Separations Technology in Petroleum Refining - Pall Corporation

Separations Technology in Petroleum Refining - Pall Corporation

Separations Technology in Petroleum Refining - Pall Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

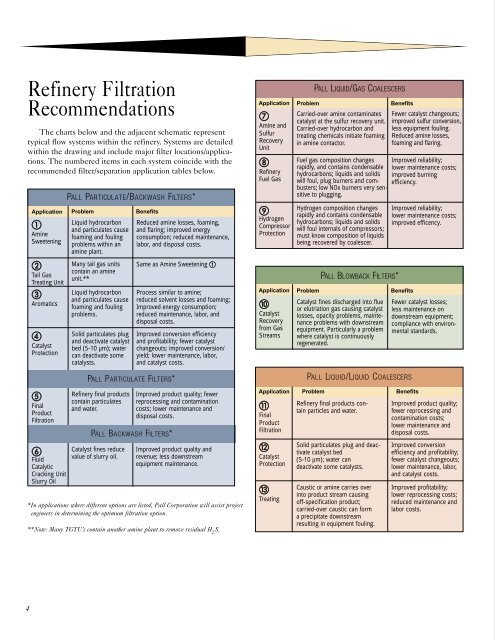

Ref<strong>in</strong>ery Filtration<br />

Recommendations<br />

The charts below and the adjacent schematic represent<br />

typical flow systems with<strong>in</strong> the ref<strong>in</strong>ery. Systems are detailed<br />

with<strong>in</strong> the draw<strong>in</strong>g and <strong>in</strong>clude major filter locations/applications.<br />

The numbered items <strong>in</strong> each system co<strong>in</strong>cide with the<br />

recommended filter/separation application tables below.<br />

Application<br />

a<br />

Am<strong>in</strong>e<br />

Sweeten<strong>in</strong>g<br />

b<br />

Tail Gas<br />

Treat<strong>in</strong>g Unit<br />

c<br />

Aromatics<br />

d<br />

Catalyst<br />

Protection<br />

PALL PARTICULATE/BACKWASH FILTERS*<br />

Problem<br />

Liquid hydrocarbon<br />

and particulates cause<br />

foam<strong>in</strong>g and foul<strong>in</strong>g<br />

problems with<strong>in</strong> an<br />

am<strong>in</strong>e plant.<br />

Many tail gas units<br />

conta<strong>in</strong> an am<strong>in</strong>e<br />

unit.**<br />

Liquid hydrocarbon<br />

and particulates cause<br />

foam<strong>in</strong>g and foul<strong>in</strong>g<br />

problems.<br />

Solid particulates plug<br />

and deactivate catalyst<br />

bed (5-10 µm); water<br />

can deactivate some<br />

catalysts.<br />

Benefits<br />

PALL PARTICULATE FILTERS*<br />

Reduced am<strong>in</strong>e losses, foam<strong>in</strong>g,<br />

and flar<strong>in</strong>g; improved energy<br />

consumption; reduced ma<strong>in</strong>tenance,<br />

labor, and disposal costs.<br />

Same as Am<strong>in</strong>e Sweeten<strong>in</strong>g a<br />

Process similar to am<strong>in</strong>e;<br />

reduced solvent losses and foam<strong>in</strong>g;<br />

Improved energy consumption;<br />

reduced ma<strong>in</strong>tenance, labor, and<br />

disposal costs.<br />

Improved conversion efficiency<br />

and profitability; fewer catalyst<br />

changeouts; improved conversion/<br />

yield; lower ma<strong>in</strong>tenance, labor,<br />

and catalyst costs.<br />

Application<br />

g<br />

Am<strong>in</strong>e and<br />

Sulfur<br />

Recovery<br />

Unit<br />

h<br />

Ref<strong>in</strong>ery<br />

Fuel Gas<br />

i<br />

Hydrogen<br />

Compressor<br />

Protection<br />

Application<br />

j<br />

Catalyst<br />

Recovery<br />

from Gas<br />

Streams<br />

PALL LIQUID/GAS COALESCERS<br />

Problem Benefits<br />

Carried-over am<strong>in</strong>e contam<strong>in</strong>ates<br />

catalyst at the sulfur recovery unit.<br />

Carried-over hydrocarbon and<br />

treat<strong>in</strong>g chemicals <strong>in</strong>itiate foam<strong>in</strong>g<br />

<strong>in</strong> am<strong>in</strong>e contactor.<br />

Fuel gas composition changes<br />

rapidly, and conta<strong>in</strong>s condensable<br />

hydrocarbons; liquids and solids<br />

will foul, plug burners and combusters;<br />

low NOx burners very sensitive<br />

to plugg<strong>in</strong>g.<br />

Hydrogen composition changes<br />

rapidly and conta<strong>in</strong>s condensable<br />

hydrocarbons; liquids and solids<br />

will foul <strong>in</strong>ternals of compressors;<br />

must know composition of liquids<br />

be<strong>in</strong>g recovered by coalescer.<br />

PALL BLOWBACK FILTERS*<br />

Problem Benefits<br />

Catalyst f<strong>in</strong>es discharged <strong>in</strong>to flue<br />

or elutriation gas caus<strong>in</strong>g catalyst<br />

losses, opacity problems, ma<strong>in</strong>tenance<br />

problems with downstream<br />

equipment. Particularly a problem<br />

where catalyst is cont<strong>in</strong>uously<br />

regenerated.<br />

PALL LIQUID/LIQUID COALESCERS<br />

Fewer catalyst changeouts;<br />

improved sulfur conversion,<br />

less equipment foul<strong>in</strong>g.<br />

Reduced am<strong>in</strong>e losses,<br />

foam<strong>in</strong>g and flar<strong>in</strong>g.<br />

Improved reliability;<br />

lower ma<strong>in</strong>tenance costs;<br />

improved burn<strong>in</strong>g<br />

efficiency.<br />

Improved reliability;<br />

lower ma<strong>in</strong>tenance costs;<br />

improved efficency.<br />

Fewer catalyst losses;<br />

less ma<strong>in</strong>tenance on<br />

downstream equipment;<br />

compliance with environmental<br />

standards.<br />

e<br />

F<strong>in</strong>al<br />

Product<br />

Filtration<br />

f<br />

Fluid<br />

Catalytic<br />

Crack<strong>in</strong>g Unit<br />

Slurry Oil<br />

Ref<strong>in</strong>ery f<strong>in</strong>al products<br />

conta<strong>in</strong> particulates<br />

and water.<br />

PALL BACKWASH FILTERS*<br />

Catalyst f<strong>in</strong>es reduce<br />

value of slurry oil.<br />

Improved product quality; fewer<br />

reprocess<strong>in</strong>g and contam<strong>in</strong>ation<br />

costs; lower ma<strong>in</strong>tenance and<br />

disposal costs.<br />

Improved product quality and<br />

revenue; less downstream<br />

equipment ma<strong>in</strong>tenance.<br />

*In applications where different options are listed, <strong>Pall</strong> <strong>Corporation</strong> will assist project<br />

eng<strong>in</strong>eers <strong>in</strong> determ<strong>in</strong><strong>in</strong>g the optimum filtration option.<br />

**Note: Many TGTU’s conta<strong>in</strong> another am<strong>in</strong>e plant to remove residual H 2 S.<br />

Application<br />

k<br />

F<strong>in</strong>al<br />

Product<br />

Filtration<br />

l<br />

Catalyst<br />

Protection<br />

m<br />

Treat<strong>in</strong>g<br />

Problem Benefits<br />

Ref<strong>in</strong>ery f<strong>in</strong>al products conta<strong>in</strong><br />

particles and water.<br />

Solid particulates plug and deactivate<br />

catalyst bed<br />

(5-10 µm); water can<br />

deactivate some catalysts.<br />

Caustic or am<strong>in</strong>e carries over<br />

<strong>in</strong>to product stream caus<strong>in</strong>g<br />

off-specification product;<br />

carried-over caustic can form<br />

a precipitate downstream<br />

result<strong>in</strong>g <strong>in</strong> equipment foul<strong>in</strong>g.<br />

Improved product quality;<br />

fewer reprocess<strong>in</strong>g and<br />

contam<strong>in</strong>ation costs;<br />

lower ma<strong>in</strong>tenance and<br />

disposal costs.<br />

Improved conversion<br />

efficiency and profitability;<br />

fewer catalyst changeouts;<br />

lower ma<strong>in</strong>tenance, labor,<br />

and catalyst costs.<br />

Improved profitability;<br />

lower reprocess<strong>in</strong>g costs;<br />

reduced ma<strong>in</strong>tenance and<br />

labor costs.<br />

4