CORRIGENDUM No. 2 - Yap State Government

CORRIGENDUM No. 2 - Yap State Government

CORRIGENDUM No. 2 - Yap State Government

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

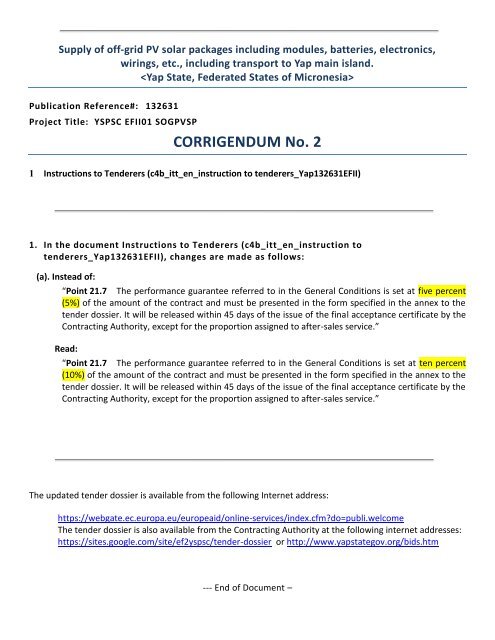

Supply of off-grid PV solar packages including modules, batteries, electronics,<br />

wirings, etc., including transport to <strong>Yap</strong> main island.<br />

<br />

Publication Reference#: 132631<br />

Project Title: YSPSC EFII01 SOGPVSP<br />

<strong>CORRIGENDUM</strong> <strong>No</strong>. 2<br />

1 Instructions to Tenderers (c4b_itt_en_instruction to tenderers_<strong>Yap</strong>132631EFII)<br />

1. In the document Instructions to Tenderers (c4b_itt_en_instruction to<br />

tenderers_<strong>Yap</strong>132631EFII), changes are made as follows:<br />

(a). Instead of:<br />

“Point 21.7 The performance guarantee referred to in the General Conditions is set at five percent<br />

(5%) of the amount of the contract and must be presented in the form specified in the annex to the<br />

tender dossier. It will be released within 45 days of the issue of the final acceptance certificate by the<br />

Contracting Authority, except for the proportion assigned to after-sales service.”<br />

Read:<br />

“Point 21.7 The performance guarantee referred to in the General Conditions is set at ten percent<br />

(10%) of the amount of the contract and must be presented in the form specified in the annex to the<br />

tender dossier. It will be released within 45 days of the issue of the final acceptance certificate by the<br />

Contracting Authority, except for the proportion assigned to after-sales service.”<br />

The updated tender dossier is available from the following Internet address:<br />

https://webgate.ec.europa.eu/europeaid/online-services/index.cfmdo=publi.welcome<br />

The tender dossier is also available from the Contracting Authority at the following internet addresses:<br />

https://sites.google.com/site/ef2yspsc/tender-dossier or http://www.yapstategov.org/bids.htm<br />

--- End of Document –

Supply of off-grid PV solar packages including modules, batteries, electronics,<br />

wirings, etc., including transport to <strong>Yap</strong> main island.<br />

<br />

Publication Reference#: 132631<br />

Project Title: YSPSC EFII01 SOGPVSP<br />

CLARIFICATIONS TO TENDERERS<br />

1 Tender Clarification Requests and Responses:<br />

I. Clarification Requests/Reponses<br />

II. (Attachment) PPA/SEAIPI Off Grid PV Power Systems Design Guidelines<br />

III. (Attachment) Letter of derogation # DEVCO/H3/BD/D (2011)<br />

1. Tender Clarification Requests and Responses:<br />

I. Clarification Requests/Reponses<br />

(a). Clarification Request #1:<br />

Annex III (Solar Batteries)<br />

As discussed with our production department on the Technical Sheet of 6V per battery requirement -<br />

"Each battery shall be a 6 volts DC (Vdc) in one robust container only, giving 6 V as nominal operating<br />

voltage; inter-cell connection shall not be exposed" - our battery is 2V per cells and provide inner-cell<br />

connector for battery bank but not produce as 6V in one robust container. Will such battery bank be<br />

acceptable<br />

Response:<br />

Yes, 6 volt or 2 volt cells will be accepted as long as the overall specifications are met.<br />

(b). Clarification Request #2:<br />

Annex III (Solar Batteries)<br />

We note that you required Flooded batteries, however will other types also be acceptable such as; GEL,<br />

ASTM, VRLA or other<br />

Response:<br />

<strong>No</strong>, only flooded batteries will be accepted.<br />

(c). Clarification Request #3:<br />

What is the exact delivery time– In the tender documents120 days as well as150 days are mentioned.<br />

Response:<br />

120 days, refer to Article 19 of the Special Conditions.<br />

(d). Clarification Request #4:<br />

Concerning the CD that shall accompany the offer – does it have to contain only the financial offer as a pdf<br />

or all documents of the offer

Response:<br />

The CD has to contain all submitted documents from the tenderer.<br />

(e). Clarification Request #5:<br />

It is nothing mentioned about the size of the containers to deliver the goods. Are there any requirements<br />

It is also not clear about the containers whether they are only used for delivering and going back to the<br />

tenderer or if you are going to keep them<br />

Response:<br />

Only 20’ containers can be accepted in <strong>Yap</strong> harbor. The containers can go back to the tenderer.<br />

(f). Clarification Request #6:<br />

PV Module Mounting Structure<br />

Can you please clarify if we also have to supply the post/poles for the array mounting structure<br />

Response:<br />

<strong>No</strong>, the modules will be ground-mounted on a concrete structure prepared by YSPSC. It is however<br />

important to include the technical drawings of the proposed mounting structure.<br />

(g). Clarification Request #7:<br />

Charge Controllers<br />

For a SCS the charge controller is specified to be 70A at 48V. Our question is can we offer a lesser amps<br />

controller than 70A if our array voltage will be configured at higher voltage to charge the 48V battery bank<br />

via MPPT technology.<br />

Response:<br />

You can offer an alternative design that we can look into however the official proposal needs to comply<br />

with the requested specs. <strong>No</strong>te that the specifications ask for a 48 V system and 3,360 Wp. It is however,<br />

possible to parallel 2 or 3 charge controllers, if this is recommended by the manufacturer. Please refer to<br />

point e.8 of Annex II.<br />

(h). Clarification Request #8:<br />

Wires, connectors and fuses<br />

Could please specify the cable run between the PV Module to Charge controller and the cable run<br />

between charge controller and battery for the SCS<br />

Response:<br />

The tender documents ask the tenderer under point g.2 to specify the wire sizes for the SCS with the note<br />

that “All wiring must be sized to keep line voltage losses to less than two percent (2%) in each sub-circuit<br />

and to allow the circuit to operate at a maximum of 60deg Celsius within the ampacity rating of the cable.”<br />

Voltage drop calculations need to be included in the proposal.<br />

(i). Clarification Request #9:<br />

Will 12V batteries be considered as well (e.g. 12V 190Ah for SHS)<br />

Response:<br />

<strong>No</strong>, the specs need to comply with the technical tender document. We have left a window open to send<br />

besides the offer that follows the set specification to propose and alternative design. For now only 6V and<br />

2V batteries will be accepted.<br />

(j). Clarification Request #10:<br />

Typically larger charge controllers (45A and above), function only as a charge controller or a load

controller, meaning that each unit does not have the capacity to control battery charge as well as load<br />

output. As the SCS system has an inverter, there is no need for the charge controller to also control the<br />

load. Thus requesting a charge controller “for a load of 70A (in 48V – 3360W)” isn’t really relevant.<br />

According to our design, a 60A charge controller is more than sufficient to manage the current from the<br />

PV array which is the primary concern when choosing such components. Please specify whether this will<br />

be acceptable.<br />

Response:<br />

<strong>No</strong>, the specs need to comply with the technical tender document. We have left a window open to send<br />

besides the offer that follows the set specification to propose and alternative design.<br />

(k). Clarification Request #11:<br />

Will 24V nominal panels with 72 cells be considered Typically panels that are larger than 130W are 24V<br />

with 72 cells, and the requirements have allowed panels up to 185W.<br />

Response:<br />

<strong>No</strong>, the specs need to comply with the technical tender document. We have left a window open to send<br />

besides the offer that follows the set specification to propose and alternative design.<br />

(l). Clarification Request #12:<br />

For the SHS will 12V designs be considered If there are 12V DC loads to be used with the system, such as<br />

lights, then a system voltage of 12V would be beneficial and eliminate the need of a DC to DC converter<br />

within the system. It also opens up the range of inverters, as 24V 300W inverters are more difficult to find<br />

that 12V 300W inverters.<br />

Response:<br />

<strong>No</strong>, the specs need to comply with the technical tender document. We have left a window open to send<br />

besides the offer that follows the set specification to propose and alternative design.<br />

It is however possible that YSPSC might go for the 12V option therefore the charge controllers need to be<br />

able to work with 12V and with 24V.<br />

(m). Clarification Request #13:<br />

Regarding the panel warranty and the following excerpt from Annex II;<br />

The PV modules shall be warranted for at least 20 years and must not experience more than 15% of rated<br />

capacity reduction in output over their lifetime. They also shall be warranted for physical defect for a<br />

period of 10 years.<br />

Typically modules are supplied with 5 year physical defect warranty and 20 or 25 year warranty for a<br />

reduction in power output no greater than 20%. Please specify whether this standard warranty will be<br />

accepted If not please recommend a supplier offering a warranty for rated capacity reduction in output<br />

of only 15%.<br />

Response:<br />

The specifications are the basis of warranty guidelines that are to be met. However alternative warrantees<br />

shall be noted and will be considered but perhaps lead to a lower rating in the evaluation process if higher<br />

warrantees are offered by other tenderers.<br />

As per contract guidelines recommendations of specific suppliers meeting this warranty are not allowed.<br />

(n). Clarification Request #14:<br />

For the SHS both 10mm2 and 6mm2 cables have been specified, please state whether these are required<br />

to be double or single core cables<br />

Response:<br />

The SHS 10mm2 and 6mm2 cables are to be provided as per the specifications of “Annex II g.) wires,<br />

connectors and fuses” and “Annex III 1.8 Wires, connectors and fuses – Ref to g.)” and shall be standard<br />

and flexible insulated single core copper cables.

(o). Clarification Request #15:<br />

REFERENCE IS MADE TO TECHNICAL SPECIFICATIONS ITEM 1.2 AND ITEM 2.2 (MOUNTING RAILS): Please<br />

clarify how the mounting rails should be done. Have they to be deemed for ground mounting or roof<br />

mounting In case of ground mounting please clarify if a steel or aluminium pole must be supplied.<br />

Response:<br />

The tender dossier states that the panels will be ground mounted – see Annex II-specifications b.2 and b.3.<br />

<strong>No</strong> poles need to be provided as the footing (poles) will be made of concrete and completed by YSPSC. The<br />

tenderer will have to send, however, their technical drawing of the mounting structure they propose. – see<br />

Annex II-specifications b.3.<br />

(p). Clarification Request #16:<br />

REFERENCE IS MADE TO TECHNICAL SPECIFICATIONS: Please clarify if the inverters and charge controller<br />

must be mounted on an electrical control board. If so should the supplier deliver them pre-mounted on<br />

the electrical board or the end users will take care of mounting Moreover, in case of electrical board are<br />

to be supplied which kind of electrical board do you need Which would be the IP protection number<br />

Response:<br />

The design of the PV system is up to the tenderer and the most appropriate design will be selected. Please<br />

note that we follow the technical guidelines for the pacific islands for the design, find attached a copy of<br />

these guidelines.<br />

(q). Clarification Request #17:<br />

REFERENCE IS MADE TO TECHNICAL SPECIFICATIONS<br />

Should the bidder supply earth grounding with earth rod<br />

Response:<br />

Yes, see technical guide and the NEC electrical code for off-grid PV installations.<br />

(r). Clarification Request #18:<br />

REFERENCE IS MADE TO THE TENDER SCOPE: Does the contract include installation or only delivery CIF In<br />

case the contract includes installation please send us the list of installation sites.<br />

Response:<br />

<strong>No</strong> installation is required under this tender.<br />

(s). Clarification Request #19:<br />

REFERENCE IS MADE TO INVERTERS QUANTITY: Please confirm that inverter quantities is 400 and -in any<br />

case - a 10% extra inverter must be included as spare parts<br />

Response:<br />

The requested quantity is 400 Sinewave inverters 24Vdc 120 Vac 60Hz 300W plus 10% spares and 20 Sine<br />

wave inverter 48Vdc 120Vac 60Hz 3000W plus 10% spares<br />

(t). Clarification Request #20:<br />

Rules of Origin: Clause 3 of Instructions to Tenderers.<br />

Please provide list of countries applicable for this project. Could you provide us with the copy of the<br />

Reference note of derogation # DEVCO/H3/BD/D (2011)<br />

Response:<br />

See the attached copy of the “Letter of Derogation”:

(u). Clarification Request #21:<br />

Photovoltaic Modules – a.4);<br />

PV modules must be framed with marine graded aluminum. I believe this refers to Anodized Aluminum<br />

frame<br />

Response:<br />

Anodized Aluminum will also be accepted<br />

(v). Clarification Request #22:<br />

Photovoltaic Modules – a.4);<br />

NEC requires PV Power Source to have Disconnect Switches, is this required for this project<br />

Response:<br />

Yes – All NEC guidelines must be followed<br />

(w). Clarification Request #23:<br />

Photovoltaic Modules – a.4);<br />

Confirm that PV Structure will be grounded using grounding bolts, lugs & screws<br />

Response:<br />

Correct<br />

(x). Clarification Request #24:<br />

Photovoltaic Modules – a.4);<br />

Please confirm if these structures will be mounted on a concrete pad embedded in ground<br />

Response:<br />

The systems will be installed on concrete poles. The poles will be prepared by YSPSC but the tenderer must<br />

provide the technical drawings of the mounting requirements for the system that they are proposing<br />

(y). Clarification Request #25:<br />

Solar Batteries;<br />

Will batteries with higher number of cycles be given preference over the price<br />

Response:<br />

Yes – All components must meet and/or exceed tender dossier specification<br />

(z). Clarification Request #26:<br />

Solar Batteries;<br />

Will batteries that have never been used in Pacific Island be considered if they meet the specifications are<br />

better priced over the battery that has proven track record in Pacific Island but may be higher in price<br />

Response:<br />

Yes – All components must meet and/or exceed tender dossier specification<br />

(aa). Clarification Request #27:<br />

Solar Batteries;<br />

Will batteries be given preference with 5 years Guarantee instead of warranty<br />

Response:<br />

Refer to the tender specifications for batteries that shall be follow and require a “warranty”

(bb). Clarification Request #28:<br />

Solar Batteries;<br />

NEC requires each equipment to have disconnect switch, is this required for this project<br />

Response:<br />

All NEC guidelines must be followed. All main components shall be able to be disconnected by a breaker<br />

and/or disconnect switch<br />

(cc). Clarification Request #29:<br />

Solar Batteries;<br />

Any preference on Battery Casing – transparent, clear etc<br />

Response:<br />

<strong>No</strong> preference is given to the color of the battery casing, but note that the acid level must be visible from<br />

outside.<br />

(dd). Clarification Request #30:<br />

Battery Enclosures;<br />

Will the Batteries be installed indoors or outdoors<br />

Response:<br />

Outdoors<br />

(ee). Clarification Request #31:<br />

Battery Enclosures;<br />

Any specific requirement for Battery Enclosure Material<br />

Response:<br />

The battery enclosure must have a long lifetime and must be suitable for outdoor marine environment<br />

usage.<br />

(ff). Clarification Request #32:<br />

Battery Enclosures;<br />

Do you intend to attach the Enclosure to the wall or floor or it will be just sitting on the ground etc<br />

Response:<br />

On the ground<br />

(gg). Clarification Request #33:<br />

Charge Controllers (SHS & SCS);<br />

Will MPPT Charge Controllers be considered for this project, MPPT Charge controllers are more efficient<br />

but there is cost difference as well<br />

Response:<br />

Yes<br />

(hh). Clarification Request #34:<br />

Charge Controllers (SHS & SCS);<br />

Is Battery Temperature Sensor required for temperature compensation charging, this will be of great help<br />

due to temperature variance<br />

Response:<br />

Refer to the requirements in the technical specifications for charge controllers. For the SCS a battery sensor<br />

would be required

(ii). Clarification Request #35:<br />

Since the panels will be installed outside and the controller inside, do we have to provide disconnect<br />

switches at the Array and also before the Charge Controller Entry. This means 2 disconnection points<br />

between the PV Array and Charge Controller. Please confirm.<br />

Response:<br />

Refer to the tender specifications for your systems designs for installation. These systems are to be<br />

packaged component stand-alone outside compact systems which are to be installed as complete units<br />

externally from the location being served by each system. All NEC guidelines must be followed as needed<br />

for design. Follow the instructions and you can include changes and/or additions in your design for<br />

evaluation.<br />

(jj). Clarification Request #36:<br />

As per the NEC guidelines, we can isolate one conductor and ground the other conductor or isolate both<br />

current carrying conductors by using appropriate circuit breakers. Please confirm if we can to supply these<br />

isolators / disconnection devices with this tender<br />

Response:<br />

All NEC and SEIAPI technical guidelines must be followed for design of stand-alone system. The guidelines<br />

are available online and have been attached with this email. The tenderer must design the system<br />

following these guidelines.<br />

(kk). Clarification Request #37:<br />

We have a question regarding the mounting structures for the modules.<br />

Will they be rammed into the ground or will there be a concrete foundation<br />

Response:<br />

The systems will be installed on concrete poles. The poles will be prepared by YSPSC but the tenderer<br />

proposal must provide the technical drawings for the poles along with the mounting requirements for the<br />

system/s that they are proposing.<br />

(ll). Clarification Request #38:<br />

Since SCS will be installed outside (compact installation)<br />

please confirm if both the controllers, inverters and all other accessories to be installed outside<br />

Response:<br />

SCS to be outside and please refer to the complete tender dossier and especially the documents of<br />

“Instruction for Tenderers” long with “Annex II” for definition of “PV solar packages” and “complete”<br />

system for both the SCS/SHS. All system components to be included with such.<br />

(mm). Clarification Request #39:<br />

Is SHS also a compact system with controllers and inverters mounted outdoors<br />

Response:<br />

Correct and again please refer to tender document Annex II item “h).” which provides guide to the region<br />

and conditions of the where these systems will be installed. Reference to “<strong>Yap</strong>, Federated <strong>State</strong>s of<br />

Micronesia” is made and which also encompasses the outer islands of the state of <strong>Yap</strong>, FSM. Research and<br />

becoming familiar with this region and the conditions that can be encountered is strongly encouraged.<br />

(nn). Clarification Request #40:<br />

Confirmation on Tender Guarantee<br />

If TG is submitted in another form, say Bank Guarantee or Bank Draft, will the company be disqualified<br />

from the tendering process

Response:<br />

The tender dossier requires that EU “Tender Guarantee Form” format must be used and submitted with the<br />

tender proposal<br />

(oo). Clarification Request #41:<br />

“Continuous Power at 25°C minimum 300W – maximum 400W”<br />

We can offer an Inverter with this value expressed in [VA] instead of [W]. Due to the missing data on<br />

number and type of devices that will be loaded by the grid-off plants, we cannot give the value for<br />

Continuous power expressed in [W]. Would you please be so kind to tell us if the range of Continuous<br />

power of 650-800 [VA] will be good as well.<br />

Exactly the same thing we would like to know regarding the technical specification for SCS plants as<br />

follows:<br />

“Continuous Power at 25°C minimum 3000W – max.3500W”<br />

Our proposal for the Continuous power is 5000 [VA] .Could it be suitable for SCS needs<br />

Response:<br />

It is acceptable to express the inverter values in “VA” as well as “W”. The ratings shall be within the<br />

guideline ranges as noted in the specifications of Annex II f.1) and f.2). Each tenderer must conclude to the<br />

best of their knowledge the best practiced design and component/materials provision meeting the<br />

specified guidelines. The overall design and technical specifications will be given preference and systems<br />

with established histories of performance shall be preferred.<br />

(pp). Clarification Request #42:<br />

Equipment delivery must be carried out in kits, in a grouped format, or it can be delivered each of their<br />

components separately: panels, regulators, inverters, batteries and accessories.”<br />

Response:<br />

Reference to “Equipment Delivery in kits” is not found & therefore refer to Annex II document (Annex II -<br />

Specificationsv2_final) related to this components delivery question as to be “supplies are to be made in<br />

one lot and to be delivered….”<br />

(qq). Clarification Request #43:<br />

At point a.3) of technical specifications standard IEEE 1262 is required<br />

IEEE 1262 served its purpose as the first consensus qualification test standard for thin film modules but, in<br />

this tender, are silicon types. Therefore, the standard IEEE 1262 is not applicable.<br />

Response:<br />

This is a United <strong>State</strong>s informational standard basis for PV panels that tenderers shall refer to for<br />

establishing their proposal submissions and is for reference purposes. Any subsequent standard/s for PV<br />

module qualification guidelines that have replaced and/or succeeded prior recommended practices shall be<br />

the responsibility of the tenderer and shall be followed.

II.<br />

(Attachment) PPA/SEAIPI Off Grid PV Power Systems Design Guidelines<br />

PPA/SEAIPI Off Grid PV<br />

Power Systems Design<br />

Guidelines

OFF GRID PV POWER SYSTEMS<br />

SYSTEM DESIGN GUIDELINES<br />

These guidelines have been developed by the Sustainable Energy Industry Association of the Pacific Islands in<br />

Collaboration with the Pacific Power Association<br />

They represent latest industry BEST PRACTICE for the design and installation of PV Grid Connect Systems.<br />

© Copyright 2012<br />

While all care has been taken to ensure this guideline is free from omission and error, no responsibility can be taken<br />

for the use of this information in the design of any PV grid connect system.<br />

Issue 1 September 2012

GENERAL<br />

The design of any off-grid system should consider, other than the electrical load, a number of criteria such as:<br />

o Budget<br />

o Acceptable genset runtime<br />

o Power quality<br />

o <strong>No</strong>ise levels<br />

o Environmental impact<br />

o Site accessibility<br />

o Aesthetics<br />

o Level of automation<br />

<strong>No</strong>te: This guidelines are based on d.c. bus systems and do not include the new a.c. bus hybrid systems currently available. Guidelines dedicated to<br />

hybrid Systems will be developed.<br />

ENERGY SOURCE MATCHING<br />

Heating and lighting should be supplied from the most appropriate source. For example -<br />

o cooking - gas or wood burning stove<br />

o water heating - solar water heating with gas or wood backup<br />

o Lighting - electrical lighting most often used but natural light ( daylighting ) should be considered.<br />

ENERGY EFFICIENCY<br />

All appliances should be chosen for the lowest possible energy consumption for each desired outcome, such<br />

as<br />

o High efficiency lighting<br />

o Energy efficient refrigeration<br />

STANDARDS for DESIGN<br />

System designs should follow any standards that are typically applied in the country or region where the solar<br />

installation will occur. The following lists the relevant standards in Australia, New Zealand and USA They are<br />

listed because some Pacific island countries and territories do follow those standards. These standards are<br />

often updated and amended so the latest version should always be applied.<br />

In Australia and New Zealand the main standards required include:<br />

o AS/NZS3000 Wiring Rules<br />

o AS/NZS4509 Stand-alone power systems<br />

o AS 4086.2 Secondary batteries for stand-alone power supplies<br />

o AS/NZS5033 PV Array<br />

o AS 3010.1 Electrical Installations - Supply Generating set<br />

o AS 1768 Lightning Protection<br />

o AS 3595 Energy management programs<br />

o AS 1359.51 <strong>No</strong>ise level limits<br />

In USA PV systems must be in accordance with the following codes and standards:<br />

o Electrical Codes-National Electrical Code Article 690:Solar Photovoltaic Systems and NFPA 70<br />

Uniform Solar Energy Code<br />

o Building Codes- ICC, ASCE 7<br />

o<br />

o<br />

UL Standard 1701: Flat Plat Photovoltaic Modules and Panels<br />

UL Standard 1741: Standard for Inverter, converters, Controllers and Interconnection System<br />

Equipment for use with Distributed Energy Resources<br />

Issue 1 September 2012 Page 1

INTRODUCTION<br />

Four major issues arise when designing a system:<br />

1. the load (power) required to be supplied by the system is not constant over the period of one day;<br />

2. the daily energy usage varies over the year;<br />

3. the energy available from the PV array may vary from time to time during the day;<br />

4. the energy available from the PV array will vary from day to day during the year.<br />

Since the system is based on photovoltaic modules, then a comparison should be undertaken between the<br />

available energy from the sun and the actual energy demands The worst month is when the ratio between<br />

solar energy available and energy demand is smallest.<br />

The design of an off-grid power requires a number of steps. A basic design method follows:<br />

1. Determination of the energy usage that the system must supply.<br />

2. Determination of the battery storage required.<br />

3. Determination of the energy input required from the PV array or other sources (eg battery<br />

charger/generator)<br />

4. Selection of the remainder of system components.<br />

LOAD (ENERGY) ASSESSMENT<br />

Electrical power is supplied from the batteries (DC) or via an inverter to produce either 230 volts AC (South<br />

Pacific) or 110 / 120 volts AC (<strong>No</strong>rth Pacific). Electrical energy usage is normally expressed in watt hours (Wh)<br />

or kilowatt hours ( kWh ).<br />

To determine the daily energy usage for an appliance, multiply the power of the appliance by the number of<br />

hours per day it will operate. The result is the energy (Wh) consumed by that appliance per day.<br />

Appliances can either be DC or AC. An energy assessment should be undertaken for each type, examples of<br />

these are shown in tables 1 and 2.<br />

You need to calculate the electrical energy usage with the customer. Many systems have failed over the years<br />

not because the equipment has failed or the system was installed incorrectly, BUT BECAUSE THE<br />

CUSTOMER BELIEVED THEY COULD GET MORE ENERGY FROM THEIR SYSTEM THAN THE SYSTEM<br />

COULD DELIVER. It failed because the customer was unaware of the power/energy limitations of the<br />

system.<br />

The problem is that the customer may not want to spend the time determining their realistic power and energy<br />

needs which is required to successfully complete a load assessment form. They just want to know: How much<br />

for a system to power my lights and TV<br />

A system designer can only design a system to meet the power and energy needs of the customer. The<br />

system designer must therefore use this process to understand the needs of the customer and at the same<br />

time educate the customer. Completing a load assessment form correctly (Refer to table 1 and 2 below) does<br />

take time; you may need to spend 1 to 2 hours or more with the potential customer completing the tables. It is<br />

during this process that you will discuss all the potential sources of energy that can meet their energy needs<br />

and you can educate the customer on energy efficiency.<br />

Issue 1 September 2012 Page 2

Worked Example<br />

Table 1 DC Load (energy) Assessment<br />

(1) (2) (3) (4a) (5a) (4b) (5b) (6) Comments<br />

dry season wet season Contribution<br />

Power<br />

to maximum<br />

Appliance Number<br />

Usage Energy Usage Energy demand<br />

Time<br />

Time<br />

W h Wh h Wh W<br />

Light 4 7 4 112 4 112 28<br />

Daily Load energy-d.c loads (Wh) ( DC 7a) 112 (DC 7b) 112<br />

Maximum d.c. demand (W) (DC 8) 28<br />

Table 2 AC Load (energy) Assessment<br />

(1) (2) (3) (4a) (5a) (4b) (5b) (6) (7) (8) (9a) (9b)<br />

dry season wet season<br />

Contribution<br />

Contribution to<br />

Power<br />

to max<br />

surge demand<br />

Appliance <strong>No</strong>.<br />

Power demand Surge Potential Design<br />

Usage<br />

Time<br />

Energy Usage<br />

Time<br />

Energy Factor<br />

Factor<br />

Comments<br />

W h Wh h Wh VA VA VA<br />

TV 100 3 300 3 300 0.8 125 4 500 125<br />

Refrigerator 100 12 1200 12 1200 0.8 125 4 500 500 Duty cycle of<br />

0.5 included<br />

Daily Load Energy A.C<br />

1500<br />

1500<br />

Loads (Wh) (AC10a)<br />

(AC10b)<br />

maximum demand (VA) (AC11) 250 1000<br />

Surge demand (VA) (AC12) 625<br />

Issue 1 September 2012 Page 3

In the worked example on the previous page, the TV and refrigerator are using AC electricity so we have to<br />

take into account the efficiency of the inverter. Typically the peak efficiency of the inverter may be over 90%<br />

but in many systems the inverter will sometimes be running when there is very little load on the inverter, so the<br />

average efficiency is about 85% to 90%. Then we must divide the total AC energy used by this figure to obtain<br />

the energy required to be supplied to the inverter from the battery bank.<br />

For the worked example assume the efficiency of the chosen inverter is 90%.<br />

Daily battery load (energy) from AC loads = 1500Wh ÷ 0.9 = 1667 Wh<br />

Daily battery load (energy) from DC loads = 112 Wh<br />

To get the total load(energy) as seen by the battery, you add the two figures together:<br />

1667 + 112= 1779Wh<br />

If there are no AC loads, then you only have to work out the load from the DC appliances, and not include the<br />

inverter (or the inverter efficiency).<br />

BATTERY SELECTION<br />

DETERMINATION OF SYSTEM VOLTAGE<br />

System voltages are generally 12, 24 or 48 Volts. The actual voltage is determined by the requirements of the<br />

system. For example, if the batteries and the inverter are a long way from the energy source then a higher<br />

voltage may be required to minimise power loss in the cables. In larger systems 120V or 240V DC could be<br />

used, but these are not typical household systems.<br />

As a general rule, the recommended system voltage increases as the total load increases. For small daily<br />

loads, a 12V system voltage can be used. For intermediate daily loads, 24V is used and for larger loads 48V is<br />

used.<br />

1 kWh 3-4 kWh<br />

Use 12 Volt<br />

system voltage<br />

Use 24 Volt<br />

system voltage<br />

Use 48 Volt<br />

system voltage<br />

The changes over points are roughly at daily loads of 1 kWh and 3-4 kWh but this will also be dependent on<br />

the actual power profile.<br />

One of the general limitations is that maximum continuous current being drawn from the battery should not be<br />

greater than 150A.<br />

BATTERY SIZING<br />

To convert Watt-hours (Wh) to Amp-hours (Ah) you need to divide by the battery system voltage.<br />

For the worked example the daily energy usage was 1779Wh , so we select a battery system voltage of 24<br />

Volts.<br />

This means that the daily Ah demand on the batteries will be:<br />

Issue 1 September 2012 Page 4

Ah = Wh ÷ system voltage 1779Wh ÷ 24 = 74 Ah<br />

So at the moment the minimum size battery to meet the daily energy requirements in the example is: 74Ah<br />

Battery capacity is determined by whichever is the greater of the following two requirements:<br />

1. The ability of the battery to meet the energy demand of the system, often for a few days, sometimes<br />

specified as ‘days of autonomy’ of the system;<br />

OR<br />

2. The ability of the battery to supply peak power demand.<br />

The critical design parameters include:<br />

Parameters relating to the energy requirements of the battery:<br />

a) Daily energy demand<br />

b) Daily and maximum depth of discharge<br />

c) Number of days of autonomy<br />

Parameters relating to the discharge power (current) of the battery:<br />

a) Maximum power demand<br />

b) Surge demand<br />

Parameters relating to the charging of the battery:<br />

a) Maximum Charging Current<br />

Based on the these parameters there are a number of factors that will increase the battery capacity in order to<br />

provide satisfactory performance. These correction factors must be considered.<br />

1. Days of Autonomy<br />

Extra capacity is necessary where the loads require power during periods of reduced input. The battery<br />

bank is often sized to provide for a number of days autonomy. A common period selected is 5 days.<br />

Where a generator is operating on a regular basis the autonomous period can be reduced.<br />

In other cases, where there is no auxiliary charging source, the period of autonomy is often increased to 7<br />

days or more.<br />

For the worked example assume 5 days autonomy .<br />

ADJUSTED<br />

Battery Capacity = 74 x 5 = 370 Ah<br />

2. Maximum Depth of Discharge<br />

Battery manufacturers recommend a maximum depth of discharge (DOD). If this is regularly exceeded the<br />

life of the battery is severely reduced. This could be 50% or for some solar batteries as high as 80%.<br />

For the worked example Assume a maximum DOD of 70%.<br />

ADJUSTED<br />

Battery Capacity = 370 ÷ 0.7 = 529 Ah<br />

3. Battery Discharge Rate<br />

The actual discharge rate selected is highly dependent on the power usage rates of connected loads. Many<br />

appliances operate for short periods only, drawing power for minutes rather than hours. This affects the battery<br />

Issue 1 September 2012 Page 5

selected, as battery capacity varies with discharge rate. Information such as a power usage profile over the<br />

course of an average day is required for an estimate of the appropriate discharge rate.<br />

For small systems this is often impractical.<br />

Where the average rates of power usage are low, the battery capacity for 5 days autonomy is often selected at<br />

the 100hr rate of discharge for the battery.<br />

For the worked example<br />

ADJUSTED<br />

Battery Capacity = 529 Ah (@ C 100 )<br />

Where average power usage rates are high, it may be necessary to select the battery capacity for 5 days<br />

autonomy at a higher discharge rate. eg. the 10 (C 10 ) or 20hr (C 20 ) rate<br />

4. Battery Temperature derating<br />

Battery capacity is affected by temperature. As the temperature goes down, the battery capacity reduces. The<br />

following graph gives a battery correction factor for low temperature operation. <strong>No</strong>te that the temperature<br />

correction factor is 1 at 25°C as this is the tempe rature at which battery capacity is specified.<br />

In the tropics it is often still 20°C+ in the even ings so unless the system is located in a mountainous region<br />

that does get cold then ignore the temperature derating. If you want to be conservative add 5% to the capacity<br />

to allow for this factor.<br />

BATTERY SELECTION<br />

Deep discharge type batteries / cells should be selected for the required system voltage and capacity in a<br />

single series string of battery cells.<br />

Parallel strings of batteries are not recommended.<br />

Where this is necessary each string must be separately fused.<br />

For the worked example a battery of at least 529 Ah (@C 100 ) should be used.<br />

PV ARRAY SIZING- Standard Switched Controllers<br />

The calculation for determining the size of the PV array is dependent on the type of controller used. Historically<br />

standard switched controllers were the most common controllers used. In recent years a number of maximum<br />

Issue 1 September 2012 Page 6

power point trackers (MPPT) have become available. This section determines how to size the PV array based<br />

on switched controllers based on the PV array meeting the daily load requirements all year. Later in the guide<br />

is a section on how to size a PV array using a MPPT.<br />

The size of the PV array should be selected to take account of:<br />

seasonal variation of solar irradiation<br />

seasonal variation of the daily energy usage<br />

battery efficiency<br />

manufacturing tolerance of modules<br />

dirt<br />

temperature of array (the effective cell temperature)<br />

Solar irradiation data is available from various sources. Some countries have data available from their<br />

respective meteorological department. One source for solar irradiation data is the NASA website:<br />

http:/eosweb.larc.nasa.gov/sse/. RETSCREEN, a program available from Canada, incorporates the NASA<br />

data and it is easier to use. Please note that the NASA data has, in some instances, had higher irradiation<br />

figures than that recorded by ground collection data in some countries. but if there is no other data available it<br />

is data that can be used.<br />

Solar irradiation is typically provided as kWh/m 2 however it can be stated as daily peak Sun Hours (PSH). This<br />

is the equivalent number of hours of solar irradiance of 1kW/m 2 .<br />

Attachment 1 provides data on the following sites:<br />

• Suva, Fiji (Latitude 18°08 ′S Longitude 178°25 ′E)<br />

• Apia, Samoa (Latitude 13 o 50' S' Longitude 171 o 44' W)<br />

• Port Vila, Vanuatu (Latitude 17° 44' S Longitude 168° 19' E)<br />

• Tarawa, Kiribati (Latitude 1°28'N, Longitude 173°2 'E)<br />

• Raratonga, Cook islands( Latitude 21°30'S, Longitude 160°0'W)<br />

• Nuku’alofa, Tonga (Latitude 21º14'S Longitude 175º22'W)<br />

• Honiara, Solomon Islands (Latitude 09°27'S, Lon gitude 159°57'E)<br />

• Koror ,Palau ( Latitude 7°20’N Longitude 134°28'E)<br />

• Ponapei, Pohnpei FSM (Latitude: 6°54'N, Longitude : 158°13'E)<br />

• Majuro, Marshall Islands (Latitude: 7º 12N, Longitude 171º 06E)<br />

• Alofi, Niue (Latitude 19°04' S. Longitude 169° 55' W)<br />

• Nauru (Latitude 0º55’S, Longitude 166º 91’E)<br />

• Tuvalu (Latitude 8°31 ′S, Longitude 179°13 ′E)<br />

• Hagåtña, Guam (Latitude 13°28 ′N Longitude: 144°45 ′E)<br />

• <strong>No</strong>umea, New Caledonia (Latitude 22°16 ′S Longitude: 166°27 ′E)<br />

• Pago Pago, American Samoa (Latitude 14°16 ′ S Longitude: 170°42 ′W)<br />

The variation of both the solar irradiation and the load energy requirement should be considered. If there is no<br />

variation in daily load between the various times of the year then the system should be designed on the month<br />

with the lowest irradiation that is peak sun hours (PSH).<br />

DAILY ENERGY REQUIREMENT FROM THE PV ARRAY<br />

In order to determine the energy required from the PV array, it is necessary to increase the energy from the<br />

battery bank to account for battery efficiency.<br />

.<br />

The average columbic efficiency (in terms of Ah) of a new battery is 90% (variations in battery voltage are not<br />

considered).<br />

For the worked example the daily energy requirement expressed in Ah from the battery is 74 Ah. Allowing for<br />

the battery efficiency, the solar array then needs to produce…<br />

74 Ah ÷ 0.9 = 82.2 Ah<br />

Assume the worst months PSH is 5.<br />

Issue 1 September 2012 Page 7

Therefore the required PV array output current is:<br />

82.2 Ah ÷ 5 PSH = 16.5 A<br />

OVERSIZE FACTOR<br />

If the system does not include a fuel generator which can provide extra charging to the battery bank then the<br />

solar array should be oversized to provide the equalisation charging of the battery bank. In Australia and New<br />

Zealand this is between 30% and 100%. It is recommended in the Pacific that this is 10%.<br />

For the worked example the adjusted array output current is:<br />

16.5A x 1.1 = 18.1 A<br />

DERATING MODULE PERFORMANCE<br />

The PV array will be de-rated due to:<br />

• Manufacturer’s Tolerance: Most manufacturers rate their modules ± a percentage (eg ±3%) or wattage<br />

(eg ±2W). Unless every module is tested and its actual rating is known then the modules should be derated<br />

by the manufacturer’s tolerance.<br />

• Dirt: Over a period of time dirt or salt (if located near the coast) can build up on the array and reduce<br />

the output. The output of the module should therefore be derated to reflect this soiling. The actual value<br />

will be dependent on the site but this can vary from 0.9 to 1 (i.e. up to 10% loss due to dirt).<br />

• Temperature: Modules’ output power decreases with temperature above 25°C and increases with<br />

temperatures below 25°C. The average cell temperatu re will be higher than the ambient because of the<br />

glass on the front of the module and the fact that the module absorbs some heat from the sun. The<br />

output power and/or current of the module must be based on the effective temperature of the cell. This<br />

is determined by the following formula:<br />

T cell-eff = T a.day + 25°C<br />

Where<br />

T cell-eff = the average daily effective cell temperature in degrees Celsius (°C)<br />

T a.day = the daytime average ambient temperature for the month that the sizing is being undertaken.<br />

Since the modules are used for battery charging, the current at 14 Volts (a good battery charging voltage) at<br />

the effective cell temperature should be used in calculations. If curves are unavailable to determine the current<br />

at effective cell temperature then use the <strong>No</strong>rmal Operating Cell temperature (NOCT) provided by the<br />

manufacturers.<br />

Therefore the derated module output current is calculated as follows:<br />

The Current of the module at 14V and effective cell temperature (or NOCT current)<br />

multiplied by derating due to manufacturers tolerance<br />

multiplied by derating due to dirt<br />

I (NOCT) x f man x f dirt<br />

If a module has a 3% (0.03) manufacturers tolerance, then the module current is derated by multiplying by<br />

0.97 (1-0.03).<br />

If a module has a 5% (0.05) loss due to dirt then the module current is derated by multiplying by 0.95 (1-0.05).<br />

For the worked example the selected module has a peak rating of 80W P .<br />

An 80 watt solar module (still used in many small off-grid systems) typically has the following data:<br />

Issue 1 September 2012 Page 8

Table 3: 80 W module data<br />

Rated Power<br />

80W<br />

Power Tolerance ± 5%<br />

<strong>No</strong>minal Voltage<br />

12V<br />

Maximum Power Voltage, V mp 17.6V<br />

Maximum Power Current, I mp 4.55A<br />

Open Circuit Voltage, V oc 22.1V<br />

Short Circuit Current, I sc 4.8A<br />

NOCT<br />

47±2°C<br />

Current at 14V and NOCT 4.75A<br />

Assuming a 5% dirt derating then the adjusted output current of the above module is:<br />

ADJUSTED<br />

Module current = I (NOCT) x 0.95 ( ← minus 5% for manufactures tol) x 0.95 ( ← minus 5% for dirt)<br />

= 4.75A x 0.95 x 0.95 = 4.29A<br />

NUMBER OF MODULES REQUIRED IN ARRAY<br />

First determine number of modules in series, To do this divide the system voltage by the nominal operating<br />

voltage of each module. In our example:<br />

For the worked example Number of modules in series = 24V ÷ 12V = 2<br />

Therefore the array must comprise of series connected strings of 2 modules.<br />

To determine the number of strings in parallel, the PV array output current required (in A) is divided by the<br />

output of each module (in A).<br />

For the worked example Number of strings in parallel =18.1A ÷ 4.29A = 4.22<br />

Do we round up or down If you want to be conservative you would round up. However in this example we<br />

suggest you round down since this calculation was based on the worst month and we allowed an oversize of<br />

10%.This does need to be determined for each system.<br />

For the worked example The number of modules in the array = 4 x 2 = 8<br />

The peak rating of the array is : 8 x 80W P = 640W P<br />

INVERTER SELECTION<br />

The type of inverter selected for the installation depends on factors such as cost, surge requirements, power<br />

quality and for inverter/chargers, a reduction of the number of system components necessary. Inverters are<br />

available in 3 basic output types - Square wave, modified square wave and sine wave.<br />

There are few square wave inverters used today.<br />

Modified square wave inverters generally have good surge and continuous capability and are usually cheaper<br />

than sine wave types. However, some appliances, such as audio equipment, television and fans can suffer<br />

because of the output wave shape.<br />

Sine wave inverters often provide a better quality power than the 230V (or 110V or 120V) grid supply.<br />

Issue 1 September 2012 Page 9

INVERTER SIZING<br />

The selected inverter should be capable of supplying continuous power to all AC loads<br />

AND<br />

providing sufficient surge capability to start any loads that may surge when turned on and particularly if they<br />

turn on at the same time.<br />

Where an inverter cannot meet the above requirements attention needs to be given to load control and<br />

prioritisation strategies.<br />

For the worked example<br />

From the load (energy) assessment on page 3, a selected inverter must be capable of supplying 250VA<br />

continuous with a surge capability of 625VA.<br />

CONTROLLERS- Standard Switched Controller<br />

PV controllers on the market range from simple switched units that only prevent the overcharge (and<br />

discharge) of connected batteries to microprocessor based units that incorporate many additional features<br />

such as …<br />

o<br />

o<br />

o<br />

o<br />

o<br />

PWM and equalisation charge modes<br />

DC Load control<br />

Voltage and current metering<br />

Amp-hour logging<br />

Generator start/stop control<br />

Unless the controller is a model that is currently limited these should be sized so that they are capable of<br />

carrying 125% of the array short circuit current and withstanding the open circuit voltage of the array. If there is<br />

a possibility that the array could be increased in the future then the controller should be oversized to cater for<br />

the future growth.<br />

(<strong>No</strong>te: sometimes the controller is called a regulator)<br />

For the worked example<br />

The controller chosen must have a current rating<br />

> 1.25 x 4 x 4.8 A = 24A at a system voltage of 24V.<br />

GENERATORS & BATTERY CHARGING<br />

To reduce system costs, it is common for some form of auxiliary charging to be used to provide energy when<br />

daily energy requirements are greater than the daily PV input into the system. This is usually a<br />

diesel/petrol/gas powered generator. Where the electrical output is 230V AC (or 110V or 120V) a battery<br />

charger is required.<br />

An inverter/charger can be used; otherwise a separate charger unit is needed.<br />

Factors that must be considered when using internal combustion generators are<br />

o Fuel storage and spillage precautions<br />

o <strong>No</strong>ise emission control<br />

o Ventilation<br />

o Generator loading<br />

With regards to generator loading, a generator should supply greater than 50% of its maximum rating while<br />

running. Loading of less than 50% increases running and maintenance costs and reduces generator life.<br />

Issue 1 September 2012 Page 10

( refer to genset manufacturers' information )<br />

BATTERY CHARGER SIZING<br />

A charger must be capable of supplying voltage greater than the nominal system voltage.<br />

The maximum charging current must not be greater than that recommended by the battery manufacturer but a<br />

usable estimate is a maximum charge current of around 10% of the C 10 rate.<br />

PV ARRAY SIZING- MPPT<br />

DAILY ENERGY REQUIREMENT FROM THE PV ARRAY<br />

The size of the PV array should be selected to take account of:<br />

seasonal variation of solar irradiation<br />

seasonal variation of the daily energy usage<br />

battery efficiency (wh)<br />

Cable losses<br />

MPPT efficiency<br />

manufacturing tolerance of modules<br />

dirt<br />

temperature of array (the effective cell temperature)<br />

With the standard controller the only sub-system losses was the battery efficiency and the calculations are<br />

undertaken using Ah. When using a MPPT the calculations are in Wh and the sub-system losses in the system<br />

include:<br />

• Battery efficiency (watthr)<br />

• Cable losses<br />

• MPPT efficiency<br />

In order to determine the energy required from the PV array, it is necessary to increase the energy from the<br />

battery bank to account for all the sub-system losses.<br />

For the worked example assume cable losses is 3% (transmission efficiency of 97%), MPPT efficiency of 95%<br />

and battery efficiency of 80%<br />

Subsystem efficiency = 0.97 x 0.95 x 0.8 = 0.737<br />

Energy required from the PV array = 1779Wh ÷ 0.737 = 2413Wh<br />

Assume the worst months PSH is 5.<br />

Therefore the required peak PV array output power is:<br />

2413Wh ÷ 5 PSH = 482W P<br />

OVERSIZE FACTOR<br />

If the system does not include a fuel generator which can provide extra charging to the battery bank then the<br />

solar array should be oversized to provide the equalisation charging of the battery bank. In Australia and New<br />

Zealand this is between 30% and 100%. It is recommended in the Pacific that this is 10%.<br />

For the worked example Therefore the adjusted array output current is:<br />

482W P x 1.1 = 530W P<br />

DERATING MODULE PERFORMANCE<br />

The PV array will be de-rated due to:<br />

Issue 1 September 2012 Page 11

• Manufacturer’s Tolerance: Most manufacturers rate their modules ± a percentage (eg ±5%) or wattage<br />

(eg ±2W). Unless every module is tested and its actual rating is known then the modules should be derated<br />

by the manufacturer’s tolerance.<br />

• Dirt: Over a period of time dirt or salt (if located near the coast) can build up on the array and reduce<br />

the output. The output of the module should therefore be derated to reflect this soiling. The actual value<br />

will be dependent on the site but this can vary from 0.9 to 1 (i.e. up to 10% loss due to dirt).<br />

• Temperature: Modules’ output power decreases with temperature above 25°C and increases with<br />

temperatures below 25°C. The average cell temperatu re will be higher than the ambient temperature<br />

because of the glass on the front of the module and the fact that the module absorbs some heat from<br />

the sun. The output power and/or current of the module must be based on the effective temperature of<br />

the cell. This is determined by the following formula:<br />

T cell-eff = T a.day + 25°C<br />

Where<br />

T cell-eff = the average daily effective cell temperature in degrees Celsius (°C)<br />

T a.day = the daytime average ambient temperature for the month that the sizing is being undertaken.<br />

With switched controllers the temperature effect was used to determine the operating current of the<br />

module/array. With MPPT’s the derating power factor must be calculated.<br />

The three main types solar modules available on the market each have different temperature coefficients.<br />

These are:<br />

• Monocrystalline: Modules typically have a temperature coefficient of –0.45%/ o C. That is for every<br />

degree above 25 o C the output power is derated by 0.45%.<br />

• Polycrystalline: Modules typically have a temperature coefficient of –0.5%/ o C.<br />

• Thin Film: Modules have a different temperature characteristic resulting in a lower co-efficient typically<br />

around 0%/°C to -0.25%/°C, but remember to check with the manufacturer<br />

The typical ambient daytime temperature in many parts of the Pacific is between 30 and 35 o C during some<br />

times of the year. So it would not be uncommon to have module cell temperatures of 55 o C or higher.<br />

For the worked example Assume the ambient temperature is 30 o C..<br />

Therefore the effective cell temperature is<br />

30 o C +25 o C = 55 o C<br />

Therefore this is 30 o C above the STC temperature of 25 o C.<br />

The 80 W P module used in this example is a polycrystalline module with a derating of -0.5%/ o C<br />

Therefore the losses due to temperature would be:<br />

Temperature loss = 30 o C x 0.5%/ o C = 15% loss<br />

This is a temperature derating factor of 0.85<br />

Assuming a 5% dirt derating then the adjusted output power of the 80W module is:<br />

Adjusted module power = 80 x 0.95 x 0.95 x 0.85 = 61.4W<br />

NUMBER OF MODULES REQUIRED IN ARRAY<br />

To calculate the required number of modules in the array, divide the required array power by the adjusted<br />

module power.<br />

Issue 1 September 2012 Page 12

For the worked example<br />

Number of modules in array =530 ÷ 61.4 = 8.63<br />

(<strong>No</strong>te for the switch regulator we had 4.29 parallel strings of 2 modules in series)<br />

The actual number of modules will be dependent on the MPPT selected. If it was 9 then the rating of the array<br />

is : 9 x 80W P = 720W P<br />

SELECTING MPPT<br />

The following table gives some examples of MPPT’s currently available on the market:<br />

Model d.c. battery<br />

Voltage (V)<br />

STECA<br />

Solarix<br />

MMP2010<br />

Phocos<br />

MMPT<br />

100/20-1<br />

Morningstar<br />

SS-MPPT-15L<br />

Outback Flex<br />

Max 80<br />

Outback Flex<br />

Max60<br />

Table 4: MPPT Data<br />

Input voltage Max d.c. Max(W) Solar<br />

range (V) Battery Array<br />

Current (A)<br />

12/24 17 to 100 20 250/500 10<br />

Max Load<br />

Current (A)<br />

12/24 Max 95 20 300/600 10<br />

12/24 Max 75 15 200/400 15<br />

12/24/36/48/60 Max 150 80 1250(12)<br />

2550(24)<br />

5000(48)<br />

7500 (60)<br />

12/24/36/48/60 Max 150 60 900(12)<br />

1800(24)<br />

3600(48)<br />

4500 (60)<br />

For the worked example<br />

Allowing for 125% oversizing then the required rating of the MPPT is:<br />

1.25 x 720Wp = 900 W<br />

From the table we would select the Outback Flexmax60 which has an array rating of 1800W @ 24V<br />

We could possibly use two of the others e.g. Phocos or Steca.<br />

MATCHING THE PV ARRAY TO THE MAXIMUM VOLTAGE SPECIFICATIONS OF THE MPPT<br />

The MPPT typically have a recommended minimum nominal array voltage and a maximum voltage. In the<br />

case where a maximum input voltage is specified and the array voltage is above the maximum specified, the<br />

MPPT could be damaged.<br />

Some MPPT controllers might allow that the minimum array nominal voltage is that of the battery bank.<br />

However the MPPT will work better when the minimum nominal array voltage is higher than the nominal<br />

voltage of the battery. The Outback range of MPPT’s requires that the minimum nominal array voltage is<br />

greater as shown in Table 5. Please check with the MPPT manufacturer because these could vary.<br />

Issue 1 September 2012 Page 13

Table 5 Minimum <strong>No</strong>minal Array Voltages (Outback MPPT’s)<br />

<strong>No</strong>minal Battery Voltage Recommended Minimum <strong>No</strong>minal Array<br />

voltage<br />

12V<br />

24V<br />

24V<br />

36V<br />

48V<br />

60V<br />

It is important that the output voltage of the string is matched to the operating voltages of the MPPT and that<br />

the maximum voltage of the MPPT is never reached.<br />

The output voltage of a module is affected by cell temperature changes in a similar way to the output power.<br />

The manufacturers will provide a voltage temperature coefficient. It is generally specified in V/°C (or mV/°C)<br />

but it can also be expressed as a % .<br />

To ensure that the V oc of the array does not reach the maximum allowable voltage of the MPPT the minimum<br />

day time temperatures for that specific site are required.<br />

In early morning at first light the cell temperature will be very similar to the ambient temperature because the<br />

sun has not had time to heat up the module. In the Pacific Islands the average minimum temperature is 20 0 C<br />

(this could be lower in some mountain areas) and it is recommended that this temperature is used to<br />

determine the maximum V oc. (<strong>No</strong>te: If installing in the mountains then use the appropriate minimum<br />

temperature. Many people also use 0°C, if appropriate for the ar ea). The maximum open circuit voltage is<br />

determined similar to the temperature derating factor for the power.<br />

For the worked example Assume the voltage co-efficient is 0.07V/ o C.<br />

If the minimum temperature is 20 o C this is 5 o C below the STC temperature of 25 o C. Therefore the effective<br />

variation in voltage is:<br />

5 x 0.07 = 0.35V<br />

So the maximum open circuit voltage of the module = 22.1V + 0.35V =22.45V<br />

Maximum number of modules that you can have in series = 150V ÷ 22.45V = 6.68 this is rounded down to 6.<br />

So the MPPT will allow between 3 and 6 modules in a string.<br />

The actual number of modules required was 8.68. If we round down to 8 (since an oversize factor of 10% and<br />

also worst month for PSH was used) then the array would be 2 parallel strings of 4 modules in series. If we<br />

round up to 9 then the solution could be 3 parallel strings with 3 modules in series.<br />

Issue 1 September 2012 Page 14

ATTACHMENT 1: : Table showing Peak Sunhrs for various sites and tilt angles.<br />

Location Peak Sunlight Hours (kWh/m²/day)<br />

Suva, Fiji Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 18°08 ′ South 0° Tilt ¹ 6.29 6.2 5.54 4.67 4.05 3.72 3.89 4.44 5.08 6.04 6.32 6.38 5.21<br />

Longitude: 178°25 ′ East 18° Tilt ² 6.27 5.88 5.55 4.99 4.61 4.38 4.51 4.88 5.22 5.83 6.1 6.41 5.38<br />

33° Tilt ² 5.95 5.4 5.33 5.03 4.85 4.7 4.8 5 5.1 5.43 5.71 6.12 5.29<br />

Apia, Samoa Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 13°50 ′ South 0° Tilt ¹ 5.39 5.47 5.16 5.09 4.63 4.46 4.71 5.25 5.77 5.91 5.76 5.51 5.25<br />

Longitude: 171°46 ′ West 13° Tilt ² 5.31 5.24 5.12 5.32 5.07 5 5.24 5.61 5.85 5.72 5.67 5.45 5.38<br />

28° Tilt ² 5.13 4.86 4.93 5.38 5.36 5.42 5.64 5.81 5.75 5.36 5.45 5.3 5.37<br />

Port Vila, Vanuatu Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 17°44 ′ South 0° Tilt ¹ 6.68 6.2 5.76 4.98 4.2 3.79 4.04 4.75 5.65 6.47 6.67 6.93 5.5<br />

Longitude: 168°19 ′ East 17° Tilt ² 6.69 5.9 5.78 5.33 4.76 4.42 4.66 5.22 5.82 6.26 6.46 7.01 5.69<br />

32° Tilt ² 6.38 5.43 5.56 5.39 5.02 4.75 4.98 5.39 5.72 5.83 6.07 6.73 5.61<br />

Tarawa, Kiribati Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 01°28 ′ <strong>No</strong>rth 0° Tilt ¹ 5.58 5.98 5.99 5.87 5.82 5.7 5.87 6.15 6.52 6.4 6.1 5.5 5.95<br />

Longitude: 173°02 ′ East 16° Tilt ² 5.9 6.11 5.83 5.79 5.94 5.92 6.06 6.17 6.28 6.45 6.43 5.88 6.06<br />

Rarotonga, Cook Islands Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 21°12 ′ South 0° Tilt ¹ 6.45 6.14 5.78 4.59 3.86 3.54 3.73 4.46 5.16 5.94 6.63 6.56 5.23<br />

Longitude: 159°47 ′ West 21° Tilt ² 5.9 5.82 5.86 5.04 4.56 4.2 4.35 5.07 5.39 5.74 6.11 6.51 5.38<br />

36° Tilt ² 5.19 5.34 5.62 5.08 4.8 4.49 4.6 5.22 5.27 5.35 5.41 6.11 5.21<br />

Issue 1 September 2012 Page 15

Nuku'alofa, Tongatapu, Tonga Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 21°08 ′ South 0° Tilt ¹ 6.69 6.3 5.62 4.65 4.04 3.58 3.78 4.43 5.23 6.28 6.69 6.7 5.32<br />

Longitude: 175°12 ′ West 21° Tilt ² 6.1 5.97 5.69 5.1 4.81 4.25 4.41 5.03 5.46 6.08 6.16 6.65 5.48<br />

36° Tilt ² 5.35 5.47 5.46 5.14 5.08 4.55 4.68 5.18 5.34 5.65 5.45 6.25 5.3<br />

Honiara, Solomon Islands Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 09°27 ′ South 0° Tilt ¹ 5.99 5.55 5.61 5.41 4.76 4.59 4.45 5.19 5.81 6.26 6.4 6.22 5.52<br />

Longitude: 159°57 ′ East 9° Tilt ² 5.98 5.47 5.54 5.52 5.01 4.91 4.7 5.36 5.82 6.15 6.38 6.24 5.59<br />

24° Tilt ² 5.91 5.29 5.35 5.59 5.27 5.28 4.99 5.53 5.72 5.88 6.28 6.22 5.61<br />

Koror, Palau Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 07°20 ′ <strong>No</strong>rth 0° Tilt ¹ 5.19 5.59 6.18 6.3 5.71 5.01 5.12 5.2 5.56 5.39 5.26 4.94 5.45<br />

Longitude: 134°28 ′ East 7° Tilt ² 5.4 5.7 6.16 6.22 5.7 5.01 5.11 5.15 5.49 5.45 5.44 5.16 5.5<br />

22° Tilt ² 5.75 5.86 6.06 6.01 5.66 5.03 5.1 5.03 5.3 5.51 5.74 5.54 5.55<br />

Ponape, Pohnpei FSM Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 6°54 ′ <strong>No</strong>rth 0° Tilt ¹ 4.97 5.57 5.91 5.79 5.44 5.33 5.51 5.54 5.66 5.29 5.03 4.83 5.4<br />

Longitude: 158°13 ′ East 6° Tilt ² 5.12 5.65 5.88 5.72 5.42 5.33 5.51 5.49 5.59 5.33 5.16 5 5.43<br />

21° Tilt ² 5.43 5.82 5.8 5.55 5.4 5.39 5.53 5.39 5.41 5.39 5.43 5.36 5.49<br />

Majuro, Marshall Islands Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 7°12 ′ <strong>No</strong>rth 0° Tilt ¹ 5.26 5.86 6.11 5.89 5.66 5.31 5.35 5.63 5.42 5.15 4.88 4.84 5.44<br />

Longitude: 171°06 ′ East 7° Tilt ² 5.47 5.99 6.09 5.81 5.65 5.32 5.35 5.58 5.35 5.2 5.03 5.05 5.49<br />

22° Tilt ² 5.83 6.16 5.99 5.62 5.61 5.35 5.35 5.46 5.16 5.25 5.27 5.4 5.53<br />

Issue 1 September 2012 Page 16

Alofi, Niue Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 19°04 ′ South 0° Tilt ¹ 6.47 6.2 5.67 4.8 4.26 3.86 4.01 4.61 5.35 6.02 6.53 6.46 5.34<br />

Longitude: 169°55 ′ West 19° Tilt ² 6.43 5.88 5.7 5.2 4.96 4.47 4.75 5.14 5.53 5.81 5.98 6.47 5.53<br />

34° Tilt ² 6.06 5.4 5.47 5.24 5.24 4.78 5.08 5.29 5.42 5.41 5.35 6.15 5.41<br />

Nauru Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 0°32 ′ South 0°Tilt ¹ 5.77 6.24 6.27 6.04 5.99 5.75 5.85 6.25 6.7 6.5 6.12 5.5 6.07<br />

Longitude: 166°56 ′ East 15° Tilt ² 5.94 6.26 6.07 6.06 6.28 6.16 6.21 6.4 6.52 6.45 6.27 5.69 6.19<br />

Vaiaku, Tuvalu Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 8°31 ′ South 0° Tilt ¹ 5.16 5.27 5.33 5.29 4.93 4.66 4.76 5.3 5.72 5.8 5.57 5.23 5.25<br />

Longitude: 179°13 ′ East 8° Tilt ² 5.14 5.2 5.26 5.37 5.14 4.92 5 5.45 5.71 5.71 5.54 5.22 5.31<br />

23° Tilt ² 5.09 5.05 5.08 5.43 5.42 5.3 5.33 5.62 5.61 5.49 5.47 5.21 5.34<br />

Hagåtña, Guam Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 13°28 ′ <strong>No</strong>rth 0° Tilt ¹ 5.33 5.87 6.73 7.12 7.04 6.44 6 5.3 5.42 5.46 5.16 5.05 5.9<br />

Longitude: 144°45 ′ East 13° Tilt ² 5.95 6.27 6.86 6.88 6.97 6.43 5.95 5.06 5.38 5.7 5.66 5.7 6.07<br />

28° Tilt ² 6.41 6.49 6.75 6.4 6.7 6.27 5.76 4.68 5.19 5.78 6.01 6.2 6.05<br />

<strong>No</strong>umea, New Caledonia Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 22°16 ′ South 0° Tilt ¹ 7.31 6.7 5.73 4.97 3.94 3.47 3.91 4.73 6.05 7.09 7.41 7.6 5.73<br />

Longitude: 166°27 ′ East 22° Tilt ² 6.61 6.34 5.83 5.56 4.76 4.19 4.69 5.51 6.44 6.88 6.77 7.53 5.93<br />

37° Tilt ² 5.75 5.8 5.6 5.63 5.03 4.48 5 5.7 6.33 6.38 5.94 7.03 5.72<br />

Pago Pago, American Samoa Jan Feb Mar Apr May Jun Jul Aug Sep Oct <strong>No</strong>v Dec<br />

Annual<br />

Average<br />

Latitude: 14°16 ′ South 0° Tilt ¹ 5.87 5.93 5.54 5.18 4.63 4.4 4.59 5.2 5.78 6.05 6.11 5.93 5.43<br />

Longitude: 170°42 ′ West 14° Tilt ² 5.79 5.66 5.51 5.43 5.11 4.99 5.15 5.59 5.88 5.84 6.01 5.87 5.57<br />

Issue 1 September 2012 Page 17

29° Tilt ² 5.57 5.22 5.3 5.49 5.4 5.39 5.52 5.77 5.77 5.46 5.75 5.68 5.53<br />

¹ Monthly Averaged Insolation Incident On A Horizontal Surface (kWh/m²/day)<br />

² Monthly Averaged Irradiation Incident On An Equator-Pointed Tilted Surface (kWh/m²/day)<br />

Source: NASA Surface meteorology and Solar Energy<br />

(http://eosweb.larc.nasa.gov)<br />

Issue 1 September 2012 Page 18

Appendix 1 – Table of Abbreviations and Acronyms<br />

d.c.<br />

Direct current<br />

a.c.<br />

Alternating current<br />

AS/NZS Australia Standard/New Zealand Standard<br />

UL<br />

Underwriters Laboratory<br />

ICC<br />

International Code Council<br />

NFPA National fire Protection Association<br />

ASCE American Society of Civil Engineers<br />

IEEE Institute of Electrical and Electronics Engineers<br />

Wh<br />

Watt hours<br />

kWh Kilowatt hours<br />

W<br />

Watts<br />

W P<br />

Watts peak<br />

H<br />

hours<br />

V<br />

Volts<br />

A<br />

Amps<br />

VA<br />

Volt amps<br />

Ah<br />

Amp hours<br />

DOD Depth of discharge<br />

C 100 Battery capacity when battery is discharged over 100<br />

hours<br />

PV<br />

Photovoltaic<br />

MPPT Maximum power point tracker<br />

PSH Peak sun hours( kWh/m 2 )<br />

kWh/m 2 Kilowatt hours/metres squared<br />

°C Degrees Celsius<br />

NOCT <strong>No</strong>minal operating cell temperature<br />

T cell-eff the average daily effective cell temperature (degrees<br />

Celsius)<br />

T a.day the daytime average ambient temperature for the month<br />

that the sizing is being undertaken (degrees Celsius)<br />

f man Derating due to manufacturers tolerance<br />

(dimensionless)<br />

f dirt<br />

Derating due to dirt (dimensionless)<br />

PWM Pulse Width Modulation<br />

V oc<br />

Open circuit voltage (volts)<br />

V mp<br />

Maximum power point voltage (volts)<br />

I sc<br />

Short circuit current (amps)<br />

I mp<br />

Maximum power point current (amps)<br />

STC Standard test conditions<br />

Issue 1 September 2012 Page 19

III. (Attachment) Letter of derogation # DEVCO/H3/BD/D (2011)<br />

Letter of derogation #<br />

DEVCO/H3/BD/D (2011)

The updated tender dossier is available from the following Internet address:<br />

https://webgate.ec.europa.eu/europeaid/online-services/index.cfmdo=publi.welcome<br />

The tender dossier is also available from the Contracting Authority at the following internet addresses:<br />

https://sites.google.com/site/ef2yspsc/tender-dossier or http://www.yapstategov.org/bids.htm<br />

--- End of Document –