You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ENGINE COMPONENTS<br />

PROGRAM<br />

PRODUCT INFORMATION<br />

AFTERMARKET

THERE ARE CARS,<br />

WHEREVER<br />

<strong>MAHLE</strong> IS THERE.

About us<br />

In the beginning there was innovation: the first<br />

light-alloy piston in 1921 was the prelude to the<br />

<strong>MAHLE</strong> success story in all aspects of the combustion<br />

engine. This was followed by many more<br />

market defining innovations in the engine component<br />

and filter sector: for example, the first<br />

series-produced aluminum engine block in 1976,<br />

the production of assembled camshafts in 1985,<br />

the start of production for pistons with cooled<br />

ring carriers for passenger car diesel engines in<br />

2000, the first multifunctional oil filter modules<br />

with plastic tube in 2003 or the first complete<br />

engine from <strong>MAHLE</strong> in 2004.<br />

industry, dealers and workshops can therefore<br />

be assured: a product from the <strong>MAHLE</strong> <strong>Group</strong> is<br />

always a product that can be relied on – with<br />

guarantee. In the engine component sector, we<br />

supply the aftermarket according to geographic<br />

region with a comprehensive product range of<br />

the renowned brands <strong>MAHLE</strong> Original, Metal<br />

Leve, Cofap rings, Izumi, Clevite and Perfect<br />

Circle. Thanks to the recent integration of the<br />

Mopisan <strong>Group</strong> into the <strong>MAHLE</strong> manufacturing<br />

network, the production capacity, especially for<br />

small and medium batch sizes for pistons and<br />

cylinder liners has been extended once more.<br />

As development partner of the international<br />

automotive and engine industry and in the top-<br />

3 of system suppliers, we are today not only<br />

represented in every second vehicle, but also<br />

on the racing circuits, where racers equipped<br />

with <strong>MAHLE</strong> products cross the finish line regularly<br />

in front positions – recently for instance<br />

in Formula 1, the 24 hours race in Le Mans or<br />

in Truck Racing.<br />

More than 2,500 engineers work in eight R&D<br />

centers worldwide on new and intelligent solutions<br />

for the combustion engine of the future<br />

with the aim of securing and extending this<br />

innovative advantage. Those engineers develop<br />

innovative products that are manufactured in<br />

110 production sites worldwide by about<br />

48,000 employees and sold all over the world.<br />

<strong>MAHLE</strong> has also local representations in all<br />

important world markets.<br />

All our customers benefit from this global presence<br />

– customers from the original equipment<br />

sector and those from the aftermarket. It makes<br />

no difference whether <strong>MAHLE</strong> makes a product<br />

for the automotive industry or for the independent<br />

aftermarket: our products always meet<br />

the same high standards. The automotive<br />

A look at the original equipment customer list<br />

will confirm that more than 140 renowned<br />

engine and vehicle manufacturers decide every<br />

day in favor of engine components and filters<br />

from <strong>MAHLE</strong>. Here a small selection:<br />

Alfa Romeo, Audi, BMW, Case New Holland,<br />

Caterpillar, Citroën, Cummins, Daewoo, DAF,<br />

Deutz, Ducati, Ferrari, Fiat, Ford, General Motors,<br />

Harley Davidson, Hatz, Honda, Hyundai, Isuzu,<br />

Iveco, Jaguar, John Deere, Komatsu, Lancia,<br />

Land Rover, Mack, Magna Steyr, MAN, Maserati,<br />

Mazda, Mercedes-Benz, Mitsubishi, Moto Guzzi,<br />

MWM, Nissan, Perkins, Peugeot, Porsche,<br />

Renault, RVI, Saab, Scania, Seat, Škoda, Smart,<br />

Steyr Daimler Puch, Stihl, Suzuki, Toyota, Volks -<br />

wagen, Volvo, Zettelmeyer.<br />

All <strong>MAHLE</strong> production<br />

sites are certified by re -<br />

nowned vehicle manufacturers<br />

– and by all<br />

relevant certification<br />

authorities.<br />

3

THEIR FINGERS<br />

OUR COMPETITION DOESN’T WANT TO BURN<br />

IN THE FORMULA 1.

Pistons<br />

Our pistons have to put up with extreme pressures,<br />

as their working conditions have become<br />

significantly tougher in recent years. For example,<br />

the thermal loads (with temperatures in the combustion<br />

chamber reaching 2,600 °C) and the<br />

average ignition pressures have greatly increased.<br />

Also the inertial force loads have increased due<br />

to high-speed concepts and a tendency to larger<br />

piston strokes. Naturally, the demands on pistons<br />

have also risen progressively: they are to<br />

be lighter, to have lower oil consumption and<br />

should be absolutely safe – and this even under<br />

extreme conditions such as hot and cold load<br />

capacity testing and continuous running under<br />

thermal shock.<br />

And the effects of these demands: the overall<br />

height or compression height of the pistons has<br />

decreased continuously. New solutions such as<br />

the ECOFORM ® piston concept developed by<br />

<strong>MAHLE</strong> allow further weight reductions. And with<br />

MONOTHERM ® pistons, which are single-piece<br />

steel pistons that are machined accordingly, it is<br />

possible to achieve the same weight as with<br />

pistons made from aluminum in the meantime.<br />

However, significant improvements have also<br />

been made with aluminum pistons such as the<br />

<strong>MAHLE</strong> pistons with cooled ring carriers.<br />

We also benefit in this field greatly from our successes<br />

in motorsports – after all, we are the only<br />

producer of series products who is gaining its<br />

experiences from Formula 1. As the world’s<br />

largest manufacturer of pistons, <strong>MAHLE</strong> is oper -<br />

at ing an intensive research program into the<br />

products of tomorrow and offers you today so -<br />

lu tions for almost any engine – fast, reliably and<br />

all over the world. With our pistons, we offer the<br />

aftermarket the opportunity to benefit from<br />

products of the original equipment market and<br />

the inherent safety of products that have been<br />

tried and tested in practice under most grueling<br />

conditions. We warrant this.<br />

The only supplier of<br />

series produced pistons<br />

to Formula 1: <strong>MAHLE</strong>.<br />

On the piston top, you<br />

will find the company or<br />

trade mark, the maximum<br />

piston diameter, the<br />

mounting clearance and<br />

the fitting direction ac -<br />

cording to the respective<br />

engine makers specifications.<br />

The market leader<br />

offers you security.<br />

With the non-replicable<br />

hologram on all new<br />

European engine component<br />

packaging – and<br />

the security strip that<br />

indicates whether the<br />

packaging has already<br />

been opened.<br />

5

The optimum piston for every engine<br />

ECOFORM ® pistons with<br />

pivoting side-cores<br />

Weight optimized pistons for passenger<br />

car gasoline engines. As a<br />

re sult of a special casting technology<br />

these pistons offer low weight<br />

and high structural rigidity.<br />

AUTOTHERMATIK ® /<br />

HYDROTHERMATIK ® pistons<br />

These pistons are mainly used in ga soline<br />

and diesel engines for passenger<br />

cars under heavy load conditions.<br />

They have cast-in steel strips but are<br />

not slotted. As a result, they form a<br />

uniform body with extreme strength.<br />

AUTOTHERMIK ® /<br />

HYDRO THERMIK ® pistons<br />

These very quiet running pistons are<br />

used primarily in passenger cars.<br />

The pistons have cast-in steel strips<br />

and are slotted at the transition from<br />

ring belt to skirt section.<br />

Cast solid skirt pistons<br />

Piston top, ring belt and skirt form a<br />

robust unit. Cast full-skirt pistons have<br />

a long service life and can be used<br />

in gasoline and diesel engines. Their<br />

range of applications reaches from<br />

model engines to large power units.<br />

Forged solid skirt pistons<br />

This type of piston can mainly be<br />

found in high performance serial en -<br />

gines and racing engines. Due to the<br />

manufacturing process, they are of<br />

higher strength and allow therefore<br />

reduced wall cross-sections and lower<br />

piston weight.<br />

8

Pistons<br />

Pistons with cooled ring carriers<br />

For these pistons, ring carriers and<br />

cooling galleries are combined into<br />

one system in a special production<br />

process. This provides the pistons<br />

with significantly improved heat re -<br />

moval properties, especially in the<br />

first ring groove.<br />

Ring carrier pistons with<br />

pin boss bushes<br />

These pistons for diesel engines have<br />

a ring carrier made from special cast<br />

iron that is connected metallically and<br />

rigidly with the piston material in order<br />

to make it more wear resistant, in<br />

par ticular in the first groove. With pin<br />

boss bushes made from a special<br />

material, the loadability of the pin<br />

boss is increased.<br />

Ring carrier pistons with cooling<br />

gallery and crown reinforcement<br />

These pistons are used in diesel en -<br />

gines under heavy load conditions.<br />

For additional protection and to avoid<br />

cavity edge or crown fissures, these<br />

pistons have a special hard anodized<br />

layer (HA layer) on the crown.<br />

Ring carrier pistons with<br />

cooling gallery<br />

Ring carrier pistons with cooling galleries<br />

are used in conditions with particularly<br />

high operating temperatures.<br />

Because of the high temperatures at<br />

the piston top and the ring belt, intensive<br />

cooling is provided with oil circulating<br />

through the cooling gallery.<br />

FERROTHERM ® pistons<br />

A steel piston top and an aluminum<br />

piston skirt that are connected flexibly<br />

via the gudgeon pin. Due to their high<br />

strength and low wear values, these<br />

pistons make it possible to comply<br />

with the low exhaust and emission<br />

standards, especially for diesel en gines<br />

under heavy loads.<br />

Two-stroke pistons<br />

Pistons made from special aluminum<br />

alloys that can withstand the high<br />

me chanical and thermal loads of twostroke<br />

engines.<br />

7

0.004 MM –<br />

THIS CAN<br />

MAKE THE DIFFERENCE.

Piston rings<br />

In modern engines, and for high continuous outputs,<br />

our piston rings take reliable and precise<br />

care of the welfare of their carriers. As the leading<br />

manufacturer of pistons, we work steadily to<br />

opti mize the performance and running quality of<br />

our piston rings. And we set quality standards<br />

also in this field with state-of-the-art production<br />

facilities. With decades of experience in development<br />

and production, we can assure optimum<br />

interplay between our pistons and piston rings<br />

and can satisfy the highest demands.<br />

Piston rings have three important functions in<br />

modern engines:<br />

■<br />

■<br />

■<br />

They seal the combustion chamber from the<br />

crankcase.<br />

They limit and regulate the oil consumption.<br />

They dissipate the heat that is taken up by the<br />

pistons during combustion to the cooled cylinder<br />

working surfaces.<br />

In order to satisfy these demands, the piston<br />

rings must fit tightly to the cylinder wall over their<br />

entire circumference, even if the cylinder deviates<br />

slightly from its ideal form. Due to the high inertial<br />

forces and combustion pressures as well as the<br />

high wear producing loads, the piston rings have<br />

to satisfy high demands in respect of piston ring<br />

material (strength/temperature stability) as well<br />

as surface finish and shape.<br />

The ideal ring set for every piston<br />

We offer you different versions of piston ring sets<br />

in original equipment quality or especially for<br />

engines that have already been running with the<br />

aim to reduce their compression losses and to<br />

normalize oil consumption. We can supply piston<br />

ring sets for almost any gasoline and diesel en -<br />

gine for passenger cars as well as for commercial<br />

vehicles, at diameters from 60 to 160 mm.<br />

Materials<br />

Only high-grade materials are used for our piston<br />

rings. For normal or heavy loads, lamellar<br />

graph ite cast iron materials are used and for the<br />

highest demands, nodular graphite cast iron<br />

materials or steel materials are used.<br />

Ring face coatings<br />

Special coatings can be applied to the ring<br />

faces of piston rings to increase wear resis tance<br />

and avoid the formation of scuff-marks. For<br />

instance, chromium coatings or plasma spray<br />

coatings of metallic or ceramic materials are<br />

used for this purpose.<br />

The <strong>MAHLE</strong> “N” piston<br />

ring set offers you the piston<br />

rings that are also used<br />

as original equipment.<br />

The <strong>MAHLE</strong> “V” and “G”<br />

piston ring sets have been<br />

developed especially for<br />

engines that have been<br />

running for some time.<br />

It is essential that the TOP<br />

markings are observed.<br />

Rings with TOP markings<br />

have to be fitted with these<br />

markings facing upwards<br />

in direction piston head.<br />

9

WE ARE<br />

STRICT WITH OUR<br />

TOLERANCES.

Cylinder liners<br />

The steadily rising demands on internal combus<br />

tion engines require also in the area of cylinder<br />

working surfaces continuous improvements.<br />

The precise matching of the honed cylinder liners<br />

with the pistons and piston rings, leads to im -<br />

proved results in the engine. For cylinder liners<br />

made from gray cast iron, it is therefore necessary<br />

to create optimum surfaces that contribute<br />

to lower oil consumption and blow-by, produce<br />

less wear particles and allow shorter running-in<br />

times and therefore a longer service life.<br />

<strong>MAHLE</strong> manufactures cylinder liners for international<br />

engine manufacturers for series production<br />

and the aftermarket – always according to the<br />

same strict quality standards. We manufacture<br />

our cylinder liners with very strict tolerances.<br />

There by ensuring, among other things, that the<br />

cylinder liners can be optimally fitted into the<br />

engine block. Additional important quality characteristics<br />

of our cylinder liners are the materials,<br />

the structure and the surface quality. In close<br />

co operation with engine manufacturers, we de -<br />

ter mine the composition of the melt, the treatment<br />

of the melt and the machining process.<br />

Materials<br />

In addition to aluminum, cast iron alloys are used<br />

as materials for cylinder liners. Lamellar graphite<br />

cast iron is alloyed with phosphorus. Additional<br />

alloy materials improve the wear properties and<br />

can strengthen the matrix due to bainite and very<br />

fine perlite formations.<br />

Honing methods<br />

Good honing has a positive effect on piston ring<br />

wear, particle emission, oil consumption and friction.<br />

With further developments and innovations<br />

in the honing of cylinder liners, it is attempted to<br />

keep the running-in phase of the cylinder<br />

(engine) as short as possible and to achieve<br />

improved tribological properties. An important<br />

prerequisite for good and regular honing of the<br />

cylinder liners is high material quality. This<br />

means, cast material free of voids, with homoge -<br />

neous structure and uniform hardness as well<br />

as suitable pre-machining of the bore.<br />

Lamellar graphite.<br />

Honing<br />

Method of machining, in<br />

which the tool carries out<br />

reciprocating and rotating<br />

movements. With this<br />

method, a cylinder form<br />

error below 10 μm and an<br />

even surface roughness<br />

can be achieved.<br />

Tribology<br />

The science of friction,<br />

lubrication and wear of<br />

bodies in relative motion.<br />

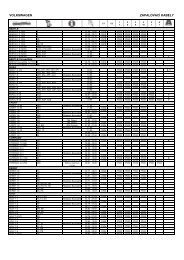

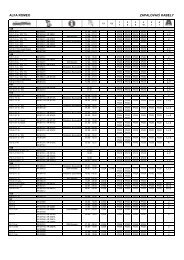

The most important honing methods in single processing steps<br />

Description<br />

Honing process<br />

Application<br />

Version<br />

1st Operation<br />

2nd Operation<br />

3rd Operation<br />

4th Operation<br />

Normal honing<br />

1<br />

2<br />

3<br />

Diamond<br />

Diamond<br />

Ceramic<br />

Diamond<br />

Ceramic<br />

Ceramic<br />

Series gasoline car<br />

Series diesel car<br />

Series commercial vehicle<br />

Plateau honing<br />

1<br />

2<br />

3<br />

Diamond<br />

Diamond<br />

Diamond<br />

Diamond<br />

Diamond<br />

Ceramic<br />

Diamond<br />

Diamond<br />

Ceramic<br />

Series gasoline car<br />

Series diesel car<br />

Series commercial vehicle<br />

Brush honing<br />

1<br />

2<br />

Diamond<br />

Diamond<br />

Diamond<br />

Ceramic<br />

Brushing<br />

Brushing<br />

Series car/commercial<br />

Liquid honing<br />

Diamond<br />

Diamond<br />

Liquid honing<br />

Micro-finishing<br />

Series diesel car<br />

Laser honing<br />

1<br />

2<br />

Diamond<br />

Diamond<br />

Laser structure<br />

Diamond/Ceramic<br />

Ceramic<br />

Laser structure<br />

Ceramic<br />

Experimental/motorsports<br />

11

WELL SUPPORTED WITH<br />

BEARINGS.

Bearings<br />

Bearings support rotating shafts such as crankshafts,<br />

camshafts, rocker arm shafts or balancer<br />

shafts in the engine block or in the connecting<br />

rods. The mechanical stress in internal combustion<br />

engines is extremely high. Our bearings<br />

have therefore to meet a number of quality charac<br />

te ristics: they have to be fatigue-resis ting,<br />

adaptable, highly loadable and wear and corrosion<br />

resistant.<br />

In cooperation with engine manufacturers, we<br />

develop and test the bearings for every single<br />

engine type. Ongoing basic research and further<br />

developments of materials and production techno<br />

logies ensure economically and technically<br />

optimized products of highest quality.<br />

Materials and production methods<br />

Material development is extremely important in<br />

order that bearings can meet the high demands.<br />

Thanks to years of experience and developments,<br />

<strong>MAHLE</strong> disposes over a large number of<br />

bearing alloys such as aluminum and bronze<br />

alloys. Depending on the application, our bearings<br />

consist of a high-strength steel backing that<br />

is coated with different bearing metals. With<br />

regard to their applications, the bearing materials<br />

are chosen in such a way that their properties<br />

compliment one another optimally.<br />

During the production process, we use different<br />

coating methods that depend, for instance, on<br />

the relative bearing loads.<br />

We offer you a comprehensive<br />

range of bearings,<br />

available under <strong>MAHLE</strong><br />

Original and – in Europe –<br />

Perfect Circle.<br />

Our product range comprises bearing shells and<br />

thrust washers in a diameter range from 27 to<br />

140 mm as well as bushings with diameters<br />

from 6 to 105 mm.<br />

Types<br />

Sputtering<br />

Coating method that works<br />

on the principle of cathode<br />

sputtering, in which atoms<br />

are knocked- out from a<br />

metal cathode due to the<br />

impacting ions from a gas<br />

discharge proc ess. The<br />

resulting atomized metal<br />

condenses on the bearing<br />

surface of the bearing shell<br />

as a uni form layer.<br />

Solid bearings<br />

Solid bearings are made completely from<br />

special bearing metal that consist of<br />

special alloys.<br />

Two-material bearings<br />

Two-material bearings are used for low<br />

to medium loads in petrol and naturally<br />

aspirated diesel engines in passenger<br />

cars. They consist of a steel backing, an<br />

intermediate layer and a layer of bearing<br />

metal. Mainly aluminum alloys are used<br />

as bearing metal.<br />

Three-material bearings<br />

Three-material composite bearings are<br />

mainly used in engines under heavier<br />

loads. They consist of a steel backing,<br />

a bearing layer, a barrier layer and the<br />

sliding layer. Sputter bearings are special<br />

three-material bearings with signif i-<br />

cantly increased hardness and wearresistance<br />

due to a special production<br />

method (sputtering). Sputter bearings<br />

are therefore ideal for supercharged<br />

engines with intercooling and can now<br />

also be found increasingly in passenger<br />

car diesel engines.<br />

13

SMALL CAUSE,<br />

BIG EFFECT.

Valve train components<br />

Not many components in engines are under<br />

as much load and tribological stress as valves<br />

and their attached parts. At temperatures up to<br />

800 °C, the red-hot exhaust valves strike the<br />

valve seats more than 70 times per second and<br />

must withstand the hot and corrosive exhaust<br />

gases that flow around them. At every valve lift,<br />

enormous acceleration forces and retractive<br />

forces occur due to the strong valve springs.<br />

Valves form a closed system together with valve<br />

seat inserts and valve guides, which has to<br />

withstand highest loads and stresses. We have<br />

there fore not only valves in our program, but<br />

also their tribological partners, valve seat inserts<br />

and valve guides. The combined development of<br />

these products in one system allows us to attain<br />

advantages in respect of wear characteristics<br />

and costs of the components.<br />

Any kind of valve<br />

<strong>MAHLE</strong> manufactures high-quality valves for in -<br />

ter nal combustion engines worldwide at several<br />

production sites. Our program includes valves of<br />

diverse designs and types for passenger cars<br />

and commercial vehicles from 5 to 12 mm stem<br />

diam eter as well as valve lengths from 80 to 210<br />

mm. Thanks to the high technical know-how, the<br />

high productivity and the outstanding quality of<br />

these products, <strong>MAHLE</strong> today is one of the<br />

world’s most important valve manufacturers.<br />

secure our quality standards. For example we<br />

use plasma powder methods in raw part production<br />

or high-speed grinding methods for<br />

mechanical finishing. In order to make valves<br />

resistant to the high loads, our valves have<br />

hard-faced seats, are hardened, chrome-plated<br />

or nitrided according to the requirements. A<br />

wide range of materials is available for every<br />

application. For special applications with extreme<br />

de mands, also sodium filled valves are available<br />

to reduce thermal loads.<br />

Valve guides and valve seat inserts<br />

The valve guides centre the valves in respect to<br />

the valve seats and compensate for the lateral<br />

forces acting on the valve shafts. In addition,<br />

they need to dissipate the generated heat<br />

towards the cylinder head. Depending on engine<br />

design, identical or different valve guides are<br />

used for the intake and exhaust side. The range<br />

of materials reaches from gray cast iron and<br />

brass to sintered materials of various alloys.<br />

The valve seat insert has the task of sealing the<br />

combustion chamber against pressure loss. In<br />

addition it is responsible for heat dissipation.<br />

Another important task is to prevent impacting<br />

of the valve into the softer cylinder head material.<br />

Valve seat inserts are predominately made<br />

from chromium-steel alloys. Also sinter materials<br />

are now increasingly being used.<br />

Tribology<br />

The science of friction,<br />

lubrication and wear of<br />

bodies in relative motion.<br />

We employ state-of-the-art production technol -<br />

ogy as part of our large-volume production to<br />

Materials<br />

Austenitic steels<br />

Martensitic steels<br />

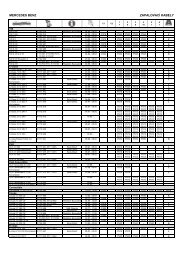

Types<br />

Mono-metal valves<br />

Bi-metal valves<br />

Valve seat<br />

Plasma powder facing<br />

Induction hardening<br />

Valve tip induction hardening<br />

Profile hardening<br />

Through hardening<br />

Tip surface hardening<br />

Hollow valves<br />

Stem size: > 6 mm<br />

Bore sealing:<br />

■ Laser welding<br />

■ Friction welding<br />

Sodium filling<br />

Fillet profile<br />

Turned, ground<br />

As forged<br />

Head top surface<br />

Machined<br />

As forged<br />

With or without dish<br />

Valve tip geometry<br />

1–3 grooves<br />

Special designs<br />

Valve length<br />

80–210 mm<br />

Valve head diameter<br />

18–65 mm<br />

Valve stem diameter<br />

5–12 mm<br />

Surface treatment<br />

Salt bath nitrided<br />

Hard chrome plated<br />

(Coating thickness: 3–35 μm)<br />

The greatest challenge is<br />

to determine the design of<br />

the valves. Our valves are<br />

designed for a wide variety<br />

of operating conditions in<br />

order to withstand the extreme<br />

mechanical, chemical<br />

and thermal loads and<br />

to assure optimum heat<br />

dissipation.<br />

15

WHAT ELSE WE HAVE BUILT-IN WITH<br />

EVERY ENGINE<br />

COMPONENT.

Sales and service<br />

The best engine component is of little use when<br />

it is not at the right place at the right time. In<br />

more than a dozen logistics centers and numerous<br />

regional bases at strategic locations in<br />

Europe, North and South America as well as<br />

Asia, <strong>MAHLE</strong> Aftermarket is therefore striving to<br />

provide an optimal flow of goods and consequently<br />

the best possible availability. This forms<br />

the basis for the worldwide supply network<br />

of the international <strong>MAHLE</strong> Aftermarket organization.<br />

for instance, of our constantly updated online<br />

catalog or our popular customer information<br />

system KIS. Furthermore, we offer our customers<br />

a demand-oriented training program. Practical<br />

sales material and informative packaging, complying<br />

with the newest security standards, are also<br />

part of our customer-oriented portfolio.<br />

In addition, we get involved in workshop co oper<br />

ations and also participate in individual advertising<br />

campaigns.<br />

However, apart from product quality and availability<br />

there are other matters to be considered.<br />

For example, the comprehensive customer care<br />

and advice or a convincing package of services.<br />

At <strong>MAHLE</strong> Aftermarket, this starts with the<br />

extensive supply of information. We think here,<br />

Comprehensive public relations work and our<br />

pre sence in the relevant trade and consumer<br />

media also assure that we are widely recog -<br />

nized and contribute to the excellent image of<br />

our brands.<br />

17

Stockholm<br />

<strong>MAHLE</strong> AFTERMARKET – AN<br />

INTERNATIONAL<br />

NETWORK.<br />

THE WORLDWIDE DISTRIBUTION NETWORK ASSURES OPTIMUM AVAILABILITY.<br />

Churubusco, US<br />

Niagara-on-the-Lake, CA<br />

Oldbury, GB<br />

Ann Arbor, US<br />

Poissy, FR<br />

Décines, FR<br />

St<br />

Olive Branch, US<br />

Alcalá de<br />

Henares, ES<br />

Mexico City, MX<br />

Limeira, BR<br />

Itajubá, BR<br />

Santo Tomé, AR

, SE<br />

uttgart, DE<br />

Krotoszyn, PL<br />

Izmir, TR<br />

Okegawa, JP<br />

Tokyo, JP<br />

Shanghai, CN<br />

Dubai, AE<br />

Gurgaon, IN<br />

Melbourne, AU

000007458E.Ra.08/08 www.mahle-aftermarket.com