Silane cross-linked polyethylene pipe INTERSOL ... - Watts Industries

Silane cross-linked polyethylene pipe INTERSOL ... - Watts Industries

Silane cross-linked polyethylene pipe INTERSOL ... - Watts Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SILANE CROSS-LINKED POLYETHYLENE PIPE<br />

2 - CROSS-LINKING METHOD<br />

4<br />

High density <strong>polyethylene</strong> is a thermoplastic macromolecular component, obtained from the polymerization of the<br />

ethylene monomer (CH2 = CH2).<br />

Its chemical formula can be represented as: - (CH2 - CH2) - n<br />

where n defines the length of the macromolecular chain (the average value of n can also lie between<br />

10,000 – 16,000). From now onwards we shall represent such chain as:<br />

Hence <strong>polyethylene</strong> consists of various macromolecular (polymer) chains, whose cohesion forces cannot strictly<br />

be considered to be true chemical bonds, rather they are electrical in nature and are commonly known as “Van<br />

der Waals” forces. Although such cohesion forces are low, the high number of intramolecular bonds favours<br />

obtaining of certain properties for the product.<br />

However the low energy of the cohesion forces makes the thermoplastic materials highly sensitive to temperature,<br />

which causes considerable decay of the properties.<br />

Suppose in addition to the “Van der Waals” forces, we introduce intramolecular chemical bonds (the so-called<br />

<strong>cross</strong>-linking bonds), the thermal properties of the product will be considerably improved.<br />

Cross-linking is a process which modifies the chemical structure of the material, by creating a three dimensional<br />

“network” structure thanks to links between the polymer chains. The new structure determines certain special<br />

characteristics, namely:<br />

• an increase in the maximum operating temperature<br />

• a reduction in creep deformation (creep)<br />

• improved chemical resistance<br />

• improved resistance to UV rays<br />

• improved abrasion resistance<br />

• greater impact strength<br />

• less notch sensitivity and abrasion<br />

• thermal memory characteristics are conferred to the material (“thermoelastic polymer”)<br />

2.1 - Classification of the <strong>cross</strong>-<strong>linked</strong> <strong>polyethylene</strong><br />

Cross-<strong>linked</strong> <strong>polyethylene</strong> is classified according to the methods used to perform the <strong>cross</strong>-linking as summed up<br />

in the following table:<br />

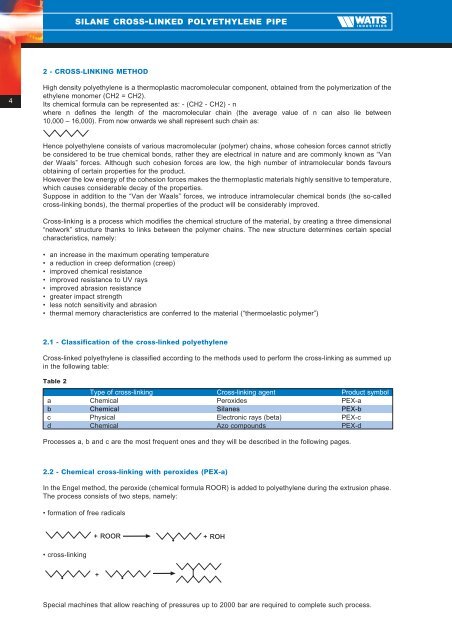

Table 2<br />

Type of <strong>cross</strong>-linking Cross-linking agent Product symbol<br />

a Chemical Peroxides PEX-a<br />

b Chemical <strong>Silane</strong>s PEX-b<br />

c Physical Electronic rays (beta) PEX-c<br />

d Chemical Azo compounds PEX-d<br />

Processes a, b and c are the most frequent ones and they will be described in the following pages.<br />

2.2 - Chemical <strong>cross</strong>-linking with peroxides (PEX-a)<br />

In the Engel method, the peroxide (chemical formula ROOR) is added to <strong>polyethylene</strong> during the extrusion phase.<br />

The process consists of two steps, namely:<br />

• formation of free radicals<br />

• <strong>cross</strong>-linking<br />

+ ROOR + ROH<br />

+<br />

Special machines that allow reaching of pressures up to 2000 bar are required to complete such process.