K - CK - CCK - Transfluid

K - CK - CCK - Transfluid

K - CK - CCK - Transfluid

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

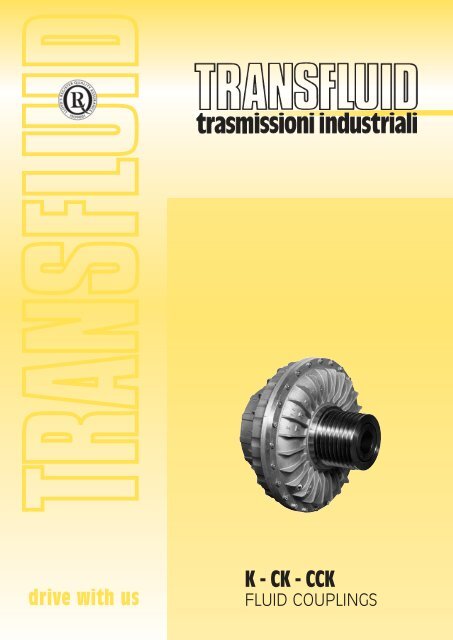

K - <strong>CK</strong> - C<strong>CK</strong><br />

FLUID COUPLINGS

INDEX<br />

DESCRIPTION pag. 2<br />

OPERATION 2 ÷ 4<br />

ADVANTAGES 4<br />

PERFORMANCE CURVES 5<br />

VERSIONS 6<br />

SELECTION 7 ÷ 10<br />

DIMENSIONS 11 ÷ 24<br />

OIL FILL 24<br />

CENTER OF GRAVITY AND MOMENT OF INERTIA 25<br />

SAFETY DEVICES 26 ÷ 28<br />

STANDARD OR REVERSE MOUNTING 29<br />

OTHER TRANSFLUID PRODUCTS 30<br />

SALES NETWORK<br />

Fluid couplings - 0808<br />

1

DESCRIPTION & OPERATING CONDITIONS<br />

1. DESCRIPTION<br />

The TRANSFLUID coupling (K series) is a constant fill type,<br />

comprising of three main elements:<br />

1 - driving impeller (pump) mounted on the input shaft.<br />

2 - driven impeller (turbine) mounted on the output shaft.<br />

3 - cover, flanged to the outer impeller, with an oil-tight seal.<br />

The first two elements can work both as pump or turbine.<br />

2. OPERATING CONDITIONS<br />

The TRANSFLUID coupling is a hydrodynamic transmission. The<br />

impellers perform like a centrifugal pump and a hydraulic turbine.<br />

With an input drive to the pump (e.g. electric motor or Diesel<br />

engine) kinetic energy is transferred to the oil in the coupling. The<br />

oil is forced, by centrifugal force, across the blades of the pump<br />

towards the outside of the coupling.<br />

The turbine absorbs kinetic energy and generates a torque<br />

always equal to input torque, thus causing rotation of the output<br />

shaft. Since there are no mechanical connections, the wear is<br />

practically zero.<br />

The efficiency is influenced only by the speed difference (slip)<br />

between pump and turbine.<br />

The slip is essential for the correct operation of the coupling -<br />

there could not be torque transmission without slip! The formula<br />

for slip, from which the power loss can be deduced is as follows:<br />

input speed – output speed<br />

slip % =<br />

input speed<br />

x 100<br />

In normal conditions (standard duty), slip can vary from 1,5%<br />

(large power applications) to 6% (small power applications).<br />

TRANSFLUID couplings follow the laws of all centrifugal<br />

machines:<br />

1 - transmitted torque is proportional to the square of input<br />

speed;<br />

2 - transmitted power is proportional to the third power of input<br />

speed;<br />

3 - transmitted power is proportional to the fifth power of circuit<br />

outside diameter.<br />

1<br />

OUTPUT<br />

INPUT<br />

INPUT<br />

OUTPUT<br />

4<br />

3<br />

2<br />

1 - INTERNAL IMPELLER<br />

2 - EXTERNAL IMPELLER<br />

3 - COVER<br />

4 - FLEX COUPLING<br />

Fluid couplings - 0808 2

PERFORMANCE CURVES<br />

2.1 <strong>Transfluid</strong> coupling fitted on electric motors<br />

Three phase synchronous squirrel cage motors are able to<br />

supply maximum torque only, near synchronous speed. Direct<br />

starting is the system utilized the most. Figure 1 illustrates the<br />

relationship between torque and current. It can be seen that the<br />

absorbed current is proportional to the torque only between 85%<br />

and 100% of the synchronous speed. With a motor connected<br />

directly to the load there are the following disadvantages:<br />

Fig. 1<br />

• The difference between available torque and the torque<br />

required by the load is very low until the rotor has accelerated<br />

to between 80-85% of the synchronous speed.<br />

• The absorbed current is high (up to 6 times the nominal<br />

current) throughout the starting phase causing overheating of<br />

the windings, overloads in the electrical lines and, in cases of<br />

frequent starts, major production costs.<br />

• Over-dimensioned motors caused by the limitations indicated<br />

above.<br />

% motor torque<br />

% motor current<br />

To limit the absorbed current of the motor during the<br />

Y<br />

acceleration of the load, a ( Δ) (wye - delta) starting system is<br />

frequently used which reduces the absorbed current by about<br />

1/3 during starting. Unfortunately, during operation of the motor<br />

under the delta configuration, the available torque is also<br />

reduced by 1/3; and for machines with high inertias to<br />

accelerate, over-dimensioning of the motor is still required.<br />

Finally, this system does not eliminate current peaks originating<br />

from the insertion or the commutation of the device.<br />

% motor speed<br />

Fig. 2<br />

Any drive system using a <strong>Transfluid</strong> fluid coupling has the<br />

advantage of the motor starting essentially without load. Figure 2<br />

compares the current demands of an electric motor when the<br />

load is directly attached verses the demand when a fluid<br />

coupling is mounted between the motor and load. The coloured<br />

area shows the energy that is lost, as heat, during start-up when<br />

a fluid coupling is not used. A <strong>Transfluid</strong> fluid coupling reduces<br />

the motor’s current draw during start-up thus reducing peak<br />

current demands. This not only reduces power costs but also<br />

reduces brown outs in the power grid and extends the life of the<br />

motor. Also at start-up, a fluid coupling allows more torque to<br />

pass to the load for acceleration than in drive systems without a<br />

fluid coupling.<br />

% motor current<br />

without fluid coupling<br />

with fluid coupling<br />

Fig. 3<br />

% start-up time<br />

% torque<br />

Motor<br />

Figure 3 shows two curves for a single fluid coupling and a<br />

characteristic curve of an electric motor. It is obvious from the<br />

stall curve of the fluid coupling (s = 100%) and the available<br />

motor torque, how much torque is available to accelerate the<br />

rotor of the motor (colored area). In about 1 second, the rotor of<br />

the motor accelerates passing from point A to point B. The<br />

acceleration of the load, however, is made gradually by the fluid<br />

coupling, utilizing the motor in optimal conditions, along the part<br />

of the curve between point B, 100% and point C, 2-5%. Point C<br />

is the typical point of operation during normal running.<br />

% motor speed<br />

Fluid couplings - 0808<br />

3

DELAYED FILL CHAMBER<br />

ADVANTAGES<br />

2.2 TRANSFLUID FLUID COUPLINGS WITH A DELAYED FILL<br />

CHAMBER<br />

A low starting torque is achieved, with the standard circuit in a<br />

maximum oil fill condition because fluid couplings limit to less<br />

than 200% of the nominal motor torque. It is possible to limit<br />

further the starting torque down to 160% of the nominal torque,<br />

by decreasing oil fill: this, contrarily creates slip and working<br />

temperature increase in the fluid coupling.<br />

The most convenient technical solution is to use fluid couplings<br />

with a delayed fill chamber, connected to the main circuit by<br />

calibrated bleed orifices. These externally adjustable valves,<br />

available from size 15<strong>CK</strong> (Fig. 4b), can be simply adjusted to<br />

vary starting time.<br />

In a standstill position, the delayed fill chamber contains part of<br />

the filling oil, thus reducing the effective quantity in the working<br />

circuit (Fig. 4a) and a torque reduction is obtained, allowing the<br />

motor to quickly reach the steady running speed as if started<br />

without load.<br />

During start-up, oil flows from the delayed fill chamber to the<br />

main circuit (Fig. 4b) in a quantity proportional to the rotating<br />

speed.<br />

As soon as the fluid coupling reaches the nominal speed, all oil<br />

flows into the main circuit (Fig. 4c) and torque is transmitted with<br />

a minimum slip.<br />

With a simple delayed fill chamber, the ratio between starting<br />

and nominal torque may reach 150 %. This ratio may be further<br />

reduced down to 120 % with a double delayed fill chamber,<br />

which contains a higher oil quantity, to be progressively<br />

transferred into the main circuit during the starting phase.<br />

This is ideal for very smooth start-ups with low torque absorptions,<br />

as typically required for machinery with large inertia values and<br />

for belt conveyors.<br />

The advantages of the delayed fill chamber become more and<br />

more evident when the power to be transmitted increases.<br />

The simple chamber is available from size 11<strong>CK</strong>, while the<br />

double chamber from size 15C<strong>CK</strong>.<br />

3. SUMMARY OF THE ADVANTAGES GIVEN BY FLUID<br />

COUPLINGS<br />

– very smooth start-ups<br />

– reduction of current absorptions during the starting phase: the<br />

motor starts with very low load<br />

– protection of the motor and the driven machine from jams and<br />

overloads<br />

– utilization of asynchronous squirrel cage motors instead of<br />

special motors with soft starter devices<br />

– higher duration and operating convenience of the whole drive<br />

train, thanks to the protection function achieved by the fluid<br />

coupling<br />

– higher energy saving, thanks to current peak reduction<br />

– limited starting torque down to 120% in the versions with a<br />

double delayed fill chamber<br />

– same torque at input and output: the motor can supply the<br />

maximum torque even when load is jammed<br />

– torsional vibration absorption for internal combustion engines,<br />

thanks to the presence of a fluid as a power transmission<br />

element<br />

– possibility to achieve a high number of start-ups, also with an<br />

inversion of the rotation direction<br />

– load balancing in case of a double motor drive: fluid couplings<br />

automatically adjust load speed to the motors speed<br />

– high efficiency<br />

– minimum maintenance<br />

– Viton rotating seals<br />

– cast iron and steel material with anticorrosion treatment<br />

valve<br />

Fig. 4 a<br />

AT REST<br />

Fig. 4 b<br />

ACCELERATION<br />

Fig. 4 c<br />

RUNNING<br />

calibrated plug<br />

Oil in reserve for<br />

use after start<br />

Oil available<br />

for initial start<br />

Oil drains from chamber<br />

into main circuit<br />

All oil in circuit<br />

Pag.4<br />

Fluid couplings - 0808<br />

4

STARTING TORQUE CHARACTERISTICS<br />

4. CHARACTERISTIC CURVES<br />

MI : transmitted torque from fluid coupling<br />

Mm : starting torque of the electric motor<br />

Mn : nominal torque at full load<br />

...... : accelerating torque<br />

K type<br />

(standard circuit)<br />

Torque<br />

200%<br />

Mm<br />

MI<br />

100%<br />

Mn<br />

180÷200%<br />

0 5 10 Time [s]<br />

<strong>CK</strong> type<br />

(circuit with a<br />

delayed chamber)<br />

Torque<br />

200%<br />

Mm<br />

MI<br />

Mn<br />

100%<br />

150÷180%<br />

0 5 10 Time [s]<br />

Torque<br />

Mm<br />

C<strong>CK</strong> type<br />

(circuit with a double<br />

delayed chamber)<br />

200%<br />

MI<br />

Mn<br />

100%<br />

120÷150%<br />

0 5 10 Time [s]<br />

Fluid couplings - 0808<br />

5

PRODUCTION PROGRAM<br />

5 VERSIONS<br />

5.1 IN LINE<br />

KR-<strong>CK</strong>R-C<strong>CK</strong>R<br />

KSD<br />

KSD<br />

KSD<br />

KSD<br />

<strong>CK</strong>SD- C<strong>CK</strong>SD<br />

<strong>CK</strong>SD-<br />

<strong>CK</strong>SD-<br />

C<strong>CK</strong>SD<br />

C<strong>CK</strong>SD<br />

<strong>CK</strong>SD- C<strong>CK</strong>SD<br />

: basic coupling (KR), with a simple<br />

(<strong>CK</strong>R) or double (C<strong>CK</strong>R) delayed fill<br />

chamber.<br />

basic coupling with elastic coupling<br />

(clamp type), or superelastic.<br />

KRG-<strong>CK</strong>RG-C<strong>CK</strong>RG :<br />

KRM-<strong>CK</strong>RM-C<strong>CK</strong>RM<br />

KRB-<strong>CK</strong>RB-C<strong>CK</strong>RB : like ..KRG, but with brake drum or<br />

…KRBP<br />

brake disc.<br />

KRD-<strong>CK</strong>RD-C<strong>CK</strong>RD : basic coupling ..KR with output shaft. It<br />

allows the utilization of other flex<br />

couplings; it is possible to place it (with<br />

a convenient housing) between the<br />

motor and a hollow shaft gearbox.<br />

EK<br />

: fluid coupling fitted with a bell housing, to<br />

be placed between a flanged electric<br />

motor and a hollow shaft gearbox.<br />

KCM-<strong>CK</strong>CM-C<strong>CK</strong>CM: basic coupling for half gear couplings.<br />

KCG-<strong>CK</strong>CG-C<strong>CK</strong>CG : basic ..KCM with half gear couplings. On<br />

request, layout with brake drum or brake<br />

disc.<br />

KDM-<strong>CK</strong>DM-C<strong>CK</strong>DM: fluid coupling with disc couplings.<br />

…KDMB<br />

…KDMBP<br />

N.B.:<br />

: like ..KDM, but with brake drum or<br />

brake disc.<br />

KSI<br />

KSI<br />

KSI<br />

KSI<br />

<strong>CK</strong>SI - C<strong>CK</strong>SI<br />

<strong>CK</strong>SI<br />

<strong>CK</strong>SI<br />

- C<strong>CK</strong>SI<br />

- C<strong>CK</strong>SI<br />

<strong>CK</strong>SI - C<strong>CK</strong>SI<br />

KSDF<br />

KSDF<br />

KSDF<br />

KSDF<br />

<strong>CK</strong>SDF - C<strong>CK</strong>SDF<br />

<strong>CK</strong>SDF<br />

<strong>CK</strong>SDF<br />

- C<strong>CK</strong>SDF<br />

- C<strong>CK</strong>SDF<br />

<strong>CK</strong>SDF - C<strong>CK</strong>SDF<br />

<strong>CK</strong>R - C<strong>CK</strong>R<br />

<strong>CK</strong>R <strong>CK</strong>R<br />

- C<strong>CK</strong>R<br />

- C<strong>CK</strong>R<br />

<strong>CK</strong>R - C<strong>CK</strong>R<br />

KCM<br />

KCM<br />

KCM<br />

KCM<br />

KR<br />

KR<br />

KR<br />

KR<br />

<strong>CK</strong>CM - C<strong>CK</strong>CM<br />

<strong>CK</strong>CM <strong>CK</strong>CM<br />

- C<strong>CK</strong>CM<br />

- C<strong>CK</strong>CM<br />

<strong>CK</strong>CM - C<strong>CK</strong>CM<br />

5.2 PULLEY<br />

KRD<br />

KRD<br />

KRD<br />

KRD<br />

<strong>CK</strong>RD - C<strong>CK</strong>RD<br />

<strong>CK</strong>RD <strong>CK</strong>RD<br />

- C<strong>CK</strong>RD<br />

- C<strong>CK</strong>RD<br />

<strong>CK</strong>RD - C<strong>CK</strong>RD<br />

KCG<br />

KCG<br />

KCG<br />

KCG<br />

Fig. A<br />

Fig. Fig.<br />

A<br />

Fig. A<br />

Fig. C<br />

Fig. Fig.<br />

C<br />

C<br />

Fig. C<br />

<strong>CK</strong>CG - C<strong>CK</strong>CG<br />

<strong>CK</strong>CG <strong>CK</strong>CG<br />

- C<strong>CK</strong>CG<br />

- C<strong>CK</strong>CG<br />

<strong>CK</strong>CG - C<strong>CK</strong>CG<br />

KSD–<strong>CK</strong>SD–C<strong>CK</strong>SD<br />

KRG<br />

KRG<br />

KRG<br />

KRG<br />

<strong>CK</strong>RG - C<strong>CK</strong>RG<br />

<strong>CK</strong>RG <strong>CK</strong>RG<br />

- C<strong>CK</strong>RG<br />

- C<strong>CK</strong>RG<br />

<strong>CK</strong>RG - C<strong>CK</strong>RG<br />

EK<br />

EK<br />

EK<br />

EK<br />

KDM<br />

KDM<br />

KDM<br />

KDM<br />

<strong>CK</strong>DM - C<strong>CK</strong>DM<br />

<strong>CK</strong>DM <strong>CK</strong>DM<br />

- C<strong>CK</strong>DM<br />

- C<strong>CK</strong>DM<br />

<strong>CK</strong>DM - C<strong>CK</strong>DM<br />

KRB<br />

KRB<br />

KRB<br />

KRB<br />

<strong>CK</strong>RBP - C<strong>CK</strong>RBP<br />

<strong>CK</strong>RBP <strong>CK</strong>RBP<br />

- C<strong>CK</strong>RBP<br />

- C<strong>CK</strong>RBP<br />

<strong>CK</strong>RBP - C<strong>CK</strong>RBP<br />

The ..KCG - ..KDM versions allow a radial disassembly without moving the motor or the driven machine.<br />

6 MOUNTING<br />

6.1 IN LINE VERSIONS MOUNTING EXAMPLES<br />

Fig. A Horizontal axis between the motor and the driven<br />

machine (KR-<strong>CK</strong>R-C<strong>CK</strong>R and similar).<br />

Fig. B It allows a radial disassembly without moving the motor<br />

and the driven machine (KCG-KDM and similar).<br />

Fig. C Between a flanged electric motor and a hollow shaft<br />

gearbox by means of a bell housing (..KRD and EK).<br />

Fig. D Vertical axis mounting between the electric motor and<br />

a gearbox or driven machine. In case of order,<br />

please specify mounting type 1 or 2.<br />

Fig. E Between the motor and a supported pulley for high<br />

powers and heavy radial loads.<br />

Fig. B<br />

Fig.<br />

Fig.<br />

BB<br />

Fig. B<br />

KDMB<br />

KDMB<br />

KDMB<br />

KDMB<br />

<strong>CK</strong>DMBP- C<strong>CK</strong>DMBP<br />

<strong>CK</strong>DMBP- <strong>CK</strong>DMBP-<br />

C<strong>CK</strong>DMBP<br />

C<strong>CK</strong>DMBP<br />

<strong>CK</strong>DMBP- C<strong>CK</strong>DMBP<br />

: basic coupling foreseen for a flanged pulley,<br />

with simple (<strong>CK</strong>..) or double (C<strong>CK</strong>..) delayed<br />

fill chamber.<br />

KSI-<strong>CK</strong>SI-C<strong>CK</strong>SI : fluid coupling with an incorporated pulley,<br />

which is fitted from inside.<br />

KSDF-<strong>CK</strong>SDF-C<strong>CK</strong>S..: basic ..KSD coupling with flanged pulley,<br />

externally mounted and therefore to be easily<br />

disassembled.<br />

Fig. D<br />

Fig. Fig.<br />

DD<br />

Fig. D<br />

Fig. F<br />

1<br />

2<br />

Fig.<br />

Fig.<br />

F<br />

F<br />

1<br />

1<br />

2<br />

2<br />

Fig. F<br />

1<br />

2<br />

Fig. G<br />

Fig.<br />

Fig.<br />

G<br />

G<br />

Fig. G<br />

Fig.<br />

Fig. E<br />

Fig.<br />

E<br />

Fig. E<br />

N.B. Version EK (fig. C) also for<br />

vertical mounting (fig. D 1-2)<br />

6. 2 PULLEY VERSIONS MOUNTING EXAMPLES<br />

Fig. F Horizontal axis.<br />

Fig. G Vertical axis. When ordering, please specify mounting<br />

type 1 or 2.<br />

1<br />

1<br />

1<br />

1<br />

2<br />

2<br />

2<br />

2<br />

Fluid couplings - 0808<br />

6

SELECTION<br />

7. SELECTION<br />

7.1 SELECTION CHART<br />

The chart below may be used to select a unit size from the<br />

horsepower and input speed. If the selection point falls on a size<br />

limit line dividing one size from the other, it is advisable to select<br />

the larger size with a proportionally reduced oil fill.<br />

Tab. A<br />

GENERAL REFERENCE HORSEPOWER CHART<br />

HP<br />

PS<br />

4500<br />

4000<br />

3500<br />

3000<br />

725<br />

870<br />

970<br />

1160<br />

1450<br />

1750<br />

2900<br />

3500<br />

3300<br />

2940<br />

2570<br />

2200<br />

kW<br />

2500<br />

1840<br />

HORSEPOWER<br />

POTENZA<br />

2000<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

350<br />

300<br />

250<br />

200<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

50<br />

40<br />

30<br />

20<br />

D46K<br />

46K<br />

D34K<br />

34K<br />

29K<br />

27K<br />

24K<br />

21K<br />

19K<br />

17K<br />

15K<br />

13K<br />

12K<br />

11K<br />

9K<br />

8K<br />

7K<br />

1470<br />

1320<br />

1175<br />

1030<br />

880<br />

735<br />

600<br />

440<br />

370<br />

295<br />

220<br />

185<br />

150<br />

120<br />

90<br />

75<br />

60<br />

45<br />

37<br />

30<br />

22<br />

15<br />

12<br />

9<br />

10<br />

9<br />

8<br />

7<br />

6K<br />

7,5<br />

5<br />

6<br />

5<br />

3,7<br />

4<br />

3<br />

3<br />

2,2<br />

2<br />

1,5<br />

1.3<br />

0,88<br />

1<br />

0,75<br />

725<br />

870<br />

970<br />

1160<br />

1450<br />

1750<br />

2900<br />

3500<br />

0,57<br />

0,5<br />

0,37<br />

500 600 800 1000 1500 2000 3000 4000 5000 6000<br />

VELOCITA' ENTRATA giri/min<br />

INPUT SPEED RPM<br />

LE LINEE DEL DIAGRAMMA INDICANO LE POTENZE E LE VELOCITA' LIMITE DEL GIUNTO<br />

145 IT-07<br />

THE CURVES SHOW LIMIT CAPACITY OF COUPLING<br />

Fluid couplings - 0808<br />

7

SELECTION<br />

7.2 SELECTION TABLE<br />

Fluid couplings for standard electric motors.<br />

Tab. B<br />

MOTOR<br />

3000 rpm<br />

() 1800 rpm<br />

1500 rpm<br />

() 1200 rpm<br />

1000 rpm<br />

TYPE<br />

80 19<br />

90S 24<br />

90L 24<br />

100L 28<br />

112M 28<br />

132 38<br />

132M 38<br />

160M 42<br />

160L 42<br />

180M 48<br />

180L 48<br />

200L 55<br />

225S 60<br />

225M<br />

55 (3000)<br />

60<br />

250M<br />

60 (3000)<br />

65<br />

280S<br />

65 (3000)<br />

75<br />

280M<br />

65 (3000)<br />

75<br />

315S<br />

65 (3000)<br />

80<br />

315M<br />

355S<br />

355M<br />

SHAFT<br />

DIA.<br />

65 (3000)<br />

80<br />

80 (3000)<br />

100<br />

80 (3000)<br />

100<br />

kW<br />

0.75<br />

1.1<br />

HP<br />

1<br />

1.5<br />

1.5 2<br />

2.2 3<br />

3 4<br />

5.5 7.5<br />

7.5 10<br />

6 K<br />

4 5.5 7 K (1)<br />

_ _ _<br />

11 15<br />

15 20<br />

18.5 25<br />

22 30<br />

9 K (1)<br />

_ _ _<br />

30 40<br />

37 50<br />

11 K (1)<br />

_ _ _<br />

45 60 11 K (1)<br />

55 75 13 K (1)<br />

75 100<br />

90 125<br />

110 150<br />

132 180<br />

160 220<br />

200 270<br />

250 340<br />

COUPLING<br />

13 K (2)<br />

_<br />

_<br />

_<br />

kW<br />

0.55<br />

0.75<br />

HP<br />

0.75<br />

1<br />

1.1 1.5<br />

1.5 2<br />

2.2 3<br />

3 4<br />

4 5.5<br />

5.5 7.5<br />

7.5 10<br />

11 15<br />

6 K<br />

7 K<br />

8 K<br />

9 K<br />

15 20 11 K<br />

250 340<br />

315 430<br />

COUPLING<br />

21 K<br />

24 K<br />

kW<br />

0.55<br />

0.75<br />

0.75<br />

1<br />

1.1 1.5<br />

1.5 2<br />

2.2 3<br />

3 4<br />

4 5.5<br />

5.5 7.5<br />

7.5 10<br />

11 15<br />

15 20<br />

6 K<br />

7 K<br />

8 K<br />

9 K<br />

11 K<br />

0.37<br />

0.55<br />

0.5<br />

0.75<br />

0.75 1<br />

1.1 1.5<br />

1.5 2<br />

2.2 3<br />

3 4<br />

4 5.5<br />

5.5 7.5<br />

7.5 10<br />

11 15<br />

18.5 25<br />

12 K<br />

(11 K) 18.5 25<br />

_ _ _ _ _ _<br />

12 K<br />

22 30 12 K 22 30<br />

15 20<br />

15 20<br />

13 K<br />

15 K<br />

13 K<br />

30 40<br />

18.5 25<br />

(12 K)<br />

30 40<br />

18.5 25<br />

22 30<br />

22 30<br />

13 K<br />

37 50<br />

37 50<br />

_ _<br />

_ _ _<br />

13 K<br />

15 K<br />

45 60<br />

45 60<br />

30 40<br />

30 40 17 K<br />

15 K<br />

55 75 15 K 55 75<br />

37 50<br />

37 50<br />

75 100<br />

19 K<br />

17 K<br />

(15 K) 75 100<br />

45 60 17 K 45 60<br />

17 K<br />

90 125<br />

90 125<br />

55 75<br />

55 75<br />

17 K<br />

21 K<br />

110 150<br />

110 150<br />

75 100 19 K 75 100<br />

19 K<br />

132 180<br />

132 180<br />

90 125 90 125<br />

19 K<br />

21 K<br />

160 220<br />

160 220<br />

110 150<br />

110 150<br />

21 K<br />

200 270 200 270<br />

132 180 132 180<br />

24 K<br />

250 340<br />

315 430<br />

24 K<br />

160<br />

200<br />

250<br />

max. max. max.<br />

HP<br />

COUPLING<br />

kW<br />

HP<br />

220<br />

270<br />

340<br />

COUPLING<br />

7 K<br />

8 K<br />

9 K<br />

11 K<br />

12 K<br />

24 K<br />

27 K<br />

kW<br />

0.37<br />

0.55<br />

0.5<br />

0.75<br />

0.75 1<br />

1.1 1.5<br />

7 K<br />

8 K<br />

1.5 2 9 K<br />

2.2 3<br />

3 4<br />

4 5.5<br />

5.5 7.5<br />

7.5 10<br />

11 15<br />

160<br />

200<br />

250<br />

HP<br />

220<br />

270<br />

340<br />

COUPLING<br />

11 K<br />

12 K<br />

13 K<br />

27 K<br />

29 K<br />

700 952<br />

27 K<br />

510 700 27 K<br />

440 598 29 K<br />

370 500 29 K<br />

NO - STANDARD<br />

MOTORS<br />

1000 1360<br />

29 K<br />

810 1100<br />

1300 1740<br />

29 K<br />

34 K<br />

800 1088<br />

1250 1700<br />

34 K<br />

D 34 K<br />

600 800<br />

880 1200<br />

34 K<br />

D 34 K<br />

1840 2500 D 34 K<br />

2000 2700 46 K 1470 2000 46 K<br />

() POWERS REFER TO MOTORS CONNECTED AT 380 V. 60 HZ<br />

(1) SPECIAL VERSION, 24 HOURS SERVICE<br />

(2) ONLY FOR KR<br />

NB: THE FLUID COUPLING SIZE IS TIED TO THE MOTOR SHAFT DIMENSIONS<br />

2500 3400 D 46 K 2000 2700 D 46 K<br />

Fluid couplings - 0808<br />

8

SELECTION<br />

7.3 PERFORMANCE CALCULATIONS<br />

For frequent starts or high inertia acceleration, it is necessary to<br />

first carry out the following calculations. For this purpose it is<br />

necessary to know:<br />

Pm - input power<br />

kW<br />

nm - input speed<br />

rpm<br />

PL - power absorbed by the load at rated speed kW<br />

n L - speed of driven machine rpm<br />

J - inertia of driven machine Kgm<br />

T - ambient temperature °C<br />

The preliminary selection will be made from the selection graph<br />

Tab. A depending upon input power and speed.<br />

Then check:<br />

A) acceleration time.<br />

B) max allowable temperature.<br />

C) max working cycles per hour<br />

A) Acceleration time t a :<br />

n u<br />

• Jr<br />

t a = (sec) where:<br />

9.55 • M a<br />

n u = coupling output speed (rpm)<br />

J r = inertia of driven machine referred to coupling shaft (Kgm 2 )<br />

M a = acceleration torque (Nm)<br />

n u = n m<br />

•<br />

(<br />

100 - S<br />

)<br />

where S is the percent slip derived from the characteristic<br />

curves of the coupling with respect to the absorbed torque M L .<br />

If S is not known accurately, the following assumptions may<br />

be made for initial calculations:<br />

4 up to size 13”<br />

3 from size 15” up to size 19”<br />

2 for all larger sizes.<br />

J r = J • (<br />

n L<br />

100<br />

)<br />

n u<br />

2<br />

2 2<br />

PD GD<br />

Note: J = or<br />

4 4<br />

2<br />

B) Max allowable temperature.<br />

For simplicity of calculation, ignore the heat dissipated during<br />

acceleration.<br />

Coupling temperature rise during start-up is given by:<br />

T a =<br />

Q<br />

C<br />

(°C)<br />

where: Q = heat generated during acceleration (kcal)<br />

C = total thermal capacity (metal and oil) of coupling<br />

selected from Tab. C (kcal/°C).<br />

n u<br />

10<br />

Q = ( + ) (kcal)<br />

The final coupling temperature reached at the end of the<br />

acceleration cycle will be:<br />

T f = T + T a + T L (°C)<br />

4<br />

•<br />

J r<br />

• nu<br />

76.5<br />

where: T f = final temperature (°C)<br />

T = ambient temperature (°C)<br />

T a = temperature rise during acceleration (°C)<br />

T L = temperature during steady running (°C)<br />

P • L S<br />

T L = 2.4 • K<br />

(°C)<br />

where: K = factor from Tab. D<br />

T f = must not exceed 150°C<br />

C) Max working cycles per hour H<br />

In addition to the heat generated in the coupling by slip<br />

during steady running, heat is also generated (as calculated<br />

above) during the acceleration period. To allow time for this<br />

heat to be dissipated, one must not exceed the max<br />

allowable number of acceleration cycles per hour.<br />

M L<br />

• ta<br />

3600<br />

H max =<br />

t a + t L<br />

where t L = minimum working time<br />

3 Q<br />

t L = 10 • (sec)<br />

T<br />

( a + T • L ) K<br />

2<br />

8<br />

M a = 1.65 M m - M L<br />

where: M m =<br />

9550 • P m<br />

n m<br />

(Nominal Torque)<br />

9550<br />

dove: M L = • P L<br />

(Absorbed Torque)<br />

n u<br />

Fluid couplings - 0808<br />

9

SELECTION<br />

7.4 CALCULATION EXAMPLE<br />

Assuming: Pm = 20 kW n m = 1450 giri/min<br />

Supponendo: P L = 12 kW n L = 700 giri/min<br />

Supponendo: J = 350 kgm 2<br />

Supponendo: T = 25°C<br />

Transmission via belts.<br />

From selection graph on Tab. A, selected size is 12K.<br />

A) Acceleration time<br />

From curve TF 5078-X (supplied on request) slip S = 4%<br />

100 - 4<br />

n u = 1450 (<br />

•<br />

)= 1392 rpm<br />

100<br />

2<br />

700<br />

J r = 350 (<br />

•<br />

)= 88.5 Kgm<br />

1392<br />

M m =<br />

9550 •<br />

20<br />

1450<br />

= 131 Nm<br />

9550 • 12<br />

M L = = 82 Nm<br />

1392<br />

2<br />

Size<br />

6<br />

7<br />

8<br />

9<br />

11<br />

12<br />

13<br />

15<br />

17<br />

19<br />

21<br />

24<br />

27<br />

29<br />

34<br />

D34<br />

46<br />

D46<br />

Tab. Tab. C C<br />

THERMAL CAPACITA' CAPACITY TERMICA<br />

Grandezza K<br />

K<br />

<strong>CK</strong><br />

<strong>CK</strong><br />

C<strong>CK</strong><br />

C<strong>CK</strong><br />

kcal/°Ckcal/C<br />

kcal/°C kcal/C kcal/°C kcal/C<br />

6<br />

0.6<br />

7<br />

81.2<br />

91.5<br />

11 2.5<br />

12<br />

3.2<br />

13<br />

4.2<br />

15<br />

17 6<br />

199<br />

12.8 21<br />

24<br />

15.4<br />

27<br />

21.8 29<br />

29 34<br />

D34 43<br />

56<br />

46<br />

D46<br />

92<br />

138<br />

–<br />

332<br />

0.6<br />

1.2<br />

-<br />

1.5<br />

--<br />

2.5<br />

-<br />

3.2 3.7<br />

4.2<br />

3.7<br />

5<br />

--<br />

6 6.8<br />

5<br />

9 10 10.3<br />

12.8 6.814.6<br />

15.8<br />

15.4 10 17.3 10.319.4<br />

21.814.6<br />

25.4 15.827.5<br />

29 32 33.8<br />

17.3 19.4<br />

43 50 53.9<br />

56<br />

25.4<br />

63<br />

27.5<br />

66.6<br />

9232<br />

99 33.8101<br />

13850<br />

- 53.9 -<br />

- -<br />

63 66.6<br />

175<br />

332 - -<br />

99 101<br />

–<br />

–<br />

–<br />

–<br />

175<br />

–<br />

M a = 1.65 •131<br />

•<br />

82<br />

= 134 Nm<br />

1392 • 88.5<br />

t a = = 96 sec<br />

9.55 • 134<br />

B) Max allowable temperature<br />

1392 88.5 • 1392<br />

•<br />

4<br />

10 76.5<br />

C = 4.2 kcal/°C (Tab. C)<br />

Q = ( + ) = 361 kcal<br />

361<br />

T a = = 86 °C<br />

4.2<br />

K = 8.9 (Tab. D)<br />

12<br />

T L = 2.4 • 4<br />

•<br />

= 13°C<br />

8,9<br />

T f = 25 + 86 + 13 = 124°C<br />

C) Max working cycles per hour<br />

3 361<br />

t L = 10 • = 724 sec<br />

86<br />

(<br />

2 + 13 ) • 8.9<br />

82 • 96<br />

8<br />

• •<br />

FACTOR COEFFICIENTE K<br />

K<br />

500<br />

350<br />

300<br />

200<br />

100<br />

80<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

D46K<br />

800 1000 1200<br />

46K<br />

D34K<br />

34K<br />

29K<br />

27K<br />

24K<br />

21K<br />

19K<br />

17K<br />

15K<br />

13K<br />

12K<br />

11K<br />

9K<br />

8K<br />

Tab. D<br />

COEFFICIENTE FACTOR K<br />

7K<br />

6K<br />

H =<br />

3600<br />

96 + 724<br />

= 4 starts per hour<br />

1<br />

500 600 700 800 1000 1400 2000 3000 4000 5000<br />

900 1200<br />

145 IT-10<br />

VELOCITA' IN USCITA giri/min<br />

OUTPUT SPEED rpm<br />

Fluid couplings - 0808<br />

10

SERIES 6 ÷ 19 KR-<strong>CK</strong>R-C<strong>CK</strong>R<br />

8. DIMENSIONS<br />

only for size “6”<br />

W<br />

C only for size “6”<br />

W<br />

CB<br />

E<br />

O B E<br />

O<br />

O<br />

O<br />

B1<br />

B1B2<br />

B2<br />

C1<br />

C1C2<br />

C2<br />

Ø40H7<br />

Ø40H7<br />

2.5<br />

2.5<br />

P<br />

P<br />

Q<br />

Q<br />

KR<br />

U N M V<br />

±0.1 f7<br />

U N M V<br />

±0.1<br />

f7<br />

T<br />

T<br />

KR<br />

KR<br />

Z<br />

S<br />

S<br />

R<br />

R<br />

J<br />

J<br />

Z<br />

bussola taper bush<br />

conica<br />

bussola conica<br />

F A<br />

F A<br />

I<br />

I N M<br />

±0.1<br />

N M f7<br />

±0.1<br />

f7<br />

P<br />

P<br />

T<br />

T<br />

Z<br />

Z<br />

<strong>CK</strong>R - C<strong>CK</strong>R<br />

<strong>CK</strong>R - C<strong>CK</strong>R<br />

In case of installation on shafts without<br />

shoulders, please contact <strong>Transfluid</strong><br />

<strong>CK</strong>R - C<strong>CK</strong>R<br />

albero con cylindrical foro cilindico bore<br />

albero con foro cilindico<br />

D<br />

D<br />

D<br />

G7<br />

D G7<br />

Dimensions<br />

J 1<br />

J 1<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

J 1<br />

J 1<br />

Size<br />

6<br />

7<br />

8<br />

9<br />

D J J 1 A B B 1 B 2 C C 1 C 2 E F I M N O P Q R S T U V W Z Weight Kg<br />

(without oil)<br />

KR <strong>CK</strong>R C<strong>CK</strong>R KR <strong>CK</strong>R C<strong>CK</strong>R Nr. Ø<br />

28 38 60 80<br />

11<br />

111<br />

325 107 68.5 200 27 195 60 88.9 8 M8 M20 42 56 M10 M12 107 27 19 15 12 14.5 2.75 3.35<br />

42••• 48• 80 110 154 83 M16<br />

28 38 60 80<br />

42 56 M10 M12<br />

12<br />

372 122 221 24 145<br />

15.5 18.5 4.1 4.8<br />

42••• 48• 80 110 75<br />

83 M16<br />

224<br />

42 48<br />

110<br />

84 M16<br />

13<br />

143<br />

398 137 180 240 28 179 80 122.2<br />

7 142 17 17 24 27 5.2 5.8<br />

55••• 60••• 110 58.5<br />

74 104 M20<br />

5 8<br />

34<br />

48 55<br />

110<br />

80 70 M16 M20<br />

15<br />

145<br />

460 151 87 135 205 273 321 35 206 259 90 136<br />

156 19 19 37 41 48.7 7.65 8.6 9.3<br />

60 65••• 140 100 M20<br />

48 55 110<br />

80 M16 M20<br />

145<br />

M10 M27<br />

17 60 65••• 140 520 170 37 103<br />

51 57 66 11.7 13.6 14.9<br />

M20 8<br />

75• 80• – 140 170<br />

103 132<br />

96 176 223 303 383 225 337 125 160 15 12<br />

180 34 24 19<br />

48 55 110 80 M16 M20<br />

145<br />

19 60 65••• 140 565 190 17 103<br />

58 64 73 14.2 16.5 18.5<br />

M20<br />

75• 80• – 140 170 103 133<br />

– D BORES RELATIVE TO TAPER BUSHES WITH A KEYWAY ACCORDING TO ISO 773 - DIN 6885/1<br />

PARTICULAR CASES:<br />

• CYLINDRICAL BORE WITHOUT TAPER BUSH WITH A KEYWAY ISO 773 - DIN 6885/1<br />

•• CYLINDRICAL BORE WITHOUT TAPER BUSH, WITH A REDUCED KEYWAY (DIN 6885/2)<br />

••• TAPER BUSH WITHOUT KEYWAY<br />

– WHEN ORDERING, SPECIFY: SIZE, MODEL, D DIAMETER<br />

EXAMPLE: 11<strong>CK</strong>R - D 42<br />

* SEE DRAWING<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Oil<br />

max lt<br />

KR <strong>CK</strong>R C<strong>CK</strong>R KR <strong>CK</strong>R C<strong>CK</strong>R<br />

19• 24• – 45 55 195 60 90.5 29 88<br />

*<br />

53<br />

*<br />

4 – – – – 68 – – 16.5 2.7 0.50<br />

19 24 40 50<br />

27 35 M6 M8<br />

228 77 112 22<br />

5.1 0.92<br />

28<br />

60<br />

M7 40 M10<br />

69<br />

114 40 73 3<br />

M12<br />

88 21 12 14<br />

24 50<br />

–<br />

–<br />

–<br />

36 M8<br />

–<br />

–<br />

256 91<br />

117<br />

18<br />

5.5<br />

1.5<br />

28 60 41 M10<br />

28 38 60 80<br />

6 43 54 M10 M12 6<br />

295 96 145 31<br />

10 1.95<br />

42••• 48•• 80 110 – – 128 79 M16 – –<br />

Fluid couplings - 0808<br />

11

SERIES 6 ÷ 19 KRG-…KRB-…KRD<br />

KRB<br />

KRB<br />

(with brake drum)<br />

(Con fascia freno)<br />

L<br />

Y<br />

C<br />

K<br />

C1<br />

C2<br />

X1 X<br />

H<br />

P G<br />

H7<br />

KRBP<br />

(with (Con brake disco disc)<br />

freno)<br />

Z<br />

Y 1<br />

KRG<br />

KRG<br />

<strong>CK</strong>RG - <strong>CK</strong>RG C<strong>CK</strong>RG<br />

- C<strong>CK</strong>RG<br />

L 1<br />

C 3<br />

C4<br />

C5<br />

G1<br />

j7<br />

KRD<br />

KRD<br />

<strong>CK</strong>RD - C<strong>CK</strong>RD<br />

<strong>CK</strong>RD - C<strong>CK</strong>RD<br />

Dimensions<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

Size<br />

6<br />

7<br />

8<br />

9<br />

11<br />

12<br />

13<br />

15<br />

17<br />

19<br />

C C 1 C 2 C 3 C 4 C 5 G G 1 H K L L 1 P Flex Brake Brake Z<br />

coupling drum disc<br />

KRG <strong>CK</strong>RG C<strong>CK</strong>RG KRD <strong>CK</strong>RD C<strong>CK</strong>RD max X - Y X 1 - Y 1<br />

Weight Kg<br />

(without oil)<br />

KRG <strong>CK</strong>RG C<strong>CK</strong>RG KRD <strong>CK</strong>RD C<strong>CK</strong>RD<br />

149 107 28 19 73 40 30 45 BT 02 on request 3.9 3<br />

189<br />

133<br />

8.3<br />

5.7<br />

–<br />

– 42 28 110 60 40 70 BT 10 160 - 60<br />

–<br />

–<br />

194 138<br />

8.7 6.1<br />

2 on request –<br />

246 – 176 – 38 16 – 11.6 –<br />

160 - 60<br />

301<br />

231 55<br />

132<br />

50 85 BT 20<br />

18 20.5 13 15.5<br />

255<br />

185<br />

42<br />

80<br />

200 - 75<br />

322 252<br />

21.5 24.5 16.7 19.7<br />

200 - 75 400 - 30<br />

285 345 212 272 70 48<br />

60 100 BT 30<br />

5 34 37 26.3 29.3<br />

170<br />

250 - 95 450 - 30<br />

343 411 459 230 298 346 80 60 110 80 120 BT 40 250 - 95 400 - 30 35 50.3 54.3 62 40.4 44.4 52.1<br />

3 315 - 118 450 - 30<br />

77 83 92 58.1 64.1 73.1<br />

362 442 522 263 343 423 90 75 250 110 100 135 BT 50 315 - 118 445 - 30 15<br />

400 - 150 450 - 30 84 90 99 65.1 71.1 80.1<br />

– G1 SHAFT BORE WITH A KEYWAY ACCORDING TO ISO 773 - DIN 6885/1<br />

– WHEN ORDERING, SPECIFY: SIZE - MODEL - D DIAMETER<br />

– UPON REQUEST: BORE G MACHINED; G 1 SPECIAL SHAFT<br />

– FOR …KRB - KRBP SERIES SPECIFY X AND Y OR X 1 AND Y 1 DIAMETER<br />

EXAMPLE: 9KRB - D38 - BRAKE DRUM = 160x60<br />

Pag12<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Fluid couplings - 0808<br />

12

SERIES 21 ÷ 34 KR-<strong>CK</strong>R-C<strong>CK</strong>R - 46C<strong>CK</strong>R<br />

W<br />

O<br />

E<br />

C<br />

B<br />

E<br />

O<br />

O<br />

B1<br />

B2<br />

C1<br />

C2<br />

P<br />

Q<br />

U N M<br />

± 0.1 f7<br />

V<br />

S<br />

D G7<br />

F<br />

A<br />

I<br />

N M<br />

±0.1 f7<br />

R<br />

J<br />

P<br />

KR<br />

T<br />

24<br />

19<br />

M14 Nr.12<br />

Z<br />

C<br />

22<br />

7<br />

M16 Nr.10<br />

C1<br />

C2<br />

35<br />

M20 Nr.24<br />

T<br />

Z<br />

C2<br />

<strong>CK</strong>R - C<strong>CK</strong>R<br />

6<br />

9<br />

Size<br />

Weight Kg<br />

(without oil)<br />

Oil<br />

max lt<br />

± 0,1<br />

f7<br />

Ø 570<br />

Ø 308<br />

Ø 200<br />

± 0,1<br />

f7<br />

Ø 480<br />

Ø200<br />

Ø 635 ± 0,2<br />

Ø 580 H7<br />

21<br />

24<br />

27<br />

29<br />

KR <strong>CK</strong>R C<strong>CK</strong>R KR <strong>CK</strong>R C<strong>CK</strong>R<br />

87 97 105 19 23 31<br />

105 115 123 28.4 31.2 39<br />

158 176 195 42 50 61<br />

211 229 239 55 63 73<br />

34KR<br />

34KR<br />

34<strong>CK</strong>R -- 34C<strong>CK</strong>R<br />

46C<strong>CK</strong>R 46C<strong>CK</strong>R<br />

34<br />

46<br />

337 352 362 82.5 92.5 101<br />

– – 918 – – 219<br />

Dimensions<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

Size<br />

D J A B B 1 B 2 C C 1 C 2 E F I M N O P Q R S T U V W Z<br />

21<br />

24<br />

KR <strong>CK</strong>R C<strong>CK</strong>R KR <strong>CK</strong>R C<strong>CK</strong>R Nr. Ø<br />

•80 90 170<br />

260 360 450 45 130 M20 M24<br />

620 205<br />

••100 210<br />

295 395 485 80<br />

165 M24<br />

110 200<br />

250 400 160 228 5 M14 M36<br />

•80 90 170<br />

260 360 450 21 130 M20 M24<br />

714 229<br />

••100 210 295 395 485 56 8 165 M24 14<br />

255 40 15 30<br />

27<br />

29<br />

120 max 210 780 278 297 415 515 6 315<br />

200 275 7 M16<br />

135 max 240 860 295 131 231 326 444 544 18 350 537 M45<br />

167 M24<br />

(for max bore)<br />

167 M24<br />

(for max bore)<br />

– –<br />

308 33<br />

– –<br />

34<br />

150 max 265 1000 368 387 518 618 19 400<br />

* * * * *<br />

200 M36<br />

(for max bore)<br />

* *<br />

– –<br />

*<br />

46<br />

180max 320 1330 – – 310 – – 797 – – 695<br />

* * * * *<br />

M52<br />

– D BORES WITH A KEYWAY ACCORDING TO ISO 773 - DIN 6885/1<br />

• STANDARD DIMENSIONS WITH A KEYWAY ISO 773 - DIN 6885/1<br />

•• STANDARD DIMENSIONS WITH REDUCED KEYWAY (DIN 6885/2)<br />

* SEE DRAWING<br />

– WHEN ORDERING, SPECIFY: SIZE, MODEL, D DIAMETER<br />

EXAMPLE: 2IC<strong>CK</strong>R - D 80<br />

145 IT-13<br />

145 IT-13<br />

190 M36<br />

(for max bore)<br />

* *<br />

– –<br />

*<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Fluid couplings - 0808<br />

13

SERIES 21÷34 …KRG…KRB…KRBP…KRD<br />

KRB<br />

KRB<br />

(with brake drum)<br />

(Con fascia freno)<br />

L<br />

Y<br />

C<br />

K<br />

C1<br />

C2<br />

X1 X<br />

H<br />

P G<br />

H7<br />

KRBP<br />

(with (Con brake disco disc)<br />

freno)<br />

Z<br />

Y 1<br />

KRG<br />

KRG<br />

<strong>CK</strong>RG <strong>CK</strong>RG - C<strong>CK</strong>RG - C<strong>CK</strong>RG<br />

L 1<br />

C 3<br />

C4<br />

C5<br />

G1<br />

j7<br />

KRD<br />

KRD<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

<strong>CK</strong>RD - - C<strong>CK</strong>RD<br />

Dimensions<br />

Size<br />

21 (3)<br />

24 (3)<br />

27<br />

29<br />

34<br />

C C 1 C 2 C 3 C 4 C 5 G G 1 H K L L 1 P Flex Brake Brake Z<br />

coupling drum disc<br />

Weight kg<br />

(without oil)<br />

KRG <strong>CK</strong>RG C<strong>CK</strong>RG KRD <strong>CK</strong>RD C<strong>CK</strong>RD max X - Y X 1 - Y 1 KRG <strong>CK</strong>RG C<strong>CK</strong>RG KRD <strong>CK</strong>RD C<strong>CK</strong>RD<br />

560 - 30<br />

433 (3) 533 (3) 623 (3) 292 (3) 392 (3) 482 (3) 400 - 150 630 - 30 129 139 147 99.5 109.5 117.5<br />

110 90 290 3 140 120 170 BT60<br />

45<br />

710 - 30<br />

500 - 190 795 - 30 147 157 165 117.5 127.5 135.5<br />

484 602 702 333 451 550<br />

710 - 30 228 246 265 178 186 215<br />

130 100 354 4 150 140 200 BT80 500 - 190 795 - 30 20<br />

513 631 731 362 480 579<br />

281 299 309 231 249 259<br />

638 749 849 437 568 667 160 140 395 5 170 150 240 BT90 630 - 236 1000 - 30 18 496 472 482 358 373 383<br />

(3) FOR BORES D 100 INCREASE DIMENSIONS BY 35 mm.<br />

– G 1 SHAFT WITH A KEYWAY ACCORDING TO ISO 773 - DIN 6885/1<br />

– UPON REQUEST, G FINISHED BORE AND G 1 SPECIAL SHAFT DIAMETER<br />

– WHEN ORDERING, SPECIFY: SIZE - MODEL - D DIAMETER FOR …KRB OR …KRBP, SPECIFY X AND Y OR X 1 AND Y 1 DIMENSIONS BRAKE DRUM OR DISC<br />

EXAMPLE: 19KRBP - D80 - BRAKE DISC 450 x 30<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Pag14<br />

Fluid couplings - 0808<br />

14

SERIES 7÷34 KCM – <strong>CK</strong>CM-C<strong>CK</strong>CM - 46C<strong>CK</strong>CM<br />

for 7 : 13 sizes<br />

F<br />

1<br />

F<br />

L<br />

C<br />

L 1<br />

F<br />

C1<br />

C2<br />

E<br />

0<br />

+0.05<br />

H<br />

0<br />

E +0.05<br />

D<br />

H<br />

H<br />

A<br />

B<br />

D<br />

D<br />

KCM<br />

<strong>CK</strong>CM - C<strong>CK</strong>CM<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

THIS FLUID COUPLING IS FORESEEN FOR THE ASSEMBLY OF HALF GEAR COUPLINGS<br />

Dimensions<br />

Size<br />

A B C C 1 C 2 D E F F 1 H L L 1 Weight kg<br />

(without oil)<br />

KCM <strong>CK</strong>CM C<strong>CK</strong>CM<br />

Nr. Ø KCM <strong>CK</strong>CM C<strong>CK</strong>CM<br />

7 228 140<br />

1/4<br />

7.3<br />

116<br />

95.25 6 6.4 28 17<br />

8 256 145 – UNF<br />

7.7 –<br />

9 295 189<br />

14.9<br />

– 7 6.5 18.5 –<br />

–<br />

11<br />

3/8<br />

16.9 19.4<br />

325<br />

152.5<br />

198 244<br />

122.22 8 9.57<br />

24<br />

12 372 198 265<br />

UNF<br />

20.5 23.4<br />

21<br />

13 398 223.5 289.5 29.6 32.6<br />

15 460 251 319 367 23 50.5 54.5 62.2<br />

17 520 213<br />

180.975 6<br />

22 65 71 80<br />

19<br />

275 355 435<br />

5/8 29<br />

565 15.87 6 – 11<br />

72 78 87<br />

21 620<br />

UNC<br />

104 114 122<br />

24<br />

240 316 416 506 206.375 8 31 25<br />

714 122 132 140<br />

27 780 408 526 626<br />

194 213 232<br />

29<br />

280<br />

241.3 3/4 51 51<br />

860 437 555 655 8 19.05 22 – 10<br />

248 266 276<br />

34 1000 318 503 634 734 279.4<br />

UNC<br />

58 58 403 418 428<br />

7/8<br />

46 1330 457.2 – – 937 400.05 14 22.225 22 – 11 – 56 – – 1058<br />

UNC<br />

Gear<br />

coupling<br />

size<br />

1”<br />

S<br />

1” 1/2<br />

S<br />

2” 1/2<br />

E (6)<br />

3”<br />

E (6)<br />

3” 1/2<br />

E<br />

4”<br />

E<br />

6”<br />

E<br />

(6) GEAR COUPLING WITH SPECIAL CALIBRATED BOLTS<br />

– WHEN ORDERING, SPECIFY: SIZE - MODEL<br />

EXAMPLE: 34C<strong>CK</strong>CM<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Fluid couplings - 0808<br />

15

SERIES 7÷34 KCG – <strong>CK</strong>CG - C<strong>CK</strong>CG - 46C<strong>CK</strong>CG<br />

N<br />

C<br />

N<br />

C1<br />

C2<br />

A<br />

G<br />

G<br />

KCG<br />

I<br />

KCG<br />

M<br />

I<br />

M1<br />

M2<br />

<strong>CK</strong>CG - C<strong>CK</strong>CG<strong>CK</strong>CG - C<strong>CK</strong>CG<br />

..KCGB (8)<br />

(with brake drum)<br />

KCGB<br />

(Con fascia freno)<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

FLUID COUPLING FITTED WITH HALF GEAR COUPLINGS, TO BE RADIALLY<br />

DISASSEMBLED WITHOUT MOVING THE MACHINES<br />

Dimensions<br />

Size<br />

A C C 1 C 2 G I I 1 M M 1 M 2 N<br />

Gear coupling<br />

I1<br />

I1<br />

KCGBP<br />

(Con disco freno)<br />

..KCGBP<br />

(with brake disc)<br />

Fascia o disco freno a richiesta<br />

Brake drum or disc upon request<br />

(8) For ..KCGB dimension<br />

M - M1 - M2 may vary<br />

(contact <strong>Transfluid</strong>)<br />

7<br />

8<br />

9<br />

11<br />

12<br />

13<br />

15<br />

17<br />

19<br />

21<br />

24<br />

27<br />

29<br />

34<br />

46<br />

KCG <strong>CK</strong>CG C<strong>CK</strong>CG max KCG <strong>CK</strong>CG C<strong>CK</strong>CG<br />

Size Weight Kg<br />

228 229<br />

50 43 101.6 143 1”<br />

44.5<br />

S<br />

4<br />

256 234<br />

–<br />

148 –<br />

(4)<br />

295 290.6<br />

192<br />

–<br />

–<br />

325 299.6 345.6<br />

65 49.3 114.3 201 247 1” 1/2<br />

50.8 S 8<br />

372 299.6 366.6 201 268<br />

398 325.1 385.1 226.5 286.5<br />

(4)<br />

460 410 478 526 256 324 372<br />

520<br />

95 77 149.4<br />

2” 1/2<br />

79.5<br />

E<br />

434 514 594<br />

280 360 440<br />

29.5<br />

565<br />

(5)(6)<br />

620<br />

503 604 693 111 91 165.1 321 422 511 93.5 3”<br />

E<br />

714<br />

(5)(6)<br />

43.1<br />

780 627 745 845<br />

134 106.5 184.2 414 532 631 3” 1/2<br />

109.5 E 68<br />

860 656 774 874 443 561 660<br />

(5)<br />

1000 750 881 981 160 120.5 203.2 509 640 739 123.5<br />

4”<br />

E (5) 97.5<br />

1330 – – 1313.4 244 188.2 304.8 – – 937 192.2 6”<br />

E (5)<br />

306<br />

(4) S = SHROUDED SCREWS<br />

(5) E = EXPOSED SCREWS<br />

(6) GEAR COUPLING WITH SPECIAL CALIBRATED BOLTS<br />

– WHEN ORDERING, SPECIFY: SIZE - MODEL<br />

EXAMPLE: 21<strong>CK</strong>CG<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Fluid couplings - 0808<br />

Pag16<br />

16

SERIES 9÷34 KDM – <strong>CK</strong>DM - C<strong>CK</strong>DM<br />

N<br />

B<br />

N<br />

N<br />

B1<br />

B2<br />

N<br />

A<br />

G<br />

G<br />

P H<br />

KDM<br />

I<br />

KDM<br />

M<br />

C<br />

I<br />

I<br />

M1<br />

M2<br />

<strong>CK</strong>DM - C<strong>CK</strong>DM<br />

I<br />

C1<br />

C2<br />

<strong>CK</strong>DM - C<strong>CK</strong>DM<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

FLUID COUPLING FITTED WITH HALF DISC COUPLINGS, WITHOUT MAINTENANCE AND PRESCRIBED FOR PARTICULAR AMBIENT CONDITIONS. TO BE<br />

RADIALLY DISASSEMBLED WITHOUT MOVING THE MACHINES.<br />

Dimensions<br />

Size<br />

9<br />

11<br />

12<br />

13<br />

15<br />

17<br />

19<br />

21<br />

24<br />

27<br />

29<br />

34<br />

A B B 1 B 2 C C 1 C 2 G H I M M 1 M 2 N P Disc<br />

coupling<br />

KDM <strong>CK</strong>DM C<strong>CK</strong>DM KDM <strong>CK</strong>DM C<strong>CK</strong>DM max KDM <strong>CK</strong>DM C<strong>CK</strong>DM size<br />

Weight kg<br />

(without oil)<br />

KDM <strong>CK</strong>DM C<strong>CK</strong>DM<br />

295 177 – 278 – 180 – 20.5 –<br />

325<br />

232<br />

335<br />

55 123 50<br />

235 51.5 76 1055 22.5 25<br />

186<br />

– 289<br />

–<br />

189<br />

–<br />

372 253 356 256 – 26 29<br />

398 216 276 339 399 65 147 60 219 279 61.5 88 1065 41.3 44.3<br />

460 246 314 362 391 459 507 75 166 70 251 319 367 72.5 104 1075 65 69 76.7<br />

520<br />

89 95 104<br />

269 349 429 444 524 604 90 192 85 274 354 434 87.5 122 1085<br />

565 96 102 111<br />

620<br />

159 169 177<br />

315 415 505 540 640 730 115 244 110 320 420 510 112.5 154 1110<br />

714 177 187 195<br />

780 358 476 576 644 762 862<br />

364 482 582<br />

289 307 326<br />

135 300 140<br />

143 196 1140<br />

860 387 505 605 673 790 890 393 511 611 342 360 370<br />

1000 442 573 673 768 899 999 165 340 160 448 579 679 163 228 1160 556 562 572<br />

– WHEN ORDERING, SPECIFY: SIZE - MODEL<br />

– FINISHED G BORE UPON REQUEST<br />

EXAMPLE: 27 <strong>CK</strong>DM<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Fluid couplings - 0808<br />

17

SERIES 12÷34…KDMB - …KDMBP<br />

KDMB<br />

KDMB<br />

(with brake drum)<br />

(Con fascia freno)<br />

R<br />

U<br />

N1<br />

Y<br />

Q<br />

B<br />

N<br />

N1<br />

B1<br />

B2<br />

N<br />

X1 X<br />

T S<br />

V G1<br />

P<br />

A<br />

G P<br />

O<br />

O<br />

KDMBP<br />

(with brake disc)<br />

(Con disco freno)<br />

KDM<br />

Z<br />

I1<br />

Y1<br />

MB<br />

CB<br />

I<br />

KDM<br />

I1<br />

MB1<br />

MB2<br />

<strong>CK</strong>DM - C<strong>CK</strong>DM<br />

I<br />

CB1<br />

CB2<br />

<strong>CK</strong>DM - C<strong>CK</strong>DM<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

Dimensions<br />

LIKE KDM, BUT FORESEEN FOR A BRAKE DRUM OR DISC ASSEMBLY<br />

Dimensions<br />

Brake Brake<br />

Weight kg<br />

(without oil, brake<br />

drum disc<br />

drum and disc)<br />

X - Y X 1 - Y 1 KDM <strong>CK</strong>DM C<strong>CK</strong>DM<br />

12<br />

on 27 30<br />

200 - 75 request<br />

13<br />

42.8 45.8<br />

–<br />

15 250 - 95 450 - 30 69.3 73.3 81<br />

17 315 - 118 500 - 30 99 105 114<br />

19 400 - 150 560 - 30 105 112 125<br />

21 400 - 150 630 - 30 179 189 197<br />

24 500 - 190 710 - 30 197 207 215<br />

Size<br />

27<br />

500 - 190 800 - 30<br />

317 335 354<br />

29<br />

370 388 398<br />

34 on request 800 - 30<br />

1000 - 30<br />

599 587 597<br />

Size<br />

12<br />

13<br />

15<br />

17<br />

19<br />

21<br />

24<br />

27<br />

29<br />

34<br />

A B B 1 B 2 CB CB 1 CB 2 G G 1 I I 1 MB MB 1 MB 2 N N 1 O P Q R S T U V Z Disc<br />

coupling<br />

KDM <strong>CK</strong>DM C<strong>CK</strong>DM KDM <strong>CK</strong>DM C<strong>CK</strong>DM max max Std max KDM <strong>CK</strong>DM C<strong>CK</strong>DM St ±0,1 f7 Nr. Ø<br />

size<br />

372 186 253 336.5 403.5<br />

55 60 50 80 206.5 273.5 51.5 99 17.5 76 67 69 128 142 8<br />

114<br />

1055<br />

–<br />

–<br />

–<br />

M8<br />

–<br />

398 216 276 440.5 500.5 65 70 60 140 240.5 300.5 61.5 163 21.5 88 78 129 155 170 140 1065<br />

170<br />

460 246 314 362 495.5 563.5 611.5 75 80 70 150 275.5 343.5 391.5 72.5 177 24.5 104 98 134 175 192 157 109 1075<br />

520<br />

107<br />

269 349 429 548.5 628.5 708.5 90 95 85 210 303.5 383.5 463.5 87.5 192 29.5 122 143 204 224 M10 185 118 1085<br />

565<br />

87<br />

160<br />

12<br />

620<br />

133<br />

315 415 505 628.5 728.5 818.5 115 120 110 358.5 458.5 548.5 112.5 201 38.5 154 137 256 276 M12 234 112 1110<br />

714<br />

109<br />

240<br />

780 358 476 576 731.5 849.5 949.5<br />

135 145 140<br />

411.5 529.5 629.5<br />

143 230.5 47.5 196<br />

107<br />

155 315 338 M14 286 133 1140<br />

860 387 505 605 760.5 878.5 978.5 180 440.5 558.5 658.5 109<br />

1000 442 573 673 845.5 976.5 1076.5 165 175 160 505.5 636.5 736.5 163 240.5 57.5 228 124 152 356 382 M16 325 130 1160<br />

– WHEN ORDERING, SPECIFY: SIZE - MODEL<br />

– G AND G 1 FINISHED BORES UPON REQUEST, AND SPECIAL I 1 DIMENSION<br />

– FOR BRAKE DRUM OR DISC, SPECIFY DIMENSIONS X AND Y OR X 1 AND Y 1<br />

EXAMPLE : 17KDMB - BRAKE DRUM 400 x 150<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Pag.18<br />

Fluid couplings - 0808<br />

18

SERIES 9÷34 KRM – <strong>CK</strong>RM - C<strong>CK</strong>RM<br />

L<br />

C<br />

B<br />

E<br />

C1<br />

C2<br />

In case of installation on shafts without<br />

shoulders, please contact <strong>Transfluid</strong><br />

Q<br />

H<br />

G<br />

H7<br />

S<br />

D F<br />

A<br />

J<br />

R<br />

shaft with cylindrical bore<br />

albero con foro cilindrico<br />

D G7<br />

Size<br />

9<br />

11<br />

12<br />

13<br />

15<br />

17<br />

19<br />

KRM<br />

COUPLING ALLOWING HIGHER MISALIGNMENTS AND THE REPLACEMENT OF THE ELASTIC ELEMENTS WITHOUT MOVING THE MACHINES<br />

Dimensions<br />

KRM<br />

NB: The arrows<br />

D J J 1 A B C C 1 C 2 E F G H L Q R S<br />

KRM <strong>CK</strong>RM C<strong>CK</strong>RM<br />

TAPER BUSH VERSION<br />

max<br />

Elastic<br />

coupling<br />

Weight kg<br />

(without oil)<br />

KRM<br />

<strong>CK</strong>RM C<strong>CK</strong>RM<br />

28 38 60 80<br />

43 54 M 10 M 12<br />

295 96 276 – 31<br />

14.5 –<br />

42••• – 80 –<br />

79 M 16<br />

128<br />

28 38<br />

60 80<br />

42 56 M 10 M 12<br />

111<br />

325 107 331 27 50 185 50 M 20<br />

53 F 16.5 19<br />

42••• 48•• 80 110<br />

83 M 16 –<br />

285 –<br />

38 80<br />

42 56 M 12<br />

372 122 352 24 145<br />

20 23<br />

42••• 48•• 80 110 83<br />

M16<br />

42 48<br />

110<br />

84<br />

143<br />

398 137 332 392 28 177 65 228 72<br />

55 F 33 36<br />

55••• 60••• 110 58.5 74 104 M 20<br />

48 55<br />

110<br />

80 70 M 16 M 20<br />

145<br />

460 151 367 435 483 35 206 70 235 80<br />

56 F 48 52 59.7<br />

60 65••• 140 100 M 20<br />

48 55<br />

110<br />

80 M16 M20<br />

145<br />

M 27<br />

60 65••• 140 520 170 37 103<br />

67 73 82<br />

M20<br />

75• 80• – 140 170<br />

105 135<br />

380 460 540 225 75 288 90<br />

58 F<br />

48 55<br />

110 80 M16 M20<br />

145<br />

60 65••• 140 565 190 17 103 M20 74 80 89<br />

75• 80• – 140 170 105 135 M20<br />

– 60 65 140<br />

105<br />

17 D BORES RELATIVE TO TAPER BUSHES WITH A KEYWAY ACCORDING TO ISO 773 - DIN 6885/1<br />

520 170 37<br />

• CYLINDRICAL<br />

* 75 * 80 BORE WITHOUT 140 170 TAPER BUSH WITH A KEYWAY ISO 773 - DIN 6885/1<br />

105 135<br />

•• CYLINDRICAL BORE WITHOUT TAPER BUSH, WITH 380 A 460 REDUCED 540 KEYWAY 225(DIN75 6885/2) 288 90 M 27<br />

M 20<br />

••• TAPER 60 BUSH 65 WITHOUT KEY 140 WAY<br />

105<br />

19<br />

565 190 17<br />

* 75 * 80 140 170 AusführuAAAA CYLINDRICAL BORE VERSION<br />

80• 90 170<br />

496 596 686 45 130 M 20 M 24<br />

21<br />

620 205<br />

100•• 210 531 631 721 80<br />

165 M 24<br />

250 90 378 110 M 36<br />

80• 90<br />

170<br />

496 596 686 21 130 M 20 M 24<br />

24<br />

–<br />

714 229<br />

100•• 210 531 631 721 56 165 M 24<br />

J 1<br />

indicate input and output in the standard version.<br />

<strong>CK</strong>RM <strong>CK</strong>RM - C<strong>CK</strong>RM<br />

- C<strong>CK</strong>RM<br />

58 F<br />

65 F<br />

67 73 82<br />

74 80 89<br />

124 134 142<br />

142 152 160<br />

27<br />

120 max 210 780 278 525 643 743 6 315 100 462 122<br />

167 M 24<br />

(for max bore)<br />

66 F 211 229 248<br />

29<br />

135 max 240 860 295 577 695 795 18 350 120 530 145 M 45<br />

167 M 24<br />

(for max bore)<br />

68 F 293 311 321<br />

34<br />

150 max 265 1000 368 648 779 879 19 400 140 630 165<br />

– D BORES WITH A KEYWAY ACCORDING TO ISO 773 - DIN 6885/1<br />

• STANDARD DIMENSIONS WITH A KEYWAY ISO 773 - DIN 6885/1<br />

•• STANDARD DIMENSIONS WITH REDUCED KEYWAY (DIN 6885/2)<br />

– WHEN ORDERING, SPECIFY: SIZE - SERIE D DIAMETER - EXAMPLE: 13 <strong>CK</strong>RM-D 55<br />

200 M 36<br />

(for max bore)<br />

610 F 467 482 492<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Fluid couplings - 0808<br />

19

SERIES 17÷34 KRG3 - <strong>CK</strong>RG3 - C<strong>CK</strong>RG3 - 46C<strong>CK</strong>RG3<br />

KRBP3<br />

3<br />

(with brake disc)<br />

(with brake disc)<br />

Y<br />

C<br />

J<br />

C1<br />

C2<br />

R<br />

A<br />

H<br />

P<br />

G<br />

H7<br />

S<br />

D<br />

G7<br />

KRB3<br />

3<br />

(with brake drum)<br />

(with brake drum)<br />

L1<br />

(only for 17-19)<br />

L<br />

K<br />

D<br />

KRG3<br />

J1<br />

J<br />

<strong>CK</strong>RG3 - C<strong>CK</strong>RG3<br />

The three pieces flexible coupling B3T, allows the removal of the elastic elements (rubber blocks), without removal of the electric<br />

motor; only with the ..KRB3 (with brake drum) coupling the electric motor must be removed by the value of ‘Y’.<br />

‘Y’ = axial displacement male part of the coupling B3T necessary for the removal of the elastic elements.<br />

Dimensions<br />

Size<br />

17<br />

19<br />

D J J 1 A C C 1 C 2 G H K L L 1 P R S Y<br />

max<br />

Elastic<br />

coupling<br />

Weight kg<br />

(without oil)<br />

KRG3 <strong>CK</strong>RG3C<strong>CK</strong>RG3<br />

48 55<br />

110 80 M16 M20<br />

145<br />

60 65••• 140 520 103<br />

84 90 99<br />

M20<br />

75• 80• _ 140 - 170<br />

103 132<br />

418 498 578 80 240 3 110 82 130<br />

82 B3T-50<br />

48 55<br />

110 80 M16 M20<br />

145<br />

60 65••• 140 565 103<br />

M20 91 97 106<br />

75• 80• – 140 - 170 103 132<br />

– D BORES RELEVANT TO TAPER BUSH WITH KEYWAY ACCORDING TO ISO773 - DIN6885/1<br />

• STANDARD CYLINDRICAL BORES WITHOUT TAPER BUSH WITH KEYWAY ACCORDING TO ISO773 - DIN6885/1<br />

••• TAPER BUSH WITHOUT KEYWAY<br />

21<br />

24<br />

80• 90 170<br />

457 557 647 130 M20 M24<br />

620<br />

100•• 210 492 592 682 110 290 3 140 78 150 165 M24<br />

80• 90 170<br />

457 557 647 130 M20 M24<br />

714<br />

100•• 210 492 592 682 165 M24<br />

82 B3T-60<br />

134 144 152<br />

152 162 170<br />

27<br />

29<br />

120 max 210 – 780 566 684 784 167 M24 247 265 284<br />

130 354 4 150 112 180 120 B3T-80<br />

135 max 240 860 595 713 813 for max hole 300 318 328<br />

34<br />

150 max 265 1000 704 815 915 130 395 5 170 119 205<br />

200 M36<br />

for max hole<br />

151 B3T-90 505 481 491<br />

46<br />

180 max 320 – 1330 – – 1092 180 490 7 195 138 290<br />

190 M36<br />

for max hole<br />

122 B3T-100 – – 1102<br />

– D CYLINDRICAL BORES WITHOUT TAPER BUSH WITH KEYWAY ACCORDING TO ISO773 – DIN6885/1<br />

• STANDARD DIMENSIONS<br />

•• STANDARD DIMENSION WITH REDUCED HIGH KEYWAY (DIN 6885/2)<br />

– ON ORDER FORM PLEASE SPECIFY: DIMENSION, MODEL, DIAMETER D - EXAMPLE: 21C<strong>CK</strong>RG3 - D80 DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Fluid couplings - 0808<br />

145 GB_20<br />

20

SERIES 6÷27 KSD - <strong>CK</strong>SD - C<strong>CK</strong>SD<br />

B<br />

KSD<br />

C<br />

P<br />

E<br />

L<br />

K<br />

M<br />

N<br />

G<br />

F ±0.1<br />

f7<br />

H<br />

cylindrical bore<br />

D<br />

G7<br />

J 1<br />

Q<br />

only for size “6”<br />

Size<br />

Weight kg<br />

(without oil)<br />

A<br />

I<br />

S<br />

D T<br />

6<br />

7<br />

KSD <strong>CK</strong>SD C<strong>CK</strong>SD<br />

3.2<br />

5.9 –<br />

8<br />

6.5<br />

B1<br />

B2<br />

<strong>CK</strong>SD-C<strong>CK</strong>SD<br />

C1<br />

C2<br />

J<br />

R<br />

D<br />

In case of installation on shafts without<br />

shoulders, please contact <strong>Transfluid</strong><br />

taper bush<br />

J 1<br />

9<br />

11<br />

12<br />

13<br />

15<br />

17<br />

19<br />

21<br />

24<br />

13 –<br />

15 17.5<br />

19 22<br />

31 34<br />

46 50 57.5<br />

74 80 89<br />

82 88 97<br />

110 120 128<br />

127 137 145<br />

NB: The arrows<br />

indicate input and output in the standard version.<br />

27<br />

184 202 221<br />

Dimensions<br />

TAPER BUSH VERSION<br />

Size<br />

D J J 1 A B B 1 B 2 C C 1 C 2 E F G H I K L M N P Q R S T<br />

6<br />

7<br />

8<br />

9<br />

11<br />

12<br />

13<br />

15<br />

17<br />

19<br />

KSD <strong>CK</strong>SD C<strong>CK</strong>SD max <strong>CK</strong>SD C<strong>CK</strong>SD Nr. Ø max<br />

•19 – 45 195 60 140 62 45 57 – 7 42 88 17 – – – 35<br />

19 24 40 50<br />

159 55 35 29 38 M 6 M 8<br />

228 77<br />

28<br />

60<br />

174 70<br />

4 M 6<br />

50 3<br />

43 M 10<br />

69<br />

–<br />

75 90<br />

8<br />

114 14 M 12<br />

50<br />

24 50<br />

–<br />

33 M 8<br />

256 91 194<br />

81 – 65<br />

28 60 43 M 10<br />

28 38 60 80<br />

–<br />

39 54 M 10 M 12<br />

•••42<br />

80<br />

295 96<br />

–<br />

250<br />

116<br />

78 M 16<br />

111<br />

96 114 85 5 128 20<br />

69<br />

28 38 60 80<br />

38 59 M 10 M 12<br />

•••42 80<br />

325 107 73.5 259 289.5 113 8 195 M 20<br />

78 M 16<br />

M8 13<br />

38 42<br />

80 110<br />

54 83 M 12 M 16<br />

•••48<br />

113<br />

110<br />

372 122 274 327 125 112 130 98 7 145 22<br />

83 M 16<br />

80<br />

80 224<br />

42 48<br />

110<br />

76 M 16<br />

•••55 •••60<br />

144<br />

110 58.5<br />

398 137 367 407 190 135 155 158 6 177 29<br />

76 106 M 20<br />

88<br />

48 55<br />

110<br />

80 70 M 16 M 20<br />

60 •••65<br />

145<br />

140<br />

460 151 92 140 390 438 486 195 150 178 259 17 159 206 28<br />

100 M 20<br />

100<br />

48 55<br />

110 12<br />

69<br />

60 •••65<br />

145<br />

140 520 170 245<br />

60<br />

M27<br />

99<br />

M10 7<br />

•75 •80 – 140 170<br />

99 139<br />

101 181 455 516 596 180 200 337 17 180 225<br />

M 20 132<br />

48 55<br />

110 69<br />

60 •••65<br />

145<br />

140 565 190 225 45 99<br />

•75 •80 – 140 170 99 139<br />

– D BORES RELATIVE TO TAPER BUSHES WITH A KEYWAY ACCORDING TO ISO 773 - DIN 6885/1<br />

60 65 140<br />

103<br />

17 PARTICUALR CASES: 520 170 245 60<br />

• CYLINDRICAL •75 •80 BORE 140 WITHOUT 170 TAPER BUSH ISO 773 - DIN 6885/1<br />

103 143<br />

••• TAPER BUSH WITHOUT A KEYWAY 101 181 455 516 596 180 200 12 M 10 337 17 180 225 M 27<br />

60 65 140<br />

103<br />

19<br />

565 190 225 45<br />

•75 •80 140 170 CYLINDRICAL BORE VERSION<br />

103 143<br />

M 20<br />

21<br />

•80<br />

•100<br />

170<br />

210<br />

505 580<br />

545<br />

670<br />

620<br />

260<br />

710<br />

190<br />

300<br />

135 M 20<br />

230<br />

165 M 24<br />

620 205<br />

57<br />

24<br />

•80 – 170<br />

115 205<br />

505 580 670 236<br />

200 228 8 M 14 400 20<br />

190<br />

7 250 M 36<br />

135 M 20<br />

•100 210<br />

714 229<br />

545 620 710 276 230<br />

46<br />

165 M 24<br />

27 120 max 210 780 278 138<br />

CONSULT OUR ENGINEERS<br />

132<br />

145<br />

• STANDARD CYLINDRICAL BORES WITH KEYWAYS ACCORDING TO ISO 773 - DIN 6885/1<br />

– WHEN ORDERING SPECIFY: SIZE - MODEL - D DIAMETER<br />

EXAMPLE: 12KSD - D 42<br />

DIMENSIONS ARE SUBJECT TO ALTERATION WITHOUT NOTICE<br />

Fluid couplings - 0808<br />

21

STANDARD PULLEYS<br />

..KSI - ..KSDFKSI - KSDF<br />

V<br />

U<br />

Z<br />

D<br />

D p<br />

...KSI<br />

..<strong>CK</strong>SI - ..<strong>CK</strong>SDF<br />

...KSDF<br />

..KSDF<br />

Dimensions<br />

Size<br />

D<br />

U<br />

Flanged<br />

pulley<br />

Dp<br />

N° type<br />

Size<br />

6<br />

7<br />

8<br />

9<br />

11<br />

12<br />

D<br />

Dimensions<br />

U<br />

Dp<br />

Integral<br />

pulley<br />

N° type<br />

63<br />

19 24 80<br />

100<br />

80<br />

19 - 24 11.5 90 2 - SPA/A<br />

100<br />

80<br />

28 26.5 90<br />

100<br />

19 - 24 90<br />

26.5<br />

28<br />

100 3 - SPA/A<br />

28 - 38 10 112 5 - SPA/A<br />

42 15 125 4 - SPB/B<br />

38 - 42<br />

48<br />

12 140 5 - SPB/B<br />

GROOVE V Z<br />

SPZ-Z 12 8<br />

SPA-A 15 10<br />

SPB-B 19 12.5<br />

SPC/C 25.5 17<br />

D 37 24<br />

3 V 10.3 8,7<br />

5 V 17.5 12.7<br />

8 V 28.6 19<br />

7<br />

8<br />

9<br />

11<br />

12<br />

13<br />

15<br />

17<br />

19<br />

21<br />

24<br />

27<br />

19 - 24 6<br />

125<br />

28 21<br />

2 - SPA/A<br />

19 - 24 36 125<br />

28<br />

9 112 3 - SPA/A<br />

28 - 38 34 160 4 - SPB/B<br />

42 58 200 3 - SPB/B<br />

50 180 4 - SPB/B<br />

38 - 42<br />

51<br />

48<br />

200 3 - SPC/C<br />

26 4 - SPC/C<br />

12.5 180 6 - SPB/B<br />

42 - 48<br />

50<br />

55 - 60<br />

250 6 - SPB/B<br />

49 5 - SPC/C<br />

12.5 200 6 - SPB/B<br />

48 - 55<br />