FUTURE IN POLYURETHANE - EPAQ

FUTURE IN POLYURETHANE - EPAQ

FUTURE IN POLYURETHANE - EPAQ

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

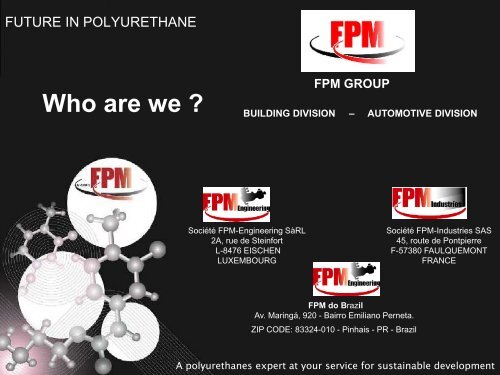

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

FPM GROUP<br />

Who are we <br />

BUILD<strong>IN</strong>G DIVISION – AUTOMOTIVE DIVISION<br />

Société FPM-Engineering SàRL<br />

2A, rue de Steinfort<br />

L-8476 EISCHEN<br />

LUXEMBOURG<br />

FPM<br />

Société FPM-Industries SAS<br />

45, route de Pontpierre<br />

F-57380 FAULQUEMONT<br />

FRANCE<br />

FPM do Brazil<br />

Av. Maringá, 920 - Bairro Emiliano Perneta.<br />

ZIP CODE: 83324-010 - Pinhais - PR - Brazil<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

LUXEMBOURG<br />

FPM<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Where are we <br />

FPM GROUP<br />

Société FPM-Engineering SàRL<br />

2A, rue de Steinfort<br />

L-8476 EISCHEN<br />

lUXEMBOURG<br />

FPM<br />

Société FPM-Industries SAS<br />

45, route de Pontpierre<br />

F-57380 FAULQUEMONT<br />

FRANCE<br />

FPM do Brazil<br />

Av. Maringá, 920 - Bairro Emiliano Perneta.<br />

ZIP CODE: 83324-010 - Pinhais - PR - Brazil<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

FPM<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

FPM-Engineering's mission,<br />

beyond the manufacture of<br />

polyurethanes injection<br />

equipments, special machines, is<br />

to improve and innovate in the<br />

field of polyurethanes with<br />

success.<br />

FPM is composed of<br />

experienced engineers in the<br />

field of polyurethane injection<br />

FPM<br />

and is the source of several<br />

patents<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Developments of<br />

new products<br />

FPM<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Sandwich panel continuous and<br />

discontinuous lines machinery<br />

Partnership<br />

FPM<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Sandwich panel continuous and discontinuous lines machinery<br />

Foaming unit :<br />

Possibility to change the formulation in<br />

continuous<br />

Improvement of the quality and control<br />

of the consumption.<br />

Automatic variation of the flow in<br />

relation with the speed<br />

FPM<br />

Control at all steps of each parameters<br />

from the vital equipments as well as<br />

periferical ones during the process.<br />

optimization to an excellent<br />

mixing of the chemicals

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Partnership<br />

Slabstock line production<br />

machinery<br />

FPM<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Automotive<br />

Building construction<br />

Appliance<br />

Cold room application<br />

FPM<br />

Furniture and house decoration items<br />

Leasure and sports<br />

Aeronautics<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Our experience<br />

of expertise<br />

FPM<br />

Our experience<br />

of advanced<br />

products

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Our experience of<br />

advanced products<br />

FOAM<br />

MATRIX<br />

FPM<br />

BOOSTER<br />

LN 180 V2

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

What purpose of this<br />

equipment <br />

TO OPTA<strong>IN</strong> AN HOMOGENIOUS<br />

STRUCTURE WITH MORE<br />

RESISTANCE<br />

FPM<br />

Pentagonal Dodecaedron

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

What are the conditions of the<br />

foam <br />

The foam :<br />

- Regular<br />

- Homogeneous<br />

-Creamy<br />

FPM<br />

- Covering all the web with a<br />

regular thickness

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

COMPARISON AIR<br />

FOAM SYSTEM AND<br />

FMB NUCLEATOR<br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Standard air system<br />

10 TO 15% OF AIR<br />

BUBBLE SIZE < 500µm<br />

Non miscible<br />

FPM<br />

The bubble will appear<br />

immediately after<br />

distribution from the<br />

gas poker

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

The nucleator<br />

15 TO 65% OF AIR<br />

BUBBLE SIZE < 5µm<br />

The air is miscible into the polyol<br />

FPM<br />

CYCLE OF 5 TO 15 TIMES

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Conclusion :<br />

The elongation, the cutting<br />

and dispersion of the<br />

bubbles allowed to delay<br />

the appearing FPM of the<br />

bubbles after the gel time<br />

and reorganize the cellular<br />

structure of the foam

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

How to reach the working<br />

conditions with our<br />

equipment <br />

The nucleator<br />

Technically, to reach this<br />

effect, you have to add in line<br />

FPM<br />

SPECIAL MIXERS <strong>IN</strong><br />

L<strong>IN</strong>E<br />

=<br />

6 BARS OF LOSS OF<br />

PRESSURE PER<br />

MIXER

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

SOLUTION<br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

BOOSTER LN 180 V2<br />

ITEM<br />

DESCRIPTION<br />

A<br />

Polyol inlet<br />

FPM<br />

B<br />

C<br />

D<br />

E<br />

F<br />

Return of nucleated<br />

product to the motor /<br />

pump dosing unit<br />

Circulation pump<br />

Pressure gauge (low<br />

pressure)<br />

Pressure gauge (of<br />

nucleation)<br />

Manual bleed valve<br />

G<br />

Pressurized air Inlet

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

BOOSTER<br />

LN 180 V2<br />

FPM<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

FPM<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Foam Filling problems of the panels<br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Solution<br />

Booster FPM<br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Problems of non<br />

homogeneous foam <br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Problems of non<br />

homogeneous foam <br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Solution<br />

Booster + mixing<br />

head =<br />

Reactor FPM<br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Problems of non homogeneous Pentane <br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Use of high pressure homogenization system for pentane<br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

FPM

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Solution<br />

Dispergator<br />

FPM<br />

Un expert en polyuréthane à votre service pour un développement durable

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

•Better foam structure<br />

•More productivity<br />

•Reduce non quality foam and panels<br />

production<br />

•Downtime of cleaning sequence<br />

•Friendly operative system<br />

• Reduce density and raw material<br />

consumption<br />

FPM<br />

A polyurethanes expert at your service for sustainable development

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

… and in facts<br />

Raw material saving<br />

FPM<br />

8,65<br />

… improving your productivity

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

How to<br />

procede to get<br />

those results <br />

FPM<br />

Société FPM-Engineering SàRL<br />

2A, rue de Steinfort L-8476 EISCHEN<br />

Tél. 00352263922 Fax. 0035226392239<br />

www.fpm.lu<br />

fpm@fpm.lu

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Step 1 - One Week<br />

Follow up of production<br />

FPM<br />

Follow up the waist<br />

Check the line performance

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Check the line performance<br />

- Recirculation Polyol <br />

- Additives in high pressure <br />

- Type of coupling <br />

- Type of high pressure pump <br />

- High pressure heat exchanger <br />

- Pressure of feeding <br />

-Type of cooling FPMcontrol<br />

- Temperature Conveyor <br />

- Temperature steel web top and<br />

bottom <br />

-

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Step 2 - Two weeks<br />

Training of the operators and trails on different<br />

thickness<br />

Modification of the line<br />

FPM<br />

Start up of the nucleator<br />

and establish a procedure

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Step 3<br />

Two month<br />

Improve the<br />

production<br />

and save 5%<br />

raw material<br />

consumption<br />

3 visits on site<br />

FPM<br />

Special technical<br />

support on tel line

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

Step 4 -<br />

Twelve<br />

month<br />

Final<br />

optimization<br />

of the line<br />

For 10 millions<br />

euros raw material<br />

consumption, 1%<br />

saving =<br />

100.000,00 per year<br />

FPM<br />

Improvement of<br />

productivity, quality<br />

by other new<br />

products

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

FPM<br />

Société FPM-Engineering SàRL<br />

2A, rue de Steinfort L-8476 EISCHEN<br />

Tél. 00352263922 Fax. 0035226392239<br />

www.fpm.lu<br />

fpm@fpm.lu

<strong>FUTURE</strong> <strong>IN</strong> <strong>POLYURETHANE</strong><br />

A polyurethanes expert at your service<br />

for sustainable development<br />

FPM<br />

Société FPM-Engineering SàRL<br />

2A, rue de Steinfort L-8476 EISCHEN<br />

Tél. 00352263922 Fax. 0035226392239<br />

www.fpm.lu<br />

fpm@fpm.lu

BON APPETIT !!!<br />

FPM<br />

Société FPM-Engineering SàRL<br />

2A, rue de Steinfort L-8476 EISCHEN<br />

Tél. 00352263922 Fax. 0035226392239<br />

www.fpm.lu<br />

fpm@fpm.lu