April 2007 - Glenair, Inc.

April 2007 - Glenair, Inc.

April 2007 - Glenair, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

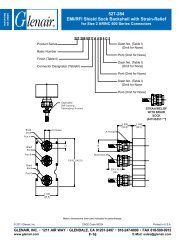

available as a strain relief clamp, or in two EMI shield sock termination options: nickel-plated<br />

copper braid sock or metalized composite thermoplastic braid sock.<br />

1.5 Test Specimens<br />

Swing Arm Backshell strain reliefs, 627A(H)122X0 type and EMI nickel-plated copper shield<br />

termination strain reliefs, 319A(H)064XO(XN) type, in sizes small, medium and large for<br />

Groups 1, 2, 3 and 4 were used as described in table 2.<br />

TABLE 2—TEST SPECIMEN DESCRIPTIONS<br />

Specimen<br />

319HxxxXO11<br />

319HxxxXO17<br />

319HxxxXO25<br />

319AxxxXN10<br />

319AxxxXN16<br />

319AxxxXN24<br />

627HxxxXO11<br />

627HxxxXO17<br />

627HxxxXO25<br />

Description<br />

38999 Series III, shell size 11, electroless nickel<br />

interface<br />

38999 Series III, shell size 17, electroless nickel<br />

interface<br />

38999 Series III, shell size 25, electroless nickel<br />

interface<br />

Shell size 10, interface I.A.W. AS85049 Figure<br />

4A, cadmium/electroless nickel selectively plated<br />

Shell size 16, interface I.A.W. AS85049 Figure<br />

4A, cadmium/electroless nickel selectively plated<br />

Shell size 24, interface I.A.W. AS85049 Figure<br />

4A, cadmium/electroless nickel selectively plated<br />

38999 Series III, shell size 11 strain relief clamp<br />

38999 Series III, shell size 17 strain relief clamp<br />

38999 Series III, shell size 25 strain relief clamp<br />

1.6 Test Preparation<br />

Qualification test specimens were grouped by shell size: small size; (shell sizes 08-13),<br />

medium size; (shells sizes 14–19) and large size; (shell sizes 20 thru 28). Three (3) samples<br />

of each size group shall be tested. Small group shell size 10/11. Medium group shell size<br />

16/17 and large group shell size 24/25 shall represent all shell sizes for purposes of this<br />

qualification. A combination of straight and 90º configured assemblies were tested.<br />

System Test Groups 2 & 3 had the cable dead end inside the dummy test connector by<br />

sealing and tape wrapping the cable to fit snuggly inside the bore (representing a wired mated<br />

connector). The assembly was wired using standard practices and <strong>Glenair</strong>’s braid sock<br />

backshell procedure GAP-027, attachment 2.<br />

Component Test Group 4 required coupons for Flammability, Smoke & Toxicity tests. Indirect<br />

lightning strike, hydrolytic stability and fluid resistance test were performed on a complete<br />

backshell assembly.<br />

QwikConnect · <strong>April</strong> <strong>2007</strong><br />

17