals<br />

110A Landis 3SEH Grinder System 3200 Grind 4 Post End Dias.<br />

110B Landis 3SEH Grinder System 3200 Grind 4 Post End Dias.<br />

115 Marposs In Line Gage Post, 4 mains, oil seal<br />

120A Landis 5RE SHD Crank Pin Grinder System 3200 Grind Pin 1<br />

120B Landis 5RE SHD Crank Pin Grinder System 3200 Grind Pin 2<br />

120C Landis 5RE SHD Crank Pin Grinder System 3200 Grind Pin 3<br />

120D Landis 5RE SHD Crank Pin Grinder System 3200 Grind Pin 4<br />

120E Landis 5RE SHD Crank Pin Grinder System 3200 Grind Pin 5<br />

120F Landis 5RE SHD Crank Pin Grinder System 3200 Grind Pin 6<br />

125 Marposs M110 Modular Gage E9096 Stroke & Index Pin Geometry Gage<br />

130A ABB IRB 4400 Robot Chamfer & Brush Out Oil Holes<br />

130B ABB IRB 4400 Robot Chamfer & Brush Out Oil Holes<br />

140 Schenck Turner Balancing Transfer Line CAB 750 Balance Crank and Gage<br />

150 Impco 1640 XT Lapping Machine Polish mains, pins, flange, post<br />

165 Marposs M110 Modular Final Inspection Gages pins<br />

170 Ingersoll Rand Crankshaft Wash Wash crankshaft<br />

Off Line Supfina/Masco Micro Flex Lapper<br />

Off Line Lincoln RL84TPR-820A Radial Drill<br />

Off Line Sharp 1340 Engine Lathe<br />

Off Line Adcole 1200 DH Inspection Machine Adcole Inspect Crankshaft<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

INGERSOLL CM SYSTEMS TRANSFER LINE (OP 10) (1 OF 3) INGERSOLL CM SYSTEMS ROTARY BROACH (OP 20)<br />

(1 OF 3) HELLER RFK 200/800/2<br />

CRANKSHAFT MILLING<br />

MACHINES (OP 30)<br />

(1 OF 2) KRUEGER OIL HOLE DRILL TRANSFER LINE (OP 70)<br />

(1 OF 2) INGERSOLL<br />

CM SYSTEMS ROTARY<br />

BROACH (OP 40)<br />

KRUEGER END WORK TRANSFER LINE (OP 90)<br />

(1 OF 2) HELLER RFK 200/800/2<br />

CRANKSHAFT MILLING MACHINES (OP 40)<br />

INGERSOLL CM SYSTEMS FILLET<br />

ROLLING MACHINE (OP 60)<br />

2.7L ENGINE LINE PG 17<br />

(1 OF 6) LANDIS 5RE CRANK PIN GRINDER (OP 120)<br />

(1 OF 2) LANDIS 5RE MULTI WHEEL<br />

MAIN BEARING GRINDER (OP 100) (1 OF 2) LANDIS 3SEH POST END GRINDER (OP 110)<br />

(1 OF 2) ABB ROBOTIC<br />

CHAMFER CELLS (OP 130) SCHENCK TURNER CRANKSHAFT BALANCING LINE (OP 140) INGERSOLL RAND WASHING MACHINE (OP 170)<br />

For more information, please visit us on the web at www.hilcoind.com

2.7L CAMSHAFT LINE<br />

OP# Manufacturer Model Capacity Machine Type Control OP Description<br />

LEFT HAND<br />

20LH/A Landis 500 SE Centerless Grinder System 3200 Grind main bearings<br />

20LH/B Landis 500 SE Centerless Grinder System 3200 Grind main bearings<br />

20LH/C Landis 500 SE Centerless Grinder System 3200 Grind main bearings<br />

25LH/A Marposs Inspection Stands E9066 Gage Inspect camshaft<br />

25LH/B Marposs Inspection Stands E9066 Gage Inspect camshaft<br />

25LH/C Marposs Inspection Stands E9066 Gage Inspect camshaft<br />

30LH/A Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30LH/B Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30LH/C Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

2.7L ENGINE LINE PG 18<br />

30LH/D Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30LH/E Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30LH/F Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

35LH/A Marposs M110 Lobe Profile Gage E9066 Gage Inspect camshaft<br />

35LH/B Marposs M110 Lobe Profile Gage E9066 Gage Inspect camshaft<br />

RIGHT HAND<br />

20RH/A Landis 500 SE Centerless Grinder System 3200 Grind main bearings<br />

20RH/B Landis 500 SE Centerless Grinder System 3200 Grind main bearings<br />

20RH/C Landis 500 SE Centerless Grinder System 3200 Grind main bearings<br />

25RH/C Marposs Main Journal Gage E9066 Gage Inspect camshaft<br />

25RH/A Marposs Main Journal Gage E9066 Gage Inspect camshaft<br />

25RH/B Marposs Main Journal Gage E9066 Gage Inspect camshaft<br />

30RH/A Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30RH/B Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30RH/C Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30RH/D Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30RH/E Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

30RH/F Landis 3L 250 X 680 Lobe Grinder System 3200 Grind cam lobes<br />

35RH/B Marposs M110 Profile E9066 Gage Inspect camshaft<br />

40LH Impco 1540 XT World Star Lapping Machine Lap camshaft<br />

40RH Impco 1540 XT World Star Lapping Machine Lap camshaft<br />

55 Marposs M110 Profile Inspection M/C E9066 Final inspection gage<br />

60 Ingersoll Washer Wash camshaft<br />

Off Line Adcole 911 Inspection Machine Adcole Inspect camshaft<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

ADCOLE 911 CAMSHAFT GAGE<br />

MEASURING MACHINE (1 OF 6) LANDIS 500SE CENTERLESS GRINDERS (OP 20) (1 OF 6) LANDIS 500SE CENTERLESS GRINDERS (OP 20)<br />

(1 OF 6) LANDIS 500SE CENTERLESS GRINDERS (OP 20) (1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30) (1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30)<br />

(1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30) (1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30) (1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30)<br />

2.7L ENGINE LINE PG 19<br />

(1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30) (1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30) (1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30)<br />

(1 OF 12) LANDIS 3L CBN CAM LOBE GRINDER (OP 30) (1 OF 2) IMPCO 1540 XT WORLD STAR LAPPING LINES (OP 40) INGERSOLL RAND WASHING MACHINE (OP 60)<br />

For more information, please visit us on the web at www.hilcoind.com

2.7L CONNECTING ROD LINE<br />

OP# Manufacturer Stations Machine Type OP Description<br />

5 Valiant Conveyor Hopper & Gantry System Conveyor lift & carry<br />

15 Valiant Conveyor Conveyor lift & carry<br />

25 Valiant Conveyor Conveyor lift & carry<br />

30 Excello 9 Transfer Line Bore & Chamfer both bores<br />

40 Excello 15 Transfer Line Drill, Chamfer, & Tap Bolt Holes<br />

50 Ingersoll Washer Wash Con-Rod<br />

60 Excello 9 Transfer Line Cracker Crack rods, Install bolts, Press bushing<br />

70 Mattison Double Disc Grinder Grind rod flat<br />

80 Excello 6 Transfer Line Finish bore both ends, mill slots<br />

90 Excello 8 Transfer Line Drill oil hole<br />

100 Nagel Honing Machine Finish hone big & small bores<br />

110 Ingersoll Washer Wash Con-Rod<br />

2.7L ENGINE LINE PG 18<br />

120 Valiant Storage System Store Con-Rods<br />

EXCELLO CON-ROD TRANSFER LINE<br />

EXCELLO CON-ROD TRANSFER LINE MATTISON DOUBLE DISC GRINDER (OP 70)<br />

EXCELLO CON-ROD CRACKER & ASSEMBLY MACHINE (OP 60)<br />

EXCELLO CON-ROD TRANSFER LINE<br />

EXCELLO CON-ROD TRANSFER LINE<br />

NAGEL CON-ROD HONING MACHINE (OP 100) NAGEL CON-ROD HONING MACHINE (OP 100) INGERSOLL RAND WASHING MACHINE (OP 100)<br />

For a preview appointment or further information, please contact Robert Levy at 248.254.9999

Located in Kenosha, Wisconsin, this campus is currently used to manufacture Chrysler 2.7L & 3.5L engines.<br />

The campus is comprised of 50 buildings ranging in size from 450 to 533,000+ square feet. Of the over 1.9 million square feet under roof,<br />

approximately 590,000 sq. ft. is office space with the balance being dedicated to manufacturing and storage. The campus sits on 109<br />

acres of land surrounded by single family homes, multi-family housing, and commercial real estate.<br />

Some of the buildings on campus have been constructed specifically to house the equipment outlined herein, so there is ample ceiling<br />

height, power generation capacity, column spacing, and floor load capacity to continue operating the facility as is. There is also<br />

significant room to expand operations in the future, if necessary.<br />

This is an excellent opportunity to purchase this turn key manufacturing facility with an experienced and available workforce.<br />

This property is a 6.6 miles east of Interstate 94 off exit 342 for Wi-158 toward Kenosha. The facility is located approximately 40 miles<br />

south of Milwaukee and 60 miles north of Chicago. It resides in a residential neighborhood approximately 1 mile from Lake Michigan.<br />

State and/or local incentives may be available to prospective purchasers.<br />

ADDRESS<br />

5555 30th Avenue • Kenosha, WI 53144<br />

BUILDING SPECIFICATIONS<br />

50 Buildings: Office - 590,000+ Sq. Ft.,<br />

Manufacturing Related - 1,300,000+ Sq. Ft.<br />

SITE AREA<br />

109+ Acres<br />

CEILING HEIGHT<br />

Ranges from 12.5' to 44'<br />

EXTERNAL AREAS<br />

Logistics Yard: 3 areas totaling 5.4 acres • 170 truck positions<br />

Employee Parking: 16.58 acres • 1,731 spaces<br />

Green Area: 12.54 acres<br />

For More Information,<br />

Please Contact the<br />

USA Office of:<br />

CONSTRUCTION<br />

Combination of precast concrete, brick, glass, & metal siding<br />

ZONING<br />

Industrial<br />

ROOF<br />

Combination of Wood/Built Up and Metal Deck<br />

Many areas installed from 1990-2002<br />

POWER<br />

The plant is fed power from We Energies Albers Substation<br />

located about 1 mile north of the facility. Power is distributed<br />

at 25,000 volts to each of the 13 substations on site.<br />

YEARS BUILT<br />

From 1917 to 2003<br />

Phyllis Riina • Phone: +1.248.936.6863<br />

Email: phyllis.riina@cbre.com<br />

Bruce Rasher• Phone: +1.248.351.2041<br />

Email: bruce.rasher@cbre.com<br />

REAL ESTATE PG 21

ALSO AVAILABLE FOR IMMEDIATE SALE<br />

Located at Detroit Axle Plant, Detroit, MI USA<br />

Old Carco Liquidation Trust<br />

owner of the assets formerly owned by<br />

Chrysler LLC<br />

Complete Axle Plant Including:<br />

Massive Gear Manufacturing Capacity<br />

OFFERED AS A COMPLETE TURN-KEY FACILITY<br />

Axles for Automotive & Light Truck FWD, RWD, & 4WD<br />

• DIFFERENTIAL CASE &<br />

CARRIER MACHINING & ASSEMBLY<br />

• AXLE TUBE MANUFACTURING<br />

REAR AXLE MACHINING & ASSEMBLY LINES<br />

INCLUDING 10 VARIOUS LINES WITH AUTOMATED WELDING<br />

REAR AXLES USED IN GRAND CHEROKEE, DAKOTA, NITRO, RAM TRUCK<br />

FWD AXLE MACHINING & ASSEMBLY<br />

FORMERLY USED IN 300M & CHALLENGER<br />

4WD FRONT AXLE<br />

(2) MACHINING & ASSEMBLY<br />

BUILT BY ABB & INSTALLED IN 2000<br />

FORMERLY USED IN DAKOTA, RAM TRUCK,<br />

GRAND CHEROKEE &<br />

COMMANDER SUV<br />

Includes Real Estate With Approximately 1.2 Million Sq. Ft. of Buildings on 55 Acres of Land<br />

Hilco Industrial, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Phone: +1.248.254.9999 or Email: dap@hilcoind.com