Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

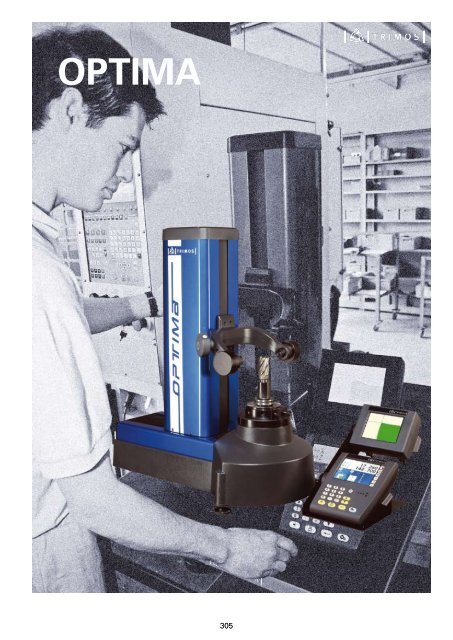

<strong>OPTIMA</strong><br />

305

<strong>OPTIMA</strong><br />

introduction<br />

<strong>OPTIMA</strong> is an universal tool presetting and<br />

measuring instrument. Its very innovative design,<br />

as well as its simplicity of use, have made it a<br />

bestseller worldwide.<br />

TRIMOS® Duo Display, composed of a control<br />

unit coupled to an intelligent vision system,<br />

allows automatic measurement of any tool<br />

profile. Therefore, checking is performed without<br />

operator influence.<br />

The user is guided by the interface in the<br />

measuring process and only essential data are<br />

displayed. All functions are rapidly accessible via<br />

the touch screen. An interactive, easy-to-use tool<br />

management system belongs to the <strong>OPTIMA</strong><br />

standard equipment. All models are available<br />

in manual or motorized version. Optima<br />

includes components supplied by world famous<br />

companies like Heidenhain, Schneeberger and<br />

Sony.<br />

The grey cast-iron structure ensures great<br />

stability to the instrument. The rounded shape<br />

of the base, specific to <strong>OPTIMA</strong>, has often been<br />

imitated, without being equalled. Its pleasant<br />

design offers great access comfort.<br />

<strong>OPTIMA</strong> allows extremely rapid measuring of<br />

any tool shape and increases your productivity<br />

significantly.<br />

Sturdy and stable construction<br />

Simple and user-friendly<br />

Interchangeable Spindle System<br />

Spindle Brake and Index System<br />

Rapid measuring of any tool shape<br />

Manual or motorized version<br />

RS232 and USB interfaces<br />

Customised measuring protocols<br />

Print-out of labels and lists of tools<br />

Post-processors available<br />

Integrated tool management system up to 999 tools<br />

Backup on USB Memory Stick<br />

No need of compressed air<br />

Available post-processors<br />

306

<strong>OPTIMA</strong><br />

description<br />

Lighting<br />

Displacement handle<br />

(manual instruments)<br />

Spindle blocking and<br />

positioning<br />

Camera<br />

Cast iron base<br />

TRIMOS® Duo Display<br />

307

optima<br />

display/software<br />

The TRIMOS® Duo Display is composed of<br />

2 screens ergonomically placed.<br />

The upper screen displays the profile of the<br />

tool. This one is recognized and measured<br />

automatically. A system of marks makes it<br />

possible to easily recognize and validate the<br />

measured sector.<br />

The lower display constitutes the control unit<br />

of the instrument. Thanks to the touch screen,<br />

only relevant functions are at disposal of the<br />

user, who is then guided in the measuring<br />

process. The graphical interface, bearing<br />

many illustrations, allows a rational use of the<br />

instrument and reduces the needs for formation<br />

to the minimum.<br />

TRIMOS® Duo Display<br />

Very simple user interface<br />

Colour touch screen<br />

Automatic recognition of any tool shape<br />

Integrated online help<br />

Tool and adapter management system<br />

Radius or diameter measurement mode<br />

Offset or differential measurement mode<br />

Print-out of lists on USB printer<br />

Print-out of tool labels<br />

RS232 data transfer<br />

Easy integration in most production systems<br />

Compatible with tool identification systems<br />

technical specifications<br />

<strong>OPTIMA</strong><br />

300/300<br />

300/400<br />

450/500<br />

450/600<br />

450/800<br />

450/1000<br />

450/1200<br />

Measuring range diameter (X)<br />

mm(in)<br />

310 (12)<br />

310 (12)<br />

462 (18)<br />

462 (18)<br />

462 (18)<br />

462 (18)<br />

462 (18)<br />

Measuring range length (Z)<br />

mm(in)<br />

320 (12)<br />

422 (16)<br />

523 (20)<br />

625 (24)<br />

828 (32)<br />

1028 (40)<br />

1228 (48)<br />

Max. concentricity error of tool spindle<br />

mm<br />

0.002<br />

Resolution<br />

mm(in)<br />

0.001 (.0001)<br />

Interfaces<br />

RS232/USB<br />

Weight<br />

kg<br />

80<br />

81<br />

85<br />

87<br />

90<br />

92<br />

95<br />

308

TRIMOS<br />

optima<br />

diagram<br />

358<br />

204<br />

211<br />

T R I M O S<br />

278<br />

815 / 917 / 1018 / 1120 / 1323 / 1523 / 1723<br />

360<br />

410<br />

476 / 552<br />

703 / 779<br />

standard instrument<br />

The Optima instruments are supplied as follows :<br />

• Instrument according to specifications (without adapter)<br />

• User’s manual<br />

• Test certificate<br />

Code number<br />

Optima 300/300<br />

Optima 300/400<br />

Optima 450/500<br />

Optima 450/600<br />

Optima 450/800<br />

Optima 450/1000<br />

Optima 450/1200<br />

Manual version<br />

700 310 00 01<br />

700 310 00 02<br />

700 310 00 07<br />

700 310 00 08<br />

700 310 00 09<br />

700 310 00 10<br />

700 310 00 51<br />

Motorized version<br />

700 310 00 05<br />

700 310 00 06<br />

700 310 00 03<br />

700 310 00 04<br />

700 310 00 53<br />

700 310 00 54<br />

700 310 00 55<br />

309

optima<br />

Applications<br />

Checking of a thread cutter<br />

Checking of a two-flute cutter<br />

Checking of a cutter<br />

Checking of a radius cutter Change of an adapter Data transfer (also wireless)<br />

<br />

<br />

Printing of tool labels<br />

Personalized creation of post-processors<br />

thanks to the software Post-prolight<br />

Automatic displacement (motorized versions)<br />

310