ROMER CIMCORE PRODUCT DATA SHEET

ROMER CIMCORE PRODUCT DATA SHEET

ROMER CIMCORE PRODUCT DATA SHEET

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ROMER</strong> Inc.<br />

27240 Haggerty Road. Suite E-20<br />

Farmington Hills, Mi. 48331 USA<br />

Phone 800-218-7125<br />

GridLOK Extended Referencing System<br />

Data Sheet<br />

July 13, 2001<br />

Page 1 of 8

<strong>ROMER</strong> Inc.<br />

27240 Haggerty Road. Suite E-20<br />

Farmington Hills, Mi. 48331 USA<br />

Phone 800-218-7125<br />

<strong>PRODUCT</strong> DESCRIPTION<br />

General<br />

The patent pending GridLOK extended referencing system is a versatile locating system<br />

based upon the positioning of conical seats installed in a concrete floor or in an optional<br />

steel plate. Each of the conical seats is permanently flush mounted and valued by a laser<br />

tracker.<br />

The system’s software utilizes mathematical algorithms to recognize which<br />

locations have been probed in order to automatically perform a reference into the grid’s<br />

coordinate system. There is no need to input any positional or X, Y & Z data while<br />

referencing or relocating.<br />

This system is much more accurate than the leapfrog method since all point locations<br />

are known and there is no accumulative error when relocating within the measurement<br />

volume.<br />

Page 2 of 8

<strong>ROMER</strong> Inc.<br />

27240 Haggerty Road. Suite E-20<br />

Farmington Hills, Mi. 48331 USA<br />

Phone 800-218-7125<br />

Any <strong>ROMER</strong> arm(s) can be used with the GridLOK system without any mechanical<br />

or electrical modifications. The GridLOK system allows the user to easily move<br />

around the measuring volume and take measurements inside or out of a vehicle or<br />

assembly.<br />

GridLOK System Components<br />

1. Portable arm support stand with laptop holder<br />

2. GridLOK Positioning Software<br />

3. Grid system, installed by <strong>ROMER</strong> technicians in concrete slab (or optional steel plate)<br />

Concrete Slab Floor - conical seats are installed into a single concrete pad in a<br />

predetermined grid pattern. Conical seats are permanently flush mounted to the<br />

pad. Each conical seat comes with a removable protective cover.<br />

The size of the measuring area is determined by the customer’s specific measuring<br />

requirements.<br />

Steel Plate Option - conical seats are machined into a steel plate of sufficient size<br />

and strength to support the item(s) being inspected. The steel plate is then installed<br />

at the inspection site.<br />

The size of the measuring area is determined by the customer’s specific measuring<br />

requirements. NOTE: Steel plate sold separately.<br />

Page 3 of 8

<strong>ROMER</strong> Inc.<br />

27240 Haggerty Road. Suite E-20<br />

Farmington Hills, Mi. 48331 USA<br />

Phone 800-218-7125<br />

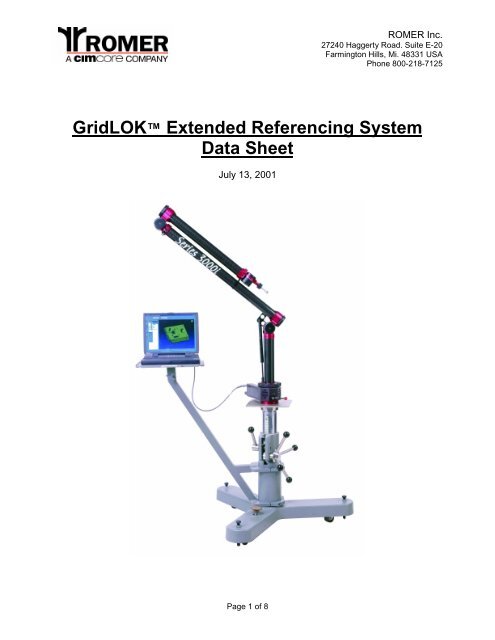

Mobile Arm Stand with Laptop Support<br />

This portable cast iron rolling post stand provides<br />

solid support for the <strong>ROMER</strong> arm with the added<br />

capability of easy transport around the<br />

measuring volume of the GridLOK System. A<br />

laptop tray is included with the mobile arm stand<br />

to support the system’s laptop computer.<br />

The stand includes a universal mounting plate<br />

designed to support all varieties of <strong>ROMER</strong> arm<br />

mounting systems including a magnetic base.<br />

The stand's three 2-inch casters with rubber tires<br />

can be retracted into the base by a foot pedal. A<br />

seamless steel tube with clamping collar and<br />

braces from the base provide additional rigidity<br />

ensure stability. The height of the stand is from<br />

23" (fully retracted) to 39" (fully extended). The<br />

stand weighs 200 lbs.<br />

Floor Based Grid System<br />

Either a single concrete slab or an optional steel plate can be used to set up the grid<br />

system. Once the desired measuring volume has been determined, the appropriate<br />

number and position of target points will be laid out on the concrete slab or steel plate.<br />

Page 4 of 8

<strong>ROMER</strong> Inc.<br />

27240 Haggerty Road. Suite E-20<br />

Farmington Hills, Mi. 48331 USA<br />

Phone 800-218-7125<br />

Conical seats, which act as targets, are then permanently installed to the slab.<br />

After the conical seats have been installed, a laser tracker is used to establish the target<br />

positions and provide a master data list that will be used to load the site map for the grid<br />

reference coordinate system.<br />

There are no electrical, mechanical or moving parts associated with the grid system;<br />

therefore there will be essentially no system downtime or required maintenance.<br />

GridLOK Positioning Software with Grid Referencing Ability<br />

All referencing is performed with <strong>ROMER</strong>’s GridLOK Positioning Software. No additional<br />

software is required and no lengthy or confusing external programs must be run to<br />

complete the grid reference. A straightforward user interface ensures no additional<br />

training when performing a grid coordinate reference.<br />

General<br />

<strong>PRODUCT</strong> DETAILED SPECIFICATIONS<br />

Standard Measuring Ranges:<br />

X: 13' (4 Meters)<br />

Y: 20' (6 Meters)<br />

Z: dependant on arm size<br />

Additional System Measuring Volumes are Customer defined and available upon request.<br />

Principal Referencing Mode:<br />

Reference Speed:<br />

Principal Modes of Operation:<br />

Automatic, software driven<br />

20 Seconds<br />

Manual, measure three points<br />

Page 5 of 8

<strong>ROMER</strong> Inc.<br />

27240 Haggerty Road. Suite E-20<br />

Farmington Hills, Mi. 48331 USA<br />

Phone 800-218-7125<br />

Location of Coordinate System Origin:<br />

Customer defined grid system<br />

Environmental<br />

NOTE: Environmental concerns are connected with the arm component of the system.<br />

Nominal Mean Temperature:<br />

Significant Mean Temperature<br />

Change (per hour):<br />

Recommended Operating Temperature<br />

Range:<br />

Air Humidity:<br />

68º F<br />

± 3.5º F<br />

68º F ± 10º F<br />

10% to 90% non-condensing<br />

Vibration:<br />

Broad Band Data<br />

Peak-to-Peak Vibration Amplitude:<br />

Frequency:<br />

0.00005” maximum<br />

Over all frequency ranges<br />

Temperature Gradients:<br />

Vertical:<br />

Horizontal:<br />

Mean air flow speed surrounding the machine:<br />

0.2º F / ft<br />

0.2º F / ft<br />

< 5 ft / min.<br />

Electrical (Arm Component)<br />

Voltage:<br />

Current:<br />

Frequency:<br />

110 V – 220 V<br />

20 A<br />

50 Hz. to 60 Hz.<br />

Surge / sag: 100V – 240 V (± 10%)<br />

Maximum Permissible Voltage Peaks:<br />

(Duration between 1µs and 100 µs)<br />

250 Vp<br />

Site Requirements<br />

Lighting:<br />

Standard shop lighting<br />

Page 6 of 8

<strong>ROMER</strong> Inc.<br />

27240 Haggerty Road. Suite E-20<br />

Farmington Hills, Mi. 48331 USA<br />

Phone 800-218-7125<br />

Flooring:<br />

Concrete Floor Thickness:<br />

Surface Finish:<br />

Flatness: maximum rate of change in slope<br />

Single concrete slab<br />

(Steel Reinforced)<br />

4" thick minimum throughout<br />

Sealed surface<br />

< 1/8" / ft<br />

NOTE: Detailed site requirements & preparation specifications will be supplied<br />

to customer after receipt of order.<br />

Volumetric Performance<br />

Operation Mode:<br />

Manual<br />

Nominal System Evaluation Location: X: 6.5' (2 m)<br />

Y: 10' (3 m)<br />

Z: 40” (1015 mm)<br />

GridLOK System Accuracy: specific arm accuracy plus ± .006”,<br />

volumetric error<br />

Page 7 of 8

<strong>ROMER</strong> Inc.<br />

27240 Haggerty Road. Suite E-20<br />

Farmington Hills, Mi. 48331 USA<br />

Phone 800-218-7125<br />

WARRANTY INFORMATION<br />

Standard GridLOK Warranty Plan<br />

With every GridLOK installation, <strong>ROMER</strong> provides a 1-year warranty that<br />

covers;<br />

1. Manufacturing defects of the conical seats.<br />

2. The installation of the conical seats.<br />

The integrity of the concrete slab is the responsibility of the customer.<br />

Standard Arm Warranty Plan<br />

With every portable arm, <strong>ROMER</strong> provides a 1-year warranty that covers;<br />

1. Repair of manufacturing defects on the following components: arm, encoders, encoder board,<br />

cables, interpolator boards, cabling to arm, probe plugs and switches.<br />

2. Software updates for the first 12 months from the date of purchase.<br />

3. Unlimited telephone technical support during the warranty period.<br />

4. Under normal usage, the carbon graphite tubes have a lifetime warranty.<br />

5. Customer assumes all shipping costs.<br />

Extended Arm Warranty Plan<br />

<strong>ROMER</strong>’s Extended Arm Warranty Plan expands the Standard Arm Warranty<br />

listed above by adding:<br />

1. <strong>ROMER</strong> will provide a replacement arm within 5 working days upon receipt of the defective<br />

arm (replacement arm configuration and length may vary).<br />

2. Customer is entitled to 1 re-calibration during each year of the warranty period (no carryover).<br />

3. Customer will receive free software updates during each year of the warranty.<br />

This program is only offered in the continental USA.<br />

Page 8 of 8