Warnakulasuriya Primal Deepthi Fernando 1

Warnakulasuriya Primal Deepthi Fernando 1

Warnakulasuriya Primal Deepthi Fernando 1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

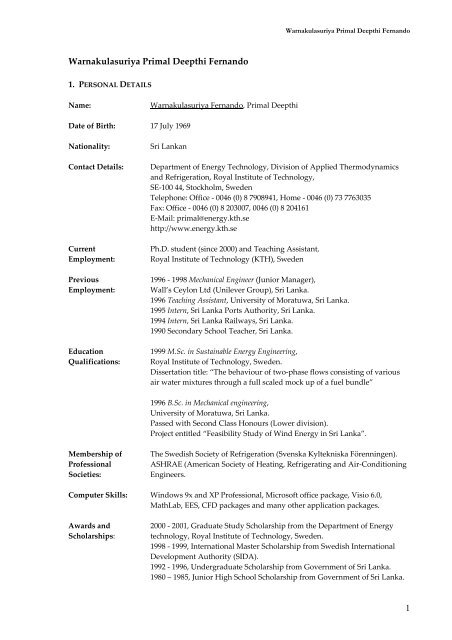

<strong>Warnakulasuriya</strong> <strong>Primal</strong> <strong>Deepthi</strong> <strong>Fernando</strong><br />

<strong>Warnakulasuriya</strong> <strong>Primal</strong> <strong>Deepthi</strong> <strong>Fernando</strong><br />

1. PERSONAL DETAILS<br />

Name:<br />

<strong>Warnakulasuriya</strong> <strong>Fernando</strong>, <strong>Primal</strong> <strong>Deepthi</strong><br />

Date of Birth: 17 July 1969<br />

Nationality:<br />

Contact Details:<br />

Current<br />

Employment:<br />

Previous<br />

Employment:<br />

Education<br />

Qualifications:<br />

Sri Lankan<br />

Department of Energy Technology, Division of Applied Thermodynamics<br />

and Refrigeration, Royal Institute of Technology,<br />

SE-100 44, Stockholm, Sweden<br />

Telephone: Office - 0046 (0) 8 7908941, Home - 0046 (0) 73 7763035<br />

Fax: Office - 0046 (0) 8 203007, 0046 (0) 8 204161<br />

E-Mail: primal@energy.kth.se<br />

http://www.energy.kth.se<br />

Ph.D. student (since 2000) and Teaching Assistant,<br />

Royal Institute of Technology (KTH), Sweden<br />

1996 - 1998 Mechanical Engineer (Junior Manager),<br />

Wall’s Ceylon Ltd (Unilever Group), Sri Lanka.<br />

1996 Teaching Assistant, University of Moratuwa, Sri Lanka.<br />

1995 Intern, Sri Lanka Ports Authority, Sri Lanka.<br />

1994 Intern, Sri Lanka Railways, Sri Lanka.<br />

1990 Secondary School Teacher, Sri Lanka.<br />

1999 M.Sc. in Sustainable Energy Engineering,<br />

Royal Institute of Technology, Sweden.<br />

Dissertation title: “The behaviour of two-phase flows consisting of various<br />

air water mixtures through a full scaled mock up of a fuel bundle”<br />

1996 B.Sc. in Mechanical engineering,<br />

University of Moratuwa, Sri Lanka.<br />

Passed with Second Class Honours (Lower division).<br />

Project entitled “Feasibility Study of Wind Energy in Sri Lanka”.<br />

Membership of<br />

Professional<br />

Societies:<br />

The Swedish Society of Refrigeration (Svenska Kyltekniska Förenningen).<br />

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning<br />

Engineers.<br />

Computer Skills: Windows 9x and XP Professional, Microsoft office package, Visio 6.0,<br />

MathLab, EES, CFD packages and many other application packages.<br />

Awards and<br />

Scholarships:<br />

2000 - 2001, Graduate Study Scholarship from the Department of Energy<br />

technology, Royal Institute of Technology, Sweden.<br />

1998 - 1999, International Master Scholarship from Swedish International<br />

Development Authority (SIDA).<br />

1992 - 1996, Undergraduate Scholarship from Government of Sri Lanka.<br />

1980 – 1985, Junior High School Scholarship from Government of Sri Lanka.<br />

1

<strong>Warnakulasuriya</strong> <strong>Primal</strong> <strong>Deepthi</strong> <strong>Fernando</strong><br />

Sports and Awards:<br />

Leisure Interests:<br />

2004 - 2005 Member of Spånga Cricket Club, Sweden.<br />

2004 - 2005, Member of Energy Football team, Department Energy<br />

Technology, Sweden<br />

1993 - 1996, Member of University of Moratuwa Football team, Inter University<br />

Champion, University Colors, Vice-Captain of the team.<br />

1993 - 1996, Member of University of Moratuwa Elle team, Inter University runnerup,<br />

University Colors.<br />

1985, Member of School Volley Ball Team, School Colors, Under 17 Age Category,<br />

National Champion.<br />

1985, Member of School Cricket Team.<br />

1980 - 1990, Member of Village Softball Cricket Club, District Champion.<br />

Singing, Traveling, Playing or watching any Kind of Sport, Talking with<br />

People and Spend time with Family and Friends<br />

2. RESEARCH<br />

I am a dedicated research scientist with a strong background in Mechanical Engineering. My<br />

expertise in this area is the product of experience gained in a variety of industrial and academic<br />

settings. My long-term goals are to develop new correlations for heat transfer in microchannel heat<br />

exchangers and modelling the heat transfer and flow behaviours in microchannel heat exchangers.<br />

My research interests are,<br />

• The study of behaviours in surface tension forces and capillary actions in microchannels<br />

• The study of boiling and condensation heat transfer of various fluids in micro channels<br />

• The study of single and multiphase flows in microchannels<br />

• The study of applications in heat pump technology for various countries<br />

I have treated above problems theoretically and experimentally.<br />

Research Experience<br />

Charge minimisation of a small capacity heat pump<br />

The environmental impacts, such as ozone depleting potential (ODP) and greenhouse warming<br />

potentials (GWP) of some commonly use refrigerants have initiated the search for new kinds of<br />

refrigerants that are environmentally friendly. Propane is an environmentally friendly refrigerant<br />

and one of the best candidates to replace conventional refrigerants in existing refrigeration systems<br />

without significant technical changes in the systems. Propane does not react with engineering<br />

materials such as aluminium, brass, bronze, copper, stainless steel, silver etc. Therefore it is fully<br />

compatible with existing components such as heat exchangers, expansion valves, compressors,<br />

lubricants and copper tubing that are currently used in refrigeration systems. It is a refrigerant that<br />

has been proposed to replace refrigerant R22 which is widely used in refrigeration and airconditioning<br />

applications as both have close type of vapour pressure curves.<br />

However, flammability of propane is a major risk associated with using it as a refrigerant. The fire<br />

danger can be reduced by minimisation of the refrigerant quantity in a system. If the refrigerant<br />

quantity of a system could be kept under 150 grams, according to safety regulations, the systems that<br />

are installed and used even inside private homes will not require special safety devices assuming that<br />

the system is “hermetic”. Moreover, the lower molecular weight of propane compared to R22 would<br />

reduce the mass used per system.<br />

The ongoing project aims to develop a heat pump that uses 150g or less propane having the heating<br />

capacity of 5kW or more based on the existing knowledge of propane based heat pumps. The longterm<br />

aim is to reach the best possible heating factor. The extent of heating capacity was chosen by<br />

2

<strong>Warnakulasuriya</strong> <strong>Primal</strong> <strong>Deepthi</strong> <strong>Fernando</strong><br />

taking into consideration of the Swedish and eventually cumulative European markets for singlefamily<br />

house heat pumps.<br />

Developments<br />

First stage of the project, a heat pump was made using two commercially available brazed plate heat<br />

exchangers. Variations of the heating capacity and coefficient of performance (COP) for various<br />

refrigerant (propane) charges were investigated. For all the investigated cases the operational<br />

conditions were kept constant (evaporation approximately at -8°C and condensing at +40°C). The<br />

amounts of propane in various parts of the heat pump (evaporator, condenser, liquid line and gas<br />

line including compressor) were measured while it was in operation. The optimum quantity of<br />

propane required to obtain best heating factor (COP) was found to be 300g. Around 70 - 80 g of<br />

propane was found in the evaporator, around 100 - 130 g of propane was found in the condenser and<br />

around 70 - 80 g of propane was found in the compressor.<br />

In the second stage of the project, the brazed plate heat exchangers were replaced by commercially<br />

available minichannel heat exchangers. Experiments showed that a reduction of the optimum<br />

refrigerant charge by 75 g. However, the performance of the heat pump was lower than that of the<br />

first stage.<br />

Based on the understanding gained from the first two stages of the project, I designed three multiport<br />

minichannel aluminium heat exchangers. The heat exchangers were manufactured in a Swedish<br />

factory under my supervision. Two of the designed heat exchangers then coupled to the heat pump<br />

as the condenser and the evaporator, replacing previous heat exchangers by them. Experiments<br />

showed that the novel design reduced the optimum refrigerant charge by 100 g. The overall heat<br />

transfer coefficients were increased by more than 50% compared to the brazed plate heat exchangers<br />

used in the first stage of the project. In addition, the heating factor (COP) of the novel heat pump was<br />

slightly improved compared to the heat pump tested in the first stage of the project.<br />

The heat transfer coefficients of the minichannel heat exchanger as the evaporator and the condenser<br />

were investigated. The novel heat exchanger was tested for single-phase water-to-water heat transfer.<br />

All experimentally evaluated heat transfer coefficients were compared with existing correlations<br />

available in literature. New correlations as well as existing correlations from the literature that is<br />

suited to explain the heat transfer rates were suggested.<br />

3. TEACHING<br />

Teaching and Demonstration<br />

1. Measuring Performance of a Compressor Refrigeration Rig (Demonstrator) (2000-2004)<br />

This is taught to International and Swedish master students in the M.Sc. course on Sustainable<br />

Energy Engineering. The duration of the session is 4 hours. Measurements were made at different<br />

evaporation temperatures on a running compressor. Refrigerating capacities, coefficients of<br />

performances and various efficiencies of the compressor were calculated and discussed.<br />

2. Determining Heat Transfer Coefficients for a Finned-Tube Heat Exchanger with Forced<br />

Convection (Demonstrator) (2000-2004)<br />

This is demonstrated to International and Swedish students in the M.Sc. course on Sustainable<br />

Energy Engineering. The object of this Lab session is to determine the overall heat transfer coefficient<br />

and the heat transfer coefficient related to the fin surface of a heat exchanger placed in an air duct<br />

with forced convection and cooled on the inside by boiling refrigerant.<br />

3

<strong>Warnakulasuriya</strong> <strong>Primal</strong> <strong>Deepthi</strong> <strong>Fernando</strong><br />

3. Investigation of heat exchangers (Demonstrator) (2000-2004)<br />

This is a lab class for 3 rd year undergraduate students. The purpose of this experiment is to compare<br />

the performance of two different types of heat exchangers. The heat transfer coefficients were<br />

investigated using Wilson-plot method.<br />

4. Natural Convection at Vertical Plates (Demonstrator) (2000-2004)<br />

3 rd year undergraduate students are taught how to determine the heat transfer coefficients on smooth<br />

vertical plates due to natural convection.<br />

5. Refrigeration capacity control of a compressor (Demonstrator) (2006)<br />

This is taught to International and Swedish master students in the M.Sc. course on Sustainable<br />

Energy Engineering. The duration of the session is 4 hours. This laboratory lesson involves<br />

measuring the refrigeration capacity and the electric power required for a refrigerating compressor<br />

that has its capacity control in different ways.<br />

6. Workshop Technology-Foundry (Demonstrator) (1996)<br />

While employed as a teaching assistant at the University of Moratuwa (Sri Lanka) I taught this to 1 st<br />

year undergraduate students.<br />

Current Teachings<br />

Energy and Environment - Clean transportations<br />

This lecture is given to M.Sc. students in Sustainable Energy Engineering. This discusses the<br />

sustainable transportations, visions of future transportation systems, emissions from fossil fuels and<br />

alternative fuels for fossil fuels. Total duration of the lecture is 4 hours.<br />

Teaching Preparations<br />

1. Sustainable energy engineering - Basic refrigeration and heat pumps<br />

This lecture is in preparation for M.Sc. students in the Program of Sustainable Energy Engineering.<br />

The lecture covers refrigeration systems, refrigeration equipments, refrigerants and properties,<br />

refrigerant mixtures, secondary refrigerants in indirect systems, vapour compression cycle,<br />

alternative cycles etc.<br />

2. Evaporators and condensers<br />

This is a special topic in refrigeration technology taught to M.Sc. students in the Program of<br />

Sustainable Energy Engineering and B.Sc. undergraduate students.<br />

3. Introductions to thermodynamics<br />

This is a lecture for undergraduate students detailing the basics of thermodynamics. The course<br />

textbook is “Introduction to thermodynamics: classical and statistical” by Sonntag and Van Wylen.<br />

4. PUBLICATIONS<br />

4.1. Refereed journal articles<br />

1. <strong>Primal</strong> <strong>Fernando</strong>, Björn Palm, Per Lundqvist and Eric Granryd, “Propane heat pump with low<br />

refrigerant charge: design and laboratory tests”, International Journal of Refrigeration Volume 27,<br />

Issue 7, November 2004, Pages 761-773,<br />

4

<strong>Warnakulasuriya</strong> <strong>Primal</strong> <strong>Deepthi</strong> <strong>Fernando</strong><br />

2. <strong>Primal</strong> <strong>Fernando</strong> and Per Lundqvist, “Refrigeration systems with minimized refrigerant charge -<br />

System design and performance”, Proc. IMechE Vol. 219 Part E: Process Mechanical Engineering, 15<br />

June 2005.<br />

3. <strong>Primal</strong> <strong>Fernando</strong>, Björn Palm, Per Lundqvist, Eric Granryd, Performance of a Single - family Heat<br />

Pump at Different Working Conditions Using Small quantity of Propane as Refrigerant, Journal of<br />

Experimental heat transfer (Accepted, Feb. 2006).<br />

4.2. Papers under internal review process<br />

1. <strong>Primal</strong> <strong>Fernando</strong>, Björn Palm, Per Lundqvist, Eric Granryd , A Multiport Minichannel Aluminium<br />

Heat Exchanger, Part I: Investigation of Single-Phase Heat Transfer Coefficients in a in Both Tube<br />

Side and Shell Side by Wilson Plot Method, Journal of Experimental heat transfer.<br />

2. <strong>Primal</strong> <strong>Fernando</strong>, Björn Palm, Per Lundqvist, Eric Granryd, A Multiport Minichannel Aluminium<br />

Tube Heat Exchanger, Part II: Working as an evaporator with refrigerant propane – Experimental<br />

Study of Heat Transfer and Comparison with Available Correlations in the Literature.<br />

3. <strong>Primal</strong> <strong>Fernando</strong>, Björn Palm, Per Lundqvist, Eric Granryd, A Multiport Minichannel Aluminium<br />

Tube Heat Exchanger, Part III: Working as an condenser with refrigerant propane – Experimental<br />

Study of Heat Transfer and Comparison with Available Correlations in the Literature.<br />

4.3. Paper presentations in conferences<br />

1. W. <strong>Primal</strong> D. <strong>Fernando</strong>, Oxana Samoteeva, Per Lundqvist and Björn Palm, “Charge Distribution in<br />

a 5kW Heat Pump Using Propane as Working Fluid. Part 1: Experimental Investigation”,<br />

Proceedings: 16. Nordiske Kolemode og 9. Nordiske Varmepumpedage, Copenhagen, Denmark,<br />

August 29-31, 2001 (page299).<br />

2. W. <strong>Primal</strong> D. <strong>Fernando</strong>, Björn Palm, Eric Granryd, Oxana Samoteeva and Klas Anderson, “The<br />

Behaviour of Small Capacity (5kW) Heat pump with Micro-Channelled Flat Tube Heat Exchangers –<br />

Proceedings: Zero Leakage and Minimum Charge”, Efficient Systems for Refrigeration Air<br />

Conditioning and Heat pumps, Stockholm, Sweden August 26-28, 2002 (page 179).<br />

3 W. <strong>Primal</strong> D. <strong>Fernando</strong>, Björn Palm, Eric Granryd and Klas Andersson, “Mini-Channel Aluminium<br />

Heat Exchangers with Small Inside Volumes” – Proceedings: 21 st IIR International Congress of<br />

Refrigeration, Washington D.C., USA, August 17-22, 2003.<br />

4. W. <strong>Primal</strong> D. <strong>Fernando</strong>, Houde Han, Björn Palm, Eric Granryd and Per Lundqvist, “The Solubility<br />

of Propane (R290) with Commonly Used Compressor Lubrication Oils. International conference on<br />

compressors and their systems”, IMECHE Conference Transactions 2003-4, Professional Engineering<br />

Publishing, ISSN 1356-1448.<br />

5. O. Samoteewa, P. <strong>Fernando</strong>, B. Palm, P. Lundquist, “Charge Distribution in a 5kW Heat Pump<br />

Using Propane as Working Fluid. Part 1I: Modelling of Liquid hold-up” Proceedings: 16. Nordiske<br />

Kolemode og 9. Nordiske Varmepumpedage, Copenhagen, Denmark, August 29-31, 2001.<br />

6. O. Samoteewa, E. Granryd, B. Palm and P. <strong>Fernando</strong>, “Modelling of the amount of refrigerant and<br />

pressure drop in a rectangular copper microchannel evaporator – Proceedings: Zero Leakage and<br />

Minimum Charge”, Efficient Systems for Refrigeration Air Conditioning and Heat pumps,<br />

Stockholm, Sweden August 26-28, 2002 (page 449).<br />

5

<strong>Warnakulasuriya</strong> <strong>Primal</strong> <strong>Deepthi</strong> <strong>Fernando</strong><br />

7. B. Palm, P. <strong>Fernando</strong>, K. Andersson, P. Lundqvist and O. Samoteeva, “Design a heat pump for<br />

minimum charge of refrigerant” , 8 th International Energy Agency, Heat Pump conference 2005,<br />

Global Advances in Heat Pump Technology, Applications and Markets, Las Vegas, Nevada, USA,<br />

May 30 – June 2, 2005.<br />

7. REFEREES<br />

Professor emeritus Eric Granryd<br />

Department of Energy Technology<br />

Division of Applied Thermodynamics and Refrigeration<br />

Royal Institute of Technology (KTH)<br />

SE-100 44 Stockholm, Sweden<br />

Phone: +46 (0) 70 7640310; Fax: +46 (0) 8 20 30 07<br />

granryd@energy.kth.se<br />

Assoc.Prof./Head of Division Björn Palm<br />

Department of Energy Technology<br />

Division of Applied Thermodynamics and Refrigeration<br />

Royal Institute of Technology (KTH)<br />

SE-100 44 Stockholm, Sweden<br />

Phone: +46 (0) 8 7907453; Fax: +46 (0) 8 20 30 07<br />

bpalm@energy.kth.se<br />

Assoc.Prof./Head of Division Per Lundqvist<br />

Department of Energy Technology<br />

Division of Applied Thermodynamics and Refrigeration<br />

Royal Institute of Technology (KTH)<br />

SE-100 44 Stockholm, Sweden<br />

Phone: +46 (0) 8 790 7452; Fax: +46 (0) 8 20 30 07<br />

perlundq@energy.kth.se<br />

6