Prime Design Rotation Rack Product Sheet - Stonebrooke Equipment

Prime Design Rotation Rack Product Sheet - Stonebrooke Equipment

Prime Design Rotation Rack Product Sheet - Stonebrooke Equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

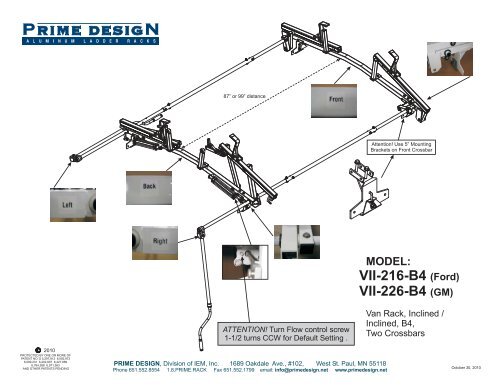

87” or 99” distance<br />

Attention! Use 5” Mounting<br />

Brackets on Front Crossbar<br />

MODEL:<br />

VII-216-B4<br />

VII-226-B4<br />

(Ford)<br />

(GM)<br />

ATTENTION! Turn Flow control screw<br />

1-1/2 turns CCW for Default Setting .<br />

Van <strong>Rack</strong>, Inclined /<br />

Inclined, B4,<br />

Two Crossbars<br />

2010<br />

PROTECTED BY ONE OR MORE OF<br />

PATENT NO.’S 5,297,912 6,092,972<br />

6,099,231 6,202,807 6,427,889<br />

6,764,268 6,971,563<br />

AND OTHER PATENTS PENDING<br />

PRIME DESIGN, Division of IEM, Inc. 1689 Oakdale Ave., #102, West St. Paul, MN 55118<br />

Phone 651.552.8554 1.8.PRIME.RACK Fax 651.552.1799 email: info@primedesign.net www.primedesign.net<br />

October 30, 2010

Attention! Use 5” Mounting<br />

Brackets on Front Crossbar<br />

MODEL:<br />

VII-216-B4<br />

VII-226-B4<br />

(Ford)<br />

(GM)<br />

Attention! Use 4.5” Mounting<br />

Brackets on Rear Crossbar<br />

Van <strong>Rack</strong>, Inclined /<br />

Inclined, B4,<br />

Two Crossbars<br />

2010<br />

PROTECTED BY ONE OR MORE OF<br />

PATENT NO.’S 5,297,912 6,092,972<br />

6,099,231 6,202,807 6,427,889<br />

6,764,268 6,971,563<br />

AND OTHER PATENTS PENDING<br />

PRIME DESIGN, Division of IEM, Inc. 1689 Oakdale Ave., #102, West St. Paul, MN 55118<br />

Phone 651.552.8554 1.8.PRIME.RACK Fax 651.552.1799 email: info@primedesign.net www.primedesign.net

VII-226-B4<br />

1. Follow the Inclined Assembly Instructions to assemble the rack as shown on the right.<br />

2. Use the High (5”) Mounting Bracket for the front right as shown in the opposite page.<br />

3. Place Ladder <strong>Rack</strong> on the van. Mounting Brackets in the Drip Rails. Rear Crossbar<br />

Mounting Brackets need to be centered to the Drip Rail connecting plate (about 16”<br />

from rear Drip Rail to Crossbar, see drawing below).<br />

4. Place 4” Vinyl Tubes onto the Drip Rail, as shown in the illustration below (shown<br />

with Z Plate removed for illustration only).<br />

5. Snug 5/16” nuts on Mounting Bracket Assemblies.<br />

6. Tighten 1/4” Bent Bolts to pull Mounting Bracket secured into the Drip Rail.<br />

7. Tighten 5/16” nuts to hold Z Plate firm against the Drip Rail.<br />

Rear Crossbar<br />

Inclined <strong>Rotation</strong><br />

Assembly<br />

Front Crossbar<br />

Inclined <strong>Rotation</strong><br />

Assembly<br />

Mounting Bracket<br />

Vinyl Tube.<br />

Apply to Drip Rail<br />

Approximately 16”<br />

87” or 99”<br />

1/4” Bent<br />

Bolt<br />

“Z Plate”<br />

5/16 x 1.5”<br />

Bolt<br />

2010<br />

PROTECTED BY ONE OR MORE OF<br />

PATENT NO.’S 5,297,912 6,092,972<br />

6,099,231 6,202,807 6,427,889<br />

6,764,268 6,971,563<br />

AND OTHER PATENTS PENDING