SmartLam GL18C Brochure - Tilling Timber

SmartLam GL18C Brochure - Tilling Timber

SmartLam GL18C Brochure - Tilling Timber

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INTRODUCTION<br />

THE PRODUCT<br />

<strong>SmartLam</strong> GL18 beams are manufactured to AS/NZS 1328 by<br />

quality Glulam manufacturers. <strong>SmartLam</strong> GL18 Glulam beams<br />

are engineered timber products with high strength, dimensional<br />

stability, great load carrying capacity, superior fire resistance,<br />

and are manufactured from select quality Pine timber.<br />

All timber used for laminating<br />

is carefully selected<br />

from production and graded<br />

according to specification.<br />

After trimming to the desired<br />

size, all stock is kiln<br />

dried to 12% average moisture<br />

content, to ensure<br />

efficient bonding in the gluing<br />

operations. The laminations<br />

are finger jointed by<br />

machine, with glue being<br />

cured by cold press system<br />

and controlled temperature.<br />

<strong>SmartLam</strong> GL18 are available<br />

in A, B & C appearance<br />

Grades and are pre-cambered to a radius of 600 metres. Uncambered<br />

<strong>SmartLam</strong> GL18 beams are available to order.<br />

BENEFITS OF <strong>SmartLam</strong> GL18<br />

COST EFFECTIVENESS - <strong>SmartLam</strong> GL18 beams high strength<br />

to weight ratio allows you to design for maximum loads over<br />

large spans with the smallest possible end sections.<br />

PRODUCT QUALITY - All <strong>SmartLam</strong> GL18 beams are manufactures<br />

in accordance with AS 1328 Glue Laminated Structural<br />

<strong>Timber</strong> and the Glued Laminated <strong>Timber</strong> Association (GLTAA)<br />

Industry standard GLTAA-4-91.<br />

FIRE SAFETY - Extensive fire test data shows that large end<br />

section timber performs well in fire situations due to the formation<br />

of a protective layer of char which usually occurs at a<br />

temperature around 250 o C. This charred area inhibits the<br />

effects of the fire on the inner portion of the timber component,<br />

hence it maintains structural load support for measurable periods<br />

of time as the fire progresses.<br />

Conversely, steel loses its strength rapidly<br />

as the temperature is raised. At about<br />

550 o C, it has lost about 50% of its original<br />

bending strength, and by 750 o C it has lost<br />

90% <strong>Timber</strong> does not loose strength in the<br />

same way, with the loss of section size<br />

through charring the major reason for any<br />

strength reduction.<br />

FAST EASY ERECTION - <strong>Timber</strong> is a user<br />

friendly building material, requiring no special<br />

tools other than those a normal builder<br />

would use, and with <strong>SmartLam</strong> GL18<br />

beams, installation is fast, easy and efficient.<br />

ENVIRONMENTAL RESPONSIBILITY - <strong>SmartLam</strong> GL18 beams<br />

are made from timber from sustainable managed forests, a<br />

natural resource that is friendly to the environment.<br />

LOW MAINTENANCE - In most applications, <strong>SmartLam</strong> GL18<br />

beams will require little or no maintenance other than that<br />

which you would ordinarily carry out to any structural material.<br />

NATURAL BEAUTY - The natural beauty of timber is desired and<br />

highly appropriate in many architectural applications. Appearance<br />

Grade A & B <strong>SmartLam</strong> GL18 beams allow you to build<br />

timber's natural warmth and beauty into your designs.<br />

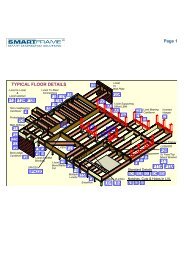

TECHNICAL DATA<br />

DESIGN CRITERIA<br />

Deflection limits<br />

The deflection limits applied in these tables are as stated in Table 1 and are in accordance the Glued Laminated <strong>Timber</strong> Association of<br />

Australia (GLTAA) Unified Design Criteria<br />

Table 1: Deflection limits<br />

BEARERS<br />

(floor loads only)<br />

MEMBER<br />

LONG TERM<br />

SHORT TERM<br />

J 2 x D.L J 2 x (DL+0.6 kPa) L.L SERVICEABILITY W.L<br />

SPAN or 15 mm<br />

300<br />

SPAN or 18 mm<br />

360<br />

BEARERS<br />

(with roof loads)<br />

SPAN or 15 mm<br />

300<br />

SPAN or 18 mm<br />

360<br />

SPAN or 9 mm<br />

250<br />

JOISTS<br />

SPAN or 15 mm<br />

300<br />

SPAN or 9 mm<br />

360<br />

LINTELS<br />

(with roof loads only)<br />

SPAN or 9 m<br />

300<br />

SPAN or 9 mm<br />

250<br />

SPAN or 9 mm<br />

250<br />

LINTELS<br />

(with roof and floor)<br />

SPAN or 10 mm<br />

300<br />

SPAN or 9 mm<br />

250<br />

SPAN or 9 mm<br />

250<br />

STRUTTING, HANGING, COUNTER<br />

BEAMS<br />

SPAN or 15 mm<br />

300<br />

SPAN or 15 mm<br />

270<br />

SPAN<br />

150<br />

HANGING/STRUTTING, COUNTER/<br />

STRUTTING<br />

SPAN or 12 mm<br />

300<br />

SPAN or 12 mm<br />

300<br />

SPAN<br />

150<br />

ROOF BEAMS, RAFTERS, HIPS<br />

SPAN or 20 mm<br />

300<br />

SPAN or 10 mm<br />

400<br />

SPAN<br />

250<br />

SPAN or 12 mm<br />

250<br />

SPAN<br />

150<br />

SPAN<br />

200<br />

PATIO & VERANDAH BEAMS<br />

For Long Term - Camber may in some circumstances be added to Deflection limits<br />

WHERE: DL = DEAD LOAD, LL = LIVE LOAD, WL = WIND LOAD, J2 = FACTOR FOR DURATION OF LOAD<br />

<strong>SmartLam</strong> G18C Design Guide 1