April 2007 - Glenair, Inc.

April 2007 - Glenair, Inc.

April 2007 - Glenair, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TestReport<br />

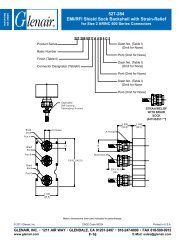

Qualification Test Report for Swing Arm Backshell<br />

1 INTRODUCTION<br />

1.1 Purpose<br />

To verify compliance with all required specifications.<br />

1.2 Scope<br />

This report covers electrical, mechanical and environmental performance testing of <strong>Glenair</strong><br />

Swing Arm Backshell strain relief clamps and EMI shield terminations with strain relief. The<br />

information in this report was obtained from a series of tests conducted by the test facilities in<br />

the table below. Test report documents are on file at <strong>Glenair</strong>, Glendale, California and are<br />

available upon request.<br />

TABLE 1—TESTS CONDUCTED<br />

Testing Agency Location Date Description of Test<br />

National Testing<br />

Systems<br />

Lightning<br />

Technologies, <strong>Inc</strong>.<br />

Boeing Company<br />

<strong>Glenair</strong> <strong>Inc</strong>,<br />

Environment<br />

Associates, <strong>Inc</strong>.<br />

Fullerton, CA<br />

Pittsfield, MA<br />

Seattle, WA<br />

Glendale, CA<br />

Santa Ana, CA.<br />

November<br />

11, 2005<br />

March 20,<br />

2006<br />

<strong>April</strong> 25,<br />

2006<br />

July 19 and<br />

July 27,<br />

2006<br />

October 16<br />

and<br />

November<br />

17, 2006<br />

Document<br />

Reference<br />

Firewall Flame 576-4617<br />

Indirect effects lightning<br />

Fluid Immersion, Flammability,<br />

Smoke Density & Toxicity<br />

Backshell Torque, GAP 027<br />

Swing Arm Assembly<br />

Procedure, Rev 3<br />

Examination of Products,<br />

Magnetic Permeability, Shell<br />

Conductivity, Life Cycling,<br />

Screw Hardware Durability,<br />

Temperature Cycling,<br />

Hydrolytic stability (Composite<br />

Only), Coupling Thread<br />

Strength, Corrosion<br />

Resistance (Salt Spray), Shell<br />

Conductivity, Vibration, Shock,<br />

Shell Conductivity, External<br />

Bending Moment, Braid<br />

Retention<br />

LT-06-2613<br />

D022Z001-03 Rev<br />

NEW<br />

OC17901-<br />

1112713B,<br />

OC18631-1013308,<br />

OC18461-0713174<br />

1.3 Conclusion<br />

The <strong>Glenair</strong> Swing Arm Backshell strain relief clamp and EMI shield termination with strain<br />

relief have been shown to meet all required specifications.<br />

1.4 Product Description<br />

The <strong>Glenair</strong> Swing Arm Backshell strain relief clamp and EMI shield termination with strain<br />

relief are circular connector cable strain relief accessories intended for application on<br />

aerospace equipment, tactical military equipment, and harsh environment commercial<br />

equipment. Swing Arm products have an articulating arm that allows the backshell to quickly<br />

adjust and lock into three positions—straight, 45, and 90. Made of injection-molded, high<br />

temperature thermoplastic composite Ultem (PEI) reinforced with fiber glass, the Swing Arm is<br />

16 QwikConnect <strong>April</strong> <strong>2007</strong>