Kinglake West Sewerage Project - Yarra Valley Water

Kinglake West Sewerage Project - Yarra Valley Water

Kinglake West Sewerage Project - Yarra Valley Water

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WA TER FOR A HEALTHY COUNTRY<br />

<strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong><br />

<strong>Project</strong><br />

Post-implementation project review<br />

CSIRO project team: Stephen Cook and Ashok Sharma<br />

YVW project Team: Francis Pamminger, Rita Narangala and Ranga Fernando<br />

June 2013<br />

Prepared by CSIRO and <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong>

<strong>Water</strong> for a Healthy Country Flagship Report series ISSN: 1835-095X<br />

Australia is founding its future on science and innovation. Its national science agency, CSIRO, is a<br />

powerhouse of ideas, technologies and skills.<br />

CSIRO initiated the National Research Flagships to address Australia’s major research challenges and<br />

opportunities. They apply large scale, long term, multidisciplinary science and aim for widespread adoption<br />

of solutions. The Flagship Collaboration Fund supports the best and brightest researchers to address these<br />

complex challenges through partnerships between CSIRO, universities, research agencies and industry.<br />

The <strong>Water</strong> for a Healthy Country Flagship aims to provide Australia with solutions for water resource<br />

management, creating economic gains of $3 billion per annum by 2030, while protecting or restoring our<br />

major water ecosystems. The work contained in this report is collaboration between CSIRO and <strong>Yarra</strong> <strong>Valley</strong><br />

<strong>Water</strong><br />

For more information about <strong>Water</strong> for a Healthy Country Flagship or the National Research Flagship<br />

Initiative visit www.csiro.au/org/HealthyCountry.html<br />

Citation<br />

Important disclaimer<br />

CSIRO advises that the information contained in this publication comprises general statements based on<br />

scientific research. The reader is advised and needs to be aware that such information may be incomplete<br />

or unable to be used in any specific situation. No reliance or actions must therefore be made on that<br />

information without seeking prior expert professional, scientific and technical advice. To the extent<br />

permitted by law, CSIRO (including its employees and consultants) excludes all liability to any person for<br />

any consequences, including but not limited to all losses, damages, costs, expenses and any other<br />

compensation, arising directly or indirectly from using this publication (in part or in whole) and any<br />

information or material contained in it.<br />

ii <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

Acknowledgements<br />

This project was co- funded by <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong> and the CSIRO <strong>Water</strong> for Healthy Country Flagship.<br />

Francis Pamminger, Ranga Fernando, and Rita Narangala of <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong>, have provided the<br />

necessary reports and data, as well as documenting their experiences with <strong>Kinglake</strong> <strong>West</strong> Sustainable<br />

<strong>Sewerage</strong> <strong>Project</strong>.<br />

The report has been co-authored by the CSIRO and <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong> project teams.

Contents<br />

Acknowledgements<br />

Contents<br />

iii<br />

iv<br />

Figures v<br />

Tables v<br />

Executive summary ...................................................................................................................................... vi<br />

1 Introduction ................................................................................................................................... 10<br />

2 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong> Overview ..................................................................................... 11<br />

2.1 <strong>Project</strong> Background .............................................................................................................. 11<br />

2.2 <strong>Project</strong> Need ........................................................................................................................ 11<br />

2.3 <strong>Kinglake</strong> <strong>West</strong> Case Study..................................................................................................... 12<br />

2.4 Development of a preferred servicing approach for <strong>Kinglake</strong> <strong>West</strong>....................................... 12<br />

2.5 <strong>Sewerage</strong> System Overview ................................................................................................. 15<br />

2.6 Impact of bushfires on the study area .................................................................................. 16<br />

3 Assessment of Individual Components ........................................................................................... 17<br />

3.1 Greywater treatment system ............................................................................................... 17<br />

3.1.1 Greywater System Performance ........................................................................................... 18<br />

3.1.2 Comparison with original sustainability objectives ............................................................... 19<br />

3.1.3 Lessons learnt ...................................................................................................................... 20<br />

3.2 Urine diverting toilets .......................................................................................................... 21<br />

3.2.1 Overview ............................................................................................................................. 21<br />

3.2.2 selection and installation ..................................................................................................... 23<br />

3.2.3 Performance of urine diverting toilets .................................................................................. 24<br />

3.2.4 Impact of Urine diverting toilets on Nitrogen Loads and the STP .......................................... 25<br />

3.3.1 Lessons learnt ...................................................................................................................... 26<br />

3.4 Agronomic trial .................................................................................................................... 27<br />

3.4.1 Yellow <strong>Water</strong> Characteristics ................................................................................................ 28<br />

3.4.2 trial methodology ................................................................................................................ 29<br />

3.4.3 Technical Performance and learnings ................................................................................... 31<br />

3.5 Sewer collection system ....................................................................................................... 32<br />

3.5.1 Selection and installation ..................................................................................................... 32<br />

3.6 <strong>Sewerage</strong> Treatment Plant ................................................................................................... 35<br />

3.6.1 Obtaining the STP site .......................................................................................................... 35<br />

3.6.2 Design of STP and Recycled <strong>Water</strong> Storage ........................................................................... 35<br />

3.6.3 STP estimated costs ............................................................................................................. 36<br />

4 Evaluation against predicted benefits ............................................................................................ 37<br />

4.1 Economic savings of up to 20%............................................................................................. 37<br />

4.2 Increased reliability in water supply from 90% to 100% ........................................................ 38<br />

4.3 Reduce wastewater discharges by up to 50% ....................................................................... 38<br />

4.4 Reduce nitrogen loads to the STP by up to 80% .................................................................... 39<br />

iv <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

4.5 Reduce greenhouse gas emissions by 30% ........................................................................... 39<br />

5 Discussion and Conclusions ............................................................................................................ 40<br />

Appendix A – Available information on <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong> 45<br />

References .................................................................................................................................................. 46<br />

Figures<br />

Figure 1 - <strong>Kinglake</strong> <strong>West</strong> case study location and site overview (circa 2006) ................................................ 12<br />

Figure 2 – Summary of scenario results from RMIT/CSIRO research for Pheasant Creek .............................. 14<br />

Figure 3 - <strong>Kinglake</strong> <strong>West</strong> household servicing configuration ........................................................................ 16<br />

Figure 4 - System configuration at the house lot ......................................................................................... 17<br />

Figure 5 - Urine diverting toilet on display at Murrindindi Shire Council offices, <strong>Kinglake</strong> <strong>West</strong> ................... 22<br />

Figure 6 – Nutrient loads in domestic wastewater by source ....................................................................... 22<br />

Figure 7 – Yellow water reuse – potential routes of human exposure.......................................................... 28<br />

Figure 8 – Nitrogen content in yellow water vs storage time ....................................................................... 29<br />

Figure 9 – Configuration of Yellow <strong>Water</strong> Turf Strips ................................................................................... 30<br />

Figure 10 – Harvested turf strips (left), Test Strip and Irrigation System ...................................................... 31<br />

Figure 11 – Installation of STEP tank ........................................................................................................... 33<br />

Tables<br />

Table 1 - Summary of servicing options explored by Sharma et al. (2006).................................................... 14<br />

Table 2 – Recycled water production from monitored greywater system .................................................... 18<br />

Table 3 - Monitored energy consumption vs manufacturer’s specifications ................................................. 19<br />

Table 4 – Greywater system installation costs ............................................................................................. 20<br />

Table 5 – UDT performance against specifications ...................................................................................... 24<br />

Table 6 - Comparison of untreated wastewater composition ...................................................................... 25<br />

Table 7- Yellow water average nutrient concentrations versus expected concentrations ............................ 28<br />

Table 8 - Comparison of yellow water N:P:K with commercially available fertilisers .................................... 29<br />

Table 9 - Cost comparison of yellow water and seasol ................................................................................. 31<br />

Table 10 - Cost of STEP tank vs grinder pump installation ............................................................................ 33<br />

Table 11 - Costs associated with STP land investigations ............................................................................. 35<br />

Table 12 – STP costs .................................................................................................................................... 36<br />

Table 13 - Comparison between estimated and realised costs..................................................................... 38

Executive summary<br />

The <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> project was undertaken by <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong> (YVW) to determine whether it<br />

was possible to deliver a more sustainable sewerage solution in a developed, unsewered ‘backlog’ area, as<br />

identified in theoretical studies. The <strong>Kinglake</strong> <strong>West</strong> region was selected for the study as it contained many<br />

of the challenges that are typical of backlog areas in that it had many failing septic systems, is remote from<br />

existing infrastructure and is in an environmentally sensitive area.<br />

Through analysis of options, the best configuration for this site was determined to consist of the following:<br />

• Greywater treatment systems on each property, providing recycled water for toilet flushing,<br />

laundry and garden irrigation;<br />

• Urine diverting toilets, with ‘yellow water’ being collected and applied at a local turf farm;<br />

• Reticulated sewerage using septic tank effluent pumps (STEP); and<br />

• A new sewerage treatment plant (STP) producing Class B effluent (yet to be completed).<br />

Such a system was considered to be more sustainable because it was considered that it could be delivered<br />

at a lower economic cost, increase the reliability in water supply, reduce wastewater discharges, reduce<br />

nitrogen loads, and reduce greenhouse gas emissions.<br />

This report has been written to firstly assess whether the predicted results have been achieved, and<br />

secondly to document the transferrable knowledge that may be useful to others in the industry.<br />

This post-implementation review has found that although environmental improvements were delivered,<br />

they were not as significant as predicted and they also came at a higher than expected cost. As a result, the<br />

additional direct costs exceeded the external environmental benefits, which had been instrumental in<br />

justifying this demonstration project as a more sustainable solution. A comparison of predicted<br />

achievements with what was actually achieved is summarised in Table 1.<br />

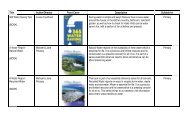

Table 1: Summary of results<br />

Parameter Theoretical prediction 1 Actual results<br />

achieved 2<br />

Economic savings Up to 20% Approximately 40%<br />

more expensive<br />

Increase in reliability in of<br />

water supply<br />

Reduction in wastewater<br />

discharges<br />

Reduced nitrogen loads to<br />

the STP<br />

Reduction in greenhouse gas<br />

emissions<br />

From 90% to 100% 100% 3<br />

Up to 50% 28%<br />

Up to 80% 56%<br />

30% Not yet determined<br />

but unlikely to be<br />

achieved 4<br />

1<br />

The theoretical results were achieved when compared against a gravity sewer - which has been the traditional servicing solution used in the<br />

Victorian water industry, and was YVW’s default servicing<br />

2<br />

The field results include the additional changes that occurred between design and construction as detailed in Section 4.<br />

3<br />

While this numerical target was achieved, it was achieved because householders selected larger rainwater tanks when they rebuilt after the<br />

bushfire, rather than from the greywater system identified from the theoretical study.<br />

4<br />

The STP is not yet operational, however it is unlikely to be achieved in part because the greywater system were more energy intensive than<br />

expected<br />

vi <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

Valuable insights have also been obtained reviewing what was required to construct the scheme and get it<br />

operating. As technologies achieve broader acceptance and uptake it is likely some of these issues would<br />

be resolved through standards development that would assist in ensuring the minimum levels of<br />

performance and reliability. It must be recognised that servicing approach taken for <strong>Kinglake</strong> <strong>West</strong> was<br />

innovative, and therefore the actual performance of approaches in the field was uncertain.<br />

The lessons learnt from this project are presented in a way to provide insights to the industry on why<br />

specific elements were successful, or what is required to make the specific elements successful. The<br />

knowledge acquired for each of the project components is summarised below:<br />

<strong>Sewerage</strong> reticulation<br />

• A highlight of the project was a successfully functioning STEP effluent sewer system – while this<br />

approach is relatively common in the United States there are very few reported examples in<br />

Australia (Asquith, 2010 );<br />

• STEP tanks offer a good approach to extending wastewater services to small communities. They<br />

enable a staged approach to providing services, while also reducing capital and operating costs for<br />

collection systems and STP.<br />

<strong>Sewerage</strong> Treatment Plant<br />

• An innovative approach to designing the STP recycled water storage was adopted, which has<br />

resulted in more accurate sizing and significant cost savings, and this has been accepted by the<br />

Victorian EPA.<br />

• The hypothesis that reduced wastewater volumes would reduce treatment plant cost did not<br />

materialise in this project. For this to occur, a mechanical aeration unit is required. Lower volumes<br />

will then translate into lower energy costs.<br />

Greywater treatment systems<br />

• Greywater systems that utilise biological processes can be affected by cold climate, which<br />

consequently lowers their reliability, and increases the power required for operation. In this case,<br />

the greywater systems also competed with rainwater tanks to increase water supply reliability, and<br />

should accordingly have been assessed for viability at each specific location.<br />

• Selection and installation of in-house units, such as greywater systems, would benefit from having a<br />

stream-lined approach responsible for the installation, supply and maintenance of such a system.<br />

Ideally, a single party managing this would be ideal, as additional responsibilities complicate the<br />

process and introduce a greater risk of potential failure somewhere along the process.<br />

• The high establishment costs of household greywater recycling systems, and the complexity of<br />

devolving some management and O&M responsibilities to householders means that these systems<br />

may be better suited to higher or medium density developments. In this setting a cluster scale<br />

approach could be implemented where a single system serves a number of households, and is<br />

managed and operated under the control of an owner’s corporation.<br />

Urine diversion and yellow water reuse<br />

• Using urine separating toilets does significantly reduce the nutrient load going to the sewage<br />

treatment plant<br />

• Harvested nutrients from domestic sewage can deliver agronomic benefits. The <strong>Kinglake</strong> <strong>West</strong><br />

agronomic trial of yellow water demonstrated the potential benefits on the crop health of<br />

turfgrass, while arguably delivering a better visual quality<br />

• Further refinements are still required to deliver a financially viable proposition for urine separating<br />

toilets. Key issues that were identified included:

o Application of yellow water from urine separating toilets was found to be in the order of<br />

100 times more expensive than commercially available fertilisers<br />

o A major contributor to the high costs was the significant dilution of the urine with toilet<br />

flush water. This dilution increased the costs associated with collecting, transporting and<br />

storing the yellow water and then increases the need for increased effort to achieve<br />

required application concentrations<br />

o The viability would be enhanced with a refined toilet design that uses less water, and/or<br />

higher density collection sites<br />

o Multi story buildings using waterless urinals are seen as a potentially feasible urine<br />

harvesting site.<br />

Adapting to changing conditions<br />

• Changes in circumstances require the flexibility to adapt. In this instance, when customers rebuilt<br />

their houses after the bush fire they installed larger rainwater tanks, and in hindsight, the need for<br />

installing greywater systems was reduced.<br />

Implementation of future trial projects<br />

• Developing a strong partnership with stakeholders contributes positively to the success of a new<br />

servicing project such as this. In this instance, a strong partnership was created among a water<br />

utility, local community, a turf farmer, regulatory authorities and research organisations.<br />

• Trialling new products in new environments would benefit from first being testing in a small-scale<br />

pilot trial. In this case, the project would have benefited from a pilot trial of the urine diverting<br />

toilets and greywater systems. This would have identified that there was a significant difference<br />

between the manufacturer’s specifications for the performance of the urine separating toilets and<br />

greywater systems with the actual performance observed at <strong>Kinglake</strong> <strong>West</strong>.<br />

• The trialling of new products often incurs unforseen costs. The uncertainly in the costs associated<br />

with innovative servicing approaches needs to be accounted for. The capital costs of the <strong>Kinglake</strong><br />

<strong>West</strong> project are likely to be as much as 60% higher than forecast.<br />

• Finally, innovative approaches benefit greatly from post implementation assessment and<br />

monitoring, such as occurred in this project. This ensures that lessons can be used for refining<br />

approaches for future YVW projects, while also providing the broader urban water sector with<br />

important knowledge that can help facilitate increased adoption of more sustainable approaches.<br />

Ultimately, the project has provided YVW with important insight into the implementation of innovative<br />

servicing projects, and could prove a useful case study to the broader water industry in Australia.<br />

viii <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

1 Introduction<br />

The <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong> was implemented by <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong> (YVW) to demonstrate an<br />

innovative approach to providing wastewater services with improved sustainability outcomes. In particular,<br />

the <strong>Project</strong> explored approaches for delivering wastewater infrastructure in peri-urban areas that are<br />

currently serviced by failing septic systems – a situation typical of many YVW “Backlog” areas. The potential<br />

options for servicing <strong>Kinglake</strong> <strong>West</strong> were initially explored using an innovative methodology that applied<br />

Life Cycle Assessment (LCA) and Life Cycle Costing (LCC). The approach ensured that in addition to<br />

traditional financial evaluation, the servicing options were assessed using economic, environmental and<br />

social criteria for sustainable development.<br />

At the time of writing, the <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong> was largely completed with the exception of the<br />

sewerage treatment plant (due for completion in mid-2013). The aim of this report was to determine if the<br />

<strong>Project</strong> delivered a more sustainable solution, as identified in a theoretical study and as a basis for a<br />

funding submission.<br />

The findings presented are based on a review of documents from the feasibility assessment and planning<br />

stages of the development, as well as post-implementation monitoring studies (See Appendix A for<br />

summary of documents provided by <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong>). Also, input was provided by YVW staff involved in<br />

the project. The remainder of the report is structured as follows:<br />

• A brief introduction to the <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>, including the context for its<br />

development and the system components implemented;<br />

• A background to the selection of the preferred sewerage servicing option for <strong>Kinglake</strong> <strong>West</strong>, which<br />

includes identifying the sustainability objectives that underpinned this selection;<br />

• An assessment of the sustainability performance of the individual components of the sewerage<br />

system, relative to the objectives in the planning and design phase of the project;<br />

• An overall assessment of the <strong>Project</strong>, including performance against the <strong>Project</strong> objectives, and the<br />

implications for future sustainable sewerage services in backlog areas.<br />

10 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

2 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong> Overview<br />

2.1 <strong>Project</strong> Background<br />

<strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong> serves over 1.7 million people through a water supply network of 9,500km and sewer<br />

network of over 9,000km, with associated pumping, storage and treatment works. Provision of new<br />

infrastructure is YVW’s largest capital expenditure. The company has a commitment to ‘provide its services<br />

within the carrying capacity of nature’, which is central to their Environment Policy and Company Strategy.<br />

Accordingly, when assessing servicing options YVW considers not only direct costs, but also the broader<br />

community costs and benefits.<br />

A major research project was initiated by YVW with CSIRO and RMIT’s Centre for Design to explore the<br />

sustainability of alternative water and sewerage servicing options (See: CSIRO, 2005; Grant and Opray,<br />

2005). Since the majority of new infrastructure provision occurs in ‘greenfield’ sites, this provided the initial<br />

focus for YVW in addressing the challenge of improved sustainability. This centred on a development in<br />

Kalkallo, in Melbourne’s northern growth corridor. Furthermore, as infill development comprises around<br />

30% of the new developments serviced by YVW, so this was the next focus with a case study in the Box Hill<br />

Principal Activity Centre.<br />

In addition to providing services to new developments, YVW has a significant Backlog Program, with more<br />

than 17,000 homes in suburban and peri-urban fringes that are currently served by septic systems. In many<br />

cases, thes systems are failing, posing environmental and public health risks. To date, the predominant<br />

method for servicing these areas has been to replace septic tanks with reticulated sewerage systems. It is<br />

estimated that completing YVW’s Backlog Program would require an investment of approximately $320<br />

million. CSIRO and RMIT were commissioned by YVW to undertake a study into more sustainable<br />

approaches for servicing these backlog areas. The research proved that it was theoretically possible to<br />

deliver alternative solutions that would be more sustainable than conventional reticulated sewerage.<br />

The aim of the <strong>Kinglake</strong> <strong>West</strong> <strong>Project</strong> was to put this theory into practice via a trial. YVW sought funding<br />

from the Victoria <strong>Water</strong> Trust and was successful on the basis that the trial would provide learnings for the<br />

broader Victoria water industry. In a 2006 review of Victoria’s Backlog program, the Victorian Auditor-<br />

General concluded that some Backlog funding may have been better used to search for alternative<br />

solutions that could more promptly and more cost effectively reduce the public health risks facing<br />

communities, as well as improving sustainability performance.<br />

2.2 <strong>Project</strong> Need<br />

There are a number of trends driving the need to consider alternative configurations for providing<br />

wastewater services in previously non-sewered areas. These were highlighted by Randall (2003), and<br />

include: population increase in the peri-urban fringe that leads to increased risk of contamination of<br />

groundwater from onsite systems, resulting both public health and ecological impacts; increasing<br />

degradation of surface water quality from sub-surface and land application wastewater practices; the fact<br />

that it may be more economical to service small communities with decentralised approaches, rather than<br />

connecting to existing centralised systems; and finally, the growing water scarcity that is driving the need to<br />

consider recycling of wastewater. In addition, it has also been recognised that there is potential value in<br />

recovering the nutrients in wastewater for food production (Cordell et al., 2009). It is against this setting<br />

that <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong> undertook to investigate more sustainable wastewater services in backlog areas.<br />

Makropoulos and Butler (2010) argued that decentralised technologies for water services are relatively<br />

unproven and untried in comparison to centralised approaches, and that there are significant knowledge<br />

gaps associated with their performance and operational costs. Larsen et al. (2009) highlighted that while<br />

there is recognition of the potential benefits of source separation of wastewater, and there have been

numerous trials and pilot projects, the associated technologies are still considered immature and risky by<br />

water professionals. This uncertainty in the performance of alternative wastewater servicing<br />

configurations is a major impediment to mainstream adoption.<br />

2.3 <strong>Kinglake</strong> <strong>West</strong> Case Study<br />

<strong>Kinglake</strong> <strong>West</strong> is located on Melbourne’s urban fringe, approximately 45 km northeast of Melbourne’s<br />

central business district. A small area of 74 residences was selected as the study area for the <strong>Project</strong> (Figure<br />

1). These properties did not have reticulated water or sewerage: potable water supply being from onsite<br />

rainwater tanks and in some cases groundwater bores, with sewage being managed using septic tanks.<br />

A report by Whitehead and Associates (2006) concluded that these properties were largely unable to<br />

manage their wastewater onsite. In winter, none of the lots studied had the capacity to manage<br />

wastewater loads due to a number of factors including allotment size, soil type and slope. The report found<br />

that even with the application of best practice technology, 72% of the wastewater generated in an average<br />

rainfall year could not be managed on-site. Accordingly, the area is on YVW’s Backlog Program but was not<br />

scheduled for servicing until 2021.<br />

Aside from the need for better sewage management, the study area was selected because it is far from<br />

existing infrastructure and would be difficult to service conventionally (i.e. by connection to the<br />

metropolitan sewerage system). It is adjacent to an environmentally sensitive National Park which will<br />

benefit from improved sewage management. Lastly, it is close to agricultural areas which are potential endusers<br />

for recycled water and other products.<br />

Figure 1 - <strong>Kinglake</strong> <strong>West</strong> case study location and site overview (circa 2006)<br />

2.4 Development of a preferred servicing approach for <strong>Kinglake</strong> <strong>West</strong><br />

YVW sought to achieve three main objectives at <strong>Kinglake</strong> <strong>West</strong>:<br />

• Objective 1: Enhance the environmental, public health and waterway health through innovative<br />

wastewater management<br />

• Objective 2: Identify a lower community cost solution<br />

12 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

• Objective 3: Demonstrate to the water sector a sustainable alternative wastewater servicing<br />

configuration for small communities.<br />

YVW commissioned CSIRO and RMIT to assess potential servicing options using an innovative methodology<br />

that applied Life Cycle Assessment (LCA) and Life Cycle Costing (LCC).<br />

- CSIRO undertook water and contaminant balance modelling for a range of servicing options<br />

(Sharma et al, 2006). Table 1 summarises the options explored;<br />

- Conceptual designs of the options were developed to determine what infrastructure components<br />

would be required;<br />

- Capital and operating costs were also estimated to calculate life cycle costs (LCC);<br />

- The outputs from the CSIRO study were then used as inputs for assessing the environmental<br />

impacts of each option. RMIT used the Life Cycle Assessment (LCA) methodology to assess options<br />

against the following environmental criteria: greenhouse gas emissions, cumulative energy<br />

demand, depletion of mineral resources and fossil fuels, eutrophication, carcinogens, land use,<br />

water use, and solid waste.<br />

A summary of the research results is shown in Figure 2.

Table 1 - Summary of servicing options explored by Sharma et al. (2006)<br />

1.1 Gravity servicing option without septic systems. Curb and channel stormwater drainage.<br />

1.2 Common effluent drainage (CED) system with existing septic systems.<br />

Swales employed for stormwater drainage.<br />

2.1B Wastewater source separation into urine, greywater and blackwater and treated greywater reuse (no<br />

storage) for garden watering.<br />

Pressure Sewer System.<br />

Swales employed for stormwater drainage.<br />

2.2B Wastewater source separation into urine, grey water and blackwater and treated greywater reuse<br />

with storage for garden watering and toilet flushing.<br />

Pressure Sewer System.<br />

Swales employed for stormwater drainage.<br />

2.2C Wastewater source separation into urine, greywater and blackwater and treated greywater reuse<br />

with storage for garden watering, toilet flushing and laundry.<br />

Pressure Sewer System.<br />

Swales employed for stormwater drainage.<br />

2.2D Same as Option 2.2C but no separate urine collection.<br />

2.4 Pressure sewer system. Swales employed for stormwater drainage.<br />

Wastewater flow Nitrogen Volumetric reliability Community cost Greenhouse Gases<br />

Comparison against base case Option 1.1<br />

120%<br />

100%<br />

80%<br />

60%<br />

40%<br />

20%<br />

0%<br />

1.1 1.2 2.1B 2.2B 2.2C 2.2D 2.4<br />

Options<br />

Figure 2 – Summary of scenario results from RMIT/CSIRO research for Pheasant Creek<br />

The results showed that alternative solutions could offer the following benefits against Option 1.1<br />

(representing conventional gravity servicing used in the Victorian water industry):<br />

• Economic savings of up to 20%<br />

14 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

• Increased reliability in water supply from 90% to 100%<br />

• Reduce wastewater discharges by up to 50%<br />

• Reduce nitrogen loads to the STP by up to 80%<br />

• Reduce greenhouse gas emissions by 30%<br />

Maximising greywater reuse reduces the volume of wastewater that is pumped for treatment, as well as<br />

the volume of rainwater pumped for use. Whilst there are some greenhouse gas emissions associated with<br />

the greywater treatment system, it was calculated that these would be offset by the aforementioned<br />

savings. The greywater systems have the additional benefit of increasing security of supply, since previous<br />

dry periods have seen residents needing to purchase water to fill their rainwater tanks from water carters.<br />

The effectiveness of a urine diversion scheme is highly dependent on how far the urine needs to be<br />

transported for reuse. There is a certain point where the greenhouse gas emissions from transporting the<br />

urine outweighs the benefits from fertiliser substitution and reduction in sewage volumes - this was found<br />

to be approximately 50km for a 1 litre flush volume (RMIT, 2007).<br />

In relation to costs, the use of a pressure sewer rather than deep gravity sewers and a pumping station was<br />

predicted to produce significant savings. Further savings were predicted to be achieved through greywater<br />

treatment. Even though greywater systems were estimated to cost $11,500 per lot, it was calculated that<br />

overall cost savings could be achieved through reduced sewage transfer and treatment.<br />

The options were further evaluated against the original project objectives, and underwent a multi-criteria<br />

assessment bringing together the economic, environmental and social considerations. Option 2.2C was<br />

selected as the optimum servicing solution – consisting of urine diversion, greywater treatment and reuse,<br />

and a pressure sewer system. Although this was not the cheapest option, it scored the highest overall due<br />

to strong environmental performance and innovation. The option is described in greater detail below.<br />

2.5 <strong>Sewerage</strong> System Overview<br />

The selected sewerage solution comprised:<br />

- Greywater treatment systems: Greywater is treated and stored for toilet flushing, garden<br />

irrigation and cold water supply to laundry (optional). The rainwater tank meets other water<br />

demands as well as providing backup supply.<br />

- Urine diverting toilets: These allow urine to be collected and stored in an onsite tank. Urine is<br />

collected by truck from each household for agricultural purposes. The urine tanks do not have<br />

overflow to sewer (in order to minimise gaseous nitrogen losses), requiring them to be emptied<br />

proactively before completely filling.<br />

- <strong>Sewerage</strong> reticulation: Blackwater is collected in a septic tank onsite for primary treatment,<br />

before being transferred via a pressurised sewer utilising septic tank effluent pumps (STEP). A<br />

local treatment plant further treats the effluent before it is irrigated on surrounding land. At the<br />

time of this report, the STP had not yet been built (expected completion in mid 2013). Until its<br />

completion, effluent is being collected at a central storage tank at the STP site and educted to<br />

Whittlesea STP.

Figure 3 - <strong>Kinglake</strong> <strong>West</strong> household servicing configuration<br />

2.6 Impact of bushfires on the study area<br />

The work described above, including the business case to the Victorian <strong>Water</strong> Trust, was completed prior to<br />

2008. Community consultation had just commenced in early 2009 when bushfires swept through the northeastern<br />

region of Melbourne, including <strong>Kinglake</strong> <strong>West</strong>. The impact was devastating, with lives lost and most<br />

of the homes in the study area destroyed.<br />

Rebuilding efforts began months later and residents started enquiring about the sewerage project, which<br />

had been put on hold. Community consultation was restarted and following a community information<br />

session in May 2009, enough support for the project was received to allow it to go ahead.<br />

The nature of the project became more typical of a ‘greenfield’ site, with onsite infrastructure being<br />

installed at the same time as homes were rebuilt. In many respects, this was easier than retrofitting an<br />

existing house. However it meant that the sewerage project needed to keep pace with construction and<br />

many tasks had to take place concurrently.<br />

16 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

3 Assessment of Individual Components<br />

This section reviews the individual components of the <strong>Kinglake</strong> <strong>West</strong> scheme, highlighting the system<br />

performance and the lessons learnt that could be applied in improving future implementation of these<br />

approaches.<br />

3.1 Greywater treatment system<br />

Greywater is collected from bathroom and washing machine wastewater where it is transferred to a sump<br />

well. It is then pumped to the treatment system where it is pre-screened to remove lint, then undergoes<br />

biofiltration and UV disinfection. The recycled water is stored in 300 litres storage and pumped on demand<br />

for garden irrigation, toilet flushing and cold water laundry supply. Excess greywater and backwash water<br />

from the filter media is fed by gravity to the septic tank.<br />

The configuration of the greywater system at the household scale is shown in Figure 4.<br />

Figure 4 - System configuration at the house lot

3.1.1 GREYWATER SYSTEM PERFORMANCE<br />

A total of 20 greywater treatment units were installed at properties in <strong>Kinglake</strong> <strong>West</strong>. The systems have not<br />

performed as expected, with the two main issues being their reliability of operation and their power<br />

consumption. There were also complaints from some householders concerning the quality of the treated<br />

greywater effluent and some odour problems<br />

Reliability of operation<br />

Most of the systems experienced frequent failures during and soon after commissioning. Many of the<br />

failures were caused by a poorly designed sump pump that accompanied the system. This was eventually<br />

rectified by the supplier who replaced it with a more established sump product. Problems were also<br />

experienced with the recycled water pump – the Davey Rainbank system which consists of a pump coupled<br />

with a switching device (marketed for rainwater harvesting applications with mains backup supply). This<br />

system was recommended by the greywater system supplier and normally functions well where the backup<br />

to greywater is reticulated mains supply. However in the case of <strong>Kinglake</strong> <strong>West</strong>, the backup supply was<br />

rainwater, and the operation of the rainwater pump conflicted with the switching device, which had to be<br />

replaced.<br />

Even after the sump and recycled water pump issues were resolved, the greywater systems continued to<br />

perform poorly. Monitoring of one system detected two failures over a 30-day period, and lower-thanexpected<br />

recycled water production the majority of the time (refer Table 2).<br />

Table 2 – Recycled water production from monitored greywater system<br />

Function of grey water system results<br />

Supply >80% of demand 3<br />

Supply 50-80% of demand 4<br />

Days<br />

Supply 1-50% of demand 14<br />

Supply 0% of demand 9<br />

Total days monitored 30<br />

Times system failed 2<br />

The low rate of recycled water production can be attributed to the relatively cold climate of <strong>Kinglake</strong><br />

affecting the biological process. The optimum operating temperature for the biofiltration process is 18<br />

degrees Celsius or greater, and efficiency is impacted at colder temperatures particularly for nitrogen and<br />

phosphorous removal (Kuk Kwun et al. 2000). <strong>Kinglake</strong> <strong>West</strong> is located at an elevation of more than 500<br />

metres, and during winter regularly experiences overnight minimum temperatures below 2 degrees Celsius<br />

(with overnight temperatures in summer usually not exceeding 12 degrees). The colder climate meant that<br />

the processer speed had to be manually adjusted, reducing the daily production of greywater by around<br />

50%.<br />

Power consumption<br />

YVW commissioned an independent company to monitor the energy consumption of the water and<br />

sewerage system components, including associated pumps. This was carried out at a household occupied<br />

by two adults and a child, and reported in <strong>Water</strong> and Energy Savers (2012). The house was one year old and<br />

had WELS 4-star rated fittings and 3-star appliances. Energy and water flows were monitored over a 30 day<br />

period at 15 minute intervals, from November to December 2011. Whilst the monitoring period and sample<br />

size are limited, the results are indicative of the performance of the greywater systems overall, and<br />

consistent with anecdotal reports and observations.<br />

During the three days when the greywater system was meeting >80% of demand, it produced 133 L/day<br />

and consumed 5.3 kWh/day on average (including sump and recycled water pump). This equates to 40.2<br />

18 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

kWh/kL produced (Lepp, 2012). However, since the greywater system was producing less than this volume<br />

the majority of the time, the average kWh/kL over the 30 day monitoring period was much higher. This is<br />

because the energy consumption of the system remains similar even when in standby mode.<br />

Table 3 - Monitored energy consumption vs manufacturer’s specifications<br />

Manufacturer’s Specifications<br />

Source: EPA Certificate of Approval<br />

106.3/07<br />

Monitoring Results<br />

Source: Lepp, 2012<br />

Daily load* (litres) 1200

In relation to supply reliability, the original CSIRO study assumed a 25 kL rainwater tank, which was the<br />

typical size observed during site visits in 2005. <strong>Water</strong> balance modelling showed that this tank size could<br />

provide about 90% reliability for indoor and garden irrigation demands (Sharma et al. 2006). However,<br />

following the 2009 bushfires, many of the homes were rebuilt with much larger tanks. An assessment of<br />

rainwater tank sizes at <strong>Kinglake</strong> <strong>West</strong> found that for 20 households surveyed, the average rainwater tank<br />

size is 45 kL (of which 10 kL is mandatory reserve for fire-fighting). Some households have up to 75 kL of<br />

storage. The bigger than anticipated size of rainwater tanks has impacted the usefulness of greywater<br />

systems in augmenting demand.<br />

The cost of the systems has proved to be significant, both in terms of capital and operating costs. In<br />

particular, installation costs were inflated due to the issues relating to the sump pump and recycled water<br />

pump (Table 4).<br />

Table 4 – Greywater system installation costs<br />

Greywater system component Cost per household Paid by<br />

Greywater system including sump<br />

pump<br />

$10,000 YVW<br />

Recycled water pump $2,000 YVW<br />

Installation $9,800 YVW<br />

Greywater and recycled water<br />

pipework*<br />

TOTAL $22,300<br />

$500 YVW/Household<br />

* Installation of separation greywater pipework and recycled water pipework (‘purple pipe’) was the responsibility of<br />

the homeowner and their builder. YVW contributed $500 towards this, however the actual costs borne by the<br />

homeowner were in some cases higher.<br />

The electricity cost of operating the greywater system was calculated to be $8.45/kL from monitoring<br />

results. This was the cost over the 3 day period when the system supplied >80% demands. When calculated<br />

over the 30 day monitoring period (taking into account low production days), the average cost per kilolitre<br />

is even higher. In addition, maintenance of the system by an approved contractor costs $420 for an annual<br />

inspection and water quality analysis.<br />

3.1.3 LESSONS LEARNT<br />

The trial of the greywater treatment systems at <strong>Kinglake</strong> <strong>West</strong> concluded in October 2012. Participants<br />

were given the option to either have the units removed by YVW, or assume responsibility for ongoing<br />

operation and maintenance. Of the 20 households who participated, 6 have opted to keep the treatment<br />

system. It is expected that it will cost $2,500 per household to decommission the systems, which includes<br />

removal of the treatment units and re-plumbing of the households.<br />

The lessons learnt in implementing greywater treatment systems are as follows:<br />

- Evaluating the need for a greywater treatment system<br />

The need for a greywater system should be evaluated on a case-by-case basis rather than<br />

implemented across the board. In <strong>Kinglake</strong> <strong>West</strong>, this would have taken into account the larger<br />

rainwater tanks as well as any secondary sources such as groundwater.<br />

Installing greywater systems solely for the sake of reducing wastewater volumes pumped and<br />

treatment was not found to be worthwhile, from either a cost or environmental perspective. It<br />

was found that the greywater system had no impact in reducing the capital or operating costs<br />

associated with the STP. Specifically, YVW officers noted that the scenario used to size the STP<br />

20 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

was based on inflows that assumed the area was fully developed and there were no greywater<br />

units or UDTs.<br />

- Selection of greywater treatment system model<br />

The greywater system selected was not suited to the climate of <strong>Kinglake</strong> <strong>West</strong>. The system’s poor<br />

performance has led to high power consumption and operating costs, and low reliability.<br />

At the time, selection was influenced by the fact that there were a limited range of Victorian EPAapproved<br />

models available at the time of tendering (only two EPA-approved systems submitted<br />

tenders). It is worth noting that subsequent to the project tender, the other EPA-approved<br />

manufacturer has gone out of business, whilst three other new systems have gained EPA<br />

approval. The transient and early nature of the industry creates an additional barrier to<br />

customers who want a dependable, proven product and long-term maintenance provider.<br />

- Installation of the system<br />

Three different parties were used for installation, supply, and maintenance of the greywater<br />

systems at <strong>Kinglake</strong> <strong>West</strong>. This approach was taken in order to keep the same installation<br />

contractor for the toilet and other plumbing work. Unfortunately, separating the functions leads<br />

to a lack of clarity and willingness to assume responsibility when there were performance issues.<br />

From YVW’s perspective, using a single party for installation, supply and maintenance of onsite<br />

systems would make future projects easier to manage, and result in better customer service for<br />

householders.<br />

- Some behavioural adaptation is required<br />

While the greywater treatment system was marketed as an automated system requiring no<br />

householder intervention, it has become evident that some behavioural changes are needed to<br />

ensure smooth operation. This includes, for example, avoiding the use of harsh household<br />

cleaning products that can impede the biological process. Engaging householders could help<br />

ensure that these changes are adopted. Such engagement is particularly important in existing<br />

communities such as <strong>Kinglake</strong> <strong>West</strong> (in contrast to new developments where residents have<br />

selected to live in a sustainable home, and already have a high degree of engagement).<br />

- Capital and operating costs<br />

High establishment costs can be a deterrent to households installing an alternative water source<br />

(Mankad and Tapsuwan, 2011). In the case of <strong>Kinglake</strong> <strong>West</strong>, this barrier was removed since the<br />

systems were paid for by YVW. However the high operating costs (particularly electricity costs)<br />

led to the eventual decommissioning of the systems.<br />

Given the relatively high standby costs of the system, it would be best suited to applications with<br />

high hydraulic loads in order to better utilise the capacity of the system (and minimise $/kL<br />

costs).<br />

3.2 Urine diverting toilets<br />

3.2.1 OVERVIEW<br />

Urine Diverting Toilets (UDTs) are still new to Australia, having been installed at only a handful of pilot sites<br />

such as Currumbin Ecovillage in Queensland and Maryborough Education Centre in Victoria (Hood et al.<br />

2009; Crockett et al. 2003) and the University of Technology Sydney. Unlike most other pilots which are<br />

based in greenfield developments, and where residents have made a conscious choice to live in a<br />

‘sustainable’ estate, <strong>Kinglake</strong> <strong>West</strong> is the first existing community to have UDTs installed. A total of 30 UDTs<br />

were installed at the 23 households who elected to participate in the trial.<br />

UDTs are designed to collect faecal matter at the back of the toilet bowl, while urine is diverted to the front<br />

(Figure 5). The faecal matter is either flushed to the sewerage system or is stored and composted. At

<strong>Kinglake</strong> <strong>West</strong>, the urine is piped to a 1,100L underground PE tank on each property. The ‘yellow water’<br />

(urine diluted with toilet flush water) is then collected manually by suction pump into portable 1kL tanks,<br />

and trucked to a nearby storage site.<br />

Figure 5 - Urine diverting toilet on display at Murrindindi Shire Council offices, <strong>Kinglake</strong> <strong>West</strong><br />

The separation of urine significantly reduces the nutrients in the wastewater stream and allows this<br />

resource to be recovered and reused for agriculture. In theory, this is a particularly effective means of<br />

separating the waste streams since urine is only a small percentage of the household wastewater volume<br />

(typically

- Decreasing environmental contamination from nutrients, pharmaceuticals and hormones;<br />

- Energy savings at wastewater treatment facilities; and<br />

- <strong>Water</strong> conservation.<br />

The original contaminant modelling by CSIRO (Sharma et al. 2006) quantified some of the above benefits<br />

for <strong>Kinglake</strong> <strong>West</strong>. It revealed the following load reductions in the wastewater discharge stream when UDTs<br />

are used:<br />

- A reduction of 81% in nitrogen loads per year (689 Kg less)<br />

- A reduction of 31% in phosphorous loads per year (69 Kg less)<br />

- A reduction of 17% in BOD loads per year (517 Kg less)<br />

The case for proceeding with UDTs was based on the potential to recover these nutrients and use them for<br />

beneficial purposes. This would also reduce nutrient loads to the STP and improve the efficiency of STP<br />

processes (YVW, 2007, Sustainable <strong>Sewerage</strong> Servicing for Small Communities – Pheasant Creek, p.9).<br />

3.2.2 SELECTION AND INSTALLATION<br />

Selection of Toilet<br />

There are currently several models of Urine Diverting Toilets (UDT) available; however none have<br />

<strong>Water</strong>Mark certifications against Australian standards. Without <strong>Water</strong>Mark Certification, a product cannot<br />

be legally installed into a plumbing system. In fact, an Australian standard does not currently exist for urine<br />

diverting toilets, which would be the first step to allowing such toilets to be installed in Australia (Schlunke<br />

et al. 2008). This has proved a stumbling block for other UDT trials in Australia (Byrne, 2011).<br />

The approach taken for this project was to select the most suitable model based on overseas experience,<br />

and seek an exemption from the Victorian Plumbing Industry Commission (PIC) for a trial. A number of UDT<br />

models were assessed during the selection process, including the Wostman Ecoflush, Dubbletten, Sealskin<br />

and Gustavsberg (the latter ceased production in 2009). The Wostman Ecoflush was selected on the basis<br />

of its similarity to existing Australian toilets considering user-friendliness, ease of maintenance,<br />

appearance, flush volume and cost. Following consultation with the PIC, a ‘modification’ was granted to<br />

install non-<strong>Water</strong>Marked UDTs in <strong>Kinglake</strong> <strong>West</strong> as part of a trial.<br />

Installation<br />

The Wostman Ecoflush is an S-trap toilet with a 100mm waste outlet pipe, and the installation method is<br />

similar to that of a conventional toilet. The exception is the 50mm urine pipework. In the same way that the<br />

main waste pipe has a water seal to prevent odours, the urine pipe also needed to be installed with a bend<br />

to form a water trap. The water trap was located upstream of the urine pipe entering the floor, where it<br />

connected to a 100mm outlet. Unfortunately this water trap was later found to be insufficient to prevent<br />

odours (see later discussion).<br />

The urine pipework was installed using 100mm PE pipe in order to reduce the risk of precipitate<br />

accumulation and blockages (Johansson et al. 2000). For the same reason, bends – which could slow down<br />

flow – were minimised.<br />

The urine collection system was designed with no overflow to the septic system, since such a connection<br />

would allow nitrogen to escape via the (septic system) waste vent. It is necessary for the urine pipework<br />

and storage system to be completely sealed since the ammonia can evaporate, reducing the valuable<br />

nitrogen content in the urine (Stintzing et al. 2007). As a consequence, a conservative approach was<br />

needed in scheduling the collection of yellow water from tanks. In many cases however, tanks were<br />

reported to be only 50% full when pumped out, which increased the costs of yellow water collection.

3.2.3 PERFORMANCE OF URINE DIVERTING TOILETS<br />

<strong>Water</strong> Usage<br />

To assist residents in adapting to the Urine Diverting Toiltes (UDT), YVW engaged the Institute of<br />

Sustainable Futures (ISF) to conduct a social research study. In parallel to the <strong>Kinglake</strong> <strong>West</strong> trial ISF also<br />

trialled the installation of UDTs at their Sydney office. As part of their trial, they commissioned Caroma to<br />

test the Wostman Eco-flush against Australian standard AS 1172.1 – 2005 <strong>Water</strong> Closets. Although this<br />

standard is not intended for testing UDTs, the results prove useful in understanding the toilet’s<br />

performance in the field. The testing showed that the Wostman used significantly greater volumes for<br />

flushing than indicated by the manufacturer (Table 5). Like most other models, the Wostman has a halfflush<br />

setting designed for flushing urine, to minimise dilution and conserve water. However, both the halfflush<br />

and the full-flush used more water than claimed in specifications.<br />

A more serious issue was the need for multiple flushing by users. Residents reported that the urine barrier<br />

(separating the urine outlet from the rest of the toilet bowl) tended to retain faecal matter. This required<br />

extra flushing to clean it. In addition, many female residents used the full-flush after urinating in order to<br />

flush away toilet paper. Some UDT installations overseas encourage their users to dispose of toilet paper in<br />

a separate bin. This was not a requirement of <strong>Kinglake</strong> <strong>West</strong> residents, being a significant behavioural<br />

change. Instead, users were encouraged to minimise toilet paper and to place it in the back section of the<br />

bowl. However, as confirmed by the Caroma testing, the half-flush fails to discharge any toilet paper and so<br />

a full-flush was required after every use. All the extra flushing diluted the yellow water, which limited its<br />

effectiveness as a fertiliser (see Section 3.4 for more details).<br />

Table 5 – UDT performance against specifications<br />

Performance criteria<br />

Manufacturer’s<br />

Specification<br />

‘Urine flush’ volume 0.2 litres* 1.3 litres<br />

Full flush Volume 2.5 litres^ 5.1 litres<br />

Actual Performance<br />

*It is unclear whether the ‘0.2L’ quoted by the manufacturer refers to the volume of water used for flushing, or the<br />

volume actually entering the urine pipe.<br />

^The manufacturer’s installation instructions state that the full flush is adjustable from 0 - 6 L, and recommends a<br />

setting of 2.5L.<br />

Odour Issues and Blockages<br />

Soon after installation, a number of residents reported odour issues with the toilets. Different approaches<br />

were tested, including installing an additional water trap in the downstream 100mm pipework (this solved<br />

many of the problems). Another strategy was to leave a residual volume in the urine tank when emptying,<br />

to prevent odours from the tank travelling back up the urine pipe into the bathroom. In addition, a number<br />

of toilets were found to have a faulty pan whereby an air gap allowed odours to escape from the waste<br />

pipe. This could be fixed using a grout fill but required the toilets to be re-installed (approximately 30% of<br />

stock was affected).<br />

Early on, some residents experienced intermittent toilet blockages. Upon investigation, this was found to<br />

be due to clogging of the urine outlet. As urea in urine degrades, it can undergo chemical precipitation into<br />

struvite and calcium phosphates, causing blockages (Stintzing et al. 2007). Hair and toilet paper contribute<br />

to the problem. Unfortunately, the design of the toilet does not protect the urine outlet from foreign<br />

matter entering. YVW distributed citric acid cleaner to residents, which helped to reduce instances of<br />

blockages. Residents were instructed to dissolve the citric acid powder in hot water and leave it to soak in<br />

the urine drain overnight, once every couple of months.<br />

No blockages were reported to occur in the urine pipe itself, which was installed using guidelines and<br />

experience from overseas UDT projects.<br />

24 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

Social Research Outcomes<br />

The use of Urine Diverting Toiltss (UDT) at <strong>Kinglake</strong> <strong>West</strong> was innovative in the Australian context, and the<br />

level of householder acceptance could only be assumed. A European review by Lienert and Larsen (2009)<br />

revealed that there has been a high degree of acceptance of UDTs in both public spaces and in the home.<br />

Users found them to compare favourably against conventional toilets in terms of design, hygiene and smell.<br />

However the drawbacks were considered to be inferior flush performance, and more laborious cleaning<br />

procedures. While Lienert and Larsen (2009) found that households were accepting of the UDT as a<br />

concept, only an improved design would motivate them to keep a UDT in their home. The review also<br />

found that users also need to be convinced of the ecological benefits. A Swedish project where most of the<br />

collected urine was transported back to the local STP resulted in very low acceptance, since people<br />

understandably did not want to endure the practical inconvenience if there was no significant benefit to<br />

the environment.<br />

The outcomes from the social research by ISF (Mitchell et al. 2011) echoed the above, in that<br />

improvements in UDT design are necessary for more widespread uptake. A couple of the UDTs in <strong>Kinglake</strong><br />

<strong>West</strong> were replaced with conventional toilets at the request of the homeowners. However, on the whole,<br />

while users recognised there were shortcomings in the UDT design, they were willing to adapt to the new<br />

technology. One factor was the intensive support provided to users in the form of materials (manuals,<br />

signage and cleaning kits) and personal contact with YVW and the social researcher. In the feedback<br />

received during the social research, the issues caused by the UDTs tended to be considered minor when<br />

compared to the problematic greywater systems.<br />

3.2.4 IMPACT OF URINE DIVERTING TOILETS ON NITROGEN LOADS AND THE STP<br />

Table 6 compares the blackwater from <strong>Kinglake</strong> <strong>West</strong> with the characteristics of typical domestic<br />

wastewater from Metcalf & Eddy (2003). It shows the impact that urine diversion (in combination with<br />

greywater reuse and primary treatment in the septic tank) has on the wastewater composition.<br />

Concentrations of N, P and BOD are reduced since urine holds a large proportion of these nutrients in a<br />

relatively small volume. Per capita loads have also been estimated based on flowrates of 127 L/capita-day<br />

of blackwater 5 . This shows that nitrogen and phosphorus loads are approximately one third of those found<br />

in typical domestic wastewater.<br />

Table 6 - Comparison of untreated wastewater composition<br />

3.3 Parameter<br />

<strong>Kinglake</strong> <strong>West</strong> Blackwater Typical Domestic Wastewater<br />

(Metcalf and Eddy, 2003)*<br />

Concentration Load Concentration Load<br />

Total nitrogen 57 mg/L 2.64 kg/year 70 mg/L 6.13 kg/year<br />

Phosphorous 8.3 mg/L 0.38 kg/year 14 mg/L 1.05 kg/year<br />

BOD 5 day 150 mg/L 6.70 kg/year 350 mg/L 30.66 kg/year<br />

*Typical ‘high strength’ domestic wastewater based on 240L/capita-day (the most similar to <strong>Kinglake</strong> <strong>West</strong> flowrates).<br />

One of the perceived benefits of urine diversion at <strong>Kinglake</strong> <strong>West</strong> was that it could reduce the energy<br />

required by the STP. At conventional STPs, oxygen delivery is required for the nitrification process<br />

(conversion of ammonia to nitrite and then nitrate). Karlsson (1996) estimated that 4 kg of oxygen is<br />

5<br />

This wastewater flow rate is based on figures from YVW on volume to eduction tank divided by connected properties and estimated household<br />

size

equired for every 1 kg of nitrogen during nitrification. Hence, if an aerator has an oxygen transfer capacity<br />

of 1 kg oxygen per kWh, then 4 kWh is required for each 1 kg of nitrogen removed.<br />

The technology proposed for the <strong>Kinglake</strong> <strong>West</strong> STP is a recirculating trickling filter system, utilising foam<br />

blocks as the biological media. This type of system is typically not designed to nitrify. Hence, urine diversion<br />

will not impact energy consumption at the STP. However, it will reduce the nitrogen and phosphorus<br />

concentrations in the STP influent and effluent. This has the benefit of minimising the amount of nutrients<br />

exported to waterways from the irrigation scheme and storage during overflow events. Furthermore, less<br />

nitrogen loading could also impact on the fugitive greenhouse gas emissions from the STP. As less nitrogen<br />

loading may result in a lower probability of incomplete denitrification taking place, leading to less fugitive<br />

N 2 O emissions occurring (Hall, et al., 2011).<br />

It was calculated that if the STP was designed for nutrient removal, then urine diversion would only reduce<br />

the energy required by around 8.5% (Tonkovic, 2012).<br />

3.3.1 LESSONS LEARNT<br />

Urine Diverting Toilets<br />

In summary, the design of the Urine Diverting Toilets (UDT) used at <strong>Kinglake</strong> <strong>West</strong> had shortcomings that<br />

inhibited user acceptance. Importantly, the UDT’s design flaws impacted on the usefulness of the yellow<br />

water as a fertiliser (discussed in the Section 3.4). The toilet’s flush volumes were higher than specified by<br />

the manufacturer, and the internal urine barrier tended to retain faecal matter, requiring extra flushing. As<br />

in the case of the greywater systems, a reliance on manufacturer specifications led to certain expectations<br />

in regards to the quality of urine and frequency (and costs) of collection. Ultimately, the cost and<br />

inconvenience of urine diversion is not considered to justify the benefits of resource recovery.<br />

Given that the main issues relate to UDT design, dilution and urine collection costs, this suggests that urine<br />

diversion may be better suited to particular contexts, such as waterless urinals in commercial buildings.<br />

Organisational Learnings<br />

An innovative project with many stakeholders (YVW, households, contractors, suppliers, regulating<br />

authorities) can be very complex to implement. As part of the social research component, ISF conducted indepth<br />

interviews and facilitated a YVW workshop to identify organisational learnings. The following key<br />

lessons can assist in ensuring more successful implementation of future innovations (Mitchell et al. 2011):<br />

• A focus on customer outcomes, with the flexibility to incorporate user feedback and adapt the<br />

project quickly in order to meet desired outcomes;<br />

• Clarifying roles and responsibilities of both YVW and households with documentation;<br />

• Pre-piloting innovative technology so there is a greater understanding of in-situ practice, both for<br />

individual elements such as UDTs but also in combination with other elements. Piloting of the UDTs<br />

would have enabled the early identification of cases where the manufacturer’s specifications were<br />

not being met so that solutions to addressing these problems could have been developed before<br />

widespread installation;<br />

• A designated project owner who assumes overall responsibility for all aspects of the project;<br />

• Consideration of whether existing organisational processes should apply, or workshopping new<br />

processes with the relevant internal stakeholders;<br />

• Improved communication and co-ordination of different tradespeople.<br />

In the case of <strong>Kinglake</strong> <strong>West</strong> some of the above, such as the pre-piloting, and were not practical to achieve<br />

given that the impact of the bushfires that meant households needed to be re-buil<br />

The trial of UDTs at <strong>Kinglake</strong> <strong>West</strong> has now concluded with the completion and evaluation of the agronomic<br />

trial. Since the viability of applying yellow water at this site was found not to be feasible, it was decided to<br />

remove all the UDTs and collection tanks. In their place, conventional toilets will be installed with<br />

connection to the STEP tank.<br />

26 <strong>Kinglake</strong> <strong>West</strong> <strong>Sewerage</strong> <strong>Project</strong>: Post-implementation sustainability assessment

3.4 Agronomic trial<br />

The application of UDTs and the recovery of yellow water for use in agricultural has received significant<br />

interest in the literature (See: Cordell et al., 2009; Larsen et al., 2009; Karack and Bhattacharyya, 2011;<br />

AdeOluwa and Cofie, 2006). The case for recovering nutrients from urine is based on the premise that urine<br />

only constitutes 1% of domestic wastewater flow but constitutes around 80% of the nitrogen and 45% of<br />

the phosphorus. Recovering the urine offers the following benefits (Fewless et al., 2011):<br />

• Reduced environmental contamination from nutrients<br />

• Energy saving at STP<br />

• More efficient anaerobic digestion of blackwater<br />

• <strong>Water</strong> conservation<br />

• Reduces demand for phosphate rock fertiliser, which is depleted non-renewable resource (Cordell,<br />

et al., 2009).<br />

However, there is a lack of empirical studies that have actually analysed the achievement of the above<br />

benefits in real case studies. Also, there is need to understand the cost effectiveness of urine diversion and<br />

recovery for agricultural production by analysing the whole supply chain of yellow water in comparison to<br />

similar growth prompters used for crop production.<br />

This section covers the collection, storage and application of yellow water in an agronomic trial. Yellow<br />

water was collected in a 1,100 L polyethylene tank on each property, which was designed to provide about<br />

60 days storage for a household of 4 people. In practice, the tanks were emptied at shorter intervals to<br />

guard against the potential of an overflow. The field maintenance data showed that in January 2012, 22<br />

household collections of yellow water were made for the month. The use of bladder tanks was avoided due<br />

to odour issues experienced at other pilots (Hood et al. 2009). Yellow water was pumped from each<br />

property into portable 1,000L plastic ‘cubes’, since these were easily transportable and could be ‘batched’<br />

for storage.<br />

A nearby turf farm in <strong>Kinglake</strong> <strong>West</strong>, Green Acres, agreed to trialling the application of yellow water. Turf<br />

production is a good candidate for yellow water application since it requires high and regular rates of<br />

fertiliser application and is not a food crop, hence minimising the risks to human health. Moreover, turf<br />