View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

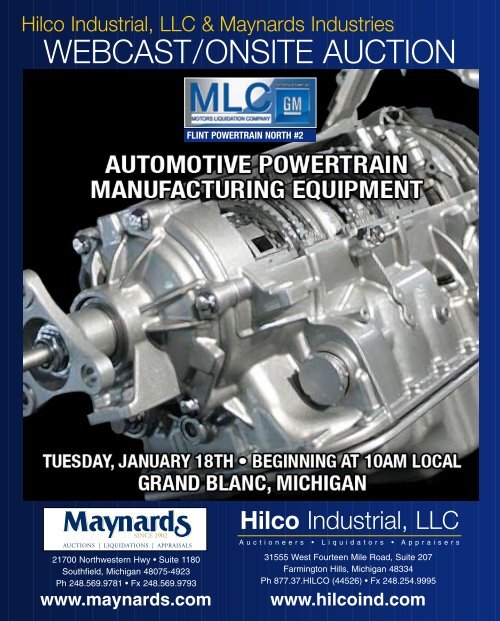

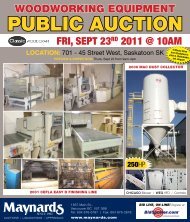

Hilco Industrial, LLC & <strong>Maynards</strong> <strong>Industries</strong><br />

WEBCAST/ONSITE AUCTION<br />

FLINT POWERTRAIN NORTH #2<br />

AUCTIONS | LIQUIDATIONS | APPRAISALS<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

Hilco Industrial, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 877.37.HILCO (44526) • Fx 248.254.9995<br />

www.hilcoind.com

HILCO INDUSTRIAL, LLC<br />

& MAYNARDS INDUSTRIES<br />

WEBCAST/ONSITE AUCTION<br />

AUCTION DATE<br />

TUESDAY, JANAURY 18 TH<br />

FLINT POWERTRAIN NORTH #2 BEGINNING AT 10AM LOCAL TIME<br />

AUCTION LOCATION<br />

GENESYS CONFERENCE & BANQUET CENTER<br />

801 HEALTH PARK BLVD. • GRAND BLANC, MI 48439<br />

DIRECTIONS TO AUCTION<br />

FROM BISHOP INTERNATIONAL AIRPORT: HEAD WEST TOWARD W BRISTOL RD. TURN RIGHT<br />

AT W BRISTOL RD. SLIGHT RIGHT TO MERGE ONTO I-75 S/US-23 S TOWARD DETROIT/ANN<br />

ARBOR. CONTINUE TO FOLLOW I-75 S FOR 7.3 MILES AND TAKE EXIT 108 FOR HOLLY RD.<br />

TURN RIGHT AT HOLLY RD. AND TAKE THE 2ND RIGHT ONTO HEALTH PARK BLVD.<br />

PREVIEW LOCATION<br />

902 HAMILTON ST. • FLINT, MI 48550<br />

DIRECTIONS TO PREVIEW<br />

FROM BISHOP INTERNATIONAL AIRPORT: HEAD EAST TOWARD W BRISTOL RD. TURN RIGHT AT<br />

W BRISTOL RD. MAKE A SLIGHT RIGHT ONTO THE US-23 N/I-75 N RAMP TO SAGINAW. CONTINUE<br />

TOWARD I-69 E. KEEP RIGHT AT THE FORK, FOLLOW SIGNS FOR I-69 E/FLINT/PORT HURON AND<br />

MERGE ONTO I-69 E. PROCEED FOR 3.3 MILES AND TAKE EXIT 137 TO MERGE ONTO I-475 N<br />

TOWARD SAGINAW. GO 1.9 MILES AND TAKE EXIT 8B FOR DAVISON RD TOWARD HAMILTON AVE.<br />

TURN LEFT AT BROADWAY BLVD. CONTINUE ONTO E HAMILTON AVE.<br />

FROM THE DETROIT AREA: TAKE I-75 NORTH TOWARDS FLINT. APPROACHING FLINT, TAKE<br />

I-475 NORTH. FOLLOW I-475 NORTH TO EXIT #8B, DAVISON ROAD/HAMILTON AVENUE. TURN<br />

LEFT AT BROADWAY BLVD. AND CONTINUE ONTO HAMILTON AVENUE. TURN INTO THE GM<br />

POWERTRAIN COMPLEX AND CHECK IN WITH SECURITY FOR FURTHER INSTRUCTIONS.<br />

PREVIEW DATE<br />

MONDAY, JANUARY 17 TH<br />

9AM TO 4PM LOCAL & MORNING OF SALE<br />

FURTHER INFORMATION<br />

• A BUYERS PREMIUM OF 13.5% FOR ALL ONSITE SALES<br />

& 16% FOR ALL WEBCAST SALES WILL BE IN EFFECT.<br />

AUCTION WILL BE CONDUCTED IN ENGLISH,<br />

ACCEPTING U.S. CURRENCY ONLY.<br />

• REMOVAL DEADLINE IS FRIDAY, FEBRUARY 11, 2010<br />

WITH HOURS OF REMOVAL BETWEEN 8AM TO 4PM<br />

MONDAY THRU FRIDAY. AFTER THE NOTED DEADLINE<br />

AT 4PM THE BUYER WILL INCUR A COST OF $500 FOR<br />

ENTRY INTO THE FACILITY.<br />

• FOR FURTHER INFORMATION ON MACHINERY &<br />

EQUIPMENT, PLEASE CONTACT KEN PLANET AT<br />

248.254.9999 x33 OR EMAIL KPLANET@HILCOIND.COM<br />

OR MARIO MAZZUCA AT 248.569.9781 OR<br />

MARIO@MAYNARDS.COM<br />

• FOR PAYMENTS PLEASE CONTACT BECKY KUZNICKI AT<br />

517.719.8134 OR EMAIL BECKY@MAYNARDS.COM<br />

• CUSTOMER SERVICE, PLEASE CONTACT<br />

SANDI NEELY AT 248.254.9999 X16 OR EMAIL<br />

SNEELY@HILCOIND.COM<br />

• REMOVAL OF ITEMS REQUIRING DISCONNECT AND<br />

RIGGING TO BE PERFORMED BY MLC APPOINTED<br />

RIGGER AT PURCHASER’S COST.<br />

(9) HIGH SPEED STRAIGHT SIDE PRESSES<br />

(3) #1, #2 & #4 PRESS LINES, EACH INCLUDING:<br />

1 – MINSTER PIECE-MAKER PM3-125-48 125-TON HIGH SPEED STRAIGHT<br />

SIDE PRESS, S/Ns 24903, 24902, 24901, 125-Ton, Bed Size 48” LR x 32”<br />

FB, Speeds Variable 0 – 500 SPM, Stroke 3”, Slide Adjustment 2”, Shut<br />

Height 19” Over Bed / 14” Over Bolster, 15” Wide Windows, Air Clutch, Air<br />

Counterbalance, Floor Standing With Dynamics Micro / Level Isolator Pads,<br />

Minster Console Control, Acon Insulated Panel Noise Suppression Enclosure<br />

1 – VAMCO MODEL BK2-6 II 6” ADJUSTABLE CAM PRESS MOUNTED ROLL<br />

FEED, S/Ns BK264615L22R, SBK264451511R, BK264615L21R<br />

1 – PERFECTO / MINSTER 2400-12-17-MHS 12” ROLL STRAIGHTENER,<br />

S/N 13-11073 VENDOR S/N S2-80216, S/N 13-11071, VENDOR S/N S2-<br />

80214, S/N 13 11072, VENDOR S2-80215<br />

1 – LITTELL 40-12 DOUBLE-END AUTOMATIC CENTERING REEL /<br />

UNCOILER, S/Ns 85492-81, 85492-81, N/A, Maximum Coil Weight<br />

4000-Lbs., Max. Coil Width 12”, Max. OD 60”, ID Range 19-24”, Manual<br />

Expansion, Pneumatic Drag Brake<br />

(3) #3, #8, #9 PRESS LINES, EACH INCLUDING:<br />

1 – MINSTER PIECE-MAKER P2-100-48 100-TON HIGH SPEED STRAIGHT<br />

SIDE PRESS, S/Ns 23792, 24708, 24433, 100-Ton, Bed Size 48” LR x 32”<br />

FB, Speeds Variable 100 – 400 SPM, Stroke 2”, Adjustment 2”, Shut Height<br />

19.5”, 16” Wide Windows, Air Clutch, Air Counterbalance, Floor Standing<br />

With Dynamics Micro / Level Isolator Pads, Minster Console Control, Acon<br />

Insulated Panel Noise Suppression Enclosure<br />

1 – MINSTER 6” PRESS MOUNTED ROLL FEEDER<br />

1 – PERFECTO / MINSTER 2400-12-17 12” ROLL STRAIGHTENER,<br />

S/N MHS-1031, VENDOR S2-78173, S/N 13-11058, VENDOR S2-80024,<br />

S/N 13-11015, VENDOR S2-79154<br />

1 – LITTELL MODEL 40-12 DOUBLE-END AUTOMATIC CENTERING REEL /<br />

UNCOILER, S/Ns 85212-79, 85446-80, 85408-80, Maximum Coil Weight<br />

4000-Lbs., Max. Coil Width 12”, Max. OD 60”, ID Range 19-24”, Manual<br />

Expansion, Pneumatic Drag Brake<br />

#6 PRESS LINE, INCLUDING:<br />

1 – MINSTER PIECE-MAKER P2-100-48 100-TON HIGH SPEED STRAIGHT<br />

SIDE PRESS, S/N 24710, 100-Ton, Bed Size 48” LR x 32” FB, Speeds<br />

Variable 100 – 400 SPM, Stroke 2”, Adjustment 2”, Shut Height 19.5”, 16”<br />

Wide Windows, Air Clutch, Air Counterbalance, Floor Standing With<br />

Dynamics Micro / Level Isolator Pads, Minster Console Control, Acon<br />

Insulated Panel Noise Suppression Enclosure<br />

1 – VAMCO QUANTUM 6, 6” PRESS MOUNTED SERVO ROLL FEED,<br />

S/N 062.52C63, Programmable Console Control<br />

1 – PERFECTO / MINSTER 2400-12-MHS 12” ROLL STRAIGHTENER,<br />

S/N 13-11059, VENDOR S/N S2-80026<br />

1 – LITTELL MODEL 40-12 DOUBLE-END AUTOMATIC CENTERING REEL /<br />

UNCOILER, S/N 85446-80, Maximum Coil Weight 4000-Lbs., Max. Coil<br />

Width 12”, Max. OD 60”, ID Range 19-24”, Manual Expansion, Pneumatic<br />

Drag Brake<br />

2<br />

To schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

PRESS LINES • CNC TURNING & MACHINING CENTERS<br />

(9) HIGH SPEED STRAIGHT SIDE PRESSES (CONTINUED)<br />

#7 PRESS LINE, INCLUDING:<br />

1 – MINSTER PIECE-MAKER P2-100-48 100-TON HIGH SPEED STRAIGHT SIDE PRESS, S/N 24709,<br />

100-Ton, Bed Size 48” LR x 32” FB, Speeds Variable 100 – 400 SPM, Stroke 2”, Adjustment 2”, Shut Height<br />

19.5”, 16” Wide Windows, Air Clutch, Air Counterbalance, Floor Standing With Dynamics Micro / Level Isolator<br />

Pads, Minster Console Control, Acon Insulated Panel Noise Suppression Enclosure<br />

1 – MINSTER 6” PRESS MOUNTED ROLL FEEDER, S/N N/A<br />

1 – PERFECTO / MINSTER 2400-12-MHS 12” ROLL STRAIGHTENER, S/N 13-11057, VENDOR S2-80023<br />

1 – LITTELL MODEL 40-12 DOUBLE-END AUTOMATIC CENTERING REEL / UNCOILER, S/N 85446-80,<br />

Maximum Coil Weight 4000-Lbs., Max. Coil Width 12”, Max. OD 60”, ID Range 19-24”, Manual Expansion,<br />

Pneumatic Drag Brake<br />

#10 PRESS LINE, INCLUDING:<br />

1 – MINSTER PIECE-MAKER P2-100-48 100-TON HIGH SPEED STRAIGHT SIDE PRESS, S/N 23791,<br />

100-Ton, Bed Size 48” LR x 32” FB, Speeds Variable 100 – 400 SPM, Stroke 2”, Adjustment 2”, Shut Height<br />

19.5”, 16” Wide Windows, Air Clutch, Air Counterbalance, Floor Standing With Dynamics Micro / Level Isolator<br />

Pads, Minster Console Control,<br />

1 – VAMCO QUANTUM 6 6” PRESS MOUNTED SERVO ROLL FEED, S/N 062.5C110, Programmable Console Control<br />

1 – PERFECTO / MINSTER 2400-12-17 12” ROLL STRAIGHTENER, S/N MHS-1032, VENDOR S2-78174<br />

1 – LITTELL 40-12 DOUBLE-END AUTOMATIC CENTERING REEL / UNCOILER, S/N 85211-78, Maximum Coil<br />

Weight 4000-Lbs., Max. Coil Width 12”, Max. OD 60”, ID Range 19-24”, Manual Expansion, Pneumatic Drag Brake<br />

CNC TURNING / MILLING CENTER<br />

1 – MAZAK SUPER QUICK TURN 28 MS CNC TURNING / MILLING CENTER, S/N 110612 (1994), Mazatrol<br />

T32-3, 12- Position Tool Turret With Live Tooling, Estimated 20” Swing, Est. 48” Between Centers, Power<br />

Tailstock, Coolant, Chip Conveyor<br />

(11) CNC TURNING CENTERS<br />

9 – OKUMA TYPE CADET MODEL LNC-8W 2-AXIS CNC TURNING CENTERS, S/Ns 0704C711, 0704C734,<br />

0704C696 0707C833, 0709C878, 0707C811, 0706C790, 0707C856, 0705C750, Okuma OSP5020L Control,<br />

Pick-N-Place Auto Load / Unload, 12-Position Tool Turret, Power Tailstock, Approx. 10” Turning Diameter, Approx.<br />

20” Turning Length, Connected Into Central Supplied Coolant System, *Note Some Machines May Be Incomplete<br />

2 – HARDINGE CONQUEST T-51 CS-51 2-AXIS CNC TURNING CENTERS, S/Ns CLT-405-C, CLT-452-C (1995)<br />

CNC ROTARY TRANSFER MACHINES<br />

3 – THYSSEN KRUPP TURMATIC SYSTEMS TYPE TURMAT 36 / 80-RO AUTOMATIC CNC ROTARY<br />

TRANSFER MACHINE, S/Ns 242-50811, 242-50810, S/N 242-50809 (All 2003)<br />

(8) CNC PISTON TURNING MACHINES<br />

8 – GIDDINGS & LEWIS CNC 2-SPINDLE VERTICAL<br />

PISTON TURNING MACHINES, S/N 94F005A, 94F004A,<br />

94F002A, 92F076B, 94F003A, NA, 04F006A, NA, Giddings<br />

& Lewis PMC-450 Operator’s Control Pendant Station,<br />

Main Control Panel, Automatic Load / Unload – Gantry<br />

Type, (2) Vertical Spindle Chucks With Power Collet Closer,<br />

Single 22 KW Spindle Drive Motor, Connected Into Central<br />

Supplied Coolant System, *Note: Some Machines May Be<br />

Incomplete<br />

(10) PISTON LINES SORTING TABLES<br />

9 – HOHL / BI-FLOW BELT TYPE PARTS SORTER /<br />

UNSCRAMBLER TABLES, S/Ns N/A, 4’ x 12’, (4)<br />

Conveyor Belt Lanes<br />

1 – AUTOMATED SYSTEMS INC / BI-FLOW BELT TYPE<br />

PARTS SORTER / UNSCRAMBLER TABLE, S/N NA, 6’ x<br />

20’ (12) 6” Wide Plastic Conveyor Belts, Main Control Panel<br />

(24) CNC TURNING CENTERS<br />

1 – MONARCH METALIST CNC TURNING CENTER,<br />

S/N 53626, General Numeric GNIO Series Control,<br />

Estimated 12” Swing x 36” Centers, Power Tailstock,<br />

8-Position Tool Turret, 25-HP<br />

1 – MAZAK QUICK TURN 10 UNIVERSAL CNC TURNING<br />

CENTER, S/N 58266, Mazatrol CAM T-2 Controls,<br />

Estimated 8” Swing x 30” Centers, Power Tailstock,<br />

8” Power Chuck, 8-Position Tool Turret, Coolant,<br />

Chip Conveyor<br />

4 – HARDINGE CONQUEST VT-200 2-AXIS CNC VERTICAL<br />

TURNING CENTERS, S/N VL-232-2, VL-235-2, VL-233-2,<br />

VL-129-2, GE Fanuc Series 18-T Control, Single 16”<br />

Vertical Workpiece Chuck, Turning Diameter (est.) 15.7”,<br />

Turning Length (Height) (est.) 19.8”, 12-Position Tool Turret,<br />

Pick-N-Place Loader Arm, 18.5 / 22 KW Spindle Motor,<br />

*Note: Some Machines May Be Incomplete<br />

18 – HARDINGE CONQUEST VT-200 2-AXIS CNC VERTICAL<br />

TURNING CENTERS, S/N VL-234-2, VL-237-2, VL-236-2,<br />

VL-238-2, VO-140-2, VL-136-2, VL-127-2, VL-138-2, VL-<br />

167-2, VL-139-2, VL-135-2, VL-169-2, VL-353-2, VL-363-2,<br />

VL-354-2, VL-364-2, VL-366-2, VL-128-2, GE Fanuc Series<br />

18-T Control, Single 16” Vertical Workpiece Chuck, Turning<br />

Diameter (est.) 15.7”, Turning Length (Height) (est.) 19.8”,<br />

12-Position Tool Turret, Pick-N-Place Loader Arm, 18.5 / 22<br />

KW Spindle Motor, With Manual Load, Independent Portable<br />

Coolant System With Magnetic Chip Conveyor, *Note: Some<br />

Machines May Be Incomplete<br />

CNC VERTICAL MACHINING CENTER<br />

1 – MONARCH CORTLAND VMC-150 CNC VERTICAL<br />

MACHINING CENTER, S/N 87501, GE General Numeric<br />

Fanuc GN-11 Series Control, Table Size 30” x 60”,<br />

40-Position Automatic Toolchanger, Monarch Taper<br />

To schedule an auction, please call <strong>Maynards</strong> <strong>Industries</strong> at 248.569.9781 3

MILLING MACHINES • LATHES • DRILLS • SAWS • GRINDERS<br />

CNC VERTICAL MILLING MACHINES<br />

1 – TREE 425 MASTER JOURNEYMAN CNC VERTICAL MILLING<br />

MACHINE, S/N 9-42-96-6018 (1999), Dynapath Delta Autocon CNC<br />

Control, Table Size 12” x 50”, Coolant<br />

1 – TREE 425 JOURNEYMAN CNC VERTICAL MILLING MACHINE,<br />

S/N 9-42-90-5045 (1990), Dynapath Systems Delta Series CNC Control,<br />

Table Size 12” x 50”, Coolant<br />

MILLING MACHINES<br />

1 – CINCINNATI MILACRON 415-16 UNIVERSAL DIAL-TYPE HORIZON-<br />

TAL MILLING MACHINE, S/N 310434073-0002, Type L-L, 16” x 80” Table,<br />

Spindle Speeds 16 – 1600 With Variable Speed Control, Vertical Head<br />

Attachment, 3-Axis Readout<br />

1 – CINCINNATI CINOVA 80 307-14 VERTICAL MILLING MACHINE,<br />

S/N 31723V5W-6, Table Size 14” x 62”, Spindle Speeds 25 – 2000 RPM,<br />

2-Axis Readout<br />

1 – BRIDGEPORT 2-HP VERTICAL MILLING MACHINE, S/N BR-281409,<br />

Variable Spindle Speeds 60 – 4200 RPM, Table Size 9” x 48”, Power Table<br />

Feed, Power Drawbar, DRO<br />

2 – BRIDGEPORT SERIES I 2-HP VERTICAL MILLING MACHINES,<br />

S/Ns 12BR-240167, BR-240163, Variable Spindle Speeds 60 -4200 RPM,<br />

Table Size 9” x 48”, Power Table & Saddle Feeds, Column Riser, 2-Axis<br />

Readout<br />

1 – BRIDGEPORT 2-HP VERTICAL MILLING MACHINE, S/N 12BR-67564,<br />

Variable Spindle Speeds 60 – 4200 RPM, Table Size 9” x 48”, Power Table<br />

Feed, Power Knee Elevation, Power Drawbar, Bridgeport Shaper<br />

Attachment<br />

LATHES<br />

1 – KINGSTON HL-2000 22 / 29” X 90” GAP BED ENGINE LATHE,<br />

S/N 10721105, (12) Spindle Speeds 25 – 1500 RPM, Quick Change<br />

Threading, 3” Hole Thru-Spindle<br />

1 – CLAUSING COLCHESTER 15” X 36” ENGINE LATHE,<br />

S/N 6/0053/35703DD, Spindle Speeds 25 – 2000 RPM, Quick Change<br />

Threading, Taper Attachment, 2-1/8” Hole Thru-Spindle, Sony 2-Axis Readout<br />

1 – TATUNG 540X1000 21.2” X 39.3” ENGINE LATHE, S/N 724784, Spindle<br />

Speeds 35 – 1000 RPM, Quick Change Threading, 2” Hole Thru-Spindle<br />

2 – HARDINGE DV-59 DOVETAIL BED TOOLROOM LATHES, S/Ns 17434,<br />

59-4760-3, Variable Speed 150 – 3500 RPM, 5C Collet Drawbar, Cabinet<br />

Base With Coolant<br />

DRILLS<br />

1 – FOSDICK 4’ ARM SENSITIVE RADIAL DRILL, S/N 20945, Spindle Speeds 75 – 1500 RPM,<br />

Power Table Elevation, Power Travels & Clamping<br />

1 – CINCINNATI BICKFORD SUPER SERVICE 21” DRILL PRESS, S/N 1L3104, Sliding Head,<br />

Box Column, (12) Geared Spindle Speeds 60 – 1200 RPM<br />

1 – LEELAND-GIFFORD 24” 2-SPINDLE DRILL PRESS, S/N NA, 25” x 37” Adjustable Table<br />

1 – WILTON 20604 20” FLOOR TYPE DRILL PRESS, S/N 59394, (8) Geared Head Spindle<br />

Speeds 120 – 1640 RPM<br />

1 – WALKER TURNER 1112-41 – 20” FLOOR TYPE DRILL PRESS, S/N 00096<br />

BANDSAWS<br />

1 – TANNEWITZ RHNE 40” VERTICAL BANDSAW, S/N 73242<br />

1 – DOALL METALMASTER 36” VERTICAL BANDSAW, S/N 36421139, Variable Blade Speeds<br />

0 – 1600 FPM<br />

1 – HYD-MECH S-20A AUTOMATIC HORIZONTAL METAL CUTTING BANDSAW,<br />

S/N 10691545, 12” Capacity, Power Shuttle Infeed & Clamping, Coolant<br />

1 – MARVEL SERIES 8 MARK I UNIVERSAL TILT-FRAME VERTICAL BANDSAW, S/N 821437-W<br />

JIG GRINDER<br />

1 – FOSDICK FOSMATIC JIG GRINDER, S/N 83920, Table Size 28” x 56”, 2-Axis Readout<br />

SURFACE GRINDERS<br />

2 – BROWN & SHARPE 1236 MICROMASTER 12” X 36” HYDRAULIC SURFACE GRINDERS,<br />

S/N 523-1236-2499, Electromagnetic Chuck, Readout, Coolant, S/N 523-1236-277,<br />

Electromagnetic Chuck With Neutrofier III Microprocessor Control, Acu-Rite Readout, Coolant<br />

2 – BROWN & SHARPE 1030 MICROMASTER 10” X 30” HYDRAULIC SURFACE GRINDERS,<br />

S/Ns 523-1030-2300, 523-1030-2325, Electromagnetic Chuck With Variable Control, Coolant<br />

1 – BROWN & SHARPE 818 TECHMASTER 8” X 18” HYDRAULIC SURFACE GRINDER,<br />

S/N 523-1818-1156, Walker Electromagnetic Chuck With Variable Control, Overhead Dresser,<br />

Coolant, Heidenhain 2-Axis Readout<br />

3 – BROWN & SHARPE 818 MICROMASTER 8” X 18” HYDRAULIC SURFACE GRINDERS,<br />

S/N 523-8186-9112, Electromagnetic Chuck With Neutrofier Variable Control, Coolant,<br />

S/N 523-8186-9102, Electromagnetic Chuck, With Flux Master Variable Control, Coolant,<br />

Acu-Rite 2-Axis Readout, S/N 523-6181-2313, Electromagnetic Chuck, Power Elevation<br />

ROTARY SURFACE GRINDER<br />

1 – HEALD 16” HORIZONTAL SPINDLE ROTARY SURFACE GRINDER, S/N 35939,<br />

16” Electromagnetic Chuck, Universal Table, 12” Wheel Size, 15-HP, Coolant<br />

4<br />

To schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

CMMs • INSPECTION • SHEARS • BENDING BRAKES & ROLLS<br />

OD & ID GRINDERS<br />

1 – CINCINNATI MILACRON / HEALD 273A UNIVERSAL ID<br />

GRINDER, S/N 910 723A88-0121 (1988), Variable Workhead<br />

Speeds 0 – 500 RPM, 12” Permanent Magnetic Chuck, Red<br />

Head 14,000 RPM ID Spindle<br />

1 – BROWN & SHARPE 1430 UNIVERSAL OD / ID GRINDER,<br />

S/N 521-1430-148, 14” Swing x 30” Centers, Motorized<br />

Workhead, Universal Wheelhead, Coolant<br />

1 – CINCINNATI R-55 HYDRAULIC OD CYLINDRICAL<br />

GRINDER, S/N 26917, 10” x 12”, Universal Wheelhead,<br />

Motorized Workhead, Coolant<br />

1 – BROWN & SHARPE NO. 13 UNIVERSAL TOOL &<br />

GRINDING MACHINE, S/N 525-13-742, Readout, Coolant<br />

1 – PRODUCTO F-4 ROTO RECIPRO TOOLMAKERS ID GRINDER,<br />

Reciprocating Vertical ID Spindle, Precise ID Spindle With<br />

Variable Speed Control, Variable Strokes Per Minute to 350 Max.<br />

CENTER HOLE GRINDER<br />

1 – BRYANT CENTER HOLE GRINDING MACHINE, S/N C-1513<br />

COORDINATE MEASURING MACHINES<br />

1 – BROWN & SHARPE ONE 7.7.5 BRIDGE TYPE<br />

COORDINATE MEASURING MACHINE, S/N 0208-7008<br />

(2008), 3-1/2” x 37” Granite Surface Plate, Renishaw PH10M<br />

Probe Head, Operator’s Joystick Pendant, PC DMIS 4.3<br />

Software, Missing Control Computer<br />

1 – BROWN & SHARPE – OOG CHAMELEON 7107 SPZ<br />

COORDINATE MEASURING MACHINE, S/N 0499-2318<br />

(1999), Granite Table Size 40” x 65”, Renishaw PH10MQ<br />

Probe Head, Renishaw SCR200 6-Station Linear Probe,<br />

Changeover Holder, Operator’s Joystick Pendant, PC DMIS<br />

3.8 Software, Operating PC<br />

TOOL PRESETTERS<br />

1 – PARLEC SERIES 2000 PRESETTER OPTICAL TOOL<br />

PRESETTER, S/N 229990-0800<br />

1 – MTS 273-EA7 OPTICAL TOOL PRESETTER, S/N 2747<br />

INSPECTION<br />

1 – SCHERR TUMICO 22-2500 30” OPTICAL COMPARATOR,<br />

S/N 837, Quadra-Chek 200 Programmable Terminal<br />

1 – SIGMA HB-400 15” BENCH TOP OPTICAL COMPARATOR,<br />

S/N 3301/5/90, Quadra-Chek 2000 Programmable Terminal<br />

1 – BROWN & SHARPE MICRO HITE 24” PROGRAMMABLE<br />

HEIGHT GAUGE<br />

1 – STARRETT 48” X 72” X 10” 2-LEDGE PINK GRANITE<br />

SURFACE PLATE<br />

TOOLROOM MISCELLANEOUS MACHINES<br />

1 – SUNNEN MBB-1660 PRECISION HONE, S/N NA<br />

1 – FARREL SELLERS 6GA DRILL POINT GRINDER, S/N 61R2306, Coolant<br />

1 – COOLEY TYPE BL-121218 BOX TYPE ELECTRIC TOOLROOM HEAT TREAT FURNACE, S/N A-1216,<br />

Maximum Temperature 2000 Degrees Fahrenheit, Honeywell Digital Temperature Control<br />

1 – BURR KING 760 2” ABRASIVE BELT GRINDER, S/N NA, With Portable Dust Collector Base<br />

1 – GARDNER 3DB DOUBLE END BUFFING / POLISHING MACHINE, S/N 3DB 244D<br />

1 – PRATT & WHITNEY 12-B 12” VERTICAL SHAPER, S/N 5400<br />

1 – T.M.I. NA CENTRAL DUST COLLECTOR, S/N NA, Dry Type, Floor Standing<br />

1 – EVERETT 20DM22 20” ABRASIVE CUT-OFF SAW, S/N 04-10149, 20-HP, 20” Blade, Pneumatic Power<br />

Clamping, Manual Feed, Dust Collector Blower<br />

1 – ECONOLINE 36” X 24” ABRASIVE BLAST CABINET, S/N NA, With Dust Collector<br />

1 – SETCO TYPE 102-202-8 SPL HEAVY DUTY 12” X 1-1/2” 2-HP DOUBLE END GRINDER, S/N 112354<br />

1 – SETCO TYPE 402-303-8 SPL 18” DOUBLE-END FACE GRINDER, S/N 112389, 3-HP<br />

POWER SQUARING SHEARS<br />

1 – PROMECAM GH 1230A 10’ X 9/16” HYDRAULIC POWER SQUARING SHEAR, S/N NA, (3) Scale /<br />

Capacity Settings: 48,000 PSI – 20 Gauge to 9/16”, 64,000 PSI – 20 Gauge to 1/2”, 85,000 PSI – 20 Gauge<br />

to 5/16”, Front Operated Power Back Gauge, 24” Throat<br />

1 – HTC 250-10A 1/4” X 10’ HYDRAULIC POWER SQUARING SHEAR, S/N A573661, Front Operated<br />

Power Back Gauge<br />

BENDING BRAKES<br />

1 – HTC 200-12H 200-TON X 12’ HYDRAULIC PRESS BRAKE, S/N 580G2010, 24” Front Operated Power<br />

Back Gauge, 126” Between Housings<br />

1 – DRIES & KRUMP CHICAGO PB-10135 10’ POWER LEAF BENDING BRAKE, S/N 120123<br />

BENDING ROLLS<br />

1 – BUFFALO 2UBR VERTICAL ANGLE BENDING ROLLS, S/N 69U6816, Hydraulic Roll Adjustment,<br />

Cleveland Size 70AF Series 25, 19:1 Ratio Mechanical Drive Gearbox<br />

1 – 48” INITIAL TYPE POWER BENDING ROLLS, S/N NA, 6” Roll Diameter<br />

To schedule an auction, please call <strong>Maynards</strong> <strong>Industries</strong> at 248.569.9781 5

BALER • AUTO LIFTS • CNC PRODUCTION BORING & TURNING MACHINES<br />

HYDRAULIC SHOP PRESSES<br />

1 – H-FRAME HYDRAULIC INDUSTRIAL TIRE PRESS, Estimated<br />

250-Ton, Bed Size 48” x 48”, 15-HP Hydraulic Power Unit<br />

1 – OTC 150-TON ROLL-BED H-FRAME HYDRAULIC SHOP PRESS,<br />

S/N NA, Extended Vertical Frame, 60” Maximum Height Under<br />

Adjustable Top Rail, Roll-Out Bottom Bed Rail, Electric Hydraulic<br />

Power Unit<br />

1 – 2-POST HYDRAULIC PRESS, Estimated 100-Ton<br />

HYDRAULIC BALER<br />

1 – PIQUA SERIES 40 VERTICAL HYDRAULIC BALER, S/N NA,<br />

Chamber Size 36” x 60”, Floor Standing, Top Mounted Hydraulics<br />

AUTOMOTIVE LIFTS<br />

1 – MOHAWK SYSTEM I-A 9000-LB. CAPACITY 2-POST<br />

AUTOMOTIVE SERVICE LIFT, S/N 9505637, Floor Standing, 2-HP<br />

3-Phase Hydraulic Unit<br />

1 – MOHAWK A-7 7000-LB. CAPACITY 2-POST AUTOMOTIVE<br />

SERVICE LIFT, S/N 9303430, Floor Standing, 2-HP 3-Phase<br />

Hydraulic Unit<br />

(22) CNC PRODUCTION BORING / TURNING MACHINES<br />

14 – SAGINAW MACHINE SYSTEMS ACCU-CELL 450-2S 2-SPINDLE<br />

VERTICAL CNC PRODUCTION BORING / TURNING MACHINES,<br />

(5) S/Ns 50118-3/90, 50117-3/90, 50089-07/89, 50088-07/89,<br />

50079-07/89 With GE Fanuc Series 15-T Operator’s CNC Pendant<br />

Box Control, (2) 15” Vertical Power Workpiece Chucking Spindles,<br />

Manual Load / Unload, (2) 30/37 KW Spindle Drive Motors,<br />

Connected Into Central Supplied Coolant System, Magnetic Chip<br />

Conveyor, (7) S/Ns 50095-07/89, NA, NA, 50078-07/89, 2677-11/86,<br />

2674-10/86, 50094-07/89 With General Numeric / Fanuc GN-11<br />

Series Control,(2) 15” Vertical Power Workpiece Chucking Spindles,<br />

Manual Load / Unload, (2) 30/37 KW Spindle Drive Motors,<br />

Connected Into Central Supplied Coolant System, (2) S/Ns<br />

50161/50119-11/90 & 50162-10/91 With General Numeric GN15<br />

Series Pendant Box CNC Control, (2) 14” Vertical Power Chucking<br />

Spindles Each With 30/37 KW Spindle Drive Motors, Metal Belt DC<br />

Motorized Chip Conveyor, All With R&L Side Overhead Tool Slides,<br />

Power Enclosure Doors, Hinged Main PLC Control Panel, Hydraulic<br />

Power Unit, *Note: Some Machines May Be Incomplete<br />

8 – OLOFSSON 1075T-14LH, 1075T-14RH, 1075T-14-RH, 1075T-14LH,<br />

SPECIAL, SPECIAL, 1075T-14LH, 1075T-14RH CNC SINGLE<br />

SPINDLE VERTICAL PRODUCTION TURNING MACHINES,<br />

S/N 13809, 13807, 13808, 13806, 13803, 13805, 13802, 13804, GE<br />

Fanuc Series 15T Control, 15” Diameter Vertical Spindle Chuck,<br />

Overhead 2-Axis Tool Spindle, 11/15KW Spindle Drive<br />

(26) PRODUCTION BORING / TURNING MACHINES<br />

4 – SAGINAW MACHINE & TOOL VC-300-2 2-SPINDLE VERTICAL AUTOMATIC PRODUCTION<br />

BORING / TURNING MACHINES, S/N 1805-0680, 1806-0680, 1961-0981, 1814-1080, (2) 10”<br />

Vertical Spindle Power Collet Closer Chucks, Single 25-HP Spindle Drive Motor, Gang Type<br />

Overhead Tool Slide, Auto Load / Unload With Slide Type Transfer, Checking Stand With<br />

Samsomatic Programmable In-Process Gaging, Main PLC Control Panel, Operator’s Push-Button<br />

Station, Machine #2-Auto, 1-Auto, 4-Auto, 3-Auto<br />

8 – SAGINAW MACHINE & TOOL V3-300-2A 2-SPINDLE VERTICAL PRODUCTION BORING /<br />

TURNING MACHINES, S/N 1956-0581, 1955-0681, 1813-0680, 1824-0680, 1807-1080, 1812-1080,<br />

1811-1080, 1823-0680, (2) Vertical Spindle With 14” Power Collet Hub Chucks, Independent 10-HP<br />

Spindle Drive Motors, Gang Type Overhead Tool Slide, Manual Load / Unload, Main PLC Control<br />

Panel, Operator’s Push-Button Station, Machine #1-Man., 2-Man., 3-Man., 4-Man., 5-Man., 6-Man.,<br />

7-Man., 8-Man.<br />

4 – OLOFSSON 44-C 2-SPINDLE VERTICAL AUTOMATIC PRODUCTION BORING / TURNING<br />

MACHINES, S/N 12699, 12698, 12775, 12774, (2) 8” Vertical Spindle Power Clamping Work<br />

Chucks, Overhead Gang Type Tool Slide, Single 15-HP Spindle Drive Motor, Manual Load / Unload,<br />

Main PLC Control Panel, Operator’s Push-Button Panel, Machine #3, 4, 6, 5<br />

1 – WERTH NA 3-SPINDLE VERTICAL PRODUCTION BORING / TURNING MACHINE, S/N NA,<br />

(3) Vertical Spindles With Power Collet Chucks, 10-HP Spindle Drive Motors, Gang Type Overhead<br />

Tool Slide, Manual Load / Unload, Main PLC Control Panel, Operator’s Push-Button Station,<br />

MayFran AC Motorized Chip Conveyor<br />

7 – WERTH 55H-3-AL 3-SPINDLE SLANT BED PRODUCTION BORING / TURNING MACHINES,<br />

S/N 4266-1080, 4204, 3949, 4202, 4264-1080, 4694-0882, 4696-0783, (3) Power Collet Chucking<br />

Spindles With Individual 20-HP Spindle Drive Motors, Slant Bed Gang Type Tool Slide, Auto Load /<br />

Unload With 2-Position Turret Type Loader, Main PLC Control Panel, Operator’s Station, Machine<br />

#1, 2, 3, 7, 8, 9, 10, *Note: Some Machines May Be Incomplete<br />

2 – NEW BRITAIN 66 2-SPINDLE VERTICAL CHUCKING / TURNING MACHINES, S/Ns 37913,<br />

5846-0785, (2) 18” Vertical Power Chucking Spindles, R&L Single Station Overhead Tool Spindles,<br />

(2) 10-HP Spindle Drive Motors, PLC Panel, Operator’s Push-Button Station, (S/N 5846-0785:<br />

Werth Re-Build)<br />

6<br />

To schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

TAB ROLLERS • VANE ASSEMBLY & DETECTION MACHINES<br />

(21) PRODUCTION DRILLING/BORING MACHINES<br />

8 – L & L MACHINE TOOL SINGLE HEAD MULTIPLE<br />

SPINDLE VERTICAL PRODUCTION DRILLING /<br />

BORING MACHINES, Sliding Head, Box Column,<br />

Manual Load / Unload, Power Workpiece Clamping,<br />

Auto-Cycle, Main PLC Control Panel, Operator’s Push-<br />

Button Control Station With Status Lights<br />

6 – L & L MACHINE TOOL SINGLE HEAD MULTIPLE<br />

SPINDLE VERTICAL PRODUCTION DRILLING<br />

MACHINES, Sliding Head, Box Column, AEG Modicon<br />

Panel Mate Plus PLC Operator’s Terminal, Main PLC<br />

Panel, (4) With Manual Load / Unload, Independent<br />

Portable Coolant System With Magnetic Chip<br />

Conveyor, (2) With Auto Clamping Fixture Table, Auto<br />

Cycle, Livonia Magnetics Magnetic Chip Conveyor<br />

4 – L & L MACHINE TOOL SINGLE HEAD HORIZONTAL<br />

PRODUCTION PILOT HOLE DRILLS, Auto Thru-<br />

Feed, Main PLC Panel, Operator’s Station<br />

1 – L & L MACHINE TOOL SINGLE SPINDLE<br />

HORIZONTAL PRODUCTION DRILLING / BORING<br />

MACHINE, AEG Modicon Panel Mate Plus PLC<br />

Operator’s Terminal, PLC Panel<br />

2 – L & L MACHINE TOOL CUSTOM TORQUE<br />

CONVERTER HUB PILOT DRILL MACHINES,<br />

Horizontal Single Head, Chip Conveyor, Modicon Panel<br />

Mate Plus PLC Operator’s Terminal Main PLC Panel<br />

(53) HYDRAULIC PIERCING /<br />

STAKING / INDENTING MACHINES<br />

39 – KOPPY 4-POST HYDRAULIC SPECIAL TOOL INDENT<br />

/ PIERCE / STAKE MACHINES, All With Self-Contained<br />

Hydraulic Power Unit, Main PLC Control Panel, (16) With<br />

Modicon Panel Mate Plus PLC Pendant Terminal, (2) With<br />

Operator’s Push-Button Control Station, With Modicon<br />

Panel Mate Plus PLC Operator’s Terminal, (21) With<br />

Operator’s Push-Button Control Station<br />

14 – KOPPY 4-POST HYDRAULIC SPECIAL TOOL<br />

PIERCE MACHINES, All With Self-Contained<br />

Hydraulic Unit, Main PLC Control Panel, Operator’s<br />

Station, (7) With Type 245 Pump Inner Piercer Op 25,<br />

(7) With Type Turbines, Op 20 Inner<br />

(19) TAB ROLLER MACHINES<br />

8 – SPEN TECH OP. 40 TAB ROLLER MACHINES, Main PLC Control Panel, Vertical Slide Single Spindle, 3-Station<br />

Index Table, Auto Unloader, Operator’s Panel With Push-Button & Status Lights<br />

1 – SPEN TECH 2-SPINDLE VERTICAL TAB ROLLER, Independent Vertical Spindles With Slide Base Head & AC<br />

Spindle Motor, 3-Station Index Table With Auto Load / Unload, 15-HP Hydraulic Power Unit, Steel Skid Base, Main<br />

PLC Control Panel, Modicon Panel Mate Plus Operator’s Terminal<br />

4 – STANDARD TOOL 2-SPINDLE VERTICAL TAB ROLLERS, Independent Spindle Heads With Vertical Slide &<br />

AC Motor, Hydraulic Power Unit, Main PLC Control Panel, Operator’s Station Panel<br />

5 – STANDARD TOOL 2-SPINDLE VERTICAL TAB ROLLERS, Independent Vertical Spindles With Head Slide &<br />

AC Motor Drive, Auto Transfer, Main PLC Panel, Operator’s Station<br />

1 – BROTHERS INDUSTRIES 2-SPINDLE VERTICAL TAB ROLLER, OP. 30 265 Turbine Tab Roll, Hydraulic Unit<br />

With (3) 10-HP Pumps<br />

TURBINE VANE ASSEMBLY MACHINES & VANE DETECTORS<br />

8 – UTICA ASSEMBLY SYSTEMS NO. 4 TURBINE VANE SETTER ASSEMBLY MACHINES, Main PLC Control<br />

Panel, Operator’s Panel With Push-Button & Status Light<br />

5 – GIDDINGS & LEWIS GILMAN VANE SETTER ASSEMBLY MACHINES, S/Ns 692-140, 692-109, 692-131,<br />

381547, 692-119, Main PLC Panel With Operator’s Push-Button Station<br />

8 – GIDDINGS & LEWIS GILMAN TURBINE OP. 60 MACHINES, S/Ns 629-149, -151, -115, -118, -144, -143, -148,<br />

-116, Main PLC Panel With Operator’s Push-Button Station<br />

4 – VANE DETECTORS, PLC Control Panel, Thru-Feed Conveyor<br />

1 – UTICA ASSEMBLY SYSTEMS 265 TURBINE VANE ASSEMBLY MACHINE<br />

1 – #3 TURBINE STAKER PRESS, Single Vertical Hydraulic Ram, 6-Station Index Table, Main PLC Panel,<br />

Operator’s Panel<br />

(28) AUTOMATED ASSEMBLY & SECONDARY MACHINES<br />

2 – ORBITAL RIVET AUTOMATED ASSEMBLY MACHINES, OP. 70, 4-Station Index Table, Auto Parts Feed /<br />

Pick-N-Place, Single Orbit Form Orbital Riveter, AEG Modicon Panel Mate Plus PLC Operator’s Terminal, Main<br />

PLC Panel, Interfaced Enclosure<br />

2 – WRIGHT-K TECHNOLOGY STATOR TORQUE CONVERTER OP. 130 & 80 SPRING & RUBBER ASSEMBLY<br />

MACHINES, Main PLC Control Panel, Vibratory Feeder Hopper / Bowl<br />

1 – STATOR TORQUE CONVERTER OP. 100 SPRING & RUBBER ASSEMBLY MACHINE, Main PLC Control<br />

Panel, Vibratory Feeder Hopper / Bowl<br />

1 – SPEN TECH STATOR TORQUE CONVERTER SNAP RING ASSEMBLY & FUNCTION TEST MACHINE,<br />

Main PLC Control Panel, Panel Mate PLC Operator’s Terminal<br />

3 – WELDUN OP. 50 STATOR SPRING & ROLLER ASSEMBLY MACHINES, Auto Feed & Transfer, In-Line,<br />

8-Station, (4) Vibratory Hoppers / Bowl Feeders, Main PLC Control Panel, Operator’s Station With Push-Button<br />

Control Panel & Status Lights<br />

4 – STATOR CAM PRESSES, Automatic Feed & Transfer, Main Control Panel With Gould Modicon 484 PLC,<br />

Operator’s Station With Push Button Panel & Status Lights<br />

2 – NEW TECHNOLOGIES INC NORTH O-RING ASSEMBLY / LEAK TEST LINES, Automatic, Main PLC Control<br />

Panel / Operator’s Station<br />

1 – UTICA ASSEMBLY SYSTEMS 265 TURBINE OP. 50 VANE ASSEMBLY MACHINE<br />

6 – HELFRECHT MACHINE CO OIL FILL & TEST MACHINES, S/Ns 806452, 806431, 806429, (3) NA, Automated<br />

Transfer, 30-HP Hydraulic Unit, Main PLC Panel, Operator’s Station With PLC Touch Screen & Push-Button Panel<br />

6 – R&B MACHINE TOOL LUG MILL OP. 60 MACHINING STATIONS, S/Ns 6792-01, 6688-01, 6631-01, 6634-01,<br />

6631-01, N/A, Common Base With (1) Vertical Column Single Head Multi-Spindle Drilling / Chamfering Head,<br />

(1) Vertical Column Single Head Multi-Spindle Milling Head, Automatic Part Transfer, Main PLC Panel, Operator’s<br />

Control Station<br />

A buyers premium will be in effect for<br />

all onsite and webcast sales.<br />

To schedule an auction, please call <strong>Maynards</strong> <strong>Industries</strong> at 248.569.9781 7

BALANCERS • BURNISHING, BROACHING & POLISHING MACHINES<br />

(27) BALANCERS<br />

3 – BALANCE ENGINEERING STATOR BALANCERS, S/Ns 2821,<br />

2757, 2756, Auto Part Load & Transfer, (6) Independent<br />

Horizontal Drill Spindle Units, CBI-55 Data Collector Terminal,<br />

Main PLC Control Panel, Operator’s Push-Button Station With<br />

Status Lights<br />

3 – BALANCE ENGINEERING OP. 50 STATOR BALANCERS,<br />

S/Ns 3375, 3374, 3519, (5) Independent Horizontal Drill Spindle<br />

Units, Auto Load / Transfer, Single Workpiece Spin / Balance<br />

Spindle, CBI-55 Data Processing Monitor, Main PLC Control<br />

Panel, Operator’s Push-Button Panel<br />

4 – BALANCE ENGINEERING TURBINE AUTO-BALANCERS,<br />

S/Ns 2776, 2775, 2830, 2777, Type STMS-45, Weld Type,<br />

5-Station, Auto Load & Transfer, Main PLC Control Panel,<br />

Operator’s Control Console With Push-Buttons, Status Lights, &<br />

CB1-58 Data Processing Terminal<br />

1 – BALANCE ENGINEERING 254 TURBINE REPAIR<br />

BALANCER, S/N 2825, Weld Type, Strip Feeder, Medar Weld<br />

Controls, Rotary Workpiece Fixture, Manual Load, CBI-55 Data<br />

Processing Terminal, Main PLC Control Panel<br />

1 – BALANCE ENGINEERING 265 TURBINE / CLUTCH<br />

BALANCER, S/N 3123, Drill Type, (3) Independent Horizontal<br />

Drill Spindle Units, Auto Load / Transfer, Main PLC Control<br />

Panel, Operator’s Station, CBI-55 Data Processing Terminal<br />

2 – BALANCE ENGINEERING 265 TURBINE OP. 90<br />

BALANCERS, S/Ns 2718, 2633, Type STR-193, Weld Type,<br />

Speed Stop Feed, Medar Medweld 700S Weld Controls, Rotary<br />

Fixture Table, Main PLC Control Panel, Operator’s Push-Button<br />

Station, CBI-55 Data Processing Terminal<br />

6 – BALANCE ENGINEERING 265 CONVERTER AUTO-<br />

BALANCERS, S/Ns 2835, 2834, 2727, 2728, 2729, 2832, OP.<br />

80, Spot Weld Type, 2-Spindle, Automatic Feed & Transfer, Main<br />

PLC Panel, Operator’s Console Control With Push-Buttons,<br />

Status Lights & Data Processing Terminal<br />

2 – BALANCE ENGINEERING 265 TORQUE CONVERTER<br />

BALANCERS, Weld Type With Medar Meldweld 700S Weld Control,<br />

Data Processing Terminal, PLC Panel, Operator’s Station<br />

4 – BALANCE ENGINEERING OP. 100 AUTOMATIC TURBINE<br />

BALANCERS, S/Ns 3372, 3371, 3373, 3370, Weld Type With<br />

Medar Medweld 700S Weld Controller Steel Strip Feed, PLC<br />

Control Panel, Operator’s Push-Button Station, Data Processing<br />

Terminal, Hydraulic Power Unit<br />

1 – BALANCE ENGINEERING CONVERTER BALANCER, S/N<br />

2738, Weld Type With Medar MIZ’R Weld Control, Manual Load,<br />

PLC Control Panel<br />

(12) AUTOMATIC INSERTION / ASSEMBLY PRESSES<br />

5 – NOVI PRECISION / GREENERD AUTOMATIC HYDRAULIC BUSHING ASSEMBLY PRESSES,<br />

Greenerd Model HBB-10, 10-Ton C-Frame Hydraulic Presses, S/Ns 94T4901, 96T5199, 96T5126,<br />

96T5160, 94T4888 (To 1996), Novi Precision Automation, Main Control Panel With AEG PLC, AEG<br />

Modicon Panel Mate Plus PLC Operator’s Terminal<br />

3 – WRIGHT-K TECHNOLOGY SPECIAL BUILT AUTOMATIC INSERTION PRESS, 6-Station Workpiece<br />

Index Table, Auto Load / Unload, Parts Feeder, Main PLC Control Panel, AEG Modicon Panel Mate Plus<br />

PLC Operator’s Terminal, *Note: Some Machines Incomplete<br />

1 – BAY CITY BORING AUTOMATIC BUSHING ASSEMBLY PRESS MACHINES, S/N 7901, 7902, 8002,<br />

8001, Automatic Parts Feed, Main PLC Control Panel, Operator’s Station With Push-Button & Status<br />

Light Panel<br />

2 – SPEN TECH OP. 40 CAM PRESSES, C-Frame Hydraulic Press Frame, Main PLC Control Panel,<br />

Tonnage Load Cell Monitor with Promess Programmable Controller<br />

1 – NEW TECHNOLOGIES INC COVER HYDRAULIC ASSEMBLY PRESS, 6-Station Index Table,<br />

Main PLC Panel, Operator’s Station<br />

(6) BURNISHING MACHINES<br />

5 – SPECIAL MACHINE & ENGINEERING 265 TORQUE CONVERTER 3-SPINDLE VERTICAL<br />

ASSEMBLY BURNISHING MACHINES, Automatic Part Transfer, Gage-Chek Programmable In-<br />

Process Checking, Main PLC Panel, Operator’s Station With Push-Button Control Panel & Status Lights<br />

1 – AGNEW SINGLE RAM VERTICAL 265 COVER BURNISHING MACHINE, Quill Advance Spindle,<br />

Manual Load / Unload, Coolant, Hydraulic Unit, PLC Panel, Operator’s Station<br />

(3) BROACHING MACHINES<br />

1 – DETROIT BROACH VERTICAL TABLE UP HYDRAULIC BROACHING MACHINE,<br />

S/N M-935018 (1994)<br />

1 – AMERICAN BROACH & MACHINE CO V-2-6 6-TON VERTICAL HYDRAULIC BROACHING<br />

MACHINE, S/N 6248, Single Ram, 24” Stroke, Hydraulic Power Unit<br />

1 – AMERICAN BROACH & MACHINE CO 4HT 4-TON VERTICAL HYDRAULIC BROACHING<br />

MACHINE, S/N 6822, Single Ram, Approx. 16” Stroke, External 5-HP Hydraulic Power Unit<br />

(4) POLISHING MACHINES<br />

3 – HEGENSCHEIDT MFD 2-STATION TORQUE CONVERTER POLISHING MACHINES, Automatic<br />

Thru-Feed Transfer, R&L Polishing Heads, Main PLC Control Panel, AEG Modicon Panel Mate Plus<br />

PLC Operator’s Terminal, *Note: Some Machines Incomplete<br />

1 – NAGEL 2-SPINDLE VERTICAL MICRO-POLISHER MACHINE, S/N NA, 265 Converter OP. 90,<br />

(2) 14” Diameter Vertical Work Spindle Chucks, R&L Overhead Strip Polishing Heads, Main PLC<br />

Control Panel, AEG Modicon Panel Mate Plus PLC Operator’s Terminal, Hoffman Coolant Filtration &<br />

Recirculation Unit<br />

Sale is<br />

being held in<br />

conjunction<br />

AUCTIONS www.maynards.com<br />

| LIQUIDATIONS | APPRAISALS<br />

8<br />

To schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

GAGING & CHECKING MACHINES • WELDERS & EQUIPMENT<br />

(12) AUTOMATIC GAGING & CHECKING MACHINES<br />

4 – AIR GAGE COMPANY COMPUTERIZED IN-PROCESS PISTON GAGING<br />

MACHINES, Automatic, Dearborn Precision Gage Operator’s Pendant<br />

Control Terminal, Eaton Panel Mate PLC Console Control, (2) Gage Comp<br />

Temperature Compensating Measurement Gages<br />

2 – AUTO LOGIC AUTOMATED VISION & INSERT PROBE INSPECTION<br />

MACHINES, Main Control Panel With AEG Modicon 878 PLC & PC System<br />

Control, Automated Workstation, Nemation PLC Monitor<br />

2 – STRATORS OP. 60, EAST & WEST VISION SYSTEMS, (5) Regulated Feed<br />

Track Conveyor Lanes, PC Control Cabinet<br />

1 – B&K MACHINE AUTOMATED TORQUE RUN-DOWN MACHINE, Automatic<br />

In-Line Transfer, Main PLC Panel With Operator’s Touch Screen, Operator’s<br />

Station With Push-Button Controls & Status Lights<br />

1 – NEW TECHNOLOGIES INC 265 TURBINE / CLUTCH O-RING LEAK TEST<br />

MACHINE, Automatic, AEG Modicon PLC<br />

1 – PICO DYNAMIC TEST MACHINE, Horizontal Double-End Opposed Heads,<br />

60-HP AC Drives With UNICO Drive, AEG Modicon Factory Mate Plus<br />

PLC Terminal<br />

1 – NOVI PRECISION AUTOMATED LUG THREAD CHECKER<br />

(10) ELECTRON BEAM WELDERS<br />

5 – SCIAKY C.V. 2-S-1DF6 ELECTRON BEAM WELDERS, S/Ns 10731, 10806,<br />

10732, 10743, N/A, Power Output: 60 KVA, 250 MA, 371 IH, 6-Station Index<br />

Worktable, Power Supply, Overhead Slide Auto Load / Unload, Vacuum Pump<br />

Units, Hydraulic Unit, Chiller, Main PLC Control Panel With Modicon Panel<br />

Mate Plus Touch Screen Terminal, Operator’s Station, Welder #5<br />

4 – LEYBOLD – HERAEUS NVW-(35) ELECTRON BEAM WELDERS,<br />

S/Ns 836, 838, (2) NA, Machine Output: 200 KV – 175 Milliamp, Workstation<br />

With 4-Station Index Table, Automatic Parts Handling, High-Voltage Power<br />

Supply, AC Generator, Vacuum Pump Systems, Main PLC Control Panel With<br />

Operator’s Panel, Operator’s Push-Button Station, DCE Dalamatic Dust /<br />

Mist Collector<br />

1 – LEYBOLD-HERAEUS ELECTRON BEAM WELDER, S/N NA, 4-Station<br />

Torque Converter Index Table, Auto Parts Load / Handling, High-Voltage<br />

Power Supply, Vacuum Pump Systems With Aercology Mist Collector,<br />

Hydraulic Power Unit, Main PLC Control Panel With AEG Modicon PLC, AEG<br />

Modicon Panel Mate Plus PLC Operator’s Terminal, Operator’s Station With<br />

Push-Button Control Panel, DCE Vokes Dalamatic Dust / Mist Collector<br />

MASS SPECTROMETERS<br />

4 – NEWCOR MASS SPECTROMETER / LEAK TEST MACHINES, S/Ns X9021,<br />

9026, 9047, N/A, 4-Station Workpiece Index Table, Automatic Parts Handling,<br />

Vacuum Pump System, Data Processing Panel, Main PLC Control Panel,<br />

Operator’s Station, Hydraulic Power Unit,<br />

1 – MASS SPECTROMETER, Vacuum System, 4-Station Workpiece Index Table,<br />

Automatic Parts Handling, Main PLC Control Panel, Data Processing Panel<br />

WELDING EQUIPMENT<br />

1 – HOBART MEGA-MIG 450 WELDING POWER SUPPLY, S/N 80WS 14915,<br />

With Hobart 70L Wire Feeder<br />

1 – MILLER SYNCRO WAVE 350 AC / DC WELDING POWER SUPPLY,<br />

S/N JK707977, With Coolmate 3 Water Cooler<br />

1 – MILLER INVISION 456P DC INVERTER WELDING POWER SUPPLY,<br />

S/N NA, With 60 Series 24V Dual Wire Feeder<br />

1 – MILLER DELTAWELD 452 CV-DC WELDING POWER SUPPLY,<br />

S/N LA091778, With Miller 60 Series 24V Cart Mounted Wire Feeder<br />

1 – MILLER MAXTRON 300 CC-CV DC INVERTER WELDING POWER<br />

SUPPLY, S/N KA868590, With XR Extended Reach Wire Feeder,<br />

Millermatic S-525 Wire Feeder, Optima 300 GMAW Control<br />

1 – THERMAL ARC PAR-TOR 10XR PLASMA CUTTER, S/N NA<br />

1 – LINCOLN SQUARE WAVE TIG-350 SQUARE WAVE AC / DC TIG & STOCK<br />

ARC WELDING POWER SUPPLY, S/N AC760200, Tig Leads<br />

1 – LINCOLN IDEALARC TIG-300/300 AC / DC WELDING POWER SUPPLY,<br />

S/N AC-280230<br />

(4) ROBOTIC MIG WELDING CELLS, EACH INCLUDING:<br />

1 – FANUC ARC-MATE 100i 6-AXIS CNC ROBOT, S/N NA (1998-1999), With System<br />

R-J3 Control<br />

1 – LINCOLN POWERWAVE 450 WELDING POWER SUPPLY, With Robotic Interface<br />

1 – GWI ENGINEERING WORK CELL, With 2-Station Workpiece Index Table, Manual Load,<br />

Interfaced Enclosure with Modicon Panel Mate Plus PLC Terminal<br />

1 – TORIT DOWNFLO SDF6 DUST COLLECTOR, Checker Board Microprocessor Control<br />

(2) ROBOTIC MIG WELDING CELL / 265 COVER ASSEMBLY NORTH &<br />

SOUTH, BOTH INCLUDING:<br />

1 – FANUC ARC-MATE 6-AXIS CNC ROBOT, S/Ns R93265999, R93265983 (1993),<br />

Type A05B-1203-B275 System R-J Control With Hand Teach Pendant<br />

1 – LINCOLN IDEALARC PULSE POWER 500 DC WELDING POWER SUPPLY, Wire<br />

Feeder, NA-5R Interface Adapter<br />

1 – GWI ENGINEERING WORK CELL, With 3-Station Workpiece Index Table, Auto-Load,<br />

Interfaced Enclosure With AEG Modicon Panel Mate Plus PLC Operator’s Terminal<br />

1 – TORIT SDF6 DOWN FLO DUST COLLECTOR, Free Standing, 10-HP, (6) Replaceable<br />

Dry-Type Cartridge Filters, Torit Checker Board Microprocessor Control Panel<br />

(13) MULTI-STATION WELDING MACHINES<br />

4 – BRA-CON SPECIAL BUILT MULTI-STATION AUTOMATIC THRU-FEED MIG WELDING<br />

MACHINES, In-Line Automatic Parts Transfer, Transfer Line Drive, Main PLC Control<br />

Panel, Operator’s Push-Button Control Station, (2) With Welding Equipment Including: (6)<br />

Thermal Arc / Hobart HMC-410 Wire Feeders, (6) Lincoln Tig Square-Wave Welding Power<br />

Supplies, (4) Hobart Welding Power Supplies, (2) Thermal-Arc Arc- Welding Power<br />

Supplies, or (6) Thermal Arc / Hobart HMC-410 Wire Feeders, (6) Thermal Arc Plasma<br />

Welding Consoles, (6) Thermal Arc Plasma Welding Power Supplies, *Note: Power<br />

Supplies & Wire Feeders May Be Offered Separately<br />

4 – NEWCOR 3-STATION AUTOMATIC MIG WELDING MACHINES, 8-Station Workpiece<br />

Index Table, Auto Parts Load, Main PLC Control Panel, Operator’s Push-Button Control<br />

Station, (2) With Welding Equipment Including: (3) Thermal Arc HMC-410 Wire Feeders,<br />

(2) Thermal Arc Arc-Master 501 Welding Power Supply’s, (1) Hobart Arc-Master 501<br />

Welding Power Supply, *Note: Welding Power Supplies May Be Offered Separately<br />

4 – NEWCOR WELD ASSEMBLY MACHINES, Newcor TIG-TACK Loose Assembly Welder<br />

OP. 30, 6-Head, Newcor Special Welding Press Frame, (6) Lincoln Square Wave TIG-350<br />

Welding Power Supplies, S/Ns NA, Support Mezzanine Mounted, (1) Hydraulic Power Unit,<br />

Main PLC Control Panel, Operator’s Station, Auto Parts Feed & Transfer<br />

1 – B&K MACHINE 265 CONVERTER WELDING MACHINE, Special Fabricated<br />

4-Post Welding Frame, (4) Lincoln Square Wave TIG-350 Welding Power Supplies, S/Ns<br />

NA, (2) Miller 330-ST Air Crafter Welding Power Supplies, S/Ns NA, Hydraulic Power Unit,<br />

Main PLC Control Panel, Operator’s Station With Push-Button Controls & Status Lights<br />

INERTIA WELDER<br />

1 – MANUFACTURING TECHNOLOGY 120 V INERTIA WELDER, S/N 12BVMF2966, Vertical,<br />

External 60-HP Hydraulic Power Unit, Single Piece Workstation With Auto Load, Main PLC<br />

Control Panel, Operator’s Station<br />

To schedule an auction, please call <strong>Maynards</strong> <strong>Industries</strong> at 248.569.9781 9

OIL MIST & DUST COLLECTORS • PARTS & THRU-FEED WASHERS<br />

(23) OIL MIST & DUST COLLECTORS<br />

2 – MONROE ENVIRONMENTAL CORP STC-260 26000 CFM OIL MIST<br />

COLLECTORS, S/Ns 00-3666-2, 00-3666-1, Floor Standing, 60-HP<br />

1 – TORIT SDF 6 DOWN FLO DUST / OIL MIST COLLECTOR,<br />

S/N IG346385-001, Free Standing, 10-HP, (6) Replaceable Dry-Type<br />

Cartridge Filters, Torit Checker Board Microprocessor Control Panel<br />

8 – TORIT DRY FLO DMC-D1 – OIL MIST COLLECTORS, 7.5-HP,<br />

Floor Standing, Control Panel With Photohelic Indicator Gauge<br />

4 – TORIT DOWN FLO DF-T4-16 DUST COLLECTORS, Pneumatic<br />

Pulse-Jet Cleaning, (8) Dry Type Replaceable Cartridge Filters, 20-<br />

HP, Floor Standing, Control Panel With (2) Dwyer Photohelic<br />

Indicator Gauges<br />

4 – TFP ELIMINATOR OIL MIST COLLECTORS, S/N IDS-745B, IDS-745-<br />

C, IDS-745-A, IDS-745-D, With Industrial Drive Service Control Panel,<br />

(2) Magnehelic & (1) Photohelic Indicator Gauges, Wall Mounted<br />

4 – AERCOLOGY NA OIL MIST COLLECTORS<br />

(17) CABINET TYPE PARTS WASHERS<br />

10 – RANSOHOFF CABINET TYPE PARTS WASHERS, Center Column<br />

With Rotary Parts Hanger Rack, Process Steam Heat Supplied, 20-<br />

HP Wash Recirculation Pump, Filters, Floor Standing, Manual Load /<br />

Unload, Light Curtain, Blow-Off, Control Panel, (1) With Powered<br />

Rotary Work Table<br />

1 – RANSOHOFF ROTARY HANGER CABINET WASHER, Center<br />

Column With Rotary Parts Hanger Rack, Process Steam Heat<br />

Supplied, 20-HP Wash Recirculation Pump, Filters, Floor Standing,<br />

Manual Load / Unload, Light Curtain, Blow-Off, Control Panel<br />

5 – RANSOHOFF ROTARY PARTS WASHERS, Process Steam Heat<br />

Supplied, Center Column Cabinet Type Base With Rotary Hanger<br />

Rack, 20-HP Wash Recirculation Pump, Filters, Heat Exchanger,<br />

Blow-Off, Mist Collector, PLC Control Panel, Manual Load / Unload<br />

1 – GRAPAR CORP U-FLOW SR. PARTS WASHER, Center Column<br />

With 12” Wide Powered Rotary Table, Ambient Temperature, Central<br />

Wash Solution Supplied, Recirculation Pumps, Control Panel, Blow-<br />

Off, Mist Collector<br />

(15) THRU-FEED WASHERS<br />

4 – CONTINENTAL EQUIPMENT CORP THRU-FEED REVERSE OSMOSIS WASHERS, Ambient<br />

Wash Temperature, 14” Wide Opening With Thru-Feed Plastic Mesh Conveyor Belt, 15’ Length,<br />

(2) 5-HP Wash-Rinse Pumps, Blow-Off, Control Panel<br />

1 – FLUID ENGINEERING REVERSE OSMOSIS WATER TREATMENT SYSTEMS, 30” x 36” x 48”<br />

Stainless Steel Tank, 500-Gallon Poly Holding Tank, (2) Fiberglass Filter Tanks, Steel Skid Base<br />

1 – CARDEN THRU-FEED WASHER, 96” Wide Overall Opening Width With (4) 4” Thru-Feed Plastic<br />

Chain Conveyor Lanes, Process Supplied Steam Heat, 12’ Length, (2) Remote 15-HP Wash /<br />

Rinse Pumps, Blow-Off<br />

6 – RANSOHOFF THRU-FEED WASHERS, S/N H0872, 84” Overall Opening Width With (4) 12” Thru-<br />

Feed Chain Conveyor Lanes, (1) Approx 40-HP & (1) Approx. 15-HP Wash Pumps, (1) Free-<br />

Standing High-Pressure Pump System, S/N H2730, Horse-Shoe Type Thru-Feed, 12” Wide Roller<br />

Conveyor, Recirculation Pumps, S/N H0993, 120” Overall Opening Width With (5) Thru-Feed<br />

Chain Conveyor Lanes, (1) 40-HP & (1) 20-HP Recirculation Pumps, S/N H1003, (1) Estimated<br />

25-HP & (1) Estimated 15-HP Wash / Rinse Pumps, (5) Thru-Feed Chain Conveyor Lanes, 84”<br />

Overall Opening Width, Above (4) With Process Steam Heat Supplied, 30’ Length, Blow-Off,<br />

Control Panel, (2) Incomplete<br />

1 – NEW TECHNOLOGIES INC THRU-FEED WASHER, S/N NA, Single 2” Wide Conveyor Track,<br />

4’ Length, Blow-Off, Pumps, PLC Control Panel, Operator’s Station<br />

2 – INDUSTRIAL METAL FABRICATORS THRU-FEED WASHERS, Process Steam Heat Supplied,<br />

(1) With 84” Overall Opening Width With (4) 12” Thru-Feed Chain Conveyor Lanes, (2) 15-HP<br />

Wash / Rinse Recirculation Pumps, 30’ Length, Blow-Off, Control Panel, (1) With 60” Overall<br />

Opening Width, (3) 14” Wide Thru-Feed Chain Conveyor Lanes, Recirculation Pumps Removed,<br />

10 To schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

MATERIAL HANDLING • GEAR CHECKING LAB EQUIPMENT<br />

(7) COOLANT FILTRATION & RECIRCULATION SYSTEMS<br />

2 – HENRY FILTERS 3500 GPM SUMP WITH PRIMARY PROCESS COOLANT<br />

FILTRATION & RECIRCULATION SYSTEM, S/Ns 6466, 6467 (2003), In-Ground,<br />

36” Wide Tank With Chain Drive Drag-Out Conveyor & Above Ground Discharge,<br />

(3) 40-HP Gormann Rupp Recirculation Pumps, Control Panel, With Dista <strong>View</strong><br />

LiquaVision Liquid Controller<br />

1 – HENRY FILTERS 2-2.5-10 CF. 900 MV-136 PROCESS COOLANT FILTRATION &<br />

RECIRCULATION SYSTEM, S/N 6465, Floor Standing, 8’ Wide Tank, Chain Drive<br />

Drag-Out Conveyor With Screw Auger Side Discharge, Paper Media Filter, Model 3000<br />

SID 2-2.5-10 CF & 900 MV-136 Super Vac Control Panel, S/N 5912, Schematic Flow<br />

Chart With Operator’s Push-Button & Status Lights, LiquaVision Liquid Controller,<br />

(2) 50-HP & (3) Est. 75-HP Recirculation Pumps<br />

4 – ADVANCED FILTRATION CONCEPTS FSC-5-010 COOLANT FILTRATION &<br />

RECIRCULATION UNITS, S/Ns AF-1381, AF-1378, AF-1380, NA (All 1994), Services<br />

(2) Oloffson 1075T-14 CNC Turning Machines, Screw Conveyor Chip Extraction,<br />

Settling Tank With Skimmer, 3-HP Recirculation Pump, PLC Control Panel<br />

CHIP BALING SYSTEM<br />

1 – FRONTIER HYDRAULICS NA 2-RAM HORIZONTAL HYDRAULIC CHIP BALER,<br />

S/N NA, Hydraulic Power Unit With (2) 75-HP Hydraulic Pumps, Bale Size Approx. 24”<br />

x 18” x Variable, Compression Chamber Size 9’ x 54” x 24” High, Overall Charging<br />

Hopper Size 9’ x 54” x 5’ High, Hydraulic Chamber Lid, Bale Exit Conveyor System<br />

With Push-Off Stand, Run-Out Table & Carrier, 78” x 30’ Long Oscillating Shaker Table,<br />

Main Control Panel With Allen Bradley PLC Control<br />

MATERIAL HANDLING<br />

1 – KENWAY AUTOMATED STORAGE & RETRIEVAL SYSTEM, 3 Rows Storage<br />

Units (2) Single Sided, (1) Double Sided, Approx 22’ Height x 75’ Length,<br />

Overhead Retrieval Crane System<br />

2 – PRAB ROBOT TYPE FA MATERIAL HANDLING & TRANSFER ROBOTS, S/Ns<br />

V-2085, V-2086, 3-Axis, Horizontal Double End Cantilever Arm With Gripper<br />

Fixtures, Track Mounted Sliding Base, PLC Control Panel<br />

1 – MT. CLEMENS CRANE CHIP BALER OVERHEAD CHARGING CRANE, 1-Ton<br />

Capacity x 25’ Span, Bottom Running With (3) Support Rail Tracks, Demag<br />

Electric Cable Hoist, With Type CE-20 20” Electromagnetic Lifting Magnet, Radio<br />

Controlled With Remote Radio Operator’s Pedestal Control<br />

2 – SPAN MASTER 5-TON CAPACITY BOTTOM RIDING SINGLE GIRDER BRIDGE<br />

CRANES, 20’ Span, Acco-Wright Work-Rated 5-Ton Electric Cable Hoist, 6-Way<br />

Power Pendant Control, 2-Speed Hoist<br />

3 – OMNI TECHNICAL SERVICE 5-POSITION GRAVITY OVER / UNDER PALLET<br />

EXCHANGE RACK, With Pneumatic Tilt Table, 2000-Lbs. Capacity Per Rack,<br />

Type 212X-45X48x25<br />

1 – LANTECH LANWRAPPER SERIES SVGSU065017AA PALLET SHRINK WRAP<br />

MACHINE, 72” Table Diameter<br />

FLUID HANDLING<br />

1 – AQUANETICS INC MORS-150-T4E PORTABLE ON-SITE FLUID<br />

RECLAMATION SYSTEM, S/N T-1207, AC Electric Vacuum Pump<br />

3 – AUTO-TRACK SYSTEMS MAG-VAC INDUSTRIAL VACUUM UNITS, S/N NA<br />

SHOP & FACTORY<br />

LARGE QUANTITY SHOP & FACTORY EQUIPMENT, Plant Support, Production<br />

Process Equipment, Production Control, etc.<br />

GEAR CHECKING LAB<br />

2 – ADCOLE 911 – COMPUTERIZED GEAR CHECKERS, With PCs<br />

2 – ZEISS CONTOURECORD 1700 SD & 1600 D SURFACE CHECKERS, With PC<br />

3 – TAYLOR HOBSON TALYROND 262 ROUNDNESS TESTERS, (2) With Table & PC<br />

1 – HOMMELWERKE SURFACE CHECKER, With Granite Table & PC<br />

1 – DORSEY BENCHMARK 16H OPTICAL COMPARATOR<br />

To schedule an auction, please call <strong>Maynards</strong> <strong>Industries</strong> at 248.569.9781 11

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX)<br />

Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • Phoenix • San Francisco • Toronto • Villahermosa (MX)<br />

Hilco Industrial, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 877-37-HILCO (44526)<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

Forwarding Service Requested<br />

HILCO INDUSTRIAL, LLC<br />

& MAYNARDS INDUSTRIES<br />

WEBCAST/ONSITE AUCTION<br />

FLINT POWERTRAIN NORTH #2<br />

HILCO Industrial, LLC is a division of Hilco Trading, LLC • Headquarters, 5 Revere Drive, Ste. 206 • Northbrook, IL 60062 • All rights reserved<br />

Printed in USA • MOTO3499 • IL License #444000215 • Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

A buyer’s premium of 13.5% for onsite sales & 16%<br />

for webcast sales is in effect. Everything will be sold to<br />

the highest bidder for cash, in accordance with the<br />

Auctioneer’s customary “Terms of Sale”, copies of which<br />

will be posted on the premises of the sale and subject to<br />

additional terms announced the day of sale. All items will<br />

be sold “as is, where-is” without any warranties, express<br />

or implied. Although obtained from sources deemed<br />

reliable, the Auctioneer makes no warranty or guarantee<br />

to the accuracy of the information herein contained.<br />

Bidders are encouraged to thoroughly inspect the items<br />

on which they intend to bid prior to sale. Absolutely no<br />

items will be removed until the day after the conclusion of<br />

the sale and payment is made in full. Subject to additions,<br />

deletions and prior sale.<br />

Payment: ALL PURCHASES MUST BE PAID IN FULL<br />

ON THE DAY OF THE AUCTION. If you intend to pay by<br />

wire transfer, we will accept payment the day after the<br />

sale ONLY IF a deposit of 25% of total purchases is made<br />

on the day of the sale. Contact our office for wire transfer<br />

instructions. Only cash, wire transfer or certified check,<br />

payable to <strong>Maynards</strong> <strong>Industries</strong> will be accepted.<br />

Company checks payable to <strong>Maynards</strong> <strong>Industries</strong> will be<br />

accepted only if accompanied by a bank letter of<br />

guarantee, (see sample letter below). All sales are subject<br />

to sales tax. Purchasers claiming exemptions from taxes<br />

must provide proof satisfactory to the Auctioneer of their<br />

entitlement to claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees payment<br />

to <strong>Maynards</strong> <strong>Industries</strong> from (Company Name). This<br />

guarantee will be valid for purchases made at the<br />

Auction of Motors Liquidation Company Flint<br />

Powertrain #2 on Tuesday, January 18, 2011.<br />

Follow<br />

Us on: