ISO 17776 Checklist

ISO 17776 Checklist

ISO 17776 Checklist

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

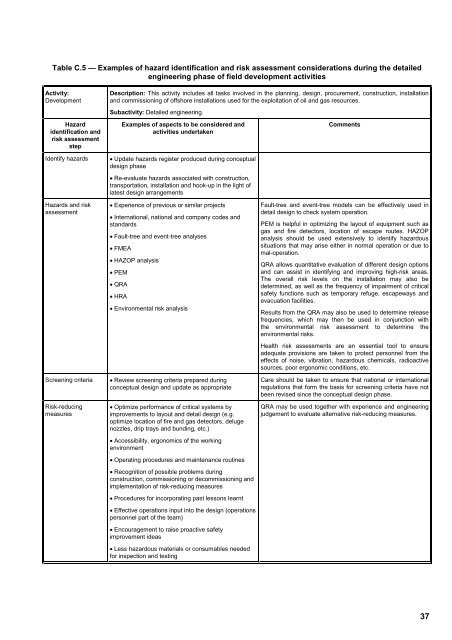

Table C.5 — Examples of hazard identification and risk assessment considerations during the detailed<br />

engineering phase of field development activities<br />

Activity:<br />

Development<br />

Description: This activity includes all tasks involved in the planning, design, procurement, construction, installation<br />

and commissioning of offshore installations used for the exploitation of oil and gas resources.<br />

Subactivity: Detailed engineering.<br />

Hazard<br />

identification and<br />

risk assessment<br />

step<br />

Identify hazards<br />

Hazards and risk<br />

assessment<br />

Screening criteria<br />

Risk-reducing<br />

measures<br />

Examples of aspects to be considered and<br />

activities undertaken<br />

Update hazards register produced during conceptual<br />

design phase<br />

Re-evaluate hazards associated with construction,<br />

transportation, installation and hook-up in the light of<br />

latest design arrangements<br />

Experience of previous or similar projects<br />

International, national and company codes and<br />

standards<br />

Fault-tree and event-tree analyses<br />

FMEA<br />

HAZOP analysis<br />

PEM<br />

QRA<br />

HRA<br />

Environmental risk analysis<br />

Review screening criteria prepared during<br />

conceptual design and update as appropriate<br />

Optimize performance of critical systems by<br />

improvements to layout and detail design (e.g.<br />

optimize location of fire and gas detectors, deluge<br />

nozzles, drip trays and bunding, etc.)<br />

Accessibility, ergonomics of the working<br />

environment<br />

Operating procedures and maintenance routines<br />

Recognition of possible problems during<br />

construction, commissioning or decommissioning and<br />

implementation of risk-reducing measures<br />

Procedures for incorporating past lessons learnt<br />

Effective operations input into the design (operations<br />

personnel part of the team)<br />

Encouragement to raise proactive safety<br />

improvement ideas<br />

Less hazardous materials or consumables needed<br />

for inspection and testing<br />

Comments<br />

Fault-tree and event-tree models can be effectively used in<br />

detail design to check system operation.<br />

PEM is helpful in optimizing the layout of equipment such as<br />

gas and fire detectors, location of escape routes. HAZOP<br />

analysis should be used extensively to identify hazardous<br />

situations that may arise either in normal operation or due to<br />

mal-operation.<br />

QRA allows quantitative evaluation of different design options<br />

and can assist in identifying and improving high-risk areas.<br />

The overall risk levels on the installation may also be<br />

determined, as well as the frequency of impairment of critical<br />

safety functions such as temporary refuge, escapeways and<br />

evacuation facilities.<br />

Results from the QRA may also be used to determine release<br />

frequencies, which may then be used in conjunction with<br />

the environmental risk assessment to determine the<br />

environmental risks.<br />

Health risk assessments are an essential tool to ensure<br />

adequate provisions are taken to protect personnel from the<br />

effects of noise, vibration, hazardous chemicals, radioactive<br />

sources, poor ergonomic conditions, etc.<br />

Care should be taken to ensure that national or international<br />

regulations that form the basis for screening criteria have not<br />

been revised since the conceptual design phase.<br />

QRA may be used together with experience and engineering<br />

judgement to evaluate alternative risk-reducing measures.<br />

37