Wafer Level Reliability Testing

Wafer Level Reliability Testing

Wafer Level Reliability Testing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Flip Chip Bonders<br />

Substrate Bonders<br />

Spin Coaters<br />

Mask Aligners<br />

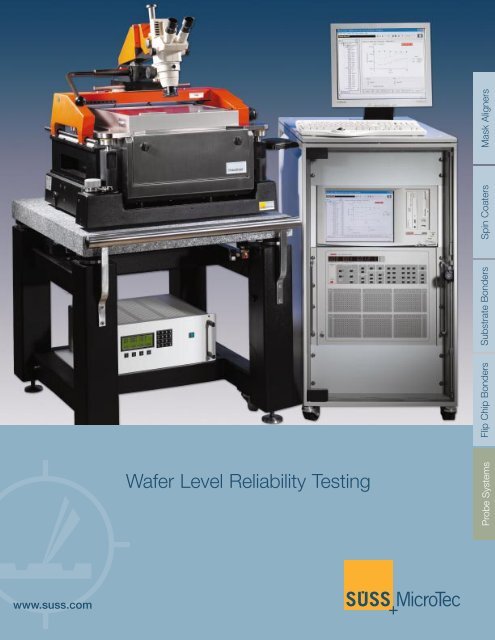

<strong>Wafer</strong> <strong>Level</strong> <strong>Reliability</strong> <strong>Testing</strong><br />

Probe Systems<br />

www.suss.com

The Celadon 220 mm Probecard tile<br />

Celadon uses the inherent benefits of ceramic –<br />

high resisivity and low noise to make ideal low leakage<br />

probe cards for reliability testing. The Celadon<br />

Ceramic Tile TM which anchors the probe needles<br />

in place is mounted mounted on a rigid aluminum<br />

chassis which can be configured with several<br />

different connector housings depending on the<br />

test requirements. The large 220mm tiles used in<br />

this application are designed to provide total wafer<br />

coverage, enabling probe placement anywhere on<br />

the wafer.<br />

whole wafer. This movement has been especially<br />

designed with user comfort in mind and has the<br />

control knobs ergonomically placed on the righthand<br />

side of the prober so that one-handed use is<br />

possible. Single chip stepping is accurately undertaken<br />

with a high resolution chuck stage.<br />

The Keithley 4200 Semiconductor<br />

Characterization System<br />

The Celadon tiles and chassis have been designed<br />

to operate consistently for thousands of hours at<br />

300°C with no deterioration in electrical performance.<br />

The rigid ceramic prevents any flex or movement<br />

with empirical evidence indicating little or no observable<br />

movement in the probes during use. High<br />

current and high voltage probes are also available.<br />

The SUSS PM8WLR ProbeShield<br />

The PM8WLR ProbeShield is a light-tight, EMI<br />

shielded probe system which has been especially<br />

designed with the demands of wafer level reliability in<br />

mind. The prober contains a thermal chuck which has<br />

a temperature range from – 60°C to + 300°C and the<br />

ProbeShield's rinsing system ensures frost-free<br />

conditions when probing at sub-zero temperatures.<br />

The Model 4200-SCS provides a total system<br />

solution for DC characterization and stress-measure/<br />

reliability testing of semiconductor devices and test<br />

structures. This advanced parameter analyzer<br />

provides intuitive and sophisticated capabilities for<br />

semiconductor device characterization. The 4200-<br />

SCS combines unprecedented measurement<br />

speed and accuracy with an embedded Windows<br />

NT- or XP based PC and the Keithley Interactive<br />

Test Environment (KITE) to provide a powerful singlebox<br />

solution.<br />

Modular and configurable, the Model 4200-SCS<br />

supports up to eight Source-Measure Units,<br />

including up to four high power SMUs with 1A/20W<br />

capability. An optional Remote PreAmp extends the<br />

resolution of any Source-Measure Unit from 100fA<br />

to 0.1fA.<br />

Probe Systems<br />

Because the probe card contacts all dies simultaneously,<br />

the microscope and not the chuck must<br />

move to perform correct probe to pad alignment.<br />

This PM8 has a special microscope stage which<br />

can move 200 mm in both X & Y to cover the

A Unique Multi-site, <strong>Wafer</strong> <strong>Level</strong> Solution for <strong>Reliability</strong> <strong>Testing</strong><br />

The demands of today’s technologies require<br />

precise and economical characterization. Until now,<br />

long-term testing of wafers took a great deal of both<br />

time and money as devices had to be packaged<br />

before testing. Recent innovations in thinner oxides<br />

and gate dielectrics makes packaging devices<br />

without damaging them difficult.<br />

Developed to meet the critical needs of 90 nm or<br />

smaller process technologies used by semiconductor<br />

manufacturers, the SUSS PM8WLR Probe-<br />

Shield system, in combination with Celadon probe<br />

cards and Keithley measurement equipment, provides<br />

long-term process reliability at temperatures up<br />

to 300°C.<br />

In order to prevent the loss of processed and therefore<br />

expensive wafers, it has become essential to<br />

be able to perform reliability tests on the wafer itself.<br />

The importance of this test option will grow in the<br />

near future as process technologies move towards<br />

the 90 nm range. Multi-site probing speeds up the<br />

process and enables the test engineer to obtain<br />

reasonable sample sizes. The need to measure and<br />

characterize now demands low leakage measurement<br />

equipment which can withstand temperatures<br />

up to and exceeding 300°C which accelerates<br />

failure mechanisms.<br />

The SUSS PM8WLR ProbeShield ® system has been<br />

especially developed for extremely accurate, hightemperature,<br />

multi-site <strong>Wafer</strong> <strong>Level</strong> <strong>Reliability</strong> (WLR)<br />

measurements, such as:<br />

● Electro-migration<br />

● TDDB<br />

● Hot carrier<br />

● <strong>Wafer</strong> level burn-in<br />

● Life test<br />

● Device characterization<br />

Features and Benefits<br />

• Light-tight and EMI shielded environment for<br />

ultra low-signal measurements<br />

• Rinsing system for a frost-free environment<br />

down to –60°C<br />

• Celadon’s 220 mm round probe cards provide<br />

total coverage for 150 mm & 200 mm wafers<br />

• Feed-through’s for 14 x 25 triaxial low-leakage<br />

cable harnesses: max. 350 different electrical<br />

signals<br />

• 50 x 50 mm X-Y high resolution chuck stage<br />

for one chip stepping<br />

• Extremely rigid and stable Z-chuck axis for<br />

high temperature and long time testing with<br />

high pin count probe cards<br />

• 200 x 200 mm X-Y ergonomic microscope<br />

movement with one handed operation<br />

• Ergonomic wafer load/unload via a pull-out<br />

chuck system

<strong>Wafer</strong> <strong>Level</strong> <strong>Reliability</strong><br />

<strong>Testing</strong> vs. Packaged<br />

Part <strong>Testing</strong><br />

<br />

Saving both time and money<br />

A simple application example can show the<br />

savings that can be gained from multi-site<br />

testing at wafer level. This example examines<br />

the time factor in TDDB testing<br />

Packaged Die: Time 300 hours<br />

Because a packaged part tester is noisy in<br />

itself, the engineer must wait for the leakage<br />

values to significantly increase above the<br />

machine's noise floor before he can be confident<br />

of accurate results.<br />

<strong>Wafer</strong> <strong>Level</strong> <strong>Testing</strong>: Time 12 Hours<br />

The much lower noise floor of the parametric<br />

analyzer, analytical probe station, and probe<br />

card allowed the customer to see precise<br />

leakage trends in an "over-night” test.<br />

Both packaged and wafer level tests were run at the<br />

same temperature and electrical stress levels.<br />

<br />

Microscope & mount provide necessary<br />

long working distance<br />

Customized Celadon 220 mm round<br />

high-temperature probe card<br />

<br />

Customized thermal chuck<br />

Temp. range: -60°C to + 300°C<br />

50 x 50 mm X - Y high resolution chuck<br />

stage with extremely stable Z-chuck axis<br />

SUSS ProbeShield EMC:<br />

Light-tight, frost-free probing in an EMI<br />

shielded environment<br />

200 x 200 mm X-Y one-handed microscope<br />

travel incl. fast and fine movement

Keithley 4200:<br />

Advanced Parameter Analyzer with<br />

point and click Window's ® based<br />

functionality<br />

Probe Systems<br />

Special remote adjustment and levelling<br />

tool for the Celadon Probecard

ASIA<br />

SUSS MicroTec KK (Japan)<br />

GITC 1-18-2, Hakusan, Midori-ku<br />

Yokohama, Kanagawa, Japan 226-0006<br />

Phone (+81)-45-9 31-56 00<br />

Fax (+81)-45-931-56 01<br />

EUROPE<br />

SUSS MicroTec S.A.S.<br />

131, impasse Bartheudet · BP24<br />

F-74490 Saint Jeoire · France<br />

Phone (+33)-(0) 4 50 35 83 92<br />

Fax (+33)-(0) 4 50 35 88 01<br />

JZ/DD · 04/2004<br />

SUSS MicroTec (Shanghai) Co., Ltd.<br />

580 Nanjing W. Rd · Nanzheng Building Room 606<br />

200041 Shanghai · PRC<br />

Phone (+86) 21-52 34 04 32<br />

Fax (+86) 21-52 34 04 30<br />

SUSS MicroTec (Taiwan) Co., Ltd.<br />

8F-11 · No. 81 · Shui-Lee Road<br />

Hsin-Chu · 300 · Taiwan<br />

Phone (+886)-(3)-5 16 90 98<br />

Fax (+886)-(3)-5 16 92 62<br />

SUSS MicroTec Co., Ltd.<br />

(South and Southeast Asia)<br />

3388/92-93 · 25th Floor · Sirinrat Building<br />

Rama IV Road · Klongtoey<br />

Bangkok 10110 · Thailand<br />

Phone (+66)-(0)-23 50 60 38<br />

Fax (+66)-(0)-26 33 57 28<br />

SUSS MicroTec Test Systems GmbH<br />

Süss-Strasse 1 · D-01561 Sacka/Dresden<br />

Germany<br />

Phone (+49)-(0) 35240-73-0<br />

Fax (+49)-(0) 35240-73-700<br />

NORTH AMERICA<br />

SUSS MicroTec Inc.<br />

228 Suss Drive<br />

Waterbury Center, VT 05677 · USA<br />

Phone (+1) (802) 244-5181<br />

Fax (+1) (802) 244-7853<br />

SUSS MicroTec Inc.<br />

Western Regional Sales Office<br />

8240 So. Kyrene Road Suite 101<br />

Tempe, AZ 85284-2117 · USA<br />

Phone (+1) (480) 557-9370<br />

Fax (+1) (480) 557-9371<br />

PM8WLR · DE · 04/2004 · #1 · 2000<br />

www.suss.com<br />

SUSS WLR Test Partners featured in Brochure:<br />

www.celadonsystems.com<br />

www.keithley.com