April 2000 - American Bonanza Society

April 2000 - American Bonanza Society

April 2000 - American Bonanza Society

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TeMls Factory Installations,<br />

by the factory ... installed by the factory.<br />

A powerful combination; for your peace of mind.<br />

~ Comprehensive factory installation.<br />

~ Complete price with no hidden cost.<br />

i'f Complete fuel system set up.<br />

'i'J' TopCare" Cylinder Warranty Program.<br />

~ No core charge delays or freight expenses.<br />

.6 TCM Link"membership included.<br />

£ Factory operational & maintenance training available.<br />

&1 Free TopCare Health Check Inspection included.<br />

!it Upgrades, modifications & new equipment available.<br />

!it Scheduled repairs & inspections.<br />

i"f Complete line services.<br />

06 Let TCM be your guide to one of America's fastest<br />

growing recreational areas.<br />

For the sophisticated aircraft owner who<br />

wants nothing but the best engine installation,<br />

there's onl y one place to go - the TCM Customer<br />

Support Center in Fairhope, Alabama. Here, your<br />

factory engine will be installed, tested and fine<br />

tuned by TCM factory technicians. This means<br />

yoW' engine leaves our customer support center in<br />

the very best of health. After the installation,<br />

we'll even personally train you on the proper<br />

operating procedures, which will help your<br />

factory engine live a long healthy life.<br />

For a scheduled, no hassle engine installation,<br />

look to the TCM Customer Support Center. Let<br />

us help turn your stay into a great vacation. Call<br />

us today for pricing and infonnation.<br />

888-TCM-Link (888-826-5465)<br />

"'~TELEDYNE<br />

CONTINENTAL MOTORS<br />

An Allegheny Teledyne Compcny<br />

© 1997 Teledyne Industries, Inc.<br />

TCM Customer SuPPort Center, Fairhope Munici pal Airport, Fairhope, AL 36532 Unicorn OAF 122.8 FAA Repair Station ·IHD4R2 54M

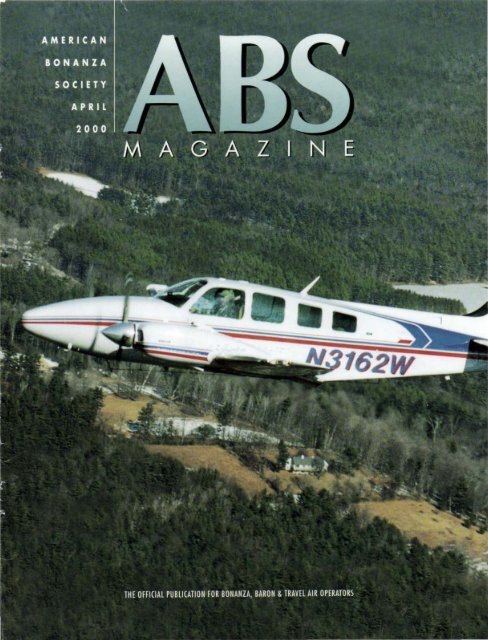

"N3162W is flowlI sOllie 250-300 hours per year for busilless alld pleasure_<br />

Livillg ill the Northeast, we get plellty of opportullity to fly illlFR<br />

cOllditiolls alld f eel very cOlllfortable ill this aircraft_" - Roger J. TU/lle<br />

1974 B58 Baron<br />

3162W is our second Baron. The<br />

first. a beautiful E55,just didn't have the<br />

legroom, nor did it have the club seating<br />

that we find so nice for long family trips.<br />

We are the third owners of N3162W.<br />

The aircrafl. SIN TH-419. was constructed<br />

in 1974 and was based in<br />

Greensboro, North Carolina. until I purchased<br />

it in August 1994 through Carolina<br />

Aircraft and George Johnson (the<br />

"<strong>Bonanza</strong> Man"). Mechanically, it was<br />

in great shape, but the original equipment<br />

and paint were beginning 10 show wear<br />

and tear. We flew it to our home base in<br />

Nashua, ew Hampshire.<br />

We have had extensive work completed<br />

since that time, including new<br />

paint in 1995 at Keyson Aircraft<br />

Refinishers at Nashua Airport. A VG kit<br />

and aftermarket shoulder harnesses for<br />

pilot and copilot were installed.<br />

In January 1998, The Radio Shop of<br />

Worcester, Massachusetts. completed an<br />

extensive avionics installation which included<br />

a new rFR-certified GPS, digital<br />

transponder, NavComms, DME, audio<br />

panel and a digital graphic engine<br />

monitor.<br />

Immediately after purchasing the aircraft,<br />

a second artificial horizon was<br />

added to the vacuum system. During a<br />

night VFR takeoff. one of the instruments<br />

cracked, causing a leak in the system that<br />

was severe enough to deny vacuum to<br />

either of the artificial horizons.<br />

After a successful flight home, a new<br />

electrically powered artificial horizon was<br />

added, gi ving us the peace of mind of two<br />

independent systems for aircraft control.<br />

I fail to understand how someone could<br />

have all the bells and whistles in their<br />

aircraft in terms of avionics and radios<br />

and nOl have two artificial horizons.<br />

N3162W is flown some 250-300<br />

hours per year for business and pleasure.<br />

Living in the ortheast, we get plenty of<br />

opportunity 10 fly in IFR conditions and<br />

feel very comfortable in thi s aircraft.<br />

We've flown allover the eastern part of<br />

the United States and have also visited<br />

Cancun, Mexico. We have even ventured<br />

as far south in the Bahamas to visit the<br />

quaint little airstrip in Pittstown, which<br />

is partly owned by Sporty's Pilot Shop.<br />

As you would expect in a Baron,<br />

maintenance is expensive to very expensive.<br />

Part of the cost is that nothing is<br />

left to be repaired at a later time or simply<br />

left to wait to the next scheduled<br />

maintenance. Our plane is hangared right<br />

next to the maintenance facility and<br />

Keyson Airways is very obliging by slipping<br />

us in when we need it. I do keep an<br />

extra starter with me since I have lost a<br />

starter three times in some out-of-theway<br />

places: amucket, San Salvador, the<br />

Bahamas and in Presque Isle, Maine.<br />

Our next big trip is scheduled for this<br />

summer when our plans will take us<br />

through the Bahamas, Puerto Rico, the<br />

Virgin Islands, St. Martin, Trinidad,<br />

Caracas, Panama City, Costa Rica. Nicaragua,<br />

Cancun, Key West and then home.<br />

Kind of a Jimmy Buffet-type of trip in<br />

the opposite direction.<br />

My 17-year-old son Ryan will help<br />

with the flying chores, and I plan on having<br />

some friends meet me along the way<br />

10 fly part of the trip with me. I'll report<br />

on the trip in the fall.<br />

Roger}. Tuttle, Merrimack, New Hampshire<br />

EQUIPMENT LlST- 1974 B58 Baron, N3162W<br />

Dual King transponders<br />

Dual KX 155<br />

KLN 89B GPS<br />

King DME<br />

avComms<br />

KingADF<br />

PS audio panel with<br />

four-place intercom<br />

RDR 100 radar<br />

WX 10 Stormscope<br />

Century III autopilot<br />

VG kit<br />

Rosen sunvisors<br />

JPI graphic engine monitor<br />

Dual artificial horizons<br />

De- ice boots, alcohol<br />

props and windshield

~<br />

MAGAZINE<br />

(ISSN 1524·5438)<br />

Pubti~hed b} AMERICAN BONANZA SOCIETY<br />

Ort1nl/.ed January 1967<br />

ASS EXECUTIVE DIRECTOR<br />

EDITOR IN CHIEF<br />

Nancy Joh n~on<br />

PUBLICATION OFFICE<br />

1922 Midfield Rood<br />

P.O. Box 12888<br />

Wichita. KS 67277<br />

316-945-1700<br />

Fa.'I. 316-945·1710<br />

ASS \Iocb sile: hnp:lfwww.bonan7.8.org<br />

ASS e-mail: bonanza2@bonanza.org<br />

Send articles/leiters to the<br />

above address/lax/e-mail.<br />

EDITOR<br />

Bclty Rowley<br />

ART DIRECTOR<br />

Jim Simpson<br />

EDITORIAL CONSULTANT<br />

f'atric Rowley<br />

DISPLAY ADVERTISI:-':O DIRECTOR<br />

John Shoemaker<br />

2779 Acro Park Dri\'c. P.O. Box 968<br />

Traverse City, MI 49684<br />

1-800-77 3-7798, ext. 3317<br />

PRINTER<br />

Village Press, Tm'erse CiIY. Michigan<br />

A P RIL <strong>2000</strong> · VO L UM E 00 · NUM B E R 4<br />

CO V E R<br />

6154 BARON OF THE MONTH:<br />

Roger Tuttle's 1974 B58 Baron<br />

FEATURES<br />

6157 BPPP ... POLISHING FLYING SKILLS<br />

By ROil Vickrey<br />

6164 A STANDBY ATIITUDE INDICATOR VS. A STANDBY<br />

VACUUM SYSTEM. WHICH IS BEST<br />

By Neil PoballZ<br />

6166 A GLIMPSE OF SAN ANTONIO<br />

By JOII RoadJeldt<br />

6167 APPROACHES TO MINIMUMS<br />

By A"drew Forgocs<br />

6169 EXHAUST TIPS<br />

By George Wilhelmse"<br />

6176 THE WCTU BOOTLEGGER INCIDENT<br />

By Joh" Miller<br />

6181 WHEELS AND BRAKES AREN 'T IMPORTANT ...<br />

UNTIL TOUCHDOWN!<br />

By SOlidi Schickel<br />

6186 CENTRAL AMERICA OR BUST<br />

By ROllald Pate<br />

DEPARTMENTS<br />

6156 PRESIDENT'S COMMENTS 6178 AVIONICS AD SECTION<br />

by Ti ldell D. Richards by l im Hughes 8175A<br />

,~,<br />

A:>Nl:AL DUES: US-$4~.<br />

Canada &: Moic0-S45 (l:5l. FOI'titD 575 (l;S)<br />

I ,Ife membershlp-$I.OOO,<br />

Conlat'l ARS Headquanm for ticllils<br />

POSTMASTER , Sen~ Mlldress chanie~,. ~:~;~::~<br />

BONANZA SOC/tTY MAGA£J.\'f. P,O. Box I ~<br />

6nn-2S8S<br />

8159 COLVIN'S CORNER 8189 SHOPTALK<br />

by Neil PohallZ and Ark)' /-o ulk by Lynn lenkills SPPP<br />

SCHEDULE<br />

8171 FORUM 6191 INSURANCE 8163<br />

by 101m Allen, Falcol/lnsurance<br />

6174 ASS MEDICAL PANEL<br />

by John Hasrings, M.D.<br />

6175 REGIONAL NEWS<br />

6192 GROUND CONTROL<br />

by Nallcy lohllSOIl<br />

6193 CALENDAR<br />

SERVICE CLINIC<br />

SCHEDULE<br />

6185<br />

Board 01 Directors Term ClCpires Term ell"pires<br />

TrLDES D. RICHARDS. President (Area 7)<br />

PO BOl; 1047. Sutler Creek. CA 95685<br />

Phone 209-267-0640. fa.,- 209-267-1546<br />

e-mail rkhard~@\olcano.nel<br />

JOS ROADFELDT. V.P. (Area 4)<br />

1548 W. Seuant. Roseville, MN 55 I 13<br />

Phone 651 -488-9385, fax 651-488-9475<br />

e-mail spcsco. inc@mci ..... orld.com<br />

HAROLD BOST, Treasurer (Area 3)<br />

760 Birkdale Drive, Fll.ycue\iilJe. GA 30215<br />

Phone 770-7 19-0638. fax 770-7 19-9826<br />

e-mail bostmail@ellrlhlink.net<br />

2002 MICHAEL HOEFnER, Secreaary (Arta I) 2001<br />

~3 Old Sugar Road. Bolton, MA 01740<br />

Phone 508-35 1-9080. fax 508-351-9081<br />

e-mail n48mh@mctiiaone.net<br />

2001 WILLIAM C. CARTER (Area 2) 2001<br />

7131 Driftwood Drive, SE. Grand Rapids. 11.1149546<br />

Ph~ 616-974-0016, fax 616-676-0346<br />

e-mail wcc@egl.net<br />

<strong>2000</strong> JACK CRO~IN (Area 6) :<strong>2000</strong><br />

261 Vine Strect. i)en'·cr. CO 80206<br />

Phone 303-333-3000. fax 303-333-<strong>2000</strong><br />

e-mail jeronin@ix.nclcom.com<br />

Term expires<br />

JOHN D. UASTlSGS. M,D, (Dire

President's Comments<br />

TILDEN D. RICHARDS<br />

SB 27-3358<br />

By the time you receive<br />

this issue, most<br />

owners of 35s. A35s,<br />

B35s and 35Rs will be aware of Raytheon Service<br />

Bulletin (5B) 27-3358 regarding the<br />

ruddervators and aft fu elage of these aircraft. At<br />

the time of this writing, we are already aware of<br />

several misunderstandings and areas that need<br />

expanded information.<br />

Raytheon arrived at this Service Bulletin after<br />

a testing program which involved real aircraft in<br />

an effort to remove the speed restriction imposed<br />

by AD 98-13-02, Paragraph (I). ABS technical<br />

staff felt the speed limit and testing were justified<br />

due to the number and severity of damage in<br />

the vibration incidents. Several conditions seemed<br />

to be neces ary for the occurrences, but speed was<br />

the obvious one.<br />

In a few cases, we could not identify aircraft<br />

condition problems, but in most cases maintenance<br />

issues were involved. We still are finding<br />

those types of problems, but without the speed<br />

factor, apparently all conditions are not present.<br />

What's included<br />

The service bulletin Lists inspection criteria<br />

which tests have shown will preclude the damage-causing<br />

vibration. Therefore, the SB as shown<br />

on page 2, paragraph E, is an alternate compliance<br />

method to the speed restriction.<br />

The SB lists many inspection conditions, but<br />

essentially covers the repetitive portion of AD 94-<br />

29-04 which, of course, should have been done<br />

already:<br />

It requires the ruddervator balance 10 meet<br />

new restricted limits.<br />

It requires a review to ensure any modifi <br />

cations are compatible with each other.<br />

It gives wear limits for hinges. dimensional<br />

limits on skin thicknesses and rivet spacings.<br />

It covers proper trim tab installation, which<br />

we are still finding wrong.<br />

It requires a propeller balance.<br />

If some of these inspections and maintenance<br />

actions have been properly documented in the<br />

logbooks, then less hours will be required.<br />

Testing requirements<br />

ABS is addressing the issue of the testing<br />

equipment specified in the SB, which lists what<br />

Raytheon uses at the factory. The way the SB is<br />

wriuen, it would be illegal 10 use any other kind<br />

of equipment, despite the fact that there are other<br />

suitable manufacturers and methods.<br />

As we go to press, your <strong>Society</strong> is proposing<br />

alternatives to the testing equipment listed in the<br />

SB. We expect to have FAA approval by the time<br />

this magazine is in your hands. Check with ABS<br />

Headquarters (316-945- 1700) for a copy of the<br />

approvalleuer and list of alternate equipment.<br />

We also have heard that some owners are concerned<br />

about complying with the SB because their<br />

shops may nO! have the required equipment. We<br />

sugge tthat, if this is the case, you consider grouping<br />

with other affected owners to hire a testing<br />

lab to come to your shop. That will make it possible<br />

to kee'p the cost within reason.<br />

Other related actions and issues are:<br />

ABS has requested Raytheon coordinate<br />

with RAPID 10 ensure availability of pans<br />

for balancing.<br />

When dynamically balancing the propeller,<br />

we suggest that you have a pickup auached<br />

to the rear of the engine 10 eliminate any<br />

chance of harmonic vibration from crankhaft<br />

weight problems.<br />

Contact Headquarters about a source for the<br />

difficult-to-find weight anachment screws.<br />

The new ruddervator balance limits may be<br />

difficult to achieve, so contact ABS for advice<br />

from our technical consultants.<br />

It is our hope that these actions will preclude<br />

further incidents of vibration so we can all return<br />

10 full enjoyment of our wonderful airplanes.<br />

Fly safe, Dave.<br />

As we go to press,<br />

your <strong>Society</strong> is<br />

proposing alternatives<br />

to the testing<br />

equipment listed<br />

in the Service<br />

Bulletin. We expect<br />

to have FAA<br />

approval by the<br />

time this magazine<br />

is in your hands.<br />

Check with ABS<br />

Headquarters<br />

(3 76-945- 7 700) for<br />

a copy of the<br />

approval letter<br />

and list of alternate<br />

equipment.<br />

PASt PRESID ENTS<br />

H J. \ 1c{l~nalun,,\ID 1%~ 1'171<br />

Hankli Rn><br />

1

BPPP. .. POLISHING FLYI<br />

OVER ST, AUGUSTINE, FLORIDA. AT 7,500 FEEl<br />

the Baron hums happily through smooth air as I<br />

enjoy ftying "on the gauges," Still. good things seem<br />

to come to an end sooner or later-and this day<br />

proves to be 100 exception, Suddenly, a distinct<br />

yawing motion to the Ie<br />

sends a clear<br />

message that something obviously is- not right with<br />

one of the engines, I concentra e on flying the<br />

airplane while identifying and verifying that<br />

indeed the left engine has failed! Failing to<br />

~ove r power aftel following established<br />

procedares, I feather the prop and secure the<br />

engine, The prop quickly coasts to a shuddering<br />

stop with one blade stanaing at sile t attention as<br />

the Baron c ontinues to soldier on at reduced<br />

airspeed, So far, so good. but then the HSI fails just as<br />

I'm instructed to enter a holding pattern at the VOR,<br />

Is this turnlnQ into d really bad day or what<br />

A (<br />

During the lunch break, instructors, attendees and guests are treated to a NASA space<br />

shuttle launch from Cape Canaveral-barely visible erupting from Bill Hale's head, center,<br />

SKILLS<br />

BY RON VICKREY<br />

Hank Canterbury, instructor. explains the importance<br />

of flying "by the numbers, •<br />

ctually, it was a really fun and rewarding day as<br />

these and other simulated emergencies plagued<br />

each of the ABS pilots enrolled in a recent BPPP<br />

recurrency flight training program,<br />

Prior to flight, each pilot was asked what he/she would<br />

like to concentrate on during the flight training sessions, As I<br />

had for each of the past six<br />

years, I chose to focus on instrument<br />

flying plus single engine<br />

and other emergency procedures<br />

during my session with<br />

B ill Hale, BPPP instructor,<br />

During this BPPP Clinic<br />

held February 10 -13 at Orlando,<br />

Florida, 96 pi lot s<br />

logged more than 384 flight<br />

training hours, An additional<br />

five pilots elected to partake<br />

of only the ground school curriculum,<br />

Especially welcome<br />

were the II pilots' companions<br />

who participated in the Companion<br />

Course on Friday and<br />

Saturday,<br />

This was the BPPP's larg-<br />

Page 6157 ABS <strong>April</strong> <strong>2000</strong>

est clinic to date, with some pilots<br />

flying on Thursday as well<br />

as the normally scheduled Saturday<br />

and Sunday. Friday was<br />

devoted to a full day of ground<br />

school at the Radisson Hotel,<br />

with addilional ground training<br />

and flight operations held on<br />

Saturday and Sunday at Orlando<br />

Executi ve airport's Showalter<br />

Flying Service facilities.<br />

Throughout 1999, more than<br />

725 ABS members participated<br />

in the BPPP program. Over the<br />

years, pilot experience levels<br />

have ranged from the newest pilots<br />

with less than 100 hours to astronauts, active military,<br />

airline, corporate and other highly experienced professional<br />

pilots. Some of them have probably accumulated more logbooks<br />

than some of us have fli ght hours.<br />

Members arrive in all our favorite Beech models-from<br />

the 1947 Model 35 <strong>Bonanza</strong> to the very latest, fresh-fromthe-factory<br />

Baron. But to a person, they all share a common<br />

commitment to improving their flying skills.<br />

As expected. the overall<br />

BPPP objective is to provide<br />

ABS member-pilots the opportunity<br />

to broaden pe rso nal<br />

knowledge and experience levels<br />

whi Ie sharpening operating<br />

techniques applicable to their<br />

<strong>Bonanza</strong>, Baron or Travel Air.<br />

Armed wi th newly refreshed<br />

skills and knowledge, members<br />

can operate their aircraft with<br />

greater confidence, safety and<br />

enjoyment throughout the full<br />

aircraft operating envelope. Ln<br />

addition, pilot companions often<br />

tell us they feel more confident<br />

and enjoy flying much more after<br />

both they and their pilot have<br />

completed the respecti ve courses. (See accompanying Companion<br />

Course comments.)<br />

During both the ground and fl ight training programs,<br />

the BPPP instructors emphasize safe, optimal flying techniques.<br />

They devote special attention to various unusual<br />

Some of the 95 beautiful <strong>Bonanza</strong>s and Barons, ready for action.<br />

r<br />

.•<br />

Marilyn Hirsch and Kathy Tatatovich register<br />

the torgest BPPP class yet.<br />

flying situations not normally encountered during a routine<br />

flig ht-all to improve a pilot 'S ability to properly<br />

handle abnormal flight situations. Pilots who meet the requirements<br />

and demonstrate acceptable proficiency can expect<br />

to recei ve an endorsement for a Required Flight Review<br />

(RFR, formerly BFR) and, if appropriate, an Lnstrument<br />

Proficiency Check (fPC, formerl y LCC).<br />

All ABS member-pilots receive a minimum of four<br />

hours of in-flight instruction in<br />

their aircraft with an experienced<br />

flight instructor, chosen especially<br />

for hislher knowledge of<br />

Beech airplanes. Each pilot also<br />

recei ves more than 12 hours of<br />

ground instruction in various subject<br />

areas. Included are aircraft<br />

mechanical systems, pilot health<br />

and medical issues, FARs, ATC,<br />

engine power management, abnormal<br />

circumstances, GPS navigation,<br />

and many other safe operating<br />

techniques considered essential<br />

to safely and efficiently<br />

operate an aircraft under both normal<br />

and abnormal conditions and<br />

situations.<br />

An added valuable benefit of thi s two-and-a-haLf days'<br />

experience is the ample opportunity it affords for pi lots<br />

and companions to meet other members with like aircraft<br />

and to share many rich experiences and knowledge.<br />

cOlllilllled 011 page 6165<br />

ABS <strong>April</strong> <strong>2000</strong><br />

Page 6158

V35 parts source<br />

Augusto Gonzalez<br />

Metro Manila, Philippines<br />

Q: I live in the Philippines and own a V35<br />

<strong>Bonanza</strong>, SIN 0-8449. I need names and contact<br />

numbers (e-mail also), preferably in the<br />

United States, of parts suppliers for <strong>Bonanza</strong>s. I<br />

travel there and usually buy my pans there. However,<br />

Arrell Aircraft, where I used to buy pans,<br />

f1€ently stopped carrying <strong>Bonanza</strong> parts.<br />

A: Our ABS Magazine is an outstanding source<br />

for parts suppliers as is Trade-A-P/ane. Following<br />

are a few of the sources you can contact.<br />

Avstat Aviation (818-780-6032 or 888-287-<br />

8283), Van Nuys, California<br />

Elliott Aviation (309-799-3 183), Moline,<br />

Illinois<br />

Jenkins Air Service (775-331-4905<br />

Iynnjenkins@att.net), Reno, Nevada<br />

RAPID (Raytheon Factory Outlet at 316-676-<br />

3300 or 800-727 -4344), Wichita, Kansas<br />

Select Airparts (540-564-0010 or 800-318-<br />

00 I 0), Harrisonburg, Virginia<br />

Woodland Aviation (916-662-9631 or 800-<br />

442-1333), Woodland, Cal ifornia.<br />

Lt's always best to have the parts numbers and<br />

your aircraft serial number handy when you call.<br />

- NP<br />

A36 dual yoke<br />

Jerry McLauchlin<br />

Ocala. Florida<br />

Q: I just purchased a 1979 A36 with a throwover<br />

yoke. I am interested in purChasing a dual<br />

y~k~ . Cao you advise a source for the dual yoke<br />

A. There are several sources li sted in the ABS<br />

Maga:ine, including Air Mech (888-282-9010)<br />

for used yoke sales and remals. Performance<br />

Aero (800-200-3141) buys and sells used yokes,<br />

and Cygnet Aerospace (650-32 1-6880) offers a<br />

new PMA dual yoke and new PMA ram 's horn<br />

wheeLs.-NP<br />

G35 panel upgrade<br />

Rick Walkup<br />

Omaha. Nebraska<br />

Q: I have a 1956 G35 with the old panel. What<br />

is my best bet for upgrading this panel I wouldn' t<br />

n~nd. even doing it from the piano keys on up.<br />

A. Aviation Research Systems (503-668-<br />

4542) and Beryl O' Shannon (800-328-4629 or<br />

www.beryldshannon.com) have approved mods<br />

to upgrade the older style panels. Also. Lew Gage<br />

has recently written excellem articles about the<br />

extensive upgrade of his G35 panei.<br />

These articles, including four photos, appear<br />

in this year's January (page 6054) and March<br />

(page 6128) issues of the ABS Magazine. Also,<br />

theABS CD-ROM comains articles submitted by<br />

members and appearing in over 30 years of ABS<br />

Magazines addressing this and numerous other<br />

modifications.-NP<br />

A36 tip tank mounting screws<br />

Dofe McGregor<br />

MoultrIe, Georgia<br />

Q: We have Osborne tip tanks on our A36.<br />

Are the screws holding on the tip tanks made of<br />

brass for a special reason Can we replace with<br />

s!)tinless steel<br />

A: I believe they should be structural steel AN<br />

or MS screws. Brass is normally only used at flux<br />

detector access plates. Stainless screws are not<br />

approved for use in structurally loaded applications<br />

such as mouming tip tanks, comrol surfaces<br />

and other areas.-NP<br />

H35parts<br />

John Nazorenko<br />

Leduc, Alberto, Canada<br />

Q: I have an H35 <strong>Bonanza</strong> with an original<br />

0-470G Continental engine SIN 74017G580. I<br />

need a new cylinder head temperature sensor (the<br />

original was an AC), a shop service manual for an<br />

Hi 5 and a new decal for the fuse panel door.<br />

A: We are fortunate there are still sources for<br />

most parts on our aircraft. I suggest you try Instrument<br />

Tech (800-229-9078) or Electronics International<br />

(503-439-8484) for your cylinder temperature<br />

sensor. TMDC (800-796-2665) bas the<br />

shop manual and Moody Aero Graphics (800-749-<br />

2462) can help you with the decal. - P<br />

C33A fuel vents<br />

AI Cosentino<br />

Fort Lauderdale, Florida<br />

Q: I have a C33A Turbo <strong>Bonanza</strong> wi th<br />

Osborne tip tanks.The main fuel bladders (40<br />

gallons each) were replaced, one in 1998 and the<br />

other in June 1999,<br />

Every time I check the fuel level, regardless<br />

of how long J've flown , the bladders seem to collapse<br />

out of shape, At times in the summer, the<br />

fuel would come out the vent. My fuel cell vent<br />

lines are only three-fourths inch long. They' re<br />

supposed to be 1.75 inches long. Could thi s be<br />

the problem along with improperly attached fuel<br />

bJedders<br />

A: Certainly the vent lines need to be the correctlength,<br />

angle and scarf angle. In addition, the<br />

snaps may not be in place on the top of the tank.<br />

ASS <strong>April</strong> <strong>2000</strong>

If the bottom just pulls up, it 's a vent<br />

problem.<br />

The shop manual has a drawing<br />

showing the correct configuration of the<br />

vent. Confirm that the check valves were<br />

installed properly after the cells were<br />

replaced with the embossed arrow pointing<br />

in toward the fuel cell and the word<br />

"hinge" appearing on top of the valves.<br />

Also, confirm there are no obstructions<br />

in any of the vents due to the presence<br />

of insects or mud daubers.-NP<br />

<strong>Bonanza</strong> floor jack<br />

Richord Ardell<br />

Peru, Vermont<br />

Q: Please recommend a brand and<br />

model of Ooor jack(s) for my <strong>Bonanza</strong>.<br />

The Beech three-point cradle is too expensive.<br />

I am not able to reach the folks<br />

at Johnson to discuss their three-point<br />

jack. We need jacks that will allow gear<br />

dll"r clearance.<br />

A: I use the Meyers jacks and they<br />

are available through Aircraft Spruce<br />

(877-477-7823). Also, jacks are fre <br />

quently advertised in theABS Magazille,<br />

so you might check there also.-NP<br />

B55 alternator belt<br />

Robert Frowe<br />

Denton. Texas<br />

Q: The left engine on my B55 Baron<br />

has a problem with the aitemator belt<br />

coming off after about 10 to 15 hours of<br />

installation. The belt literally tears itself in<br />

half. as if a violent force breaks it in two.<br />

Late in December 1999, Byam Propeller<br />

of Fort Worth, Texas, after balancing<br />

the prop and conducting a Chadwick<br />

Helmuth check. pronounced the balance<br />

rating as "good." My mechanic cannot<br />

see any misalignment in the configuration.<br />

Engine total time is approximately<br />

I i OO hours.<br />

A: This is not an unusual problem for<br />

some Barons and <strong>Bonanza</strong>s with beltdriven<br />

alternators/generators. Is this a<br />

new problem for you or did it develop<br />

only after balancing the prop or baving<br />

some other work done on the engine or<br />

alternator<br />

I also wonder if the engine/prop balance<br />

was checked by placing a sensor at<br />

the rear of the engine as well as at the<br />

front. This will often detect vibration<br />

problems emanating from the rear of the<br />

engine and possibly detecting bad crank-<br />

shaft hamlOnic balancer bushings.<br />

ormally. there are three causes of<br />

throwing belts: pulley misalignment, an<br />

engine vibration or a missing belt guard.<br />

The belt guard is a stud that is attached<br />

to the alternator tig htening bracket and<br />

protrudes rearward over the belt between<br />

the two pulleys to restrict belt Outter.<br />

Do you have the correct pulleys and<br />

are they really aligned Another member<br />

recently experienced several incidents<br />

of belt loss on both engines after<br />

having both engines overhauled. The<br />

engine shop was finally able to re-align<br />

the pulleys on both engines and it apparently<br />

has cured the problem.<br />

As a side note, I talked with Bill<br />

Carter, past ABS president, who had a<br />

similar problem with his B55. He subsequently<br />

found that there was rust in the<br />

crankshaft harmonic baJances restricting<br />

movement. Another member had a ntissing<br />

belt guard after an engine overhaul.<br />

Replacing the guard solved the problem.-NP<br />

KFC 200 autopilot<br />

Mike Nolan<br />

Phoenix, Arizona<br />

Q: The KFC 200 autopilot disconnect<br />

switch on the pilot's yoke on my<br />

1982 A36 is bad. Do you know of a good<br />

p~ce to get this part<br />

A: Try <strong>American</strong> Avionics (800-5 I 8-<br />

5858) or Elliott Aviation (309-799-<br />

3 I 83). They should have the parts you<br />

need or be able to g uide you to another<br />

source.-NP<br />

Century 11/ shop location<br />

Lyle V. Burns<br />

Bishop, Georglo<br />

Q: Please gi vc me the name of a repair<br />

faci lity near Atlanta that can fix my<br />

Century III autopilot. The trim creeps<br />

when in altitude hold function. Lowe<br />

Aviation in Macon has tried twice, but<br />

to no avail. They thought it was the trim<br />

a~p~ifier , but I still have the problem.<br />

A. Members report good service from<br />

Lowe on the Century autopilot systems<br />

and gyro instrument overhaul. Often, if<br />

a local shop can't resolve a malfunction,<br />

they may call Century Flight Systems<br />

(8 17-325-25 I 7) in Mineral Wells, Texas,<br />

discuss the problem and possibly return<br />

components to the factory for further<br />

analysis. You can do this yourself as well.<br />

Autopilot Central (918-836-64 18) in<br />

Tulsa, Oklahoma, is another good<br />

source. Quest Avionics (352-873-0000)<br />

in Ocala, Florida, also has the necessary<br />

bench test equipment for the Century<br />

series autopilots. I do not personally<br />

know of a shop in the Atlanta area.<br />

-NP<br />

33 <strong>Bonanza</strong> stabilizer spar fix<br />

Richard Strawn<br />

Moorpark, California<br />

Q: Can you recommend a product<br />

and facility here in the Ventura/Los Angeles<br />

area that can provide a permanent<br />

fix to the vertical stabilizer spar We wish<br />

to end the requirement forthis inspection.<br />

A: General Forming Corp. (3 I 0-326-<br />

0624) is a source of the reinforcements.<br />

They can be installed by any good shop.<br />

Cruise Air (760-789-8020) in Ramona,<br />

California. is also a good source. - NP<br />

V35B touch-up paint<br />

Guy Schmidt<br />

~onQ Beach, Florida<br />

bl: I am trying to purchase touch-up<br />

paint, but only have the follow ing identitication:<br />

"white 616 Alumigrip" and<br />

" light green 43757 UH Imron." 1 presume<br />

this is enough identification to order<br />

these two paints. It's all I have. Do<br />

you have a recommendation regarding<br />

a source<br />

A: Alumigrip is U.S. Paint and Lacquer<br />

from St. Louis and Irnron is Dupont,<br />

avai lable through any Dupont store that<br />

services truck fleets. One retail source<br />

would be Byerly Aviation (309-697-<br />

63(0). You might try a good local body<br />

shop. Just take a panel that has the color<br />

you want and ask them to match the paint<br />

wi th something that is compatible- NP<br />

33 Debonair low-time<br />

old engine<br />

Mike Crump<br />

Colorado Springs, Colorado<br />

Q: I just purchased a 1960 Debonair<br />

this summer. The engine has only 170<br />

hours but was rebuilt and installed in<br />

1983 and not Oown very much. I noticed<br />

that it uses about one quart of oil for every<br />

three to five hours flown . What should I<br />

look out for Other than the oil consumpti~n<br />

, . the engine seems to run very well.<br />

A. I wouldn't do anything. It may get<br />

ABS <strong>April</strong> <strong>2000</strong><br />

Page 6160

eller with usage, but if not, and it<br />

doesn't get worse, just fly it.- P<br />

855 wing bolts<br />

Ron Garlson<br />

Ventura, California<br />

Q: I had my wing bolts inspected at<br />

a recent clinic and they look fi ne. Should<br />

I replace them anyway given your new<br />

outlook on this If so, how does the shop<br />

do it Does the rigging have to be reset<br />

If so, I am reluctant since thi s airplane<br />

is beautifully rigged.<br />

A: I f there is no evidence of water in<br />

the bathtub fittings and you've owned<br />

the aircraft under the same conditions all<br />

along, you might be all right.<br />

I'd like some reports back. We' ve<br />

been seei ng some rusty heads and have<br />

received reports of corroded shanks on<br />

ones that have been changed. It should<br />

be able to be done without changing the<br />

rigging by doing one at a time.<br />

The newer ones are lubricated to prevent<br />

corrosion. The shop needs the shop<br />

manual to do this but they should have<br />

it anyway to perform work on the airplane.-NP<br />

855 wing root rubber<br />

Pete Burgher<br />

Howell, Michigan<br />

Q: Where can I obtain replacement<br />

rubber welting for the wing roots and stab~iz~r<br />

roots on my 1977 B55 Baron<br />

A. Performance Aero (800-200-3 141 )<br />

has these seals and so does any Raytheon<br />

Service Center or RAPID (888-727-<br />

4344).- NP<br />

A36 engine hiccups<br />

Phil Benanti<br />

Me/vilfe, New York<br />

Q: I have been experiencing an occasional<br />

very momentary hesitation of my<br />

IO-520BA while at cruise configuration. l<br />

am unable to determine what effect it has<br />

on rpm, fuel flow or manifold pressure.<br />

There is no noticeable change in my<br />

CHTs or EGTs on my engine graphics.<br />

It happens only on occasion and is unrelated<br />

to any particular aspect of flight.<br />

Mag checks on the run-up phase are by<br />

the book.<br />

A: It may be lead deposits on a spark<br />

plug or secondary "tracks" on a magneto<br />

distributor cap causing an occasional<br />

misfire. These typically won ' t show at<br />

run-up but occasionally do in cruise.<br />

Also, any water in the fuel system could<br />

cause similar events. There is enough lag<br />

in your instruments that a very brief occurrence<br />

may not show on the panel. A<br />

sticky valve also has a similar effect at<br />

cruise power.-NP<br />

855 fuel gauge<br />

Ron Corlson<br />

Ventura, California<br />

Q: The left fuel gauge on my Baro n<br />

shows about three-fourths of a tank when<br />

it is fu ll. After fuel burn down to that<br />

level. it is very accurate all the way to<br />

empty. The gauge works fine in the aux<br />

tank position and the right gauge always<br />

works well. The left gauge looks origina<br />

l and the right looks newer and is<br />

wi red differently at the back of the<br />

gauge. Where do I begin the troublesiA°oting<br />

A: First, I wou ld check all connections<br />

and terminal ends for corrosion and<br />

high resistance, including the splice connections<br />

at the wing root on the left side.<br />

Then check operation of the outboard<br />

sender unit. An ohmmeter can be used<br />

to check it with the power off. Both John<br />

Wolfe Co.(440-942-0083) and Air Parts<br />

of Lock Haven (570-748-0823) can do<br />

repairs in some cases.- P<br />

C35 electric boost pump<br />

BobStewort<br />

Dol/os, Texas<br />

Q: I want to add an auxiliary fuel<br />

boost pump to assist the wobble pump. 1<br />

have a C35 with an £-225-8 engine and<br />

pressure carburetor. Pump specs are<br />

10- 14 psi , 34 gph and 12VDC. What<br />

model Dukes pump is applicable I reviewed<br />

the CD-ROM and fou nd model<br />

numbers for a Weldon pump. but no<br />

Dukes pump. This will be a field mod. Is<br />

there a 337 applicable to submit to the<br />

FAA inspector<br />

A: Warren James (9 I 8-786-4506) has<br />

an STC for the Dukes pump at a reasonable<br />

price.-NP<br />

N35 leaking fuel cell<br />

Robert St. George<br />

Mastic Beach, New York<br />

Q: 1 have a leaking 40-gallon right<br />

side fuel cell. I would like to know how<br />

to remove and replace the bladder, and<br />

what is actually involved. Who would<br />

you recommend I contact for the replace<br />

Il)(nt and ball park price<br />

J-\: I would call Carl Hartwig at Eagle<br />

Fuel Cells (800-437-8732) as a reliable<br />

source of knowledge for either rebuilding<br />

or replacing your fuel cells. We've<br />

also published articles detailing the process<br />

in back ABS issues which are avai l<br />

able from Headquarters (3 I 6-945- I 700)<br />

on the ABS CD-ROM. The price wi ll<br />

vary considerably depending on the condition<br />

of your internal wing tape and experience<br />

of installers. It is a labor-intensive<br />

job and requires a properly certified<br />

mechanic.- P<br />

535 leaking gear box<br />

Mlchoel Meek<br />

Brandon, MiSSissippi<br />

Q: I have discovered that I have a<br />

leaking landing gear gearbox. The leak<br />

is coming from around the emergency<br />

crank handle. 1 checked the fluid level as<br />

per the maintenance manual and had to add<br />

approximately two ounces. I cleaned up<br />

as best 1 could (the floors and carpet were<br />

soaked) and then placed paper towels<br />

around the crank handle to detect further<br />

leakage. After making three retractions and<br />

extensions, the leak continues. Is it possible<br />

to reseal the handle without overhauling<br />

the gearbox If so, what will this inv)!!ve<br />

and what is the procedure<br />

J-\: The gear box should be fi lled only<br />

to the level where the gear picks up<br />

grease as it turns. The O-ring on the<br />

manual shaft is not normally changed in<br />

the field. Aero Electric (316-943-6 I 00)<br />

and Cruise Air (760-789-8020) are two<br />

sources of repair.-NP<br />

C33 mice invasion<br />

Merton Musser<br />

Billings, Montono<br />

Q: Is there any good defense against<br />

mice entering an airplane and making a<br />

mess I've kept the interior free of any<br />

food or water that might attract them. 1<br />

put out poison around the hangar, but<br />

tlJry.still seem to get into the plane.<br />

A 1<br />

Some of our back issues have articles<br />

on a barrier made of sheet metal<br />

fastened around the tires, high enough<br />

to prevent most rodents from jumping<br />

over, and faste ned at the joint well<br />

Page 6161<br />

A BS <strong>April</strong> <strong>2000</strong>

enough to prevent gaps. They do seem<br />

to work pretty well. h is good that you<br />

are concerned and working to solve the<br />

problem. Rodent urine can cause very<br />

serious corrosion damage in a very short<br />

time-often in the belly of the aircraft<br />

or in the wings.<br />

See Dick Pedersen's article "Mickey,<br />

The Only Good Mouse!" in the August<br />

1996 ABS Maga~ille.-NP<br />

A36 avionics upgrade<br />

Hal Beers<br />

Son Jose, California<br />

Q: Our club is upgrading avionics to<br />

the point where the aircraft is a much<br />

more tempting target for thievery, and<br />

it·s time to upgrade the door locking<br />

scheme as wel l. I have noticed on another<br />

A36 the installation of barrel-type<br />

locks on both the passenger door and<br />

utility door. In the case of the passenger<br />

door, the mod provides a spring-loaded<br />

dead bolt into the aft door frame. The<br />

lock is the type that requires a cylindric~<br />

key-very difficult to pick.<br />

A: Security lock sets are available<br />

from Performance Aero (800-200-3141)<br />

and Aviation Research Systems (502-<br />

668-4542 or 616-957-4920).-NP<br />

895 Travel Air info<br />

Tom Phillips<br />

Clarkston. Michigan<br />

Q: I'm considering buying a 1960<br />

B95 Travel Air. Where can I find info<br />

on what to look for, i.e. wing bolts, spar<br />

c5('cks, etc<br />

A: The ABS CD-ROM has all back<br />

issues with a great search engine as well<br />

as ADs, STCs, etc. Our position on wing<br />

bolts is that if they 've never been out,<br />

then it might be good to change them.<br />

We're seeing some corrosion, but<br />

haven't had one break. The wing spar<br />

carry through is worth looking at, as<br />

some inspectjons haven't been done correctly,<br />

and the Barons have been the ones<br />

with cracks. I don ' t know if there have<br />

ever been any Travel Airs found to have<br />

cracks. There has been some thought that<br />

the engines may provide twisting moments<br />

on landings or in gusts.<br />

The kit to repair cracks is best done<br />

by someone with considerable experience<br />

doing thjs specific repair. Make sure<br />

any prop AD has been complied with.<br />

Some people represent it as having been<br />

done and forget to note that there are short<br />

repetitive cycles for some inspections.<br />

Look for fuel cell leaks and corrosion<br />

on magnesium controls. Get assistance<br />

from an experienced mechanic on a prebuy<br />

survey of the logs and airplane.<br />

-NP<br />

A36 CUp holders<br />

Gary Tillery<br />

Moriarty. New Mexico<br />

Q: Do you know of anybody who has<br />

created a kit fo r cup holders in the interior<br />

front door panels that would fit a<br />

1993 A36 <strong>Bonanza</strong>, Model E-2811 The<br />

ash trays are useless, and it would be nice<br />

to have cup holders in their place.<br />

A: You can try Aviation Research Systems<br />

(503-668-4542). One member<br />

found a cup holder with a flexible plastic<br />

strap that conforms to differing door<br />

thicknesses. It fits down between the<br />

door panel and the window or will hang<br />

on the emergency window release rod. It<br />

can be easily removed when not needed<br />

and is available from auto supply stores or<br />

car washes for a few dollars.-NP<br />

855 annual<br />

Tom Moe<br />

Richardson. Texas<br />

Q: I am about to start the first annual<br />

inspection on a B55 that I recently acquired.<br />

I am looki ng for any help or<br />

checklists that might be available. Any<br />

resources you could recommend would<br />

b1.. greatly appreciated.<br />

A: The checklists are in the back of<br />

the shop manuals and are also avai lable<br />

through Raytheon Service organizations<br />

and TMDC at 800-796-2665. This airplane<br />

is complex enough that I recommend<br />

you also have a copy of the shop<br />

manual to perform maintenance.- NP<br />

T34 wing inspection AD<br />

William Mayher<br />

Albany. Georgia<br />

Q: It has been a while sinee I heard<br />

anything about the T-34 wing inspection<br />

AI( . ~ you have any current infonnation<br />

A. SB 57-3329, issued February <strong>2000</strong>,<br />

is a 63-page document detailing the inspection<br />

methods. It 's available through<br />

Raytheon at 800-796-2665 or 3 16-676-<br />

8238.-NP<br />

G35 aileron rivets<br />

Bob Beckham<br />

Fort Worth. Texas<br />

Q: I would like to know the part number<br />

of the rivets that attach the magnesium<br />

skin to the end bay of the ailerons<br />

on my G35, SIN D-4673, and where they<br />

cX' be obtained.<br />

A: The ri vets are 5356 alloy and PIN<br />

AN470B of the appropriate diameter and<br />

length. An AN470AD ri vet, which is an<br />

alloy that could interact with the magnesium,<br />

is not to be used. Mr. Stebbins<br />

(800-852-8 155), who does reskinning,<br />

verified that they use this rivet. Order by<br />

part number plus the length and dianleter<br />

from any large aircraft parts house.-NP<br />

A36TCPOH<br />

Dina Salvatore<br />

Venice, Italv<br />

Q: I recently have purchased an<br />

A36TC. In the Pilots Operating Handbook,<br />

there are several sections that are<br />

doubled as with or without Kit 36-9008-1<br />

per Service Bulletin 2033. I do not see<br />

any difference between the with or without<br />

section.<br />

Sorry about my ignorance but I do not<br />

know what this kit is about. How do I<br />

find out if it has been installedon thespecific<br />

airplane and what the operating diff){e~ces<br />

are between the two version s<br />

A. No need to be sorry. This is a good<br />

question. This kit is now obsolete. It consisted<br />

of a modification to the fuel lines<br />

to reduce the probability of engine flooding.<br />

If it was installed, the aircraft log<br />

should show an entry along with the serial<br />

number of the kit.-NP<br />

35 AD 76.05,04 inspection<br />

Tom Spencer<br />

Addison. Vermont<br />

Q: This airplane is subject to the AD<br />

76-05-04 inspection of the stabilizers attaching<br />

fining. and the next I,OOO-hour<br />

inspection is comi ng up. I would like to<br />

eliminate this AD by replacing the fittjng<br />

with the aluminum fitting. Where<br />

c~ul I find one-preferably a used one<br />

1-\ I<br />

Replacing this fitting is a good<br />

choice. When either a PIN 35-650044-1<br />

or PIN 35-405130-3 stabilizer attach fitting<br />

has been installed, the requirements<br />

of this AD no longer apply. I would<br />

check with Dave Monte (775-782-5282)<br />

or Crossroads (972-239-0263).-NP<br />

ABS <strong>April</strong> <strong>2000</strong><br />

Page 6162

Shaw Aero<br />

fuel restrictor plates<br />

Dwight Pladsen<br />

~d City. South Dakota<br />

Ic:::::.l: Shaw Aero used to have kits to<br />

install restrictor plates/caps in the main<br />

fuel cell tank openings. Some insurance<br />

companies give a reduced rate/refund if<br />

you install them. Can you tell me of an<br />

STC to install them besides factory new<br />

Shaw says they make them, but you have<br />

to go through the aircraft manufacturer<br />

n~w because of legalities.<br />

f\: There is no STC shown in the FAA<br />

listing. What Shaw told you is what I've<br />

heard also. Beech Kit 36-5012- 1 S is for<br />

B36TC and 5013-1 S is for the other<br />

models per SB 2045-NP<br />

H35 starter adapter<br />

Ken DeYoung<br />

Laurens, Iowa<br />

Q: I have an H35 with an 10-470.<br />

I've had it three months and used it about<br />

30 hours. The starter adapter was bad<br />

when we bought it. I put a used one in it<br />

and it lasted about 20 hours. Then I<br />

bought a remanufactured one and it<br />

lasted 10 hours and six starts. The spring<br />

is always broken. What am I doing<br />

wJ..0~g and what can I do to solve this<br />

f\, I would suspect something is<br />

wrong with your timing marks. Broken<br />

springs are usually a result of a kick-back<br />

event. If you have impulse couplings, are<br />

they the correct ones for the engine<br />

model IT you have a shower of sparks<br />

system, check to make sure the primary<br />

points are grounding out and that the<br />

right mag is grounded in the start position.<br />

Check your timing mark against a<br />

timing wheel indexed to the TDK position.<br />

The 15W50 oil won't cause the broken<br />

spring to my knowledge.-NP<br />

<strong>Bonanza</strong> door reseal<br />

David Plyler<br />

Sherman. Texas<br />

Q: Do you know of a maintenance<br />

facility in or around the north Texas area<br />

that has a demonstrated ability to adjust<br />

a'Ad reseal the <strong>Bonanza</strong> door<br />

f\: Scott Goodley at All-<strong>American</strong><br />

Aviation (972-392-7555) in Addison,<br />

Texas, is a possible source. Another possibility<br />

is Crossroads Aviation (972-239-<br />

0263).-NP<br />

Nitrogen for filling struts<br />

Thomas R. Lombard<br />

Broomall. Pennsylvania<br />

Q: Where can I buy a nitrogen tank<br />

to fill the struts for my <strong>Bonanza</strong>- a<br />

welding shop or medical supply How<br />

much pressure is required to fill the K35<br />

frRnt strut and mains<br />

f\: The nitrogen tanks are normally<br />

leased from welding supply companies.<br />

You will also need a gauge and regulator.<br />

Depending on aircraft weight and the<br />

friction within indi vidual struts, I generally<br />

see 200-500 psi on the gauge.<br />

- NP<br />

E33 shutdown fuel leak<br />

Dwayne Konicek<br />

Festus, Missouri<br />

Q: What causes fuel to come out of<br />

the two vent lines upon engine shutdown<br />

after a flight It is enough to make a sixinch<br />

spot on the pavement or kill grass,<br />

and I need to address it soon. I also have<br />

a fuel odor in the cabin at high-power<br />

setting and am wondering if the two<br />

could be related.<br />

The fuel selector was seeping a bit<br />

and new O-rings fixed that, but the odor,<br />

although less, is still there. The aircraft<br />

has an auto fuel STC. I feel your eyebrows<br />

raise, but it has had it for 15 years<br />

with no problems. What other sources<br />

of fuel in the cabin are there<br />

A: It is very important to remember<br />

that the auto fuel STC is dependent on<br />

our using the correct fuel specified by<br />

the STC and it being free of contamination<br />

with other fuels. A lit~e alcohol, common<br />

in some auto fuel, can ruin O-rings.<br />

It is possible that the vent check valve<br />

(siphon check valve) either has a bad seal<br />

or is stuck. It's located at the front outboard<br />

upper end of the fuel tank. It has a<br />

hinge marked for the top and an arrow<br />

to show the direction of air flow toward<br />

the tank.<br />

The fuel pressure line can be an additional<br />

source of leaks in the cabin, but<br />

fuel vent fumes can also be introduced<br />

through the cabin vent system.-NP<br />

Neil Pobanz, ABS technical consultant, is a<br />

retired u.s. Army civilian pilot and maintenance<br />

manager. Neil has been an A&P and<br />

fA (or 40 years.<br />

Clen NArky " Foulk, whose business is Delta<br />

Strut, is an ABS assistant technical consultant<br />

who has served as a part-time ABS Service<br />

Clinic inspector since 1988.<br />

Please send your<br />

questions and/or tips<br />

and tec hniques to:<br />

<strong>American</strong> <strong>Bonanza</strong> <strong>Society</strong><br />

Attn Nell Poba nz<br />

P.O. Box 12888<br />

Wichita, KS 67277<br />

Fax 316-945- 1710 or<br />

e-mail at bononzo2@bononzo.org<br />

BPPP INC. SCHEDULE FOR <strong>2000</strong><br />

<strong>Bonanza</strong>s/Barons/Travel Airs at all locations. Subject to change,<br />

DATE LOCATION PHASE CUTOFF DATE<br />

May 12-14 Milwaukee, Wis. Initial/Recurrent Apr. 10<br />

June 2-4 Spokane. WOsh, Initial/Recurrent May 10<br />

June 23-25 Colorado Springs, Colo. Mountain Flying May 20<br />

Sept, 22-24 Uttle Rock. Ark, Initial/Recurrent Aug. 21<br />

Oct 1>-8 Fresno. Calif. Initial/Recurrent Sept. 21<br />

Oct 20-22 Nashua. N,H. Initial/Recurrent Sept. 20<br />

Nov, 3-5 Norfolk. Va. Initial/Recurrent Oct 12<br />

Cockpit Companion course available at all locations except Colorado Springs.<br />

CALL TH E BP PP. INC. REGISTRATION OFFICE to make<br />

arrangements to attend: 970-377-1877 or fax 970-377-1512.<br />

Page 6163<br />

ABS <strong>April</strong> <strong>2000</strong>

A STANDBY ATTITUDE INDICATOR<br />

VS. A STANDBY VACUUM SYSTEM<br />

WHICH IS BEST BY NEIL POBANZ<br />

I intend to have a standby attitude system installed<br />

in my V35. The February <strong>2000</strong> issue of<br />

Aviation Consumer suggests that I would be<br />

better off installing an electric attitude indicator<br />

from R.C . Al len instead of a standby<br />

vacuum/pressure system . Your thoughts, please.<br />

- Skip McConnel, Macungie, Pennsvlvania<br />

I<br />

agree. Personally, [ prefer to have additional electrically<br />

powered directional and attitude indicators as a standby<br />

system. Actuall y, having both a standby vacuum system plus<br />

these electric gyros wo uld be even better. Still, we need to<br />

real ize that although both gyro and vac uum system failures<br />

can be potentially serious events, they are definitely setting us<br />

up for the real challenge that fo llows.<br />

As reasonably current and competent instrument pilots, we<br />

should be able to operate without an attitude indicator andlor a<br />

directional gyro while we fly partial panel with needle ball<br />

and airspeed in normal [Me conditions. This is especiall y so if<br />

these are the only instruments we have to work with and the<br />

other instruments have been covered-usually by our flight<br />

instructor. This is required performance on fli ght tests and it<br />

isn't a big deal if we're current.<br />

However, contrast this simulated situation with an unanticipated<br />

real-time failure demanding quick determination of<br />

whether an attitude indicator. a directional gyro, a vacuum<br />

pump or a pi tot system has failed, before we lose control of the<br />

aircraft in [MC-perhaps within seconds. Suddenly, most likely<br />

for the first time in our flying experience, we are faced with<br />

conllicti ng information from coeor more instruments that have<br />

never "lied" to us before.<br />

Unfortunately, we may fixate on the "bad" instrument(s)<br />

that slowly, and often without warning, drift to incorrecl indications.<br />

We make our usual contrOl movements to get "bad" instruments<br />

to respond properly, while forgetting to scan and interpret<br />

what the "good" instruments are telling us.<br />

In these situations, more than at any other time, we must<br />

quickly gather and interpret information from all fli ght instruments<br />

to determine which have failed, which are reliable and<br />

what corrective action is required. Ironically, we may fixate<br />

on the AI andlor the Dl which are providing faulty indicationsnot<br />

the properly operating turn coordinator or turn needle, airspeed<br />

indicator, VS[ or the altimeter that we have probably<br />

been neglecting in our confusion.<br />

An exception would be if we had an iced-up pitot/static system.<br />

By the time we have sorted it out (if ever), the aircraft<br />

may have entered an unusual attitude-all too often with disastrous<br />

results.<br />

This scenario is not unique to single pilot light aircraft. Professional<br />

fli ght crews in large iet aircraft, plus a high percentage<br />

of pilots in flight simulators, have flown aircraft into the<br />

ground by trying to follow tumbled gyros or other bad indications<br />

resulting from frozen or taped-over pi tot tubes.<br />

What can we do First, we must carefully maintain our aircraft<br />

flight instrument systems and consider backup systems<br />

appropriate to our aircraft and our flight requirements.<br />

ext, we must constantly practice our full instrument scan<br />

and partial panel instrument fly ing. Use your PC fli ght simulator<br />

if you have one with system failing features. In your ai r<br />

craft, having our instructor place a simple picture of a tumbled<br />

Al over our real AI can add an amazing bit of realism to a<br />

training exercise. Pilots have been known to t1xate on the picture.<br />

Pull the circuit breaker on some HS[ units and the card<br />

will fail. Check to see if the VOR/LOC/GS needles still indicate<br />

properly.<br />

Next, if we have a GPS moving map positioned close enough<br />

to OUf normal instrument scan area, include it in our scan. Most,<br />

if not all, GPS units can be set up to provide track, groundspeed<br />

and altitude information to back up our traditional sources<br />

and help to identify the failed instrument(s).<br />

[also suggest carrying the rubber instrument covers available<br />

from aviation supply houses or sticky paper notes to quickly obscure<br />

any failed instruments as soon as they are identified.<br />

If we consider which backup systems are appropriate to our<br />

needs, follow good maintenance procedures, frequently practice<br />

flying partial panel and develop system failure recognition<br />

techniques, we will have armed ourselves with the best<br />

possible weapons to deal with these kinds of failures. -@-<br />

When faced with conflicting information<br />

from one or more instruments that have never<br />

"lied" to us before, we may fixate on the "bad"<br />

instrument(s) that slowly, and often without<br />

warning, drift to incorrect indications. We make<br />

our usual control movements to get "bad" instruments<br />

to respond properly, while forgetting<br />

to scan and interpret what the "good" instruments<br />

are telling us.<br />

ABS <strong>April</strong> <strong>2000</strong><br />

Page 6164

BPPP ... POLISHING flYING SKlll~<br />

continued from page 6158<br />

So if you haven ' t had any recent extensive<br />

recurrency training in your aircraft, consider a BPPP<br />

Clinic coming to an airport near you.<br />

Ron Vickrey, ABS past preSident, flies a 855 Baron. He holds<br />

a commercia/license with SMEL and instrument ratings plus<br />

Flight Instructor 5MEL airplanes and instruments and advanced<br />

ground instructor ratings.<br />

BPPP participants enjoyed the Friday night dinner after a full day<br />

of classroom activities.<br />

JUDY SCHLANGER<br />

I would like to share my experience in<br />

the weekend Companion Course provided<br />

.1:8<br />

•';!;II'<br />

'. . , .<br />

'M.".,,,,<br />

(<br />

"<br />

by the <strong>Bonanza</strong>/Baron Pilot Proficiency<br />

Program in February in Orlando, Florida.<br />

I admit I had no idea what to expect. Once<br />

I arrived. they handed me the schedule and<br />

I became a nervous wreck. When I saw<br />

words like aerodynamics, cockpit instruction,<br />

navigation , com munications, etc., Judy Schlanger<br />

that was it. I was ready to spend the weekend at Disney!<br />

But Friday morning we met our instructor, Dave Treinis,<br />

and the other 10 companions and Dave made us feel immediately<br />

comfortable. He encouraged us to ask questions; said it<br />

was going to be very informal and that he wanted us to enjoy<br />

ourselves. By the time he completed the cockpit instruction, I<br />

was feeling very relieved. Dave did such a wonderful job simplifying<br />

the entire course that we were able to understand and<br />

visualize what he was explaining. No question was too simple.<br />

Then Dan Ramirez took over and began to explain charts.<br />

Talk about intimidation- l thought I would probably hate this<br />

Dave Treinis. instructor. and the companions had a great day in class<br />

followed by airport and control tower activities.<br />

-'<br />

session. However, by the time he was through, I knew what a<br />

quad, tick marks and MEF all represent. How exciting to now<br />

be able to understand and make some sense of those charts.<br />

The point I am trying to make is that the classes were well<br />

worth my time. Dave and Dan made everything easy and having<br />

fun was very important. My advice to all companions is,<br />

"Take tbe course." I walked away with a lot more knowledge<br />

than I expected.<br />

Do you know how to contact anyone in case of an emergency<br />

What communications frequency do you enter I rest<br />

my case ...<br />

VICKI McDOUGLE<br />

I strongly recommend the BPPP Companion<br />

Course to anyone spending time in<br />

the right seat.<br />

The first day of interactive classroom<br />

study was led by excellent instructors who<br />

presented valuable information in a very informal<br />

selling. Prior flying knowledge was<br />

not a requirement and there were no tests! Vicki McDougle<br />

The following day included a trip to the airport where we<br />

actually saw in action everything we had learned. After performing<br />

a "walk around inspection" of a <strong>Bonanza</strong><br />

and a Baron, we headed off for a wonderful<br />

tour of the Orlando Executive Airport<br />

Control Tower where we watched and listened<br />

to several very busy controllers talking to our<br />

pilots as they flew with their BPPP instructors.<br />

The program taught me how to be an asset<br />

to my pilot and significantly increased my confidence<br />

while we are in the air. My pilot and I<br />

were both very pleased with the BPPP and plan<br />

to attend future courses.<br />

As a bonus, we met more ABS members<br />

and have already made plans to meet with several<br />

of them at upcoming events. -@.--<br />

Page 6165 ABS <strong>April</strong> <strong>2000</strong>

A<br />

N<br />

After our recent trip to San Antonio to begin<br />

plans for the ABS Convention in September,<br />

I would like to share some observations.<br />

I<br />

JON ROADFELDl ABS VICE PRESIDENT<br />

y traveling companion/wife Ginny and I arrived on a<br />

Saturday evening- a full day earlier than requiredso<br />

we could do a little wandering around before getting<br />

serious about the business at hand. After checking in at the<br />

Adams Mark Hotel, we went for a hike along the Paso Del Rio,<br />

or Ri ver Walk, that is accessible right off the hotel 's ri verside<br />

patio. It is a little more than a fi ve-minute walk to where the<br />

Ri ver Walk pubs and restaurants begin.<br />

It was Valentine's Day weekend so there were a lot of folks<br />

taking advantage of the beautiful evening along the river. Many<br />

restaurants provided live music that added to the festive scene.<br />

They all provide tables where you can enjoy people-watching, see<br />

the festive lights hung from trees, buildings and adorning the<br />

water taxis as they glide by.<br />

We found a table at Ibiza's and enjoyed some fajitas and<br />

white wine while gloating a bit on being able to enjoy dining<br />

outside in Texas rather than being snowbound in Minnesota.<br />

After the meal, we retraced our route back to the hotel. The<br />

cOlllil1t1ed on page 6168<br />

Stinson Air Service where the annual hangar party will be held. Note the T-6<br />

In the background.<br />

ABS member Don Barnett of Kerrville, Texas, claims to be the first arrival into<br />

Stinson for the Convention.<br />

A REALLY UNIQUE OPPORTU<br />

NITY IN SAN ANTONIO WILL<br />

BE OFFERED AT OUR HOST<br />

AIRPORT, Stinson Municipal. For<br />

anyone with a suppressed desire to<br />

fly in something a little different,<br />

here's your chance. Stinson Air<br />

Center, our lead FBO, offers an opportunity<br />

to ride in a 300 HP<br />

Stearman, a T-6D advanced trainer<br />

of WW-1J fame with a P&W 1340,<br />

a Pitts S2B with the 10-540<br />

Lycoming and a Bell 470 Helicopter<br />

(similar to the type seen in the<br />

TV series "MASH").<br />

Stinson Air Service will also provide<br />

a course in Emergency Maneuvers<br />

Training in a Super Decathlon<br />

for those interested in adding to their<br />

flying skills. For scheduling and<br />

other information, call them at 210-<br />

924-6634. --@-<br />

ABS <strong>April</strong> <strong>2000</strong><br />

Page 6166

In most of our IFR flying, instrument<br />

approaches are done in relatively good<br />

weather. From repetition, the approaches<br />

to our home base are fairly routine.<br />

Things generally get only slightly<br />

more tense at unfamiliar airports. However,<br />

when the weather gets reall y<br />

wormy, the workload can go up dramatically.<br />

Add to the worsening weather an<br />

unfamiliar, high-traffic-density airport,<br />

and suddenly the simple approach can<br />

become a fairly complicated maneuver.<br />

Low visibility approaches are very<br />

demanding of a pilot's skills. Lowered<br />

ceiling and visibility at the end of an approach<br />

means reduced decision-making<br />

time for the pilOllO find the runway and<br />

complete the landing.<br />

Vou have 15 seconds to find the runway<br />

and land from a 200-foot DH at 120<br />

knots, and three to four seconds of that<br />

is used up as you transition your vision<br />

from inside to outside the aircraft. Planning,<br />

aircraft and pilot preparation-and<br />

maintaining IFR currency-are the keys<br />

to making even a night approach to minimums<br />

a straightforward (though perhaps<br />

not tension-free) operation.<br />

Planning<br />

The first step in the process of simplifying<br />

a relatively hazardous approach<br />

is planning. When you hear from the<br />

ATIS or ATC that the weather at the destination<br />

is going down or has not improved<br />

as expected, that's the time to start<br />

considering your options. Do I still want<br />

to go there Are the minimums for the<br />

available approach adequate for me to get<br />

into the field Am I current enough and<br />

capable of completing this approach<br />

Assuming that you decide to continue<br />

to your planned destination, start planning<br />

for the approach procedure when<br />

you 're still in the letdown from cruise<br />

altitude. If you start reviewing charts at<br />

least 30 to 40 miles out, you have ample<br />

time to plan how you will be executing<br />

any approach procedure. ATIS will provide<br />

the approach in use, or ask ATC<br />

what to expect if there is no ATIS.<br />

Each approach chart has four areas that<br />

should be examined prior to beginning any<br />

APPROACHES<br />

TO<br />

BY ANDREW FORGACS<br />

approach: Plan view, Prof~e view, Missed<br />

Approach information, Airport diagram.<br />

Plall view - From the overhead view of<br />

the approach procedure, determine obstruction<br />

and terrain data, navaid information<br />

and the initial missed approach<br />

course. Vou should be able to vis ual ize<br />

which way you are approaching the initial<br />

approach course, set up nav radios<br />

for the approach and the miss, and if expecting<br />

vectors, select your point for reaching<br />

approach speed and configuration.<br />

Profile view - Note the initial and final<br />

approach altitudes, distances to fixes, and<br />

time to missed approach point, if nonprecision.<br />

Missed approach iI11017110tioll- Vou need<br />

to determine when to execute a miss<br />

(based on time or crossing a fi x) and the<br />

missed approach procedure to follow.<br />

Never assume an approach will be successful.<br />

Memorize the initial portion of the<br />

missed approach, e.g. climbing right tlll7l<br />

to 3,000 direct the VOR.<br />

Airport diagram - You need to find the<br />

type of approach lighting available- so<br />

you know what to expect-and the alignment<br />

of the final approach course to the<br />

The first step in the process<br />

of simplifying a relatively<br />

hazardous approach is<br />

planning. If you start reviewing<br />

charts at least 30 to 40<br />

miles out, you have ample<br />

time to plan how you will be<br />

executing any approach<br />

procedure. ATIS will provide<br />

the approach in use, or ask<br />

ATC what to expect if there<br />

is no ATIS.<br />

landing runway-so you know where the<br />

runway will be when you look out the<br />

windshield. (On Jepp's, the runway alignment<br />

is shown in the Plan View section.)<br />

Remember, your heading on final may not<br />

be pointing the aircraft down the runway<br />

if you're crabbing inlO a crosswind.<br />

Prepare the aircraft<br />

Your goal is a stabilized approach<br />

during all phases of the procedure. "Stabilized"<br />

means it requires minimum control<br />

input to maintain specific aircraft<br />

speed and attitude. By maintaining a<br />

stable configuration, you have more time<br />

to concentrate on the approach procedure<br />

instead of being busy trying to keep the<br />

aircraft upright.<br />

Establish a standard procedure for<br />

yourself that configures the aircraft at<br />

approach airspeed and flap setting at the<br />

same point on every approach. Use time<br />

to the lAF, DME or GPS distance from<br />

an initial fix , or the base leg heading of a<br />

vectored approach as a target point. Every<br />

time you fly a simi lar approach procedure,<br />

your goal should be to have the aircraft<br />

stable and configured for the approach at<br />

that same relative point.<br />

Prepare yourself<br />

Remember, it's darker under an overcast<br />

than on top. Remove sunglasses, set<br />

cockpit lighting, turn on nav and landing<br />

lights (unless they cause vision problems<br />

in the clouds), ask the tower to turn<br />

up the approach lights or activate the<br />

HIGH setting for pilot controlled lights.<br />

If it's been a long flight, sit up and stretch<br />

a little so you can shake off the cobwebs.<br />

Now that you're ready for the approach,<br />

anticipate problems. Be prepared<br />

for a missed approach at any time. You<br />

never know when an aircraft may pull onto<br />

a runway, or if you will be able to maintain<br />

visual to the runway when you break out.<br />

Anticipate where the runway will be<br />

when you break out of the clouds.<br />

Be aware of the tendency to lose altitude<br />

on level-off, especially if it 's a<br />

circie-IO-land- and watch the altimeter.<br />

Prepare for the horizon-shortening errors<br />

caused by fog and flat light.<br />

Page 6167<br />

ABS <strong>April</strong> <strong>2000</strong>

If it's night, remember the inherent<br />

depth perception errors of the eye and<br />

fly the VASI closely. [f there is no VASI,<br />

plan to remain high and land long.<br />

Training<br />

Keep up your IFR currency. That<br />

means actually flying under a hood or in<br />

the clouds, not fl ying on top in VFR on<br />

autopilot. Fly with an instructor occasionally.<br />

Take a simulator-based IFR refres<br />

her course so you can practice emergencies<br />

without damaging or endangering<br />

the aircraft.<br />