spark plug (k3- ve )

spark plug (k3- ve )

spark plug (k3- ve )

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TO INDEX<br />

ENGINE<br />

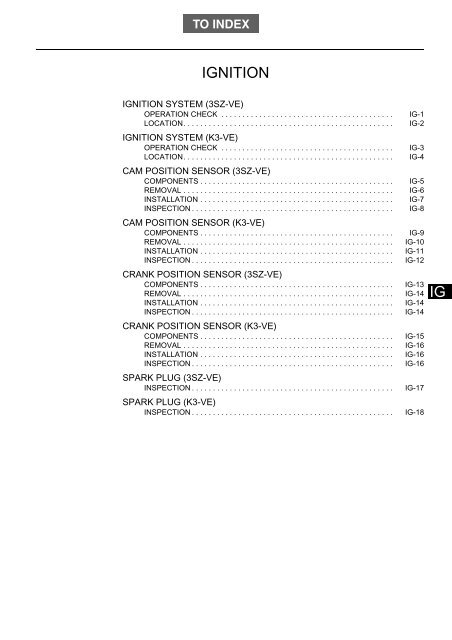

IGNITION<br />

IGNITION SYSTEM (3SZ-VE)<br />

OPERATION CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

LOCATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

IGNITION SYSTEM (K3-VE)<br />

OPERATION CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

LOCATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

CAM POSITION SENSOR (3SZ-VE)<br />

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

CAM POSITION SENSOR (K3-VE)<br />

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

CRANK POSITION SENSOR (3SZ-VE)<br />

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

CRANK POSITION SENSOR (K3-VE)<br />

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

SPARK PLUG (3SZ-VE)<br />

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

SPARK PLUG (K3-VE)<br />

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

IG-1<br />

IG-2<br />

IG-3<br />

IG-4<br />

IG-5<br />

IG-6<br />

IG-7<br />

IG-8<br />

IG-9<br />

IG-10<br />

IG-11<br />

IG-12<br />

IG-13<br />

IG-14<br />

IG-14<br />

IG-14<br />

IG-15<br />

IG-16<br />

IG-16<br />

IG-16<br />

IG-17<br />

IG-18<br />

IG

IG<br />

IG–1<br />

IGNITION SYSTEM (3SZ-VE)<br />

ENGINE<br />

IGNITION - IGNITION SYSTEM (3SZ-VE)<br />

OPERATION CHECK<br />

1. PERFORM SPARK TEST<br />

(a) Check for diagnostic trouble codes. (See page ES-8)<br />

NOTICE:<br />

If a DTC is detected, perform the troubleshooting procedures<br />

for the corresponding DTC.<br />

(b) Perform the <strong>spark</strong> test.<br />

(1) Remo<strong>ve</strong> the air cleaner assembly.<br />

(2) Disconnect the connector from the ignition coil.<br />

(3) Remo<strong>ve</strong> the ignition coil.<br />

(4) Remo<strong>ve</strong> the <strong>spark</strong> <strong>plug</strong>.<br />

(5) Install the <strong>spark</strong> <strong>plug</strong> to the ignition coil and connect the<br />

connector.<br />

(6) Disconnect all connectors of the fuel injector assembly.<br />

(7) Ground the <strong>spark</strong> <strong>plug</strong>.<br />

(8) Make sure that <strong>spark</strong>s occur when the engine is cranking.<br />

NOTICE:<br />

• Be sure to ground the hexagonal part or the thread<br />

of the ground electrode of the <strong>spark</strong> <strong>plug</strong>.<br />

• If the ignition coil has been dropped or struck,<br />

replace it.<br />

• Do not crank the engine for more than 2 seconds.<br />

(9) Connect the connector of the fuel injector assembly.<br />

(10) Install the <strong>spark</strong> <strong>plug</strong>s.<br />

Torque: 20 N*m (204 kgf*cm)<br />

(11) Install the ignition coils.<br />

Torque: 7.5 N*m (76 kgf*cm)<br />

(12) Connect the connector to the ignition coil.<br />

(13) Check for diagnostic trouble codes.

LOCATION<br />

IGNITION - IGNITION SYSTEM (3SZ-VE)<br />

IG–2<br />

IGNITION COIL ASSEMBLY<br />

CAMSHAFT POSITION SENSOR<br />

IG<br />

CRANKSHAFT POSITION SENSOR<br />

SPARK PLUG<br />

A137728J01

IG<br />

IG–3<br />

IGNITION SYSTEM (K3-VE)<br />

ENGINE<br />

IGNITION - IGNITION SYSTEM (K3-VE)<br />

OPERATION CHECK<br />

1. PERFORM SPARK TEST<br />

(a) Check for diagnostic trouble codes. (See page ES-8)<br />

NOTICE:<br />

If a DTC is detected, perform the troubleshooting procedures<br />

for the corresponding DTC.<br />

(b) Perform the <strong>spark</strong> test.<br />

(1) Remo<strong>ve</strong> the air cleaner assembly.<br />

(2) Disconnect the connector from the ignition coil.<br />

(3) Remo<strong>ve</strong> the ignition coil.<br />

(4) Remo<strong>ve</strong> the <strong>spark</strong> <strong>plug</strong>.<br />

(5) Install the <strong>spark</strong> <strong>plug</strong> to the ignition coil and connect the<br />

connector.<br />

(6) Disconnect all connectors of the fuel injector assembly.<br />

(7) Ground the <strong>spark</strong> <strong>plug</strong>.<br />

(8) Make sure that <strong>spark</strong>s occur when the engine is cranking.<br />

NOTICE:<br />

• Be sure to ground the hexagonal part or the thread<br />

of the ground electrode of the <strong>spark</strong> <strong>plug</strong>.<br />

• If the ignition coil has been dropped or struck,<br />

replace it.<br />

• Do not crank the engine for more than 2 seconds.<br />

(9) Connect the connector of the fuel injector assembly.<br />

(10) Install the <strong>spark</strong> <strong>plug</strong>s.<br />

Torque: 20 N*m (204 kgf*cm)<br />

(11) Install the ignition coils.<br />

Torque: 7.5 N*m (76 kgf*cm)<br />

(12) Connect the connector to the ignition coil.<br />

(13) Check for diagnostic trouble codes.

LOCATION<br />

IGNITION - IGNITION SYSTEM (K3-VE)<br />

IG–4<br />

IGNITION COIL ASSEMBLY<br />

CAMSHAFT POSITION SENSOR<br />

IG<br />

CRANKSHAFT POSITION SENSOR<br />

SPARK PLUG<br />

A137728J01

IG–5<br />

IGNITION - CAM POSITION SENSOR (3SZ-VE)<br />

CAM POSITION SENSOR (3SZ-VE)<br />

ENGINE IGNITION<br />

COMPONENTS<br />

AIR CLEANER ASSEMBLY<br />

T=7.5{76}<br />

T=18{184}<br />

T=7.5{76}<br />

CAMSHAFT POSITION SENSOR<br />

IG<br />

T=7.5{76}<br />

AIR CLEANER HOSE NO. 1<br />

TIGHTENING TORQUE<br />

A139037J01

IGNITION - CAM POSITION SENSOR (3SZ-VE)<br />

IG–6<br />

REMOVAL<br />

1. REMOVE AIR CLEANER HOSE NO. 1 (See page CO - 15)<br />

2. REMOVE AIR CLEANER ASSEMBLY (See page EM - 146)<br />

3. REMOVE CAM POSITION SENSOR<br />

(a) Remo<strong>ve</strong> the bolt, then remo<strong>ve</strong> the wire harness clamp.<br />

A138814<br />

(b)<br />

Disconnect the connector.<br />

IG<br />

A138817<br />

(c)<br />

(d)<br />

Remo<strong>ve</strong> the bolt, then remo<strong>ve</strong> the wire harness clamp.<br />

Disconnect the connector.<br />

A138988

IG–7<br />

IGNITION - CAM POSITION SENSOR (3SZ-VE)<br />

(e)<br />

Remo<strong>ve</strong> the bolt, then remo<strong>ve</strong> the cam position sensor.<br />

INSTALLATION<br />

1. INSTALL CAM POSITION SENSOR<br />

(a) Apply a light coat of engine oil to the O-ring.<br />

A138990<br />

IG<br />

(b)<br />

(c)<br />

Using a priset torque wrench, install the cam position sensor<br />

with the bolt.<br />

Torque: 7.5 N*m (76 kgf*cm)<br />

NOTICE:<br />

Be careful that the O-ring is not cracked or pinched when<br />

installing it to the cylinder head.<br />

Connect the connector.<br />

A138990

IGNITION - CAM POSITION SENSOR (3SZ-VE)<br />

IG–8<br />

(d)<br />

Install the wire harness clamp with the bolt.<br />

A138988<br />

(e)<br />

Install the wire harness clamp with the bolt.<br />

IG<br />

A138817<br />

(f)<br />

(g)<br />

Install the wire harness clamp with the bolt.<br />

Connect the connector.<br />

2. INSTALL AIR CLEANER ASSEMBLY (See page EM - 167)<br />

3. INSTALL AIR CLEANER HOSE NO. 1 (See page CO - 19)<br />

INSPECTION<br />

A138814<br />

1. INSPECT CAM POSITION SENSOR<br />

(a) Using a tester, measure the resistance between the connector<br />

terminals.<br />

Standard:<br />

1850 to 2450 Ω (20°C)<br />

2 1<br />

A105341J05

IG–9<br />

IGNITION - CAM POSITION SENSOR (K3-VE)<br />

CAM POSITION SENSOR (K3-VE)<br />

ENGINE IGNITION<br />

COMPONENTS<br />

AIR CLEANER ASSEMBLY<br />

T=7.5{76}<br />

T=18{184}<br />

T=7.5{76}<br />

CAMSHAFT POSITION SENSOR<br />

IG<br />

T=7.5{76}<br />

AIR CLEANER HOSE NO. 1<br />

TIGHTENING TORQUE<br />

A139037J01

IGNITION - CAM POSITION SENSOR (K3-VE)<br />

IG–10<br />

REMOVAL<br />

1. REMOVE AIR CLEANER HOSE NO. 1 (See page CO-22)<br />

2. REMOVE AIR CLEANER ASSEMBLY (See page EM-173)<br />

3. REMOVE CAM POSITION SENSOR<br />

(a) Remo<strong>ve</strong> the bolt, then remo<strong>ve</strong> the wire harness clamp.<br />

A138814<br />

(b)<br />

Disconnect the connector.<br />

IG<br />

A138817<br />

(c)<br />

(d)<br />

Remo<strong>ve</strong> the bolt, then remo<strong>ve</strong> the wire harness clamp.<br />

Disconnect the connector.<br />

A138988

IG–11<br />

IGNITION - CAM POSITION SENSOR (K3-VE)<br />

(e)<br />

Remo<strong>ve</strong> the bolt, then remo<strong>ve</strong> the cam position sensor.<br />

INSTALLATION<br />

1. INSTALL CAM POSITION SENSOR<br />

(a) Apply a light coat of engine oil to the O-ring.<br />

A138990<br />

IG<br />

(b)<br />

(c)<br />

Using a pri set torque wrench, install the cam position sensor<br />

with the bolt.<br />

Torque: 7.5 N*m (76 kgf*cm)<br />

NOTICE:<br />

Be careful that the O-ring is not cracked or pinched when<br />

installing it to the cylinder head.<br />

Connect the connector.<br />

A138990

IGNITION - CAM POSITION SENSOR (K3-VE)<br />

IG–12<br />

(d)<br />

Install the wire harness clamp with the bolt.<br />

A138988<br />

(e)<br />

Install the wire harness clamp with the bolt.<br />

IG<br />

A138817<br />

(f)<br />

(g)<br />

Install the wire harness clamp with the bolt.<br />

Connect the connector.<br />

2. INSTALL AIR CLEANER ASSEMBLY (See page EM-194)<br />

3. INSTALL AIR CLEANER HOSE NO. 1 (See page CO-26)<br />

INSPECTION<br />

A138814<br />

1. INSPECT CAM POSITION SENSOR<br />

(a) Using a tester, measure the resistance between the connector<br />

terminals.<br />

Standard:<br />

1850 to 2450 Ω(20°C)<br />

2 1<br />

A105341J05

IG–13<br />

IGNITION - CRANK POSITION SENSOR (3SZ-VE)<br />

CRANK POSITION SENSOR (3SZ-VE)<br />

ENGINE IGNITION<br />

COMPONENTS<br />

IG<br />

ENGINE UNDER COVER<br />

T=7.5{76}<br />

T=5.4{55} ×11 CRANKSHAFT POSITION SENSOR<br />

TIGHTENING TORQUE<br />

A136972J01

IGNITION - CRANK POSITION SENSOR (3SZ-VE)<br />

IG–14<br />

REMOVAL<br />

1. REMOVE ENGINE UNDER COVER<br />

2. REMOVE CRANK POSITION SENSOR<br />

(a) Disconnect the connector.<br />

(b)<br />

Remo<strong>ve</strong> the bolt, then remo<strong>ve</strong> the crank position sensor.<br />

INSTALLATION<br />

1. INSTALL CRANK POSITION SENSOR<br />

(a) Apply a light coat of engine oil to the O-ring.<br />

A137749<br />

A137749<br />

(b) Install the crank position sensor with the bolt.<br />

Torque: 7.5 N*m (76 kgf*cm)<br />

NOTICE:<br />

Be careful that the O-ring is not cracked or pinched when<br />

installing it to the cylinder head.<br />

(c) Connect the connector.<br />

2. INSTALL ENGINE UNDER COVER (See page CO-26)<br />

INSPECTION<br />

IG<br />

2<br />

1<br />

1. INSPECT CRANK POSITION SENSOR<br />

(a) Check the resistance.<br />

(1) Using a tester, measure the resistance between the connector<br />

terminals.<br />

Standard:<br />

1850 to 2450 Ω (20°C)<br />

A133584

IG–15<br />

IGNITION - CRANK POSITION SENSOR (K3-VE)<br />

CRANK POSITION SENSOR (K3-VE)<br />

ENGINE IGNITION<br />

COMPONENTS<br />

IG<br />

ENGINE UNDER COVER<br />

T=7.5{76}<br />

T=5.4{55} ×11 CRANKSHAFT POSITION SENSOR<br />

TIGHTENING TORQUE<br />

A136972J01

IGNITION - CRANK POSITION SENSOR (K3-VE)<br />

IG–16<br />

REMOVAL<br />

1. REMOVE ENGINE UNDER COVER<br />

2. REMOVE CRANK POSITION SENSOR<br />

(a) Disconnect the connector.<br />

(b)<br />

Remo<strong>ve</strong> the bolt, then remo<strong>ve</strong> the crank position sensor.<br />

INSTALLATION<br />

1. INSTALL CRANK POSITION SENSOR<br />

(a) Apply a light coat of engine oil to the O-ring.<br />

A137749<br />

A137749<br />

(b)<br />

(c)<br />

Install the crank position sensor with the bolt.<br />

Torque: 7.5 N*m (76 kgf*cm)<br />

NOTICE:<br />

Be careful that the O-ring is not cracked or pinched when<br />

installing it to the cylinder head.<br />

Connect the connector.<br />

2. INSTALL ENGINE UNDER COVER (See page EM-195)<br />

INSPECTION<br />

IG<br />

2<br />

1<br />

1. INSPECT CRANK POSITION SENSOR<br />

(a) Check the resistance.<br />

(1) Using a tester, measure the resistance between the connector<br />

terminals.<br />

Standard:<br />

1850 to 2450 Ω(20°C)<br />

A133584

IG–17<br />

IGNITION - SPARK PLUG (3SZ-VE)<br />

SPARK PLUG (3SZ-VE)<br />

ENGINE IGNITION<br />

INSPECTION<br />

1. INSPECT SPARK PLUG<br />

(a) Inspect <strong>spark</strong> <strong>plug</strong> gap.<br />

NOTICE:<br />

• Because an iridium <strong>plug</strong> is used, do not adjust the gap<br />

of the <strong>spark</strong> <strong>plug</strong> except when using a new <strong>plug</strong> (when<br />

the <strong>ve</strong>hicle was dri<strong>ve</strong>n 1000 km or less).<br />

• Do not damage the iridium tip.<br />

Standard<br />

Manufacturer<br />

Type<br />

Specified Value<br />

(mm)<br />

Maximum (mm)<br />

NGK IKR7C 0.8-0.9 1.1<br />

IG<br />

(b)<br />

(c)<br />

If the gap is larger than the maximum, replace the <strong>spark</strong> <strong>plug</strong><br />

because the iridium tip is worn out.<br />

NOTICE:<br />

Because a long-reach <strong>plug</strong> is used, be sure to replace the<br />

<strong>plug</strong> with the specified <strong>plug</strong>.<br />

Clean the <strong>spark</strong> <strong>plug</strong>.<br />

NOTICE:<br />

Do not clean the <strong>spark</strong> <strong>plug</strong> as it may damage the iridium<br />

tip.Howe<strong>ve</strong>r, if the <strong>plug</strong> is extremely dirty due to smoke<br />

damage or for other reasons, the <strong>spark</strong> <strong>plug</strong> may be<br />

cleaned for <strong>ve</strong>ry short time (less than 20 seconds) using a<br />

<strong>spark</strong> <strong>plug</strong> cleaner. In order to pre<strong>ve</strong>nt damage to the electrode,<br />

do not exceed 20 seconds.

IGNITION - SPARK PLUG (K3-VE)<br />

IG–18<br />

SPARK PLUG (K3-VE)<br />

ENGINE IGNITION<br />

INSPECTION<br />

1. CHECK SPARK PLUG<br />

(a) Inspect <strong>spark</strong> <strong>plug</strong> gap.<br />

Standard<br />

Manufacturer Type Specified Value (mm)<br />

NGK BKR6EY-11 1.0-1.1<br />

DENSO K20R-U11 1.0-1.1<br />

(b)<br />

(c)<br />

(d)<br />

(e)<br />

Inspect for smoke damage or excessi<strong>ve</strong> burning on the <strong>spark</strong><br />

<strong>plug</strong>.<br />

Check the <strong>plug</strong> gap using a <strong>plug</strong> gap gauge.<br />

If the gap is larger than the maximum, replace the <strong>spark</strong> <strong>plug</strong><br />

because the iridium tip is worn out.<br />

Clean the <strong>spark</strong> <strong>plug</strong>.<br />

IG<br />

TO INDEX<br />

TO NEXT SECTION