- Page 1 and 2: Rotary Seals Deutsch Your Partner f

- Page 3 and 4: Rotary Seal General description ...

- Page 5 and 6: Rotary Seal n GENERAL DESCRIPTION T

- Page 7 and 8: Rotary Seal V—Rings Family V—Ri

- Page 9 and 10: Rotary Seal PTFE Rotary Shaft seals

- Page 11 and 12: Rotary Seal n Introduction Rotating

- Page 13 and 14: Rotary Seal Shaft run out and eccen

- Page 15: Rotary Seal n Quality criteria The

- Page 19 and 20: Rotary Seal Surface finish In order

- Page 21 and 22: Radial Oil Seal Sealing element Mat

- Page 23 and 24: Radial Oil Seal Fluorinated Rubber

- Page 25 and 26: Radial Oil Seal Metal case The prin

- Page 27 and 28: Radial Oil Seal Peripheral speed an

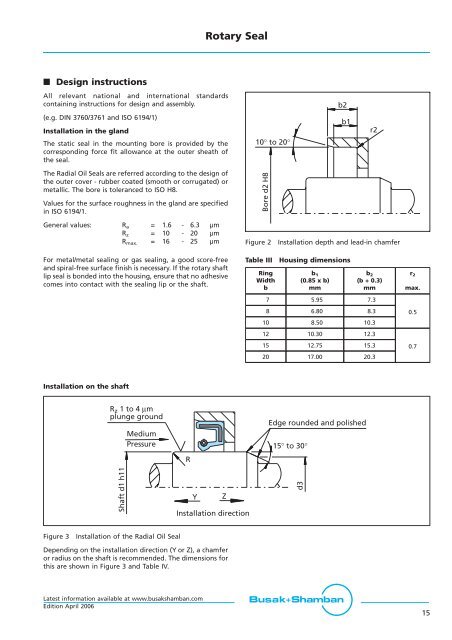

- Page 29 and 30: Radial Oil Seal n Shaft and housing

- Page 31 and 32: Radial Oil Seal n Standard types of

- Page 33 and 34: Radial Oil Seal Table VI Materials

- Page 35 and 36: Radial Oil Seal Dimension Part no.

- Page 37 and 38: Radial Oil Seal Dimension Part no.

- Page 39 and 40: Radial Oil Seal Dimension Part no.

- Page 41 and 42: Radial Oil Seal Dimension Part no.

- Page 43 and 44: Radial Oil Seal Dimension Part no.

- Page 45 and 46: Radial Oil Seal Dimension Part no.

- Page 47 and 48: Radial Oil Seal Dimension Part no.

- Page 49 and 50: Radial Oil Seal Dimension Part no.

- Page 51 and 52: Radial Oil Seal Dimension Part no.

- Page 53 and 54: Radial Oil Seal Dimension Part no.

- Page 55 and 56: Radial Oil Seal n Busak+Shamban typ

- Page 57 and 58: Radial Oil Seal Dimension Part no.

- Page 59 and 60: Radial Oil Seal Dimension Part no.

- Page 61 and 62: Radial Oil Seal Dimension Part no.

- Page 63 and 64: Radial Oil Seal Dimension Part no.

- Page 65 and 66: Radial Oil Seal Dimension Part no.

- Page 67 and 68:

Radial Oil Seal Ordering example oi

- Page 69 and 70:

Radial Oil Seal Table X Materials S

- Page 71 and 72:

Radial Oil Seal Dimension Part no.

- Page 73 and 74:

Radial Oil Seal Dimension Part no.

- Page 75 and 76:

Radial Oil Seal n Busak+Shamban typ

- Page 77 and 78:

Radial Oil Seal Dimension Part no.

- Page 79 and 80:

Radial Oil Seal Dimension Part no.

- Page 81 and 82:

Radial Oil Seal n Busak+Shamban typ

- Page 83 and 84:

Radial Oil Seal Dimension Part no.

- Page 85 and 86:

Radial Oil Seal Dimension Part no.

- Page 87 and 88:

Radial Oil Seal Dimension Part no.

- Page 89 and 90:

Radial Oil Seal n Busak+Shamban typ

- Page 91 and 92:

Radial Oil Seal Dimension Part no.

- Page 93 and 94:

Radial Oil Seal n Special types of

- Page 95 and 96:

Radial Oil Seal Table XVIII Materia

- Page 97 and 98:

Radial Oil Seal Table XIX Materials

- Page 99 and 100:

Radial Oil Seal Ordering example oi

- Page 101 and 102:

Radial Oil Seal Table XXI Materials

- Page 103 and 104:

Radial Oil Seal n STEFA type 12CC -

- Page 105 and 106:

Radial Oil Seal n Busak+Shamban typ

- Page 107 and 108:

Radial Oil Seal Dimension Part no.

- Page 109 and 110:

Radial Oil Seal n Busak+Shamban typ

- Page 111 and 112:

Radial Oil Seal Dimension Part no.

- Page 113 and 114:

Radial Oil Seal n Rotary and axial

- Page 115 and 116:

Radial Oil Seal n Product descripti

- Page 117 and 118:

Radial Oil Seal n STEFA standard AP

- Page 119 and 120:

Radial Oil Seal n STEFA 1B/APJ and

- Page 121 and 122:

End Cover n END COVER General descr

- Page 123 and 124:

End Cover Bore D H8 Width B Chamfer

- Page 125 and 126:

End Cover n Busak+Shamban type YJ 3

- Page 127 and 128:

Shaft Repair Kit n SHAFT REPAIR KIT

- Page 129 and 130:

Shaft Repair Kit n Installation rec

- Page 131 and 132:

Shaft Repair Kit n Installation rec

- Page 133 and 134:

Shaft Repair Kit Shaft diameter imp

- Page 135 and 136:

Shaft Repair Kit Shaft diameter imp

- Page 137 and 138:

Cassette Seal n System 3000 n Syste

- Page 139 and 140:

Cassette Seal ID d 1 OD Width Syste

- Page 141 and 142:

Cassette Seal Temperature limits fo

- Page 143 and 144:

Cassette Seal Shaft run out Shaft r

- Page 145 and 146:

Cassette Seal System 5000 The Syste

- Page 147 and 148:

V—Ring 70 65 60 d=190 V-Rings in

- Page 149 and 150:

V—Ring recommended to arrange an

- Page 151 and 152:

V—Ring The power losses are influ

- Page 153 and 154:

V—Ring n Dimension table - V—Ri

- Page 155 and 156:

V—Ring For shaft diameter d 1 Ins

- Page 157 and 158:

V—Ring n Dimension table - V—Ri

- Page 159 and 160:

V—Ring n Dimension table - V—Ri

- Page 161 and 162:

V—Ring Ordering example V—Ring,

- Page 163 and 164:

V—Ring For shaft diameter d 1 Ins

- Page 165 and 166:

V—Ring For shaft diameter d 1 Ins

- Page 167 and 168:

V—Ring n Dimension table - V—Ri

- Page 169 and 170:

V—Ring V—Ring AX larger than 20

- Page 171 and 172:

GAMMA Seal Figure 64 70 TBP/RB RB 5

- Page 173 and 174:

GAMMA Seal b b ø d + 0.5 ø d Figu

- Page 175 and 176:

GAMMA Seal Table XLVII Materials St

- Page 177 and 178:

GAMMA Seal n GAMMA-seal type TBR/9R

- Page 179 and 180:

Axial Shaft Seal n AXIAL SHAFT SEAL

- Page 181 and 182:

Axial Shaft Seal n Applications Fie

- Page 183 and 184:

Axial Shaft Seal Design instruction

- Page 185 and 186:

Axial Shaft Seal Shaft Dimensions M

- Page 187 and 188:

Axial Shaft Seal Ordering example A

- Page 189 and 190:

Axial Shaft Seal Shaft Dimensions M

- Page 191 and 192:

Turcon ® Roto Glyd Ring ® n TURCO

- Page 193 and 194:

Turcon ® Roto Glyd Ring ® Table L

- Page 195 and 196:

Turcon ® Roto Glyd Ring ® 30 10 -

- Page 197 and 198:

Turcon ® Roto Glyd Ring ® Materia

- Page 199 and 200:

Turcon ® Roto Glyd Ring ® Table L

- Page 201 and 202:

Turcon ® Roto Glyd Ring ® Orderin

- Page 203 and 204:

Turcon ® Roto Glyd Ring ® Table L

- Page 205 and 206:

Turcon ® Roto Glyd Ring ® Orderin

- Page 207 and 208:

Turcon ® Roto Variseal ® n TURCON

- Page 209 and 210:

Turcon ® Roto Variseal ® blend ra

- Page 211 and 212:

Turcon ® Roto Variseal ® n Instal

- Page 213 and 214:

Latest information available at www

- Page 215 and 216:

Latest information available at www

- Page 217 and 218:

Latest information available at www

- Page 220:

For further information: Europe Tel