DMN_34-523 - Distribution Technology Home - Eskom

DMN_34-523 - Distribution Technology Home - Eskom

DMN_34-523 - Distribution Technology Home - Eskom

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Task Manual<br />

Group <strong>Technology</strong><br />

Title:<br />

ISOLATOR: KARG, LEL AND<br />

SPEEDCRAFT<br />

TYPE: SINGLE PHASE CUT-<br />

OUT<br />

RATING: 11kV-22kV; 400A-<br />

1600A<br />

MODE OF OPERATION:<br />

HAND OPERATED<br />

Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

Part<br />

11 - Maintenance<br />

Area of Applicability: <strong>Distribution</strong> Engineering<br />

Documentation Type:<br />

Task Manual<br />

Revision: 1<br />

Total Pages: 19<br />

Next Review Date: January 2022<br />

Disclosure Classification:<br />

Controlled Disclosure<br />

Compiled by<br />

Approved by (SCOWT SC Chairperson)<br />

Kevin Layley<br />

Advisor<br />

Ajith Persadh<br />

Senior Advisor<br />

Date: 21/11/2011 Date: 21/11/2011<br />

Functional Responsibility<br />

Authorized by<br />

Colin Smith<br />

DTEP Manager<br />

Prince Moyo<br />

Power Delivery Engineering GM (Acting)<br />

Date: 28/11/2011 Date: 18/12/2011<br />

B Morrison / January 2012 / Rev 1<br />

ESKOM COPYRIGHT PROTECTED

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 2 of 19<br />

Content<br />

Foreword ........................................................................................................................................................ 3<br />

Introduction .................................................................................................................................................... 5<br />

1 Scope .................................................................................................................................................. 5<br />

1.1 Purpose ....................................................................................................................................... 5<br />

1.2 Applicability .................................................................................................................................. 5<br />

1.3 Roles and Responsibilities .......................................................................................................... 5<br />

2 Normative / Informative references ..................................................................................................... 6<br />

2.1 Normative .................................................................................................................................... 6<br />

2.2 Informative ................................................................................................................................... 6<br />

3 Definitions and abbreviations .............................................................................................................. 6<br />

3.1 Definitions .................................................................................................................................... 6<br />

3.2 Abbreviations ............................................................................................................................... 7<br />

4 Requirements ...................................................................................................................................... 7<br />

4.1 First and Second Line Maintenance ............................................................................................ 7<br />

4.2 Specialist maintenance ................................................................................................................ 7<br />

4.3 Modification ................................................................................................................................ 14<br />

5 Testing ............................................................................................................................................... 14<br />

6 Related/Supporting Documents ........................................................................................................ 14<br />

6.1 Related Documents ................................................................................................................... 14<br />

6.2 Forms and Records ................................................................................................................... 14<br />

7 Spares ............................................................................................................................................... 14<br />

Annex A - Isolator Maintenance Checksheet .............................................................................................. 15<br />

Annex B - Impact assessment ..................................................................................................................... 16<br />

Page<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 3 of 19<br />

Foreword<br />

This task manual was compiled to conform or align with NRS 082, NRS 090 and NRS 090-1-1 in ensuring<br />

that equipment in our network are maintained.<br />

KARG, LEL AND SPEEDCRAFT ISOLATORS<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 4 of 19<br />

Revision History<br />

This revision cancels and replaces revision no 0 of document no. DWN_<strong>34</strong>-<strong>523</strong><br />

Date Rev. Clause Remarks<br />

Jan 2012 1 - Compiled By: KC Layley<br />

-<br />

Reformat only. No content change.<br />

Document number changed to <strong>DMN</strong>_<strong>34</strong>-<strong>523</strong><br />

Jan 2008 0<br />

Compiled By: DM Ntombela<br />

The template / format and ref. number changed;<br />

Revision date<br />

• Normative references updated;<br />

2, 3 • Definitions and abbreviation updated;<br />

• Re-numbered all the titles and added more information;<br />

• Included Revision History information;<br />

• Included impact assessment form; and<br />

• Reference number changed to DWN <strong>34</strong>-<strong>523</strong><br />

April 2004 0 Compiled By: EO Mutloane<br />

Original issues as SCSINAAJ4<br />

Acceptance<br />

This document has been seen and accepted by:<br />

Name<br />

Designation<br />

P Moyo<br />

Power Delivery Engineering GM (Acting)<br />

C Smith<br />

A Persadh<br />

DTEP Manager<br />

Care WG Chairperson<br />

This task manual shall apply throughout <strong>Eskom</strong> Holdings Limited, its divisions, subsidiaries and entities<br />

wherein <strong>Eskom</strong> has a controlling interest.<br />

Development team<br />

This task manual was previously prepared by:<br />

J.H.Coetzer<br />

G Kruger<br />

D.M.Ntombela<br />

C.D.Smith<br />

A.M.Jacobs<br />

O.E.Mutloane<br />

J.J.Olivier<br />

A.M.Stoffberg<br />

O.Turner<br />

This task manual was revised by:<br />

DM Ntombela<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 5 of 19<br />

Introduction<br />

This task manual was compiled to document the tasks procedure in maintaining ISOLATORS to ensure that<br />

maintenance tasks are carried out in a safe manner where risks and hazards are analysed and mitigating<br />

measures are incorporated.<br />

This task manual is the revision of isolator document which was initially compiled and titled “ISOLATOR:<br />

KARG, LEL AND SPEEDCRAFT; TYPE: SINGLE PHASE CUT OUT, Rating: 11kV-22kV, 400A-1600A,<br />

MODE OF OPERATION: HAND OPERATED” to formalize the procedures of performing tasks when<br />

carrying maintenance tasks out. The document includes the latest updates in information, format, safety<br />

precautions and diagrams to make it more user-friendly.<br />

Keywords<br />

Top contact; Bottom contact; Fuse element; and Insulator<br />

Bibliography<br />

Not applicable.<br />

1 Scope<br />

1.1 Purpose<br />

The purpose of this task manual is to standardise maintenance instruction on KARG, LEL AND<br />

SPEEDCRAFT ISOLATORS type SINGLE PHASE CUT OUT, rated at 11kV-22kV; 400A-1600A with a<br />

manually operated MECHANISM.<br />

1.2 Applicability<br />

This document shall apply throughout <strong>Eskom</strong> <strong>Distribution</strong> division and contractor employed by distribution.<br />

1.3 Roles and Responsibilities<br />

1.3.1 Plant Managers shall be responsible for:<br />

a) Ensuring that equipment job plans are available and issued for specific maintenance.<br />

b) Ensuring that the maintenance feedback information that is available in the maintenance<br />

management system is analysed.<br />

1.3.2 Each Field Services Manager shall be responsible for:<br />

a) Ensuring that staff carrying out maintenance tasks is trained, competent and authorized to<br />

perform maintenance on the specific equipment;<br />

b) Ensuring that instructions are implemented and adhered to and equipment is maintained in<br />

accordance to relevant work instructions.<br />

c) Ensuring that the maintenance feedback information / data is captured and recorded into the<br />

system for future maintenance planning.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 6 of 19<br />

2 Normative / Informative references<br />

Parties using this document shall apply the most recent edition of the documents listed below:<br />

2.1 Normative<br />

The following documents contain provisions that, through reference in the text, constitute requirements of<br />

this task manual. At the time of publication the revisions indicated were valid. All standards are subject to<br />

review and parties to agreements based on this work instruction are encouraged to investigate the<br />

possibility of applying the most recent revision of the documents listed below. Information on currently valid<br />

national and international standards may be obtained from the Information Centre at Megawatt Park and<br />

<strong>Technology</strong> Standardization Department.<br />

Occupational Health and Safety Act and Regulations (OHSAct);<br />

NRS079-1: Mineral Insulating Oils<br />

DST_32-332: Oil spill clean-up and rehabilitation.<br />

EPL_32-94: Environmental management policy.<br />

DST_<strong>34</strong>-1710: Personal protective clothing manual.<br />

DPC_<strong>34</strong>-444: Procedure for the application and maintenance of portable earthing gear.<br />

DPC_<strong>34</strong>-227: Procedure for the identification of risk prior to the commencement of work.<br />

DPC_<strong>34</strong>-908: Procedure for barricading.<br />

Manufacturer`s manual.<br />

OPR 6204: Rev 5, Operating regulations for high voltage systems<br />

2.2 Informative<br />

DST_<strong>34</strong>-4, Procedure For The Preparation And Administration Of <strong>Distribution</strong> Standards<br />

Manufacturers manual<br />

3 Definitions and abbreviations<br />

3.1 Definitions<br />

All definitions in NRS040 and OHSAct 85 of 1993 are applicable.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 7 of 19<br />

3.2 Abbreviations<br />

CDP: Career Development Programme;<br />

PTO: Principal Technical Officer;<br />

STO: Senior Technical Officer;<br />

TO: Technical Officer; and<br />

CCC: Change Control Committee<br />

4 Requirements<br />

4.1 First and Second Line Maintenance<br />

a) Insulators shall be inspected for chips and breakage. A maximum of 20% of chipped or broken<br />

sheds is permitted on an insulator. Chips or breaks shall be painted with Glyptol at the earliest<br />

opportunity.<br />

b) Pollution levels on insulators shall be monitored. An anti-pollution medium shall be applied in<br />

accordance with local requirements.<br />

c) Check to ensure that all three phases are properly closed and correctly aligned.<br />

d) Check for hot connections.<br />

e) The operating label shall be securely mounted and shall be legible from the operating position.<br />

f) All metal work shall be checked for corrosion or rust.<br />

g) The earth straps shall be in a good condition and effectively connected.<br />

NOTE: All defects found are to be reported to the Work Management Centre with the work order feedback.<br />

4.2 Specialist maintenance<br />

4.2.1 Pre-planning<br />

4.2.1.1 Spares and Materials<br />

a) Approved Contact grease<br />

b) Approved Lubrication grease.<br />

c) Approved electrical cleaner.<br />

d) Sterilized cloth.<br />

e) Spare fuses<br />

f) Plastic scourer.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 8 of 19<br />

4.2.1.2 Tools and Equipment<br />

a) Standard set of tools;<br />

b) Grease gun;<br />

c) Cleaning tray;<br />

d) Fuse holder;<br />

e) Fuse element (different Amperages);<br />

f) Insulator;<br />

g) Ductor tester; and<br />

h) D C clip-on ammeter.<br />

4.2.1.3 Personal Protective Equipment<br />

All personal protective equipment shall be in accordance with DST_<strong>34</strong>-1710 and those identified by risk assessment<br />

(DPC<strong>34</strong>-227).<br />

a) Overall<br />

b) Hard hat<br />

c) Safety boots<br />

d) Fall Arrest System<br />

e) Barrier cream.<br />

f) Gloves<br />

4.2.2 Safety and preparation<br />

a) Isolate and earth the line in accordance with NRS040.<br />

b) Erect scaffolding (where required).<br />

c) Ensure all tools, equipment and materials are placed inside the barricaded area where they will<br />

not hinder or obstruct any worker.<br />

d) Environmental hazards shall be removed in accordance with DST_32-332.<br />

e) Ensure that isolator is isolated in terms of NRS040 and where applicable any LV protection supply<br />

is switched OFF before commencing with the next steps.<br />

4.2.3 Isolator Maintenance<br />

Risk assessment and critical task analysis shall be done in accordance to DPC_<strong>34</strong>-227 and approved safe<br />

work procedures before the commencement of work.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 9 of 19<br />

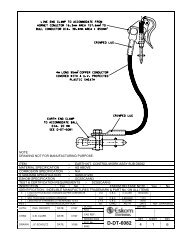

4.2.3.1 Replacing of the burnt replaceable fuse element<br />

a) Disengage the fuse holder by pulling the fuse holder from the latch at the top contact with a link<br />

stick (see figure 1).<br />

Figure 1<br />

NOTE: Before opening the isolator ensure that it is under no load condition by opening the circuit-breakers on either<br />

the load side or supply side of the isolator.<br />

b) Disengage the bottom part of the fuse holder by lifting the fuse holder a little bit so as to<br />

disconnect from the hinge at the bottom contact (see figure 2).<br />

Figure 2<br />

c) After bringing down the fuse holder, unscrew the fuse holder contact tip at the top so as to access<br />

the replaceable fuse element (see figure 3).<br />

d) Pull out the fuse element remaining part (see figure 3).<br />

e) Loosen the fuse element holding bolt at the bottom contact and remove the old fuse element tail.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 10 of 19<br />

Figure 3<br />

f) Inspect the top and bottom contact-points for burn marks, overheating and / or oxidation (refer to<br />

figures 1&2 and see figure 4).<br />

g) Where arcing contacts are in place examine them and the arc shields for excessive wear and<br />

burning (refer to figure 3 above).<br />

h) Fit the washer onto the fuse element, insert the element into the fuse holder and screw the<br />

contact tip onto the holder so as to hold the fuse element in position (refer to figure 3 above) and<br />

see figure 4).<br />

Figure 4<br />

i) Straighten or hold the fuse holder in a charged position, pull the element tail and engage it on or<br />

around the holding bolt and tighten it.<br />

j) Raise the fuse holder assembly with a link stick, engage it bottom first into the isolator hinge<br />

(pivot) and push the other end (unhinged or contact tip end) into the top contact (refer to the main<br />

pictures under “Foreword” above).<br />

NOTE: Ensure that solid contact is made with the top part / fuse holder contact tip.<br />

4.2.3.2 Removal of isolator from the structure (if required)<br />

NOTE: Ensure that both sides of the isolator have been earthed as per NRS040.<br />

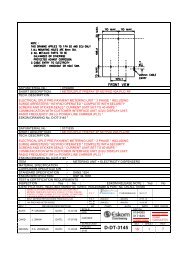

a) Loosen and remove the bolts / nuts connecting the jumper onto the top contact of the isolator and<br />

remove the jumper from the isolator (see figure 5).<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 11 of 19<br />

Top and bottom<br />

jumper connecting<br />

nuts<br />

Figure 5<br />

b) Tie the jumper to the structure or to the isolated and earthed line to prevent it from swinging into<br />

any live apparatus in the vicinity or interfering with the work.<br />

c) Loosen and remove the bolts / nuts connecting the jumper onto the bottom contact of the isolator<br />

and remove the jumper (refer to figure 5 above).<br />

d) Tie the jumper to the structure or to the isolated and earthed line to prevent it from swinging into<br />

any live apparatus in the vicinity or inferring with the work.<br />

e) Support the isolator, loosen and remove the bolts securing the isolator onto the structure and<br />

remove the isolator (see figure 6).<br />

Isolator mounting<br />

bracket with<br />

bracket securing<br />

Support<br />

insulator<br />

Figure 6<br />

f) Make provision for the isolator to be brought down safely by using either a rope or a second<br />

person to help in lowering the equipment to ground level.<br />

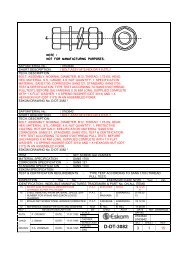

4.2.3.3 Inspection of the top contacts<br />

a) Check the condition of the top contacts and clean the contacts using the plastic scourer and<br />

electrical cleaner (see figure 7).<br />

b) Examine the both contact assemblies for burn marks, carbon built-up, excessive wear and or<br />

pitting (see figure 7).<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 12 of 19<br />

c) Examine the tensioning springs for tension loss (refer to figure 4 and see figure 7).<br />

Figure 7<br />

d) Check that the nuts securing the contacts to the support insulators are tight.<br />

e) Check that the link latch tension is in order (refer to figure 4 above).<br />

f) Check, clean and grease all the pins.<br />

g) If any of the above mentioned parts are faulty replace them with new ones.<br />

NOTE: If the contacts are permanently fixed to the insulator then the whole isolator set must be replaced.<br />

4.2.3.4 Inspection of the bottom contacts<br />

a) Check the condition of the bottom contact assemblies (refer to figure 2 above).<br />

b) Examine the contact assembly for burn marks, excessive wear, spring tension loss and or pitting.<br />

c) Clean the contacts using the plastic scourer and electrical cleaner.<br />

d) Check that the bolts / nuts securing the contacts to the support insulators are tight (see figure 8).<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 13 of 19<br />

Figure 8<br />

e) Check that the link / isolator is in alignment when fully closed and re-align if necessary.<br />

f) Check that the link / isolator hinge is in order (refer to figure 8 above).<br />

g) Check, clean and grease all pivoting pins.<br />

h) If any of the above mentioned parts are faulty replace them with new ones.<br />

NOTE: If the contacts are permanently fixed to the insulator then the whole isolator set must be replaced.<br />

4.2.3.5 Inspection of the insulators<br />

a) Check the support insulators for tracking and or severe pollution build-up.<br />

b) Test the support insulator for cracks by using "RING TESTING".<br />

c) Check the support insulator for strength.<br />

NOTE: Some insulators may be porous due to age and that may cause problems for operators.<br />

d) If there are problems with support insulators, the whole isolator set shall be replaced.<br />

e) Clean the insulators thoroughly with an approved cleaner and the scourer.<br />

4.2.3.6 Refitting new isolator onto the structure (if required)<br />

a) Safely lift the isolator up to the mounting position by using either a rope or a second person to<br />

help.<br />

b) Place the isolator onto the structure, align the isolator bracket / base to the mounting holes, insert<br />

the securing bolts and tighten them.<br />

c) Untie the jumper of the top contact from the structure or the isolated and earthed line.<br />

d) Ensure that the jumper connection ends / lugs and clamp are clean, place the jumper onto the<br />

isolator top contact terminal connection hole, insert the connection bolts and tighten it.<br />

e) Untie the jumper of the bottom contact from the structure or the isolated and earthed line.<br />

f) Ensure that the jumper connection ends / lugs and clamp are clean, place the jumper onto the<br />

isolator bottom contact terminal connection hole, insert the connection bolts and tighten it.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 14 of 19<br />

g) Where all three phases are to be replaced repeat steps a) to f) above on the remaining phases.<br />

4.2.3.7 Mechanism<br />

Not applicable.<br />

4.2.3.8 Adjustments<br />

Not applicable<br />

4.3 Modification<br />

Not applicable<br />

5 Testing<br />

Not applicable.<br />

6 Related/Supporting Documents<br />

6.1 Related Documents<br />

a) Critical task analysis:<br />

1. High Voltage Operating; and<br />

2. Work with/on Extension/Single Ladders.<br />

b) Training module;<br />

c) Relevant Manufacturers manual.<br />

6.2 Forms and Records<br />

The attached report shall form the record of work done.<br />

The completed report must be returned to the Work Co-ordinator together with the work order and a copy to<br />

the Technical Services Group.<br />

7 Spares<br />

Refer to 4.2.1.1 above<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 15 of 19<br />

Annex A - Isolator Maintenance Checksheet<br />

(Normative)<br />

ISOLATOR MAINTENANCE CHECKSHEET<br />

Substation Name: _________________________<br />

Panel: __________________________________<br />

Customer Order Number: ___________________<br />

Maintained by: ____________________________<br />

Isolator make: ___________________________<br />

Type: __________________________________<br />

Serial Number: ___________________________<br />

Isolator Rating: ___________kV _________ Amp<br />

Date: ___________________________________<br />

Task Task Done Comments<br />

Yes/No<br />

1. Remove jumper clamps and measure contact resistance<br />

before maintenance.<br />

2. Remove completely strip and maintain male arms<br />

3. Remove completely strip and maintain female contacts.<br />

4. Maintain turning head/transfer contact assembly<br />

5. Maintain inter-phase rods<br />

6. Maintain mechanism box<br />

7. Clean and inspect post insulator<br />

8. Maintain jumper clamps<br />

9. Measure after-maintenance contact resistance.<br />

10. Refit the jumpers and re-align main contact arms<br />

11. Functional test (open and close isolator) a few times to<br />

check alignment.<br />

12. Check for rust<br />

13. Torque bolts in accordance with maintenance instruction<br />

manual<br />

14. Lubricate all parts correctly.<br />

15. Maintain and refit the jumper clamps<br />

Measure<br />

Point<br />

Recommend<br />

Readings<br />

Before<br />

Maintenance<br />

Red Phase White Phase Blue Phase<br />

After<br />

Maintenance<br />

Before<br />

Maintenance<br />

After<br />

Maintenance<br />

Before<br />

Maintenance<br />

After<br />

Maintenance<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

I<br />

J<br />

Note: If the after-maintenance reading is more than the before -maintenance reading, then establish the reason for it<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 16 of 19<br />

1 Guidelines<br />

Annex B - Impact assessment<br />

(Normative)<br />

o All comments must be completed.<br />

o Motivate why items are N/A (not applicable)<br />

o Indicate actions to be taken, persons or organisations responsible for actions and deadline for<br />

action.<br />

o Change control committees to discuss the impact assessment, and if necessary give feedback to<br />

the compiler of any omissions or errors.<br />

2 Critical points<br />

2.1 Importance of this document. E.g. is implementation required due to safety deficiencies,<br />

statutory requirements, technology changes, document revisions, improved service quality,<br />

improved service performance, optimized costs.<br />

Comment: Statutory requirements and or document revisions<br />

2.2 If the document to be released impacts on statutory or legal compliance - this need to be<br />

very clearly stated and so highlighted.<br />

Comment: No impact on statutory or legal compliance and mainly document revisions<br />

2.3 Impact on stock holding and depletion of existing stock prior to switch over.<br />

Comment: N/A - No new equipment or item need to be acquired for implementation of this document.<br />

2.4 When will new stock be available<br />

Comment: N/A –see 2.3 above.<br />

2.5 Has the interchange ability of the product or item been verified - i.e. when it fails is a straight<br />

swap possible with a competitor's product<br />

Comment: N/A – It is a maintenance document and also see 2.3 above.<br />

2.6 Identify and provide details of other critical (items required for the successful<br />

implementation of this document) points to be considered in the implementation of this document.<br />

Comment: Consult / Refer to DST_<strong>34</strong>-1454 for routine inspections when implementing the document.<br />

2.7 Provide details of any comments made by the Regions regarding the implementation of this<br />

document.<br />

Comment: None.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 17 of 19<br />

3 Implementation timeframe<br />

Annex B<br />

(continued)<br />

3.1 Time period for implementation of requirements.<br />

Comment: N/A – No technical changes were made to this document.<br />

3.2 Deadline for changeover to new item and personnel to be informed of DX wide change-over.<br />

Comment: None.<br />

4 Buyers Guide and Power Office<br />

4.1 Does the Buyers Guide or Buyers List need updating<br />

Comment: NO.<br />

4.2 What Buyer’s Guides or items have been created<br />

Comment: NONE.<br />

4.3 List all assembly drawing changes that have been revised in conjunction with this<br />

document.<br />

Comment: NONE<br />

4.4 If the implementation of this document requires assessment by CAP, provide details under 5<br />

Comment: N/A – The revision requires no new equipment.<br />

4.5 Which Power Office packages have been created, modified or removed<br />

Comment: NONE:<br />

5 CAP / LAP Pre-Qualification Process related impacts<br />

5.1 Is an ad-hoc re-evaluation of all currently accepted suppliers required as a result of<br />

implementation of this document<br />

Comment: NO<br />

5.2 If NO, provide motivation for issuing this specification before Acceptance Cycle Expiry date.<br />

Comment: N/A – The document doesn’t specify but stipulates the maintenance procedures on the existing<br />

equipment.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 18 of 19<br />

Annex B<br />

(continued)<br />

5.3 Are ALL suppliers (currently accepted per LAP), aware of the nature of changes contained in<br />

this document<br />

Comment: N/A – The specification document is the document supplied to the suppliers not this one.<br />

5.4 Is implementation of the provisions of this document required during the current supplier<br />

qualification period<br />

Comment: Yes – This is the revision of document that is presently being implemented and requires no<br />

change to the supplier’s qualification period.<br />

5.5 If Yes to 5.3, what date has been set for all currently accepted suppliers to comply fully<br />

Comment: N/A – see 5.3 above.<br />

5.6 If Yes to 5.4, have all currently accepted suppliers been sent a prior formal notification<br />

informing them of <strong>Eskom</strong>’s expectations, including the implementation date deadline<br />

Comment: N/A – see 5.4 above.<br />

5.7 Can the changes made, potentially impact upon the purchase price of the<br />

material/equipment<br />

Comment: N/A – No new material / equipment is required.<br />

5.8 Material group(s) affected by specification: (Refer to Pre-Qualification invitation schedule for<br />

list of material groups)<br />

Comment: N/A – No new material is required.<br />

6 Training or communication<br />

6.1 State the level of training or communication required to implement this document. (E.g.<br />

none, communiqués, awareness training, practical / on job, module, etc.)<br />

Comment: Practical / On job and training module.<br />

6.2 State designations of personnel that will require training.<br />

Comment: TSO, PTO & STO.<br />

6.3 Is the training material available Identify person responsible for the development of<br />

training material.<br />

Comment: Yes – DT- Training is revising earthing related training manual which will address the changes in<br />

this document.<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE<br />

ISOLATOR: KARG, LEL AND SPEEDCRAFT Unique Identifier: <strong>34</strong>-<strong>523</strong><br />

TYPE: SINGLE PHASE CUT-OUT<br />

Type:<br />

<strong>DMN</strong><br />

RATING: 11kV-22kV; 400A-1600A<br />

Revision: 1<br />

MODE OF OPERATION: HAND OPERATED<br />

Page: 19 of 19<br />

Annex B<br />

(continued)<br />

6.4 If applicable, provide details of training that will take place. (E.G. sponsor, costs, trainer,<br />

schedule of training, course material availability, training in erection / use of new equipment,<br />

maintenance training, etc).<br />

Comment: Safety and Maintenance training.<br />

6.5 Was Training & Development Section consulted w.r.t training requirements<br />

Comment: Yes.<br />

7 Special tools, equipment, software<br />

7.1 What special tools, equipment, software, etc will need to be purchased by the Region to<br />

effectively implement<br />

Comment: NONE.<br />

7.2 Are there stock numbers available for the new equipment<br />

Comment: N/A – No new equipment is required.<br />

7.3 What will be the costs of these special tools, equipment, software<br />

Comment: N/A – No new equipment is required.<br />

8 Finances<br />

8.1 What total costs would the Regions be required to incur in implementing this document<br />

Identify all cost activities associated with implementation, e.g. labour, training, tooling, stock,<br />

obsolescence<br />

Comment:<br />

No costs other than the training will be incurred by the regions and this will depend on the arrangements<br />

made for training i.e. Training is held regionally or nationally.<br />

Impact assessment completed by:<br />

Name: Ajith Persadh<br />

Designation: Senior Advisor, Engineering Processes, IARC<br />

ESKOM COPYRIGHT PROTECTED<br />

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user<br />

to ensure it is in line with the authorised version on the WEB.