tungsten carbide production - Resansil

tungsten carbide production - Resansil

tungsten carbide production - Resansil

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CONTENTS<br />

3<br />

PROGRESS<br />

AREAS OF USE<br />

COMPANY PROFILE<br />

SIMON GROUP<br />

RAW MATERIALS<br />

TUNGSTEN CARBIDE PRODUCTION<br />

DEVELOPMENT<br />

TOOLMAKING<br />

MANUFACTURING<br />

SYSTEM PARTNERSHIP<br />

SUPPORT<br />

PAGE [04]<br />

PAGE [06]<br />

PAGE [08]<br />

PAGE [11]<br />

PAGE [12]<br />

PAGE [14]<br />

PAGE [15]<br />

PAGE [16]<br />

PAGE [17]<br />

PAGE [20]<br />

PAGE [21]<br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

07<br />

FOUNDATION DRILLING PAGE [22]<br />

HORIZONTAL DIRECTIONAL DRILLING<br />

[HDD] PAGE [34]<br />

TRENCHING PAGE [35]<br />

MINING AND TUNNELLING PAGE [39]<br />

HYDRAULIC MILLING CUTTERS PAGE [44]<br />

RECYCLING PAGE [46]<br />

TUNGSTEN CARBIDE PAGE [53]

4<br />

PROGRESS<br />

High-performance tools.<br />

Giving the edge to masters<br />

of construction!<br />

Anyone working in construction, agriculture or<br />

recycling is made of tough stuff. The job has to be<br />

done in all weathers and under the most adverse of<br />

conditions. For these men we make our tools to a<br />

standard of quality on which they can rely. These tools<br />

include wear-resistant bits, studs, teeth, cutters and<br />

holders that are durable and thus only need changing<br />

once in a while, work perfectly and are simple to<br />

switch. That saves on construction site costs, and<br />

everyone is able to give of their best: The construction<br />

site team, the machine operator – and the machine<br />

itself, as it can be driven at a high rate of feed.

“The end of a hard, but very productive<br />

day! Thanks to Betek we’ve made<br />

greater progress than with any other<br />

tool system!”

6<br />

AREAS OF USE<br />

milling<br />

drilling<br />

trenching<br />

cutting<br />

1 – Road milling<br />

crushing<br />

stabilising<br />

5 – Foundation drilling<br />

with Betek<br />

tools<br />

9 – Trenching<br />

13 – Agriculture

AREAS OF USE<br />

7<br />

2 – Surface mining<br />

3 – Stabilising<br />

4 – Recycling<br />

6 – Diaphragm wall cutting<br />

7 – Horizontal directional drilling HDD<br />

8 – Mining<br />

10 – Tunnelling 11 – Hydraulic milling cutter 12 – Forest mulching<br />

14 – Rail track construction 15 – Abrasive wear protection 16 – Mine clearing

COMPANY PROFILE<br />

9<br />

Thinking ahead – To stay in<br />

the lead with innovative<br />

products<br />

Betek produces wear parts tipped with <strong>tungsten</strong><br />

<strong>carbide</strong>. The company does so with a level of expertise<br />

based on decades of experience in <strong>tungsten</strong> <strong>carbide</strong><br />

<strong>production</strong>. Using leading edge manufacturing<br />

technology, the entire product range is made at our<br />

site in Aichhalden in the Black Forest. Our team of 140<br />

employees is constantly finding new ways to fine-tune<br />

our activities in development, <strong>production</strong> and sales – in<br />

order to achieve greater efficiency, greater flexibility<br />

and greater customer focus. Product innovations are<br />

created in the process that go on to set new benchmarks<br />

for progress with users all around the globe.<br />

Nor do we ever lose sight of what benefits our<br />

customers most. The result is constant growth and an<br />

excellent global market position in every field, while<br />

our role as a technical pioneer is secured through<br />

numerous patents. Yet, despite all this activity, the<br />

name Betek also stands for continuity and reliability,<br />

shown through adherence to deadlines and a stable<br />

pricing policy.

“Changing tools is back-breaking work.<br />

Anything to make it easier is very welcome.<br />

That’s why I swear by Betek bits!”

SIMON GROUP<br />

11<br />

A solid foundation for growth<br />

Betek is part of the Simon Company Group, to which six further companies also belong. The Group has<br />

evolved from the Karl Simon Company, the roots of which stretch back to 1918.<br />

Central Services, including administration, purchasing, quality management, toolmaking, maintenance,<br />

laboratories, personnel, electronics and training workshops, guarantee a flat hierarchy and flexible<br />

working processes within the Group. The exchange of know-how and close collaboration between its<br />

companies produces above-average levels of innovation with simultaneously high standards of quality<br />

and customer focus.<br />

Every year, the Group offers apprenticeships for young people in an extremely wide variety of jobs. Through<br />

the diversity of the Group’s business activities they are able to find the ideal prerequisites for all-round<br />

training.<br />

Since 1992, the Simon Company Group has belonged to the quoted INDUS Holding AG, which assists in<br />

the areas of finance, accounting, law and taxation and provides at the same time the financial capacity for<br />

innovation and growth.<br />

A strong team.<br />

The other six companies of the Simon Group<br />

FURNITURE FITTINGS<br />

COMPANY GROUP<br />

GALVANIZING<br />

SINTERING TECHNOLOGY<br />

TOOLMAKING

12<br />

RAW MATERIALS<br />

Close inspection.<br />

For quality from the outset<br />

For wear-resistant <strong>tungsten</strong> <strong>carbide</strong> tools the<br />

<strong>tungsten</strong> <strong>carbide</strong> and cobalt have to be of the<br />

highest purity. Our central laboratory therefore<br />

makes a close inspection of all raw material supplies.<br />

Any trace of impurity can have an effect on product<br />

quality. Every other step in the <strong>production</strong> process is<br />

also accompanied by laboratory tests, with our own<br />

powder mixes and granulates, the intermediate and<br />

final products all checked. State of the art equipment<br />

is on hand for the broad array of laboratory<br />

work, such as hardness measurements, magnetic<br />

identification and determining levels of carbon and<br />

oxygen content.

“To say that quality has its price is and isn’t right.<br />

When I add everything up, I’m better off with<br />

Betek. Why Because I simply make huge<br />

savings in time and money!”

14<br />

TUNGSTEN CARBIDE PRODUCTION<br />

1,450 degrees Celsius and<br />

consistently high standards<br />

Precise management of the process is key to achieving quality in <strong>tungsten</strong> <strong>carbide</strong> <strong>production</strong>. This starts<br />

with the composition of the <strong>tungsten</strong> <strong>carbide</strong> powder, which varies depending on the desired characteristics<br />

of the final product. The grain size is also matched precisely to the product’s intended use. For percussive<br />

drilling used in tunnelling, for instance, a grain size of 4 µm is ideal, while for road milling the best size is<br />

20 µm.<br />

As the powder is pressed into shape, the press parameters are electronically monitored. Great stability is<br />

also maintained at the sintering stage of the process, when the pressed forms acquire their outstanding<br />

<strong>tungsten</strong> <strong>carbide</strong> qualities at a temperate of 1,450 degrees Celsius: Great hardness with exactly the right<br />

degree of toughness. This process is accompanied by permanent quality checks. These too are based on<br />

high standards, thus ensuring that the tools are free of cavities, contain the optimum amount of carbon<br />

and have the correct transverse rupture strength.

DEVELOPMENT<br />

15<br />

Flexibility through direct<br />

dialogue with users<br />

The development process at Betek is never a<br />

one-way street, but rather a case of constructive<br />

collaboration between machine manufacturers,<br />

tool users and Betek’s engineers. While innovations<br />

may be produced using ultramodern 3-D CAD<br />

systems, experience is incorporated from the<br />

construction sites of the world. In the process,<br />

we always keep our eye on the interplay between<br />

machine, tool and the job at hand. Thanks to our<br />

many years of experience and through the use of<br />

FEM analyses and rapid prototyping, we are able to<br />

keep the time needed for new developments very<br />

short. This flexibility enables us to respond quickly<br />

to customer requests.

16<br />

TOOLMAKING<br />

Ensuring one matches the other to the n<br />

degree<br />

Consistent tool quality requires precision – and an instinctive feel. The Simon Group’s toolmaking division<br />

is the epitome of both. This is where the moulds for our <strong>tungsten</strong> <strong>carbide</strong> parts are made. And one really<br />

is the same as another down to ±5µm.<br />

The people working here therefore have great specialist knowledge - in electrical discharge machining,<br />

in working with <strong>tungsten</strong> <strong>carbide</strong> and in the expert operation of powerful CAD/CAM systems.<br />

They work in close collaboration with every division of the company, thus enabling us to achieve fast<br />

<strong>production</strong> times for our clients.<br />

And what does all that have to do with you, as a customer of ours It means you can rely on always<br />

having identical tools to hand, always in the very best of shape!<br />

th

MANUFACTURING<br />

17<br />

A clever join of steel<br />

and <strong>tungsten</strong> <strong>carbide</strong><br />

Fully automatic inert protective gas soldering system<br />

Steel and <strong>tungsten</strong> <strong>carbide</strong> – two materials with<br />

totally different expansion coefficients when<br />

subjected to heat. It is nevertheless of steel and<br />

<strong>tungsten</strong> <strong>carbide</strong> that our tools are made: Tungsten<br />

<strong>carbide</strong> for the wear-resistant tip, steel for the<br />

tool shank. As tools can become very hot in use,<br />

extreme tensile stress is generated. This is absorbed<br />

by a special solder that joins the <strong>tungsten</strong> <strong>carbide</strong><br />

tip to the steel section.<br />

We have developed our own methods and<br />

soldering systems for this soldering process,<br />

which is itself carried out on fully automatic<br />

machinery under an inert protective gas – with<br />

full monitoring and documentation of the<br />

manufacturing parameters. The soldering is<br />

also checked for resistance to shearing – all<br />

measures that ensure that our ’masters of<br />

construction’ lose no time due to broken tools.<br />

Inert protective gas soldering system<br />

µm

“You can rely on Betek’s engineers. Whenever<br />

I’ve got difficult ground conditions and need<br />

a quick solution, they’re always there. And<br />

even as a pro, I’ve still learnt a thing or two<br />

from Betek’s training.”

20<br />

SYSTEM PARTNERSHIP<br />

Ensuring progress with system partnerships<br />

System partnerships with machine manufactures, above all with Wirtgen, form the basis of our success<br />

– in every respect. Such partnerships begin with tool development, ensuring that tool, holder and machine<br />

create a perfect system. The coordinated components provide users with great potential for saving money<br />

on operating costs, as the machines runs more smoothly and show less wear, and because the tools rotate<br />

perfectly and are thus in use for longer.<br />

Another incalculable benefit is the great reliability of supply provided by a one-stop shop: Construction site<br />

teams can be certain that their requests and suggestions will be dealt with quickly and result in innovative<br />

product developments.<br />

W<br />

Wirtgen<br />

Job<br />

Machine<br />

Holder system / Drum<br />

Bit

SUPPORT<br />

21<br />

Assistance from experienced<br />

engineers<br />

Just give us a call or send us an e-mail, and we’ll give you advice<br />

on all issues related to our tool systems. This includes advice on<br />

the choice of bit, which has to be matched to the intended job<br />

and the ground conditions.<br />

Changing tools at the right time saves money. We can therefore<br />

tell you how best to use our tool systems – if required, right there<br />

with you on site. Our support includes solving even the trickiest<br />

of problems and can extend all the way to developing new tools.<br />

At Betek, customer service also include training – at our own<br />

plant, with our system partners or at our users’ own premises.

22<br />

FOUNDATION DRILLING<br />

Welding bars<br />

35<br />

38<br />

29<br />

90<br />

70<br />

50<br />

➜<br />

➜<br />

BA01<br />

➜ BA04<br />

➜ BA09<br />

BA90-35 ➜ BA70-38 ➜ BA50-29<br />

26,5<br />

22<br />

42<br />

50<br />

55<br />

90<br />

➜<br />

➜<br />

BA10<br />

➜ BA13<br />

➜ BA24<br />

BA50-26.5 ➜ BA55-22 ➜ BA90-42<br />

32<br />

83<br />

60<br />

52<br />

100<br />

75<br />

➜<br />

➜<br />

BA32<br />

➜ BA38<br />

➜ BFZ26<br />

BA60-32/2 ➜ BA100x52 ➜ BFZ83x75x45/1

FOUNDATION DRILLING<br />

23<br />

Welding bars<br />

Quick change bars<br />

33<br />

65<br />

90<br />

80<br />

➜<br />

➜<br />

BFZ72/B<br />

BFZ65x90x30<br />

➜ BA07<br />

➜ BA80-33/2<br />

Dragon’s tooth<br />

Ø22.5<br />

80<br />

60<br />

88.5<br />

50<br />

39<br />

40<br />

Ø22<br />

➜<br />

BHA02<br />

➜<br />

BFR07<br />

➜<br />

BHR133<br />

➜ BHA60/2<br />

➜<br />

BFR46-22<br />

➜ B10/22-F<br />

Service number + 49 (0) 74 22 / 5 65 -144 Fax + 49 (0) 74 22 / 5 65 -122<br />

www.betek.de · info@betek.de

24<br />

FOUNDATION DRILLING<br />

Flat teeth<br />

70<br />

80<br />

50<br />

Ø38<br />

75<br />

Ø38<br />

100<br />

75<br />

Ø94<br />

Ø30<br />

Ø38<br />

161<br />

Ø30<br />

Ø75<br />

Ø30<br />

➜<br />

BFZ162<br />

➜<br />

BHR112<br />

➜<br />

BHR39<br />

➜ BFZ100x70/2<br />

➜<br />

B75<br />

➜<br />

B48<br />

65<br />

80<br />

155<br />

253<br />

23<br />

65<br />

➜ BFZ65HM<br />

➜<br />

BHF02<br />

➜ BFZ80<br />

➜ BFZ65/2<br />

➜<br />

B65-22<br />

➜ BFZ80<br />

Weld-on teeth<br />

25<br />

71<br />

108<br />

31<br />

110<br />

40<br />

65<br />

25<br />

➜<br />

BHR73<br />

➜<br />

BFZ25R<br />

➜<br />

BFZ96<br />

➜<br />

BHZ80/2<br />

➜ BFZ25-R<br />

➜<br />

BFZ71x25

FOUNDATION DRILLING<br />

25<br />

Pilots<br />

50<br />

50<br />

50<br />

1"-8 UNC<br />

M36<br />

1 1/4 - 5 STUB<br />

ACME THREAD<br />

➜ BP01<br />

➜<br />

BP04<br />

➜<br />

BP51<br />

➜ BP51/1"-HD3<br />

➜<br />

BP51/M36-HD3<br />

➜<br />

BP51x87<br />

1"-8 UNC<br />

M36<br />

➜<br />

➜<br />

BPH02<br />

Threaded bushing GH-1"<br />

➜ BPH01<br />

➜ Threaded bushing GH-M36<br />

Service number + 49 (0) 74 22 / 5 65 -144 Fax + 49 (0) 74 22 / 5 65 -122<br />

www.betek.de · info@betek.de

26<br />

FOUNDATION DRILLING<br />

Round shank cutter bits 11,3 mm / 0,44”<br />

Ø16<br />

Ø8<br />

Ø16<br />

53<br />

53<br />

51<br />

28<br />

28<br />

28<br />

Ø11.3<br />

Ø11.3<br />

Ø11.3<br />

Ø20<br />

Ø17.5<br />

Ø20<br />

➜<br />

BM10<br />

➜<br />

BM11<br />

➜<br />

BM46<br />

➜ BM4-11.3<br />

➜<br />

BM8-11.3<br />

➜<br />

BM3-11.3<br />

Bit holders 11,3 mm / 0,44”<br />

Round shank cutter bits 13 mm / 0,512”<br />

Ø8<br />

Ø8<br />

Ø11.5<br />

57<br />

28<br />

30<br />

25<br />

55<br />

Ø13<br />

Ø13<br />

Ø20<br />

Ø20<br />

➜<br />

BHR03<br />

➜<br />

BM34<br />

➜<br />

BM42<br />

➜<br />

B11<br />

➜<br />

BM8-13/H<br />

➜<br />

BM8-13/HT<br />

Ø16<br />

Ø16<br />

Ø8<br />

55<br />

55<br />

64<br />

28<br />

28<br />

30<br />

Ø13<br />

Ø13<br />

Ø13<br />

Ø19<br />

Ø20<br />

Ø20<br />

➜<br />

BM51<br />

➜<br />

BM62<br />

➜<br />

BM64<br />

➜ BM4-13/HS<br />

➜<br />

BM3-13/H<br />

➜<br />

BM8-13/HS

FOUNDATION DRILLING<br />

27<br />

Round shank cutter bits 14 mm / 0,55”<br />

Ø8<br />

Ø16<br />

Ø8<br />

59<br />

55<br />

55<br />

34<br />

32<br />

32<br />

Ø14<br />

Ø20<br />

Ø14<br />

Ø20<br />

Ø14<br />

Ø20<br />

➜ BM49<br />

➜ BM8-14/HB<br />

➜ BM55<br />

➜ BM4-14/2<br />

Bit holders 14 mm / 0,55”<br />

➜ BM56<br />

➜ BM8-14/2<br />

Ø16<br />

Ø14<br />

Ø26<br />

32<br />

Ø14<br />

55<br />

Ø20<br />

➜ BM60<br />

➜ BM3-14/H<br />

➜ BHR109<br />

➜ B14<br />

Service number + 49 (0) 74 22 / 5 65 -144 Fax + 49 (0) 74 22 / 5 65 -122<br />

www.betek.de · info@betek.de

28<br />

FOUNDATION DRILLING<br />

Round shank cutter bits 15,8 mm / 0,622”<br />

Round shank cutter bits<br />

18,65 mm / 0,735”<br />

Ø8<br />

Ø16<br />

Ø12<br />

26<br />

87<br />

47<br />

Ø18.65<br />

Ø27<br />

➜ BTR02<br />

➜ B43HDK12<br />

Ø16<br />

83.5<br />

44<br />

Ø18.65<br />

Ø27<br />

➜ BTR03<br />

➜ B43/3<br />

Round shank cutter bits 19,4 mm / 0,765”<br />

Ø16<br />

Ø16<br />

86<br />

85<br />

84<br />

45<br />

44<br />

44<br />

65<br />

34<br />

Ø15.8<br />

Ø22<br />

➜<br />

BM07<br />

➜ BHR142<br />

➜<br />

BM8-15.8/FS<br />

➜ B16<br />

Bit holders 18,65 mm / 0,735”<br />

Ø19<br />

Ø42<br />

➜ BHR20<br />

➜ DV8<br />

Ø12<br />

Ø19.4<br />

Ø27<br />

Ø19.4<br />

Ø27<br />

Ø19.4<br />

Ø27<br />

➜<br />

➜<br />

BSH05 ➜ BSH09 ➜ BSK12<br />

B1HDK12 ➜ B3 ➜ B3K

FOUNDATION DRILLING<br />

29<br />

Round shank cutter bits 19,4 mm / 0,765”<br />

Ø9<br />

Ø11<br />

Ø12<br />

84<br />

84<br />

84<br />

44<br />

44<br />

44<br />

Ø19.4<br />

Ø27<br />

Ø19.4<br />

Ø27<br />

Ø19.4<br />

Ø27<br />

➜<br />

➜<br />

BSK15 ➜ BSK16 ➜ BSK17<br />

B1K9K<br />

➜ B1HDK11K<br />

➜ B1HDK12K<br />

Bit holders 19,4 mm / 0,765”<br />

Ø8<br />

Ø20<br />

Ø20<br />

Ø42<br />

86<br />

46<br />

39<br />

Ø19.4<br />

Ø27<br />

➜<br />

BSK19<br />

➜<br />

BHR07<br />

➜<br />

BHR12<br />

➜ B1K8K<br />

➜<br />

DV9<br />

➜<br />

DV12<br />

Service number + 49 (0) 74 22 / 5 65 -144 Fax + 49 (0) 74 22 / 5 65 -122<br />

www.betek.de · info@betek.de

30<br />

FOUNDATION DRILLING<br />

Round shank cutter bits 25 mm / 1”<br />

Ø9.1<br />

Ø12<br />

Ø15<br />

118<br />

121<br />

61<br />

64<br />

Ø25<br />

Ø33<br />

Ø25<br />

Ø38<br />

➜<br />

BTK03<br />

➜<br />

BTK10<br />

➜ B40HDK12<br />

➜<br />

B40HDS<br />

Ø16<br />

Ø30<br />

Ø17.5<br />

121<br />

121<br />

123.5<br />

64<br />

64<br />

66.5<br />

Ø25<br />

Ø33<br />

Ø25<br />

Ø44<br />

Ø25<br />

Ø38<br />

➜<br />

BTK16<br />

➜<br />

BTK26<br />

➜<br />

BTK70<br />

➜<br />

B40/3 ➜ B40J1HBL ➜ B40K17.5<br />

Ø15<br />

64<br />

64<br />

121<br />

64<br />

Ø25<br />

Ø33<br />

➜<br />

BTK01<br />

➜ B40K9<br />

Ø22<br />

Ø19<br />

64<br />

Ø25<br />

Ø60<br />

121<br />

Ø25<br />

Ø60<br />

121<br />

Ø25<br />

Ø60<br />

121<br />

➜<br />

BTK80<br />

➜ BTK81<br />

➜ BTK82<br />

➜<br />

WR8-E<br />

➜ WR-15<br />

➜ WR6-SG

FOUNDATION DRILLING<br />

31<br />

Round shank cutter bits<br />

25 mm / 1”<br />

Bit holders 25 mm / 1”<br />

Ø24.4<br />

Ø25.5<br />

Ø25.5<br />

44<br />

Ø54<br />

Round shank cutter bits 38 / 30 mm<br />

Ø17.5<br />

Ø19<br />

Ø19<br />

125<br />

125<br />

140<br />

65<br />

65<br />

80<br />

121<br />

64<br />

Ø25<br />

Ø42<br />

➜ BTK87<br />

➜ B40/9<br />

➜ BHR31<br />

➜ DV25<br />

➜ BHR121<br />

➜ DV25KS<br />

Ø30<br />

Ø38<br />

Ø50<br />

Ø30<br />

Ø38<br />

Ø50<br />

Ø30<br />

Ø38<br />

Ø50<br />

➜<br />

BKH28<br />

➜<br />

BKH40<br />

➜ BKH41<br />

➜ B47K17.5-H<br />

➜<br />

B47K19-H<br />

➜<br />

B47K19LK80-H<br />

Service number<br />

+ 49 (0) 74 22 / 5 65 -144 Fax + 49 (0) 74 22 / 5 65 -122<br />

www.betek.de · info@betek.de

32<br />

FOUNDATION DRILLING<br />

Round shank cutter bits 38 / 30 mm<br />

Bit holders 38 / 30 mm<br />

Ø22<br />

Ø30<br />

Ø38<br />

Ø66<br />

Ø30<br />

Ø38<br />

Ø60<br />

➜ BKH47<br />

➜ BKH81<br />

➜ B47K30/60-H<br />

Accessories<br />

Ø38<br />

Ø72<br />

Ø30<br />

➜<br />

BHR113<br />

➜ BZ12<br />

➜<br />

BRV02<br />

➜ B43K<br />

➜ Bit puller for H series<br />

civil engineering<br />

➜<br />

BRV-G88/L<br />

W 76x1/6"<br />

100<br />

40<br />

38<br />

38<br />

130.5<br />

124<br />

70.5<br />

64<br />

Ø30<br />

Ø38<br />

Ø50<br />

Ø30<br />

➜ B47K22-H<br />

➜ BHR38<br />

➜ B43H<br />

Screw connections<br />

➜<br />

BRV03<br />

➜<br />

BRV08<br />

➜ BRV32<br />

➜ BRV-K88/L<br />

➜<br />

BRV75/38LV<br />

➜ BRV-AK

Name<br />

Application/<br />

Info.<br />

Product<br />

code<br />

Screw connections for walls 30 mm thick<br />

BRV-G46-14<br />

BRV-K46-14<br />

BRV60/29/4<br />

d=460<br />

d=460<br />

–<br />

BRV19<br />

BRV18<br />

BRV20<br />

Screw connections for walls 40 mm thick<br />

BRV-G64/B<br />

BRV-K64/B<br />

BRV-G64/L<br />

BRV-K64/L<br />

BRV-G88/L<br />

BRV-K88/L<br />

BRV-G118/L<br />

BRV-K118/L<br />

BRV-G150/L<br />

BRV-K150/L<br />

BRV-G80-100-B<br />

BRV-K80-100-B<br />

BRV75/38LV<br />

BRV75/38LV/4<br />

BRV75/37/12°/BV<br />

BRV75/38LV/4<br />

O-Ring 5x60<br />

d=620 - 640<br />

d=620 - 640<br />

d=620 - 640<br />

d=620 - 640<br />

d=880<br />

d=880<br />

d=1180<br />

d=1180<br />

d=1500 - 1800<br />

d=1500 - 1800<br />

d=800 - 1000<br />

d=800 - 1000<br />

(6kt.SW27)<br />

(4kt.SW26)<br />

–<br />

(4kt.SW29)<br />

–<br />

BRV04<br />

BRV05<br />

BRV14<br />

BRV15<br />

BRV02<br />

BRV03<br />

BRV06<br />

BRV07<br />

BRV12<br />

BRV11<br />

BRV30<br />

BRV31<br />

BRV08<br />

BRV10<br />

BRV16<br />

BRV23<br />

SI116<br />

Screw connections for walls 50 mm thick<br />

BRV75/48/4<br />

BRV-G140-23<br />

BRV-K140-24,5<br />

Other<br />

–<br />

d=1400 - 1500<br />

d=1400 - 1500<br />

BRV17<br />

BRV21<br />

BRV22<br />

BRV-AK (Stop wedges) BRV32

34<br />

HORIZONTAL DIRECTIONAL<br />

DRILLING [HDD]<br />

Weld-on teeth<br />

18<br />

Ø16<br />

23<br />

18<br />

Round shank cutter bits 11,3 mm / 0,44” + 15,8 mm / 0,622” + Special type<br />

Ø16<br />

Ø16<br />

Ø15<br />

51<br />

66<br />

90<br />

28<br />

32<br />

52.5<br />

40<br />

52<br />

34<br />

33<br />

Service number<br />

+ 49 (0) 74 22 / 5 65 -144<br />

Fax + 49 (0) 74 22 / 5 65 -122<br />

➜<br />

BFZ144<br />

➜<br />

BFZ158<br />

➜<br />

BFZ18/L<br />

➜<br />

BFZ3<br />

Ø15<br />

50<br />

➜ BFZ207<br />

➜<br />

BFZ260<br />

➜<br />

BFZ87<br />

➜ BFZ1<br />

➜<br />

BFZ42x40x23<br />

➜<br />

BFZ18/2<br />

Ø11.3<br />

Ø20<br />

Ø15.8<br />

Ø21<br />

Ø28.3<br />

Ø34<br />

➜<br />

BM46<br />

➜ BM73<br />

➜<br />

BSR110<br />

➜<br />

BM3-11.3<br />

➜<br />

BM3-15.8/F<br />

➜ BSR15/S28

TRENCHING<br />

35<br />

Round shank cutter bits<br />

19,4 mm / 0,765”<br />

Round shank cutter bits<br />

22 mm / 0,875”<br />

Ø16<br />

Ø11<br />

96,5<br />

45<br />

Ø22<br />

Ø31<br />

➜<br />

➜<br />

BC01<br />

B1HDK11/22/S<br />

Ø22<br />

Ø17.2<br />

Ø11<br />

94<br />

87<br />

87<br />

52<br />

45<br />

45<br />

100<br />

46<br />

Ø19.4<br />

Ø38<br />

➜ BC26<br />

➜ B3KS<br />

Ø22<br />

Ø38<br />

Ø22<br />

Ø38<br />

Ø22<br />

Ø31<br />

➜ BC03<br />

➜ B8S/22<br />

➜ BC04<br />

➜ B5S/22<br />

➜ BC05<br />

➜ B1HDK11/22<br />

Service number + 49 (0) 74 22 / 5 65 -182 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

36<br />

TRENCHING<br />

Round shank cutter bits 22 mm / 0,875”<br />

Ø16<br />

Ø12<br />

Ø12<br />

98,5<br />

106<br />

42<br />

46<br />

Ø22<br />

Ø38<br />

Ø22<br />

Ø27<br />

➜<br />

BC36<br />

➜<br />

BC39<br />

➜<br />

B1-12/22/SI26<br />

➜<br />

B1-12KS/22<br />

Ø24.4<br />

Ø16<br />

86<br />

87<br />

44<br />

45<br />

102,5<br />

46<br />

Ø22<br />

Ø38<br />

➜ BC33<br />

➜ B3KS22<br />

Ø16<br />

87<br />

45<br />

Ø22<br />

Ø38<br />

Ø22<br />

Ø38<br />

Ø22<br />

Ø27<br />

➜ BC41<br />

➜ B3S/22<br />

➜<br />

➜<br />

BC43<br />

➜ BC49<br />

B9/22 ➜ B3/22<br />

Bit holders 22 mm / 0,875”<br />

Ø22.5<br />

Ø22.5<br />

Ø22.5<br />

Ø42<br />

44<br />

42<br />

➜<br />

➜<br />

BHR120OL<br />

➜ BHR27<br />

➜ BHR30<br />

B22S ➜ DV8/22 ➜ DV22

TRENCHING<br />

37<br />

Round shank cutter bits 25 mm / 1”<br />

Ø12<br />

Ø17.5<br />

Ø19<br />

141.5<br />

141.5<br />

141.5<br />

64<br />

64<br />

64<br />

Ø25<br />

Ø44<br />

Ø25<br />

Ø44<br />

Ø25<br />

Ø48<br />

➜<br />

BTK07<br />

➜ BTK11<br />

➜ BTK14<br />

➜<br />

B40KS12/44<br />

➜ B40KS17.5/44<br />

➜ B40KS19/48<br />

Ø15<br />

Ø19<br />

Ø12<br />

141.5<br />

141.5<br />

141.5<br />

64<br />

64<br />

64<br />

Ø25<br />

Ø44<br />

Ø25<br />

Ø60<br />

Ø25<br />

Ø60<br />

➜<br />

BTK29<br />

➜ BTK62<br />

➜ BTK63<br />

➜<br />

B40KS15/44<br />

➜ B40KS19/60<br />

➜ B40KS12/60<br />

Service number + 49 (0) 74 22 / 5 65 -182 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

38<br />

TRENCHING<br />

Round shank cutter bits 25 mm / 1”<br />

Ø15<br />

Ø12<br />

Ø15<br />

141.5<br />

118<br />

121<br />

64<br />

61<br />

64<br />

Ø25<br />

Ø60<br />

Ø25<br />

Ø33<br />

Ø25<br />

Ø38<br />

➜<br />

➜<br />

BTK64<br />

➜ BTK03<br />

➜ BTK10<br />

B40KS15/60 ➜ B40HDK12 ➜ B40HDS<br />

Bit holders 25 mm / 1”<br />

Ø25.5<br />

66<br />

54<br />

➜<br />

BHR34<br />

➜<br />

BHR121<br />

➜<br />

DV40VS<br />

➜<br />

DV25KS<br />

Accessories<br />

Lock washer<br />

➜<br />

BZ22 ➜ BZ27 ➜<br />

SI79/K<br />

➜<br />

Bit puller<br />

➜<br />

Assembly tool<br />

➜ Lock washer

MINING AND TUNNELLING<br />

39<br />

Holder bushing<br />

119<br />

29<br />

Ø30<br />

Ø50<br />

Ø72<br />

➜<br />

➜<br />

BR71<br />

BR49.8-35-119<br />

Round shank cutter bits 35 mm / 1,38”<br />

Ø19<br />

Ø19<br />

Ø24.4<br />

183<br />

183<br />

190<br />

89<br />

89<br />

96<br />

Ø34.7<br />

Ø55<br />

Ø34.7<br />

Ø55<br />

Ø34.7<br />

Ø55<br />

➜<br />

➜<br />

BSR111<br />

➜ BSR112<br />

➜ BSR68<br />

BSR19LK89/S35-H/E ➜ BSR19LK89/S35-K/E ➜ BSR24LK96/S35-K<br />

Service number + 49 (0) 74 22 / 5 65 -202 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

40<br />

MINING AND TUNNELLING<br />

Round shank cutter bits 38 mm / 1,5”<br />

Round shank cutter bits<br />

43/35mm<br />

Ø25<br />

Ø22<br />

Ø22<br />

147<br />

147<br />

222<br />

70<br />

70<br />

102<br />

Ø38<br />

Ø57<br />

Ø38<br />

Ø58<br />

Ø35<br />

Ø43<br />

Ø60<br />

➜<br />

➜<br />

BSR46<br />

➜ BSR72<br />

➜ BSR70<br />

BSR25LK70/S38-K ➜ BSR22/S38-K ➜ BSR22LK102/S35x43-H<br />

Round shank cutter bits 30 / 38 mm<br />

Ø24.4<br />

Ø25<br />

146<br />

70<br />

Ø30<br />

Ø38<br />

Ø60<br />

➜ BKF08<br />

➜ B47K24LK70-F<br />

Ø19<br />

Ø17.5<br />

Ø12<br />

138.5<br />

144,5<br />

138,5<br />

64<br />

70<br />

64<br />

153<br />

77<br />

Ø30<br />

Ø38<br />

Ø70<br />

➜ BKF10<br />

➜ B47K25-F<br />

➜ SI35/22<br />

➜ Lock washer<br />

Ø30<br />

Ø38<br />

Ø60<br />

Ø30<br />

Ø38<br />

Ø60<br />

Ø30<br />

Ø38<br />

Ø60<br />

➜<br />

BKS111<br />

➜<br />

BKS112<br />

➜<br />

BKS117<br />

➜ B47K19/60<br />

➜<br />

B47K17.5LK70/60<br />

➜<br />

B47K12/60

MINING AND TUNNELLING<br />

41<br />

Ø22<br />

Ø12<br />

Ø19<br />

138.5<br />

64<br />

Ø30<br />

Ø38<br />

Ø48<br />

Ø30<br />

Ø38<br />

Ø48<br />

➜<br />

BKS13<br />

➜<br />

BKS39<br />

➜ B46K12LK77<br />

➜<br />

B47K19<br />

Bit holders 30 / 38 mm<br />

Ø12<br />

Ø38<br />

Ø66<br />

138.5<br />

64<br />

138.4<br />

151.5<br />

63.9<br />

77<br />

Ø30<br />

Ø38<br />

Ø52<br />

➜<br />

BKS124<br />

➜ B47K22/P<br />

Circlip<br />

2.5<br />

Ø30<br />

Ø38<br />

Ø50<br />

Ø30<br />

➜ BKS75<br />

➜ B46K12<br />

➜ BHR38<br />

➜ B43H<br />

➜ SR51<br />

➜ Circlip<br />

Service number + 49 (0) 74 22 / 5 65 -202 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

42<br />

MINING AND TUNNELLING<br />

Round shank cutter bits 30 mm / 1,18”<br />

Ø15<br />

Ø17.5<br />

Ø17.5<br />

146<br />

172<br />

159<br />

64<br />

90<br />

77<br />

Ø30<br />

Ø52<br />

Ø30<br />

Ø48<br />

Ø30<br />

Ø60<br />

➜ BGK05<br />

➜ BGK16<br />

➜<br />

BGK19<br />

➜ B47GK15/3-K<br />

➜ B47GK17.5LK90-K<br />

➜<br />

B47GK17.5LK77-K<br />

Ø22<br />

Ø22<br />

Ø11<br />

146<br />

159<br />

160<br />

64<br />

77<br />

84<br />

Ø30<br />

Ø52<br />

Ø30<br />

Ø60<br />

Ø30<br />

Ø51<br />

➜<br />

BGK38<br />

➜<br />

BGK77<br />

➜<br />

BGK81<br />

➜ B47GK22-K<br />

➜ B47GK22LK77/60-K<br />

➜<br />

B46GK11-4F-K<br />

Bit holders 30 mm / 1,18”<br />

Micro-tunnelling<br />

Ø30<br />

Ø30.4<br />

70<br />

80<br />

66.5<br />

87<br />

➜<br />

BHR35<br />

➜<br />

BHR75<br />

➜<br />

BFM07<br />

➜<br />

B30.65<br />

➜ B30.65H<br />

➜ BFM144x70

MINING AND TUNNELLING<br />

43<br />

Micro-tunnelling<br />

100<br />

50<br />

70<br />

60<br />

87<br />

126<br />

➜<br />

BFM08<br />

➜ BFM16<br />

➜<br />

BFM71<br />

➜<br />

BFM112x50/S<br />

➜<br />

BFM144x86x70<br />

➜ BFM183x126x100<br />

38<br />

50<br />

60<br />

50<br />

50<br />

56.5<br />

➜<br />

BFZ163<br />

➜<br />

BFZ35M<br />

➜<br />

BFZ51<br />

➜<br />

BFZ56<br />

➜<br />

BFZ38/M<br />

➜ BFZ51<br />

Service number<br />

+ 49 (0) 74 22 / 5 65 -202 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

44<br />

HYDRAULIC MILLING CUTTERS<br />

Round shank cutter bits 30 mm / 1,18”<br />

Ø17.5<br />

Ø25<br />

Ø17.5<br />

70<br />

77<br />

Ø30<br />

Ø54<br />

153<br />

Ø30<br />

Ø70<br />

146<br />

➜<br />

BGS09<br />

➜<br />

BGS16<br />

➜<br />

B47GK17.5LK77<br />

➜<br />

B47GK25LK70/70<br />

Ø30<br />

Ø17.5<br />

153<br />

151<br />

77<br />

75<br />

Ø30<br />

Ø70<br />

Ø30<br />

Ø55<br />

➜<br />

BGS20<br />

➜<br />

BGS80<br />

➜ B47GK30LK77/70<br />

➜<br />

B47GK17.5LK75<br />

Ø19<br />

Ø17.5<br />

140<br />

151<br />

146<br />

64<br />

75<br />

70<br />

64<br />

Ø30<br />

Ø50<br />

140<br />

➜<br />

BGS17<br />

➜ B47GK17.5<br />

Ø17.5<br />

153<br />

75<br />

Ø30<br />

Ø60<br />

➜<br />

BGS66<br />

➜ B47GK17.5LK77/60<br />

Ø22<br />

Ø30<br />

Ø70<br />

Ø30<br />

Ø70<br />

Ø30<br />

Ø70<br />

➜<br />

BGS88<br />

➜<br />

BGS89<br />

➜<br />

BGS90<br />

➜ B47GK19/70-E<br />

➜ B47GK17.5LK75-E<br />

➜<br />

B47GK22LK70-E

HYDRAULIC MILLING CUTTERS<br />

45<br />

Round shank cutter bits<br />

30 mm / 1,18”<br />

Bit holders 30 mm / 1,18”<br />

Ø9<br />

Ø30<br />

66.5<br />

➜<br />

BHR35<br />

➜ B30.65<br />

Round shank cutter bits<br />

25 mm / 1”<br />

Ø7<br />

Round shank cutter bits<br />

19,4 mm / 0,765”<br />

Ø7<br />

Ø30<br />

Ø66<br />

126.5<br />

104<br />

50<br />

51<br />

143.5<br />

64<br />

Ø30<br />

Ø60<br />

➜<br />

BSR58<br />

➜ BSR9/LK64/S30<br />

Ø25<br />

Ø38<br />

Ø19.4<br />

Ø38<br />

➜ BHR94<br />

➜<br />

BSR78<br />

➜<br />

BSR63<br />

➜ B43G<br />

➜<br />

BSR7LK51.5/S25-KS<br />

➜<br />

BSR7LK50/S20-F<br />

Service number + 49 (0) 74 22 / 5 65 -202 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

46<br />

RECYCLING<br />

Bandit<br />

25.5<br />

19.6<br />

71<br />

142<br />

7/8"-14 UNF<br />

➜<br />

➜ BFZ195<br />

➜ BFZ212<br />

➜<br />

BFS70x50x22<br />

➜ BFZ142x25-7/8”<br />

25<br />

142<br />

142<br />

50<br />

7/8"-14 UNF<br />

BFS291<br />

➜ BFZ142x25-7/8”/5<br />

12.2<br />

32<br />

142<br />

142<br />

7/8"-14 UNF<br />

7/8"-14 UNF<br />

7/8"-14 UNF<br />

➜<br />

BFZ223<br />

➜ BFZ232<br />

➜ BFZ262<br />

➜<br />

BFZ142x25/HS<br />

➜ BFZ142x40-7/8”<br />

➜ BFZ142x32-7/8”<br />

Duratech<br />

30<br />

83<br />

28<br />

38<br />

➜<br />

BFS142<br />

➜<br />

BFS146<br />

➜<br />

BHS14<br />

➜<br />

BFS45x40x83/2<br />

➜ BFS195x117x30/1<br />

➜<br />

BHS227x205x30

RECYCLING<br />

47<br />

Duratech<br />

Jenz<br />

35<br />

99<br />

80<br />

➜ BHS32<br />

➜ BHS232x202x35<br />

➜<br />

➜<br />

BFS184<br />

BFS99x80/2<br />

Morbark<br />

101<br />

115.5<br />

108<br />

74<br />

84<br />

81<br />

➜ BFS23/1<br />

➜<br />

BFS219<br />

➜<br />

BFS236<br />

➜ BFS103x80/1<br />

➜ BFS116x74x52/1<br />

➜<br />

BFS108x84x45<br />

Service number<br />

+ 49 (0) 74 22 / 5 65 -182 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

➜<br />

➜ BFS70x70x46/1<br />

Vermeer<br />

BFS153<br />

70<br />

68<br />

BFS105x70x56<br />

➜<br />

➜<br />

Seppi<br />

BFS18<br />

70<br />

➜<br />

➜<br />

PPC<br />

BFS70x70x46/3<br />

BFS70x70x46/7<br />

➜<br />

➜<br />

BFS121<br />

68<br />

68<br />

BFS265<br />

68<br />

68<br />

➜<br />

➜ BFS40x40/A/78<br />

Plaisance<br />

BFS15<br />

78<br />

46<br />

RECYCLING<br />

48<br />

➜<br />

➜<br />

➜<br />

➜<br />

BFS116x74x52/2 BFS80x58x133/1 BFS86x60/1<br />

➜<br />

➜<br />

BFS253<br />

115.5<br />

72<br />

BFS274<br />

133<br />

82<br />

BFS88<br />

86<br />

62<br />

➜<br />

➜ BFS116x74x52/4<br />

BFS335<br />

115.5<br />

74<br />

Morbark

RECYCLING<br />

49<br />

Vermeer<br />

60<br />

94<br />

25<br />

74<br />

➜ BFS286<br />

➜ BFS94x78x50<br />

➜ BHS15<br />

➜ BHS298x241x60<br />

Weld-on teeth<br />

➜ BFS266<br />

➜ BFS200x137x49/L/2<br />

78<br />

60<br />

25,5<br />

38<br />

19<br />

➜ BFS418<br />

➜<br />

BFS21<br />

➜ BFZ133<br />

➜ BFS200x137x49/L/4<br />

➜<br />

BFS40x40x78/3<br />

➜<br />

BFZ60x19/2<br />

Service number<br />

+ 49 (0) 74 22 / 5 65 -182 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

50<br />

RECYCLING<br />

Rayco<br />

13.5<br />

13.5<br />

13.5<br />

58<br />

56<br />

56<br />

➜<br />

BFS304<br />

➜<br />

BFS305<br />

➜<br />

BFS306<br />

➜ BFS65x58x14<br />

➜<br />

BFS65x57x14/R<br />

➜<br />

BFS65x57x14/L<br />

63<br />

63<br />

63<br />

M16x1.5<br />

5/8"-18 UNF<br />

72<br />

72<br />

72<br />

➜<br />

BHS43<br />

➜<br />

BHS44<br />

➜<br />

BHS46<br />

➜ BHS72x63x25/S<br />

➜ BHS72x63x25/G<br />

➜<br />

BHS72x63x25/G/Z<br />

Sandberger / Neuson<br />

228<br />

290<br />

102<br />

162<br />

➜ BFS221<br />

➜ BFS220x100x12<br />

➜<br />

➜<br />

BFS258<br />

BFS290x162x12/Re

TUNGSTEN CARBIDE<br />

53<br />

In all shapes, sizes and grades<br />

We would be pleased to advise you on the many options for<br />

using <strong>tungsten</strong> <strong>carbide</strong> and, on request, can also produce<br />

unusual shapes for you.<br />

Just tell us what problem you have with abrasive wear.<br />

We'll find you an economic solution – even for areas<br />

of use where until now steel has provided the abrasive<br />

wear protection.<br />

Our guarantee: We always match the <strong>tungsten</strong> <strong>carbide</strong><br />

grade to the intended use. That ensures the necessary<br />

toughness while simultaneously providing good resistance<br />

against wear.<br />

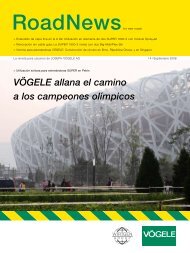

Grade overview<br />

Shown here are the reference values of the Betek <strong>tungsten</strong> <strong>carbide</strong> grades suited to your application.<br />

Grade<br />

TC<br />

weight-%<br />

Co<br />

weight-%<br />

TiC/<br />

TaNbC<br />

weight-%<br />

Average<br />

grain size<br />

µm<br />

Density<br />

g/cm³<br />

Hardness<br />

HV 10<br />

Hardness<br />

HRA<br />

Transverse<br />

rupture<br />

strength<br />

N/mm²<br />

B-10 F<br />

94,0<br />

6,0<br />

< 0,20<br />

4<br />

14,90<br />

1475<br />

89,8<br />

2900<br />

B-10 F2<br />

94,0<br />

6,0<br />

–<br />

3<br />

14,90<br />

1535<br />

90,3<br />

3000<br />

B-15<br />

92,5<br />

7,5<br />

< 0,20<br />

4<br />

14,75<br />

1350<br />

88,8<br />

2800<br />

B-20<br />

90,5<br />

9,5<br />

< 0,20<br />

4<br />

14,55<br />

1300<br />

88,4<br />

2800<br />

B-25<br />

90<br />

10<br />

–<br />

6<br />

14,50<br />

1200<br />

87,5<br />

2800<br />

B-30<br />

89,0<br />

11,0<br />

–<br />

6<br />

14,40<br />

1150<br />

87,0<br />

2800<br />

B-40<br />

85,0<br />

15,0<br />

–<br />

6<br />

14,00<br />

1050<br />

85,8<br />

2800<br />

B-10 G<br />

94,0<br />

6,0<br />

< 0,20<br />

20<br />

14,90<br />

1200<br />

87,6<br />

2200<br />

B-20 G<br />

91,5<br />

8,5<br />

< 0,20<br />

20<br />

14,65<br />

1100<br />

86,5<br />

2100<br />

B-25 G<br />

90,5<br />

9,5<br />

–<br />

25<br />

14,55<br />

1050<br />

85,8<br />

2100<br />

B-40 G<br />

85,0<br />

15,0<br />

< 0,20<br />

20<br />

14,00<br />

900<br />

84,8<br />

2000<br />

Service number<br />

+ 49 (0) 74 22 / 5 65 -256 Fax + 49 (0) 74 22 / 5 65 -181<br />

www.betek.de · info@betek.de

© BETEK GmbH · Edition 2007 · 5000 · Subject to technical changes · Atelier Türke<br />

US<br />

GB<br />

BETEK Bergbau- und Hartmetalltechnik<br />

Karl-Heinz Simon GmbH & Co. KG<br />

Sulgener Str. 19-23<br />

D-78733 Aichhalden Germany<br />

Tel +49(0)7422/565-0<br />

Fax+49(0)7422/565-122<br />

info@betek.de<br />

www.betek.de