Grooving & API THREADING, - Dorian Tool International

Grooving & API THREADING, - Dorian Tool International

Grooving & API THREADING, - Dorian Tool International

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

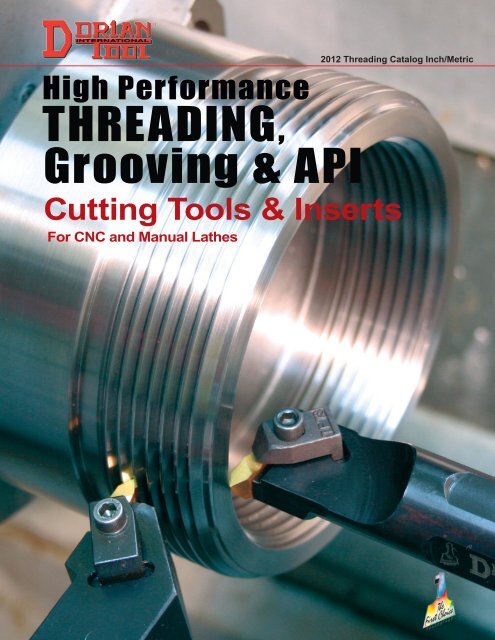

High Performance<br />

<strong>THREADING</strong>,<br />

<strong>Grooving</strong> & <strong>API</strong><br />

Cutting <strong>Tool</strong>s & Inserts<br />

For CNC and Manual Lathes<br />

2012 Threading Catalog Inch/Metric<br />

Threading Catalog $3.95

Enrico R. Giannetti<br />

President<br />

A Word from the President:<br />

S<br />

ince the introduction of the Quadra Index <strong>Tool</strong><br />

Post in 1982, the <strong>Dorian</strong> Evolution has never<br />

stopped. By developing new ideas and promoting<br />

new technology, <strong>Dorian</strong> <strong>Tool</strong> has continuously<br />

improved our service, technical support, and<br />

delivery to our customers.<br />

At <strong>Dorian</strong> <strong>Tool</strong>, the quest for innovative tools will never end.<br />

Our highly trained and skilled engineers have developed technology<br />

that set new standards in the industry and changed the<br />

machining process forever.<br />

Today, <strong>Dorian</strong> <strong>Tool</strong> offers a wide selection of products for manual<br />

and CNC machines. From carbide inserts to toolholders; knurling<br />

tools to marking tools; machine tool accessories to automated<br />

turrets & rotary tables; tool setters to tool presetters; our tool<br />

selection has become the First Choice Technology for thousands<br />

of small and large shops around the world.<br />

Thank you for making <strong>Dorian</strong> <strong>Tool</strong> successful. Our success comes<br />

from the original commitment we made to our customers:<br />

Technology, Quality, & Service<br />

Corporate Headquarters &<br />

40,000 SQ Foot Manufacturing Plant<br />

East Bernard, Texas U.S.A.<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

Table Of Contents<br />

Page<br />

Jet-Stream Thru Coolant System 2-3<br />

Threading and <strong>Grooving</strong> Recommendation Form 4<br />

Threading and <strong>Grooving</strong> System 5<br />

Threading & <strong>Grooving</strong> Technical Data 6-12<br />

Threading & <strong>Grooving</strong> Insert Grades 13<br />

Threading & <strong>Grooving</strong> Insert Index 14<br />

On Edge<br />

• On Edge Threading and <strong>Grooving</strong> Inserts 15-20<br />

• On Edge Threading and <strong>Grooving</strong> <strong>Tool</strong>holders 21-26<br />

Laydown<br />

• Laydown Threading Inserts 27-36<br />

• Laydown Threading and <strong>Grooving</strong> <strong>Tool</strong>holders 37-42<br />

DorNotch<br />

• DorNotch Threading and <strong>Grooving</strong> Inserts 43-48<br />

• DorNotch Threading and <strong>Grooving</strong> <strong>Tool</strong>holders 49-54<br />

V-Bottom<br />

• V-Bottom Threading and <strong>Grooving</strong> Inserts 53<br />

• V-Bottom Threading and <strong>Grooving</strong> <strong>Tool</strong>holders 54<br />

<strong>API</strong><br />

• <strong>API</strong> On Edge Threading and <strong>Grooving</strong> Inserts 56-47<br />

• <strong>API</strong> On Edge Threading and <strong>Grooving</strong> <strong>Tool</strong>holders 58-59<br />

• <strong>API</strong> Laydown Threading Inserts 60-64<br />

• <strong>API</strong> Laydown Threading <strong>Tool</strong>holders 65-67<br />

• <strong>API</strong> V-Bottom Threading and <strong>Grooving</strong> Inserts 68<br />

• <strong>API</strong> V-Bottom Threading and <strong>Grooving</strong> <strong>Tool</strong>holders 69<br />

• <strong>API</strong> DorNotch Threading and <strong>Grooving</strong> Inserts 70<br />

• <strong>API</strong> DorNotch Threading and <strong>Grooving</strong> <strong>Tool</strong>holders 71-72<br />

• L-<strong>API</strong> Threading Inserts 73-75<br />

• L-<strong>API</strong> Threading <strong>Tool</strong>holders 76<br />

• <strong>API</strong> Chaser Threading Inserts 77<br />

• <strong>API</strong> Chaser Threading <strong>Tool</strong>holders 78<br />

Threading & <strong>Grooving</strong> Spare Parts 79-80<br />

Threading & <strong>Grooving</strong> Product Index 81-83<br />

Catalog Request Form 84<br />

Sales Policy 85<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 1

On Target!<br />

At The Cutting Edge<br />

70 to 1400 psi (5 - 100 Bar)<br />

<strong>Dorian</strong> Jet-Stream<br />

Thru Coolant System Will:<br />

Improve Quality!<br />

Improve Productivity!<br />

Improve Insert Life!<br />

Ask for a copy of<br />

our Jet-Stream<br />

Catalog for<br />

Thru Coolant<br />

Turning, Boring<br />

and Threading<br />

<strong>Tool</strong>s<br />

<strong>Dorian</strong> <strong>Tool</strong>’s Jet-Stream Thru Coolant Cutting <strong>Tool</strong>s use a<br />

patented thru-coolant locking clamp which is precisely aimed to<br />

direct high pressure, high velocity coolant exactly onto the cutting<br />

edge of the carbide insert, from a short distance of ¼”.<br />

This controlled Jet-Stream coolant, directed onto the insert chip<br />

interface (right under the chip and over the insert cutting edge) will<br />

dissipate the generated heat very effectively as well as lubricate<br />

the cutting edge of the insert, causing the chips to hydroplane<br />

over the insert surface instead of adhering to it. As a result, the<br />

insert will operate at a constant low temperature, with a clean<br />

and undamaged cutting edge, changing the way metal is cut.<br />

Higher speeds and feeds can be achieved, with a better<br />

surface finish, tolerance control and machining performance.<br />

The insert life is extended up to 200%.

Performance is Improved With:<br />

• Extreme Lubrication at the cutting edge<br />

• Extreme Heat Dissipation at the cutting edge<br />

• Constant Low Cutting Edge Temperature<br />

• Greater Chip Control and Evacuation<br />

• Chip Breaking at High Pressures<br />

• Smooth Cutting Action and Surface Finish<br />

• Increased Speeds and Feeds<br />

Why The <strong>Dorian</strong> Jet-Stream<br />

The advanced and unique technology of the Jet-Stream Thru<br />

Coolant System, offers the ability to process the coolant supplied<br />

from the machine’s pump with maximum efficiency, speed<br />

and volume. The speed and volume of the coolant coming out<br />

of the Jet-Stream nozzle directly onto the insert cutting edge<br />

will improve machining performance.<br />

Anyone who is even casually involved with metalworking<br />

knows that cutting tools generate large amounts of heat, which<br />

is detrimental to the usable life of carbide inserts.<br />

To overcome this problem with standard turning tools, the operator<br />

aims the coolant by hand at the tool using snap together<br />

plastic beads or copper tubing. Every operator does it differently,<br />

and during machining operation the coolant lines are<br />

frequently pushed out of alignment so that the operator has<br />

to manually readjust the aim of the coolant, often every time<br />

they change a part. One coolant manufacturer estimates that<br />

40% of the time the coolant doesn’t hit the tool or the part.<br />

Even when the coolant hits the tool there is no directional control;<br />

it typically comes from the top and hits the chips before it<br />

can reach the insert’s cutting edge where heat is accumulating.<br />

Real process control from setup to setup and throughout a production<br />

run is virtually nonexistent.<br />

Improved Productivity:<br />

The Jet-Stream Thru Coolant System will immediately improve<br />

machine performance with higher sfm (surface footage),<br />

extended tool life, ability to hold closer tolerances, and<br />

improvement of surface finish. The Jet-Stream tooling will<br />

excel because it makes machining simple and easy for materials<br />

ranging from low carbon steel to high temper alloys, exotics<br />

and aerospace materials.<br />

How to Optimize Productivity:<br />

A minimum of 70 psi is required for the Jet-Stream to show<br />

improvements in machining performance. To reach optimum<br />

results, higher coolant pressure and volume are necessary.<br />

Maximum performance will be achieved at 1000 psi with a coolant<br />

volume of ½ gpm (gallon per minute) per machine horsepower.<br />

Example: A 15 HP machine will need a coolant pump of<br />

1000 psi with 7.5 gpm of coolant volume.<br />

How To Guarantee Results:<br />

• DO NOT exceed the insert machining data.<br />

• DO Not take too deep of a cut without the proper<br />

coolant pressure and volume.<br />

• If the chips are not breaking your machining data<br />

or insert are incorrect.<br />

• Make sure you have a large enough coolant pump on<br />

the machine to supply sufficient coolant volume when<br />

high and super high pressure is required.<br />

Jet-Stream Threading <strong>Tool</strong>s on Pages:<br />

• On Edge Jet-Stream see pages 25-26 & 59 (<strong>API</strong>)<br />

• Laydown Jet-Stream see Pages 41-42 & 65-67 (<strong>API</strong>)<br />

• DorNotch Jet-Stream see Pages 51-52 & 72 (<strong>API</strong>)<br />

• V-Bottom Jet-Stream see Pages 54 & 69 (<strong>API</strong>)<br />

For more information you can also refer to our<br />

Jet-Stream catalog.<br />

Chip Flush<br />

Vertical Locking<br />

Force<br />

Locking<br />

Screw Rotation<br />

Horizontal<br />

Pull Locking Force<br />

Jet-Stream Threading Bars<br />

Air or Liquid<br />

Coolant<br />

1/8 NPT<br />

Locking<br />

Screw Rotation<br />

Horizontal<br />

Pull Locking Force<br />

Vertical Locking<br />

Force<br />

Jet-Stream Threading <strong>Tool</strong>holders<br />

Air or Liquid<br />

Coolant<br />

1/8 NPT<br />

Allows quick connection to CNC Turret<br />

1/8 NPT<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 3

Threading and <strong>Grooving</strong> Recommendation Form<br />

When selecting an indexable threading tool & Insert you must check the appropriate box for each area below and fax to 979-282-2951.<br />

1. Operations O.D. Threading O.D. <strong>Grooving</strong> I.D. Threading I.D. <strong>Grooving</strong> O.D. <strong>API</strong> I.D. <strong>API</strong><br />

2. Thread Size inch mm inch mm inch mm inch mm inch mm inch mm<br />

3. Material Carbon Steel<br />

Hardened Steel<br />

PH Series Stainless Steel<br />

300 Series Stainless Steel<br />

Aluminum<br />

Non-Ferrous<br />

Alloy Steel<br />

Martensitic Stainless Steel<br />

400 Series Stainless Steel<br />

Cast Iron<br />

High Temper Alloy<br />

4. <strong>Tool</strong> Shank OnEdge Laydown DorNotch V Bottom L-<strong>API</strong> <strong>API</strong> Chaser<br />

5. <strong>Tool</strong> Size Square Shank Size: Threading Bar Size:<br />

6. Cutting Direction<br />

Square Shank<br />

Threading Bar<br />

Right Hand Left Hand Right Hand Left Hand<br />

7. Machine Type Manual Swiss CNC Other<br />

8. Insert Geometry On Edge Laydown DorNotch V-Bottom L-<strong>API</strong> <strong>API</strong> Chaser<br />

9. Insert Size I.C. 3/8" I.C. 6mm No. 2 84 43 I.C. Buttress<br />

1/2" I.C. 8mm No. 3 85 Ext. Buttress SET<br />

T<br />

I.C.<br />

60°<br />

5/8" I.C. 11mm No. 4 96 Round<br />

16mm No. 6 98 Round SET<br />

22mm 120 Line Pipe<br />

27mm<br />

10. (a) Insert TPI<br />

Inch Diameter Length TPI<br />

Distance<br />

between tooth<br />

10. (b) Insert Pitch<br />

Metric Diameter Length Metric Pitch<br />

Quote No.<br />

P.O. No.<br />

Recommended By : To be Completed by <strong>Dorian</strong> <strong>Tool</strong> Engineering Department Company Name:<br />

UPC No. 733101- Description Delivery<br />

Contact Name:<br />

Square Shank Phone No: ( )<br />

Threading Bar Fax No: ( )<br />

Insert<br />

Address<br />

4 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

<strong>Dorian</strong> <strong>Tool</strong> Threading, <strong>API</strong>, and <strong>Grooving</strong> System<br />

On Edge<br />

"THE ECONOMY SYSTEM"<br />

Laydown Threading<br />

"THE CLEARANCE SYSTEM"<br />

DorNotch Threading<br />

"THE RIGIDITY SYSTEM"<br />

3 Cutting Edge<br />

3 Cutting Edge<br />

2 Cutting Edge<br />

External<br />

External<br />

External<br />

Internal<br />

Internal<br />

Internal<br />

The most popular threading and grooving system in<br />

the industry. The toolholders and boring bars are to<br />

be used with threading or grooving inserts, for either<br />

external or internal applications, in right or left hand<br />

cutting direction.<br />

• Two (2) types of locking systems available:<br />

• "M" - Multi lock system for TNMA style insert<br />

• "S" - Torx screw locking system for TNMC style<br />

insert<br />

On edge 60° triangle threading inserts have three (3)<br />

cutting edges. The insert is mounted on the side or end<br />

of the threading holder or boring bar. The same insert<br />

can be used for either OD or ID threading, in right hand<br />

or left hand cutting direction.<br />

• "A" style with straight hole for "M" style holder and<br />

boring bar<br />

• "C" style with double countersink for "S" style holder<br />

and boring bar<br />

The on edge system offers a complete selection of<br />

thread, <strong>API</strong>, and groove form inserts.<br />

The most compact system designed for external or<br />

internal threading applications, for right and left hand<br />

cutting direction. The great advantage of this system over<br />

others, is the ability to thread the smallest bore diameters<br />

allowed in single point threading operation.<br />

The three (3) cutting edge insert is locked down in horizontal<br />

position over the holder or boring bar, allowing<br />

the chip to flow without restriction.<br />

The laydown threading system offers the most complete<br />

selection of thread-form insert line in inches (TPI), metric<br />

(ISO), and <strong>API</strong> with single and multi thread form, in full<br />

or partial thread profile.<br />

The unique clamping design of DorNotch, makes it the<br />

most rigid threading system. The insert nested on the<br />

side of the holder or the end of the boring bar is held<br />

extremely secure with a top clamp, forcing the insert<br />

down and against the walls of the pocket. This assures<br />

the best tool life, a chatter free surface finish, and a<br />

precise workpiece quality.<br />

DorNotch threading and grooving holders and boring<br />

bars are built with precise quality. They are available in<br />

many sizes, making the DorNotch holders and boring<br />

bars the perfect choice for heavy duty threading applications,<br />

for either OD or ID applications, in right hand or<br />

left hand cutting direction.<br />

The DorNotch threading and grooving system offers<br />

a large selection of thread, <strong>API</strong>, and groove form<br />

inserts.<br />

Machining Applications Machining Applications Machining Applications<br />

Best Good Best Not Available Best Best<br />

External Threading <strong>Grooving</strong> Internal Threading <strong>Grooving</strong> Threading Int. & Ext. <strong>Grooving</strong><br />

NA<br />

Positive<br />

Rake<br />

Insert Cutting Edge Insert Cutting Edge Insert Cutting Edge<br />

Threading <strong>Grooving</strong> Threading Threading <strong>Grooving</strong><br />

Negative<br />

Rake<br />

Positive<br />

Rake<br />

Negative<br />

Rake<br />

Positive<br />

Rake<br />

Positive<br />

Rake<br />

Negative<br />

Rake<br />

Positive<br />

Rake<br />

Negative<br />

Rake<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 5

Technical Data<br />

Threading, <strong>Grooving</strong> & <strong>API</strong> Methods<br />

O.D Threading I.D. Threading <strong>Grooving</strong> <strong>API</strong><br />

Thread Terminology<br />

ANSI Distance<br />

between tooth<br />

ISO<br />

Distance<br />

between tooth<br />

Single Lead Thread<br />

Single Start<br />

Double Lead Thread<br />

Double Start<br />

Thread Definitions<br />

Crest - The outer most surface<br />

of the thread form which<br />

joins the flanks.<br />

Helix angle - The angle between<br />

the direction of the<br />

threads around a screw and<br />

a line running at a right angle<br />

to the shank.<br />

Lead - The distance a thread<br />

will advance along its axis in<br />

one complete revolution.<br />

major diameter - The largest<br />

diameter of a straight screw<br />

thread.<br />

Minor diameter - The smallest<br />

diameter of a screw<br />

thread. Also known as the<br />

“root diameter.”<br />

Pitch - The distance from<br />

any point on a thread to<br />

the corresponding point on<br />

the adjacent thread measured<br />

parallel to the axis.<br />

Pitch diameter - The diameter<br />

of a thread at an<br />

imaginary point where the<br />

width of the groove and<br />

the with of the thread are<br />

equal.<br />

Root - The inner most surface<br />

of a thread form.<br />

Thread angle - The angle<br />

formed by the two sides of<br />

the thread (or their projections)<br />

with each other.<br />

Right Hand Thread<br />

Left Hand Thread<br />

Triple Lead Thread<br />

Triple Start<br />

6 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

Profile Selection Chart<br />

Industry Standard Threads<br />

Thread Type ISO Metric American UN Whitworth American NPT<br />

Profiles<br />

Thread Use General Purpose Pipe fittings for gas, water and sewer<br />

Thread Type Round Round BSPT American NPTF<br />

Profiles<br />

Thread Use Pipe fittings for food service applications Pipe fittings for steam, gas and water<br />

Thread Type American Buttress Metric Buttress UNJ<br />

Profiles<br />

Thread Use Pipe fittings for steam, gas and water Aerospace applications<br />

Thread Type 30º Trapez ACME ACME Stub ACME<br />

Profiles<br />

Thread Use<br />

Motion transmissions<br />

Thread Type <strong>API</strong> Round Buttress Rotary Shoulder<br />

Profiles<br />

Thread Type X-Line Hughes H90<br />

Profiles<br />

Thread Use<br />

Oil and gas<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 7

Technical Data<br />

Thread Cutting Methods<br />

In-feed Angle & Cutting Directions (<br />

) Shown below<br />

Single Infeed Angle<br />

Single Infeed Angle<br />

Infeed & Crossfeed Angle<br />

Infeed & Double Crossfeed Angle<br />

1 1<br />

2<br />

1<br />

1<br />

2 3<br />

Radial Infeed<br />

(Cut both sides simultanousely)<br />

Flank Infeed<br />

(Cut one side only)<br />

Modified Flank<br />

(Cut one side only & finish opposite)<br />

Alternating Flank<br />

(Multicut)<br />

Pros:<br />

• Most commonly used. Often only choice in<br />

mechanical operations<br />

• Edge is protected from chipping since all of the<br />

cutting edge is located in the cut<br />

Pros:<br />

• Leading edge of insert is used to make the cut<br />

resulting in better chip flow<br />

• Reduced Burring<br />

Pros:<br />

• Edge is protected from chipping since all of the<br />

cutting edge is located in the cut<br />

Pros:<br />

• Mainly used for large profiles<br />

• Increased <strong>Tool</strong> Life<br />

• Insert wears evenly<br />

Cons:<br />

• Channel chip is created that may be difficult<br />

to control<br />

• Burr condition is increased<br />

• Tends to chatter<br />

Cons:<br />

• Trail edge of insert is prone to chipping<br />

• Poor choice of soft materials like aluminum,<br />

stainless steel or low carbon steel<br />

Cons:<br />

• Channel chip is created that may be difficult<br />

to control<br />

• Burr condition is increased<br />

• Tends to chatter<br />

Cons:<br />

• Difficult to achieve manually<br />

• Requires special programs on CNC<br />

machines<br />

Infeed Values for Threading<br />

a p<br />

= Depth of cut (doc) Inch/mm<br />

a 1<br />

= Infeed 1 Inch/mm<br />

a #<br />

= Accumulated depth per pass Inch/mm<br />

Threading Formulas<br />

P = Pass number Inch/mm<br />

l #<br />

= Infeed per pass Inch/mm<br />

Note: # = Infeed pass number 2, 3, 4, etc<br />

Infeed for<br />

Pass 1<br />

25% of Total<br />

a 1<br />

=<br />

a p<br />

4<br />

Example:<br />

Determine the first pass infeed(a 1<br />

) for a thread with a total depth(a p<br />

)<br />

of 0.132 inches.<br />

a 1<br />

= 0.132<br />

4<br />

= 0.033 in<br />

Accumulated<br />

Infeed for Additional<br />

Passes<br />

a #<br />

= a 1<br />

x P<br />

Example:<br />

Determine the accumulated infeed(a #<br />

) for the fourth pass(P) on<br />

a thread with a total depth(a p<br />

) of 0.132 inches and a first pass<br />

infeed(a 1<br />

) of 0.033 inches.<br />

a 4<br />

= 0.033 x 4 = 0.066 in<br />

Infeed per<br />

Individual Pass<br />

I p<br />

= a #<br />

- a #-1<br />

Example:<br />

Determine the infeed for third pass of a threading operation with<br />

an accumulated infeed for the third pass(a #<br />

) of 0.0572 and an<br />

accumulated infeed of 0.0467 for the second pass(a #-1<br />

).<br />

lp = 0.0572 - 0.0467 = 0.0105<br />

Multi-Tooth<br />

Applications<br />

• As a rule of thumb, divide the total number<br />

of infeed passes required for a single tooth<br />

insert by the number of teeth on a multi-tooth<br />

insert to find total infeed passes needed.<br />

• Find accumulated infeed depths for multiples<br />

of the tooth number<br />

(For 3 teeth find a p<br />

for passes 1, 3, 6, 9, etc)<br />

8 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

Technical Data<br />

Recommended Infeed Values for External UN Threads - Steel<br />

No. Of<br />

Passes<br />

TPI<br />

4 5 6 7 8 9 10 11 12 13 14 16 18 20 24 28 32 36 40 44 48<br />

1 .0353 .0298 .0248 .0213 .0197 .0175 .0169 .0157 .0152 .0142 .0136 .0125 .0124 .0119 .0118 .0112 .0098 .0087 .0078 .0073 .0065<br />

2 .0146 .0122 .0105 .0088 .0082 .0073 .0070 .0066 .0064 .0057 .0059 .0054 .0053 .0049 .0048 .0046 .0042 .0036 .0032 .0028 .0027<br />

3 .0113 .0094 .0078 .0077 .0063 .0056 .0053 .0048 .0048 .0044 .0043 .0039 .0039 .0039 .0039 .0036 .0031 .0028 .0028 .0022 .0020<br />

4 .0095 .0079 .0067 .0059 .0053 .0047 .0045 .0041 .0042 .0037 .0036 .0034 .0033 .0032 .0031 .0031 .0026 .0024 .0020 .0020 .0019<br />

5 .0084 .0070 .0058 .0050 .0047 .0042 .0039 .0036 .0036 .0033 .0032 .0029 .0029 .0028 .0027<br />

6 .0076 .0063 .0052 .0045 .0043 .0037 .0036 .0031 .0032 .0030 .0029 .0026 .0026 .0025<br />

7 .0070 .0058 .0048 .0041 .0039 .0034 .0031 .0028 .0029 .0027 .0026 .0024 .0024 .0023<br />

8 .0065 .0054 .0045 .0038 .0036 .0032 .0030 .0026 .0027 .0025 .0024 .0022 .0022<br />

9 .0061 .0051 .0042 .0036 .0034 .0030 .0029 .0025 .0026 .0024 .0023 .0021<br />

10 .0057 .0048 .0040 .0034 .0032 .0028 .0028 .0024 .0025 .0023 .0022 .0020<br />

11 .0054 .0045 .0038 .0032 .0031 .0027 .0027 .0023 .0023 .0022 .0021<br />

12 .0052 .0043 .0036 .0031 .0029 .0026 .0026 .0022 .0022 .0021<br />

13 .0049 .0042 .0035 .0030 .0027 .0025 .0025 .0021<br />

14 .0048 .0041 .0034 .0029 .0026 .0024 .0024 .0020<br />

15 .0046 .0040 .0033 .0028 .0025 .0023<br />

16 .0044 .0039 .0032 .0027 .0025 .0022<br />

17 .0043 .0038 .0031 .0026<br />

18 .0042 .0037 .0030 .0025<br />

19 .0041<br />

20 .0039<br />

Recommended Infeed Values for Internal UN Threads - Steel<br />

No. Of<br />

Passes<br />

TPI<br />

4 5 6 7 8 9 10 11 12 13 14 16 18 20 24 28 32 36 40 44 48<br />

1 .0303 .0255 .0213 .0183 .0169 .0150 .0145 .0132 .0131 .0120 .0117 .0107 .0106 .0102 .0101 .0096 .0084 .0075 .0067 .0061 .0056<br />

2 .0125 .0105 .0090 .0076 .0073 .0062 .0064 .0055 .0054 .0050 .0048 .0043 .0044 .0042 .0042 .0039 .0035 .0031 .0029 .0025 .0023<br />

3 .0096 .0083 .0069 .0058 .0053 .0047 .0046 .0044 .0041 .0038 .0037 .0034 .0033 .00323 .0032 .0033 .0027 .0023 .0021 .0019 .0017<br />

4 .0081 .0068 .0057 .0049 .0047 .0040 .0038 .0035 .0035 .0032 .0031 .0028 .0028 .0027 .0027 .0025 .0023 .0021 .0018 .0018 .0011<br />

5 .0071 .0060 .0050 .0043 .0041 .0035 .0034 .0031 .0031 .0028 .0027 .0025 .0025 .0024 .0023<br />

6 .0064 .0054 .0045 .0039 .0036 .0032 .0031 .0028 .0028 .0025 .0025 .0029 .0023 .0022<br />

7 .0059 .0050 .0041 .0036 .0033 .0029 .0028 .0026 .0026 .0023 .0023 .0021 .0021 .0021<br />

8 .0055 .0046 .0038 .0033 .0030 .0027 .0026 .0024 .0024 .0022 .0021 .0020 .0029<br />

9 .0052 .0043 .0036 .0031 .0028 .0025 .0024 .0022 .0022 .0021 .0020 .0019<br />

10 .0049 .0041 .0034 .0029 .0027 .0024 .0023 .0022 .0022 .0020 .0019 .0018<br />

11 .0046 .0039 .0032 .0028 .0026 .0023 .0022 .0020 .0020 .0019 .0018<br />

12 .0044 .0037 .0031 .0027 .0025 .0022 .0021 .0019 .0019 .0018<br />

13 .0042 .0036 .0030 .0026 .0024 .0021 .0020 .0018<br />

14 .0041 .0035 .0029 .0025 .0023 .0020 .0019 .0017<br />

15 .0040 .0034 .0028 .0024 .0022 .0019<br />

16 .0039 .0033 .0027 .0023 .0021 .0019<br />

17 .0038 .0032 .0026 .0022<br />

18 .0037 .0031 .0025 .0021<br />

19 .0036<br />

20 .0035<br />

Note: Information provided in these charts and<br />

found using the formulas on the preceding page<br />

are to be used as a starting point only and may<br />

need to be adjusted to accommodate actual<br />

working conditions.<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 9

Technical Data<br />

<strong>Grooving</strong> Methods<br />

Internal/External <strong>Grooving</strong> Profiling Undercutting<br />

Always make sure that the toolholder is held at a 90º angle to<br />

the material being turned.<br />

<strong>Grooving</strong><br />

Insert center height should be kept at the center line of the<br />

workpiece to .005 above the centerline<br />

For best results keep the fade rate between .003 and .012 ipr<br />

Dwell tool in bottom of cut no more than three revolutions.<br />

Back Turning<br />

Insert center height should be kept at the center line of the<br />

workpiece to .005 above the centerline<br />

For best results keep the fade rate between .003 and .012 ipr<br />

Maximum depth of cut should be kept below .110 for .250 IC<br />

inserts and .150 for .375 IC inserts<br />

Wide Grooves<br />

Plunge both sides of the groove width first.<br />

Plunge the center area to clean out the remaining material.<br />

If angled walls are required for the groove, perform as a final<br />

operation.<br />

For best results keep the fade rate between .003 and .012 ipr<br />

See profiling to finish the groove.<br />

Profiling<br />

Rough the profile as if cutting a wide groove.<br />

Plunge from each end and turn to the center of the profile in<br />

order to ensure wall perpendicularity<br />

If using a radius insert, depth of cut should not exceed the<br />

insert radius size.<br />

10 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

Technical Data<br />

Threading & <strong>Grooving</strong> Application Data Chart<br />

Material Application Non Ferrous Ferrous Ferrous & Non Ferrous<br />

Industry standard Insert Grade<br />

Insert Coating PVD+TiN PVD+TiN PVD-TiN+TiAlN+TiN<br />

(A.N.S.I. - C3-C4, C7-C8)<br />

(I.S.O. - K05-K15, K05-, K10-K30)<br />

(A.N.S.I. -C5-C6)<br />

(I.S.O. -P15-P35, M20-M35)<br />

(A.N.S.I. - C2-C3, C6-C7)<br />

(I.S.O. - K05-K25, K15-K35)<br />

<strong>Dorian</strong> Insert Grade DVK10 DVP656 DASK25B<br />

Sharper Edge Honed Edge Honed Edge<br />

Insert<br />

Rake<br />

Material to be Machined<br />

Recommended Surface Speed per Minute - Feet /min - sfm (Vc)<br />

(m)<br />

Low Carbon Steel and<br />

free Machining Steel<br />

250 - 450<br />

(76 - 137)<br />

300 - 500<br />

(91 - 152)<br />

Negative<br />

Carbon steel, Alloy Steel and<br />

<strong>Tool</strong> Steel

Technical Data<br />

Trouble Shooting<br />

Problem Cause Solution<br />

Edge<br />

Wear<br />

• Cutting speed too high<br />

• Infeed depth too shallow<br />

• Insert is above senter line<br />

• Increase feeds<br />

• Adjust fenter feights<br />

• Reduce speed<br />

• Use tnsert with more wear resistant grade<br />

Heat<br />

Deformation<br />

• Cutting temperature too high<br />

• Pressure too high<br />

• Not enough coolant<br />

• Reduce speed<br />

• Reduce feed<br />

• Reduce the largest infeed depth<br />

• Increase coolant flow<br />

Chipping<br />

• Excessive load<br />

• Infeed depths too shallow<br />

• Change edge preparation<br />

• Check rigidity of the insert<br />

• Reduce speed<br />

• Use insert with a more wear resistance grade<br />

Built-up<br />

Edge<br />

• Cutting temperature too low<br />

• Low cutting speed<br />

• Negative cutting geometry<br />

• Increase feed<br />

• Increase speed<br />

• Apply coolant at a constant rate<br />

Insert<br />

Breakage<br />

• Grade too brittle<br />

• Excessive load<br />

• Weak insert geometry<br />

• Insert too small<br />

• Reduce depth of cut<br />

• Reduce speed and feed<br />

• Apply coolant at a constant rate<br />

• Check ridigity of the insert<br />

• Use stronger insert geometry<br />

Threading Problems & Solutions<br />

Torn Thread Finish Shallow Thread Finish Poor Surface Quality Chatter<br />

1. Use full profile insert<br />

2. Check for insert wear<br />

3. Modify infeed<br />

4. Increase coolant flow and<br />

pressure<br />

1. Adjust tool center height<br />

2. Check workpiece diameter<br />

3. Index the insert<br />

1. Increase cutting speed<br />

2. Adjust tool center height<br />

3. Use alternate infeed angle<br />

1. Use minimum tool overhang<br />

2. Adjust tool center height<br />

3. Check for deflection<br />

4. Check for insert, toolholder,<br />

and material rigidity<br />

12 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

Threading and <strong>Grooving</strong> Insert Grades<br />

Material<br />

<strong>Dorian</strong><br />

Grade<br />

Coating<br />

Specfications<br />

ANSI<br />

ISO<br />

Insert Grade Specficatications<br />

Ferrous Material<br />

P<br />

C5-C6<br />

P15-P35<br />

Free Cutting Steel, Low<br />

Carbon Steel, Alloy Carbon<br />

Steel, <strong>Tool</strong> Steel, Under<br />

35HRC, Ferretic Stainless<br />

Steel 400<br />

DVP656<br />

PVD-TiN<br />

M20-M35<br />

Well balanced substrate with cobalt<br />

enriched periphery, with a very good thermal<br />

resistance and mechanical shack. PVD TiN<br />

coating to dissipate friction and protect the<br />

cutting edge. First Choice For threading all<br />

ferrous material with medium cutting sfm<br />

MNKS<br />

Aluminum,<br />

Stainless Steel, Cast Iron,<br />

Plastic Materials<br />

DVK10<br />

PVD-TiN<br />

C3-C4<br />

N05-N15<br />

M10-M30<br />

K05-K15<br />

Fine micro-grained substrate with PVD-TiN<br />

coating, with high viscosity and with hard<br />

cutting edge and wear resistance to abrasion,<br />

First Choice for threading all the non<br />

ferrous metals at medium to high sfm, Use<br />

wet<br />

MNKS<br />

Ferrous and<br />

Non Ferrous Material<br />

DASK25B<br />

PVD TiN+<br />

TiAlN TiN<br />

Multi Layer<br />

C6-C7<br />

C2-C3<br />

P5-P25<br />

M15-M35<br />

K15-K25<br />

S05-S25<br />

Hard and tough ultra micro substrate, Multi<br />

layer hard coating PVD-TiN+TiAlN+TiN with<br />

high oxidation and wear resistance properties,<br />

enhancing high lubricity to avoid edge<br />

built up. First Choice for threading ferrous<br />

and non ferrous metals, and High Temper Alloyed<br />

Aerospace Materials. Threading operation<br />

on all the materials at high sfm. Use wet<br />

limit. Used wet or dry.<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 13

Threading and <strong>Grooving</strong> Insert Index<br />

On Edge Threading and <strong>Grooving</strong> Inserts<br />

On Edge <strong>API</strong><br />

TNMA / TNMC<br />

• NV 60° Thread Pg. 17<br />

• NT ACME Thread Pg. 17<br />

• NT Stub ACME Thread Pg. 17<br />

• NG <strong>Grooving</strong> Pg. 18<br />

Laydown Threading Inserts<br />

TPMA / TPMC<br />

• NV 60° Thread Pg. 19<br />

• NT ACME Thread Pg. 19<br />

• NT Stub ACME Thread Pg. 19<br />

• NG <strong>Grooving</strong> Pg. 20<br />

<strong>API</strong> - TNMA / TNMC<br />

• <strong>API</strong> Buttress Thread Pg.56<br />

• <strong>API</strong> Hughes H90 Thread Pg.56<br />

• <strong>API</strong> Rotary Shoulder Thread Pg.56<br />

• <strong>API</strong> Round Thread Pg.57<br />

• <strong>API</strong> VAM Thread Pg.57<br />

• <strong>API</strong> X-Line Thread Pg.57<br />

Laydown <strong>API</strong><br />

• 60° Partial Profile Thread Pg. 31<br />

• 60° Full Profile Thread Pg. 31<br />

• UN 60° Full Profile Mini. Thread Pg. 31<br />

• NTP-NPTF 60° Full Profile Mini. Thread Pg. 31<br />

• UN 60° Full Profile Thread Pg. 32-33<br />

• UN/UNJ 60° Full Profile Multi Tooth Thread Pg. 34<br />

• 29° ACME Thread Pg. 34<br />

• 29° Stub ACME Thread Pg. 35<br />

• NPT Full Profile Thread Pg. 35-36<br />

• NPTF Dryseal Thread Pg. 36<br />

DorNotch Threading and <strong>Grooving</strong> Inserts<br />

• <strong>API</strong> Round Thread Pg.60<br />

• <strong>API</strong> Buttress Casing Thread Pg.60<br />

• <strong>API</strong> Rotary Shoulder Thread Pg.60<br />

• <strong>API</strong> Hughes H90 Thread Pg.60<br />

• <strong>API</strong> VAM Thread Pg.61<br />

• <strong>API</strong> X-Line Thread Pg.61<br />

• <strong>API</strong> VO55 Thread Pg.61<br />

• <strong>API</strong> Round Multi Tooth Thread Pg.61<br />

• <strong>API</strong> Standard Buttress Thread Pg.62<br />

• <strong>API</strong> Push Buttress Thread Pg.62<br />

<strong>API</strong>- Metric DIN<br />

• <strong>API</strong> Buttress Thread Pg.63<br />

• <strong>API</strong> 30º Round Thread Pg.63<br />

• <strong>API</strong> MJ 60° Full Profile Thread Pg. 64<br />

• <strong>API</strong> PG 80° Full Profile Thread Pg. 64<br />

DorNotch <strong>API</strong><br />

• NT 60° Partial Profile Pg. 45<br />

• NPT / NPTF 60° Partial Profile Pg. 45<br />

• NTK / NJ 60° Partial Profile Pg. 45<br />

• NA 29° ACME Thread Pg. 46<br />

• NAS 29° Stub ACME Thread Pg. 46<br />

• NU <strong>Grooving</strong> Pg. 46<br />

• NV Poly-Vee <strong>Grooving</strong> Pg. 46<br />

• NG <strong>Grooving</strong> Pg. 47<br />

• NGP <strong>Grooving</strong> Pg. 48<br />

• NR / NRP Full Radius <strong>Grooving</strong> Pg. 48<br />

• <strong>API</strong> American Buttress Thread Pg.70<br />

• <strong>API</strong> Rotary Shoulder Thread Pg.70<br />

• <strong>API</strong> Round Thread Pg.70<br />

• <strong>API</strong> Buttress Thread Pg.70<br />

V-Bottom Threading and <strong>Grooving</strong> Inserts<br />

• V84 / 85 60° Thread Pg. 53<br />

• V84 / 85 29° ACME Thread Pg. 53<br />

• V84 / 85 29° Stub ACME Thread Pg. 53<br />

• V84 NPT (National Pipe Thread) Pg. 53<br />

• NG <strong>Grooving</strong> Pg. 53<br />

V-Bottom <strong>API</strong><br />

• <strong>API</strong> V84 Round Thread Pg.68<br />

• <strong>API</strong> V84 Buttress Thread Pg.68<br />

• <strong>API</strong> Hughes H90 Thread Pg.68<br />

• <strong>API</strong> V85 Rotary Shoulder Thread Pg.68<br />

• <strong>API</strong> V84 VAM Thread Pg.68<br />

• <strong>API</strong> V84 X-Line Thread Pg.68<br />

L-<strong>API</strong> Threading Inserts<br />

• L43 / 53 - <strong>API</strong> Buttress Thread Pg. 73<br />

• L53 - <strong>API</strong> Hughes Thread H90 Pg. 73<br />

• LDS54 - <strong>API</strong> Hughes H90 Thread Pg. 73<br />

• L43 / 53 - <strong>API</strong> Rotary Shoulder Pg. 74<br />

• L43 / 53 - <strong>API</strong> Round Thread Pg. 74<br />

• LDS43 / 54 - <strong>API</strong> Round Thread Pg. 74<br />

• LDS54 - Double Sided Straight Topping Thread Pg. 75<br />

• LDS54 - Double Sided Follow Topping Thread Pg. 75<br />

• LPGC32 / 43 - <strong>API</strong> Round Thread Pg. 75<br />

• L43 - <strong>API</strong> VAM Thread Pg. 75<br />

• L43 - <strong>API</strong> X-Line Thread Pg. 75<br />

<strong>API</strong> Chaser Threading Inserts<br />

• <strong>API</strong> Buttress Thread Pg. 77<br />

• <strong>API</strong> Buttress Thread SET Pg. 77<br />

• <strong>API</strong> Round Thread Pg. 77<br />

• <strong>API</strong> Round Thread SET Pg. 77<br />

• <strong>API</strong> Line Pipe Thread Pg. 77<br />

14 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

On Edge Threading Methods<br />

On Edge <strong>Tool</strong>holder Threading Method<br />

On Edge Threading Bar Threading Method<br />

On Edge Gangtool Threading Method<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 15

On Edge Inserts<br />

On Edge Threading Insert Identification System<br />

1-Insert Style 3-Tolerence 5-Insert Style I.C.<br />

7-Cutting Style<br />

2-Rake Angle 4-Hole Style 6-Insert Thickness 4-Width of Cut<br />

TPI for ACME Threading:<br />

TPI for Stub ACME Threading:<br />

E- External<br />

On Edge Threading Insert Grade & Application Chart<br />

Threading Application Non Ferrous Ferrous Ferrous & Non Ferrous<br />

VC High Medium Very High<br />

sfm 200"-600" 70-180mm 330"-750" 100-230mm 200"-2600" 61-362mm<br />

Note:<br />

Threading<br />

information<br />

provided is for<br />

reference only.<br />

Actual Threading<br />

data will be<br />

determined<br />

in the application.<br />

Condition Wet Wet Dry-Wet<br />

Industry standard Insert Grade (A.N.S.I. -C1-C2) (I.S.O. -K15-K30) (A.N.S.I. -C5-C6) (I.S.O. -P15-P35) (A.N.S.I. - C3 C4) (I.S.O. - K10-K20)<br />

Insert Coating PVD-TiN PVD-TiN PVD Multi-Layer<br />

Insert Grade Specifications<br />

Hard micro-grained substrate with PVD-TiN<br />

coating, with high viscosity, hard cutting edge<br />

and wear resistance for machining with high<br />

sfm.<br />

Well balanced substrate with a very good<br />

resistance to thermal and mechanical shock<br />

PVD-TiN coating, best finishing applications<br />

medium cutting sfm.<br />

Ultra fine and hard micro-grained substrate<br />

with hard coating, enhancing sliding wear,<br />

load capacity with high lubricity to avoid edge<br />

built up. For precision threading operation at<br />

high sfm.<br />

Insert Aptitude Wet Wet Wet<br />

Medium Toughness Wear Resistant<br />

<strong>Dorian</strong> Insert Grade DVK10 DVP656 DASK25B<br />

16 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

On Edge Inserts<br />

Please call to check availability of Inserts.<br />

On Edge<br />

TNMA-TNMC<br />

First Choice General Purpose General Purpose High Performance<br />

Material Application<br />

Non Ferrous Ferrous Ferrous & Non Ferrous<br />

Stainless Steel,<br />

Cast Iron,<br />

Aluminum & H.T.A.<br />

Carbon Steel,<br />

Alloy Steel &<br />

Stainless Steel<br />

Carbon Steel,<br />

Alloy Steel & Stainless Steel ,<br />

Cast Iron, Aluminum & H.T.A.<br />

<strong>Dorian</strong> Insert Grade DVK10 DVP656 DASK25B<br />

Description UPC No 733101- Insert Dimensions<br />

NV 60º TNMA TNMC TNMA TNMC TNMA TNMC TNMA TNMC I.C. Thick<br />

Threading<br />

Negative Rake<br />

TNMA-32NV TNMC-32NV 72529 72004 72528 72003 72530 72005 .375 .125 .150<br />

TNMA-43NV TNMC-43NV 72536 72008 72535 72010 72537 72011 .500 .187 .203<br />

TNMA-43NV .010R TNMC-43 NV .010R 72543 72018 72542 72017 72544 72019 .500 .187 .203 .010 4-20<br />

TNMA-54NV TNMC-54NV 72557 72032 72556 72031 72558 72033 .625 .250 .250<br />

TNMA-54NV .010R TNMC-54NV .010R 72564 72039 72563 72038 72565 72040 .625 .250 .250 .010 4-20<br />

TNMA-64NV TNMC-64NV 72592 72067 72591 72066 72593 72068 .750 .250 .312<br />

TNMA-66NV TNMC-66NV 72599 72074 72598 72073 72600 72075 .750 .375 .312<br />

NT ACME 29º TNMA TNMC TNMA TNMC TNMA TNMC TNMA TNMC I.C. Thick<br />

Threading<br />

Negative Rake<br />

T<br />

T<br />

I.C.<br />

I.C.<br />

60°<br />

W 29°<br />

TNMA-32NT-6P TNMC-32NT-6P 72603 72078 72602 72077 72604 72079 .375 .125 .150 .0566 6<br />

TNMA-32NT-8P TNMC-32NT-8P 72607 72082 72606 72081 72608 72083 .375 .125 .150 .0411 8<br />

TNMA-32NT-10P TNMC-32NT-10P 72611 72086 72610 72085 72612 72087 .375 .125 .150 .0319 10<br />

TNMA-32NT-12P TNMC-32NT-12P 72615 72090 72614 72089 72616 72091 .375 .125 .150 .0283 12<br />

TNMA-32NT-14P TNMC-32NT-14P 72619 72094 72618 72093 72620 72095 .375 .125 .150 .0239 14<br />

TNMA-32NT-16P TNMC-32NT-16P 72623 72098 72622 72097 72624 72099 .375 .125 .150 .0206 16<br />

TNMA-43NT-4P TNMC-43NT-4P 72627 72102 72626 72101 72628 72103 .500 .187 .203 .0875 4<br />

TNMA-43NT-5P TNMC-43NT-5P 72631 72106 72630 72105 72632 72107 .500 .187 .203 .0689 5<br />

TNMA-43NT-6P TNMC-43NT-6P 72635 72110 72634 72109 72636 72111 .500 .187 .203 .0566 6<br />

TNMA-43NT-8P TNMC-43NT-8P 72639 72114 72638 72113 72640 72115 .500 .187 .203 .0411 8<br />

TNMA-43NT-10P TNMC-43NT-10P 72643 72118 72642 72117 72644 72119 .500 .187 .203 .0319 10<br />

TNMA-43NT-12P TNMC-43NT-12P 72647 72122 72646 72121 72648 72123 .500 .187 .203 .0283 12<br />

TNMA-43NT-14P TNMC-43NT-14P 72651 72126 72650 72125 72652 72127 .500 .187 .203 .0239 14<br />

TNMA-43NT-16P TNMC-43NT-16P 72655 72130 72654 72129 72656 72131 .500 .187 .203 .0206 16<br />

TNMA-54NT-3P TNMC-54NT-3P 72659 72134 72658 72133 72660 72135 .625 .250 .250 .1184 3<br />

TNMA-54NT-4P TNMC-54NT-4P 72663 72138 72662 72137 72664 72139 .625 .250 .203 .0875 4<br />

TNMA-54NT-5P TNMC-54NT-5P 72667 72142 72666 72141 72668 72143 .625 .250 .203 .0689 5<br />

TNMA-55NT-2.5P TNMC-55NT-2.5P 72671 72146 72670 72145 72672 72147 .625 .312 .203 .1431 2.5<br />

TNMA-66NT-2P TNMC-66NT-2P 72675 72150 72674 72149 72676 72151 .750 .375 .312 .1802 2<br />

Hole<br />

Dia.<br />

Hole<br />

Dia.<br />

Rad.<br />

.003<br />

.005<br />

.003<br />

.005<br />

.008<br />

.010<br />

.008<br />

.010<br />

.008<br />

.010<br />

W<br />

TPI<br />

8-36<br />

5-24<br />

4-20<br />

4-20<br />

3-12<br />

TPI<br />

NT Stub ACME TNMA TNMC TNMA TNMC TNMA TNMC TNMA TNMC I.C. Thick<br />

Threading<br />

Negative Rake<br />

T<br />

I.C.<br />

W 29°<br />

TNMA-32NT-6P-S TNMC-32NT-6P-S 72679 72154 72678 72153 72680 72155 .375 .125 .150 .0652 6<br />

TNMA-32NT-8P-S TNMC-32NT-8P-S 72683 72158 72682 72157 72684 72159 .375 .125 .150 .0476 8<br />

TNMA-32NT-10P-S TNMC-32NT-10P-S 72687 72162 72686 72161 72688 72163 .375 .125 .150 .0370 10<br />

TNMA-32NT-12P-S TNMC-32NT-12P-S 72691 72166 72690 72165 72692 72167 .375 .125 .150 .0326 12<br />

TNMA-32NT-14P-S TNMC-32NT-14P-S 72695 72170 72694 72169 72696 72171 .375 .125 .150 .0276 14<br />

TNMA-32NT-16P-S TNMC-32NT-16P-S 72699 72174 72698 72173 72700 72175 .375 .125 .150 .0238 16<br />

TNMA-43NT-4P-S TNMC-43NT-4P-S 72703 72178 72702 72177 72704 72179 .500 .187 .203 .1004 4<br />

TNMA-43NT-5P-S TNMC-43NT-5P-S 72707 72182 72706 72181 72708 72183 .500 .187 .203 .0793 5<br />

TNMA-43NT-6P-S TNMC-43NT-6P-S 72711 72186 72710 72185 72712 72187 .500 .187 .203 .0652 6<br />

TNMA-43NT-8P-S TNMC-43NT-8P-S 72715 72190 72714 72189 72716 72191 .500 .187 .203 .0476 8<br />

TNMA-43NT-10P-S TNMC-43NT-10P-S 72719 72194 72718 72193 72720 72195 .500 .187 .203 .0370 10<br />

TNMA-43NT-12P-S TNMC-43NT-12P-S 72723 72198 72722 72197 72724 72199 .500 .187 .203 .0326 12<br />

TNMA-43NT-14P-S TNMC-43NT-14P-S 72727 72202 72726 72201 72728 72203 .500 .187 .203 .0276 14<br />

TNMA-43NT-16P-S TNMC-43NT-16P-S 72731 72206 72730 72205 72732 72207 .500 .187 .203 .0238 16<br />

TNMA-54NT-3P-S TNMC-54NT-3P-S 72735 72210 72734 72209 72736 72211 .625 .250 .250 .1356 3<br />

TNMA-54NT-4P-S TNMC-54NT-4P-S 72739 72214 72738 72213 72740 72215 .625 .250 .250 .1004 4<br />

TNMA-54NT-5P-S TNMC-54NT-5P-S 72743 72218 72742 72217 72744 72219 .625 .250 .250 .0793 5<br />

TNMA-66NT-2P-S TNMC-66NT-2P-S 72747 72222 72746 72221 72748 72223 .750 .375 .312 .2060 2<br />

Hole<br />

Dia.<br />

W<br />

TPI<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 17

On Edge Inserts<br />

Please call to check availability of Inserts.<br />

On Edge<br />

TNMA-TNMC<br />

First Choice General Purpose General Purpose High Performance<br />

Material Application<br />

Non Ferrous Ferrous Ferrous & Non Ferrous<br />

Stainless Steel,<br />

Cast Iron,<br />

Aluminum & H.T.A.<br />

Carbon Steel,<br />

Alloy Steel &<br />

Stainless Steel<br />

Carbon Steel,<br />

Alloy Steel & Stainless Steel ,<br />

Cast Iron, Aluminum & H.T.A.<br />

<strong>Dorian</strong> Insert Grade DVK10 DVP656 DASK25B<br />

Description UPC No 733101- Insert Dimensions<br />

NG TNMA TNMC TNMA TNMC TNMA TNMC TNMA TNMC I.C. Thick<br />

<strong>Grooving</strong><br />

Negative Rake<br />

TNMA-32-NG-031 TNMC 32 NG 031 72751 72226 72750 72225 72752 72227 .375 .125 .150 .031 0.75<br />

TNMA-32-NG-062 TNMC-32NG-062 72755 72230 72754 72229 72756 72231 .375 .125 .150 .062 .150<br />

TNMA-32-NG-094 TNMC-32NG-094 72759 72234 72758 72233 72760 72235 .375 .125 .150 .094 .150<br />

TNMA-32-NG-125 TNMC-32NG-125 72763 72238 72762 72237 72764 72239 .375 .125 .150 .125 .150<br />

TNMA-32-NGR-031 TNMC-32NGR-031 72767 72242 72766 72241 72768 72243 .375 .125 .150 .031 .075<br />

TNMA-32-NGR-062 TNMC-32NGR-062 72771 72246 72770 72245 72772 72247 .375 .125 .150 .062 .150<br />

Hole<br />

Dia.<br />

W<br />

Depth<br />

I.C.<br />

TNMA-32-NGR-094 TNMC-32NGR-094 72775 72250 72774 72249 72776 72251 .375 .125 .150 .094 .150<br />

NG<br />

TNMA-32-NGL-031 TNMC-32NGL-031 72779 72254 72778 72253 72780 72255 .375 .125 .150 .031 .075<br />

TNMA-32-NGL-062 TNMC-32NGL-062 72783 72258 72782 72257 72784 72259 .375 .125 .150 .062 .150<br />

TNMA-32-NGL-094 TNMC-32NGL-094 72787 72262 72786 72261 72788 72263 .375 .125 .150 .094 .150<br />

TNMA-43-NG-062 TNMC-43NG-062 72791 72266 72790 72265 72792 72267 .500 .187 .203 .062 .156<br />

NGL<br />

TNMA-43-NG-094 TNMC-43NG-094 72795 72270 72794 72269 72796 72271 .500 .187 .203 .094 .215<br />

TNMA-43-NG-125 TNMC-43NG-125 72799 72274 72798 72273 72800 72275 .500 .187 .203 .125 .215<br />

TNMA-43-NG-156 TNMC-43NG-156 72803 72278 72802 72277 72804 72279 .500 .187 .203 .156 .215<br />

NGR<br />

TNMA-43-NG-187 TNMC-43NG-187 72807 72282 72806 72281 72808 72283 .500 .187 .203 .187 .215<br />

TNMA-43-NGR-062 TNMC-43NGR-062 72811 72286 72810 72285 72812 72287 .500 .187 .203 .062 .156<br />

TNMA-43-NGR-094 TNMC-43NGR-094 72815 72290 72814 72289 72816 72291 .500 .187 .203 .094 .215<br />

TNMA-43-NGR-125 TNMC-43NGR-125 72819 72294 72818 72293 72820 72295 .500 .187 .203 .125 .215<br />

TNMA-43-NGR-156 TNMC-43NGR-156 72823 72298 72822 72297 72824 72299 .500 .187 .203 .156 .215<br />

TNMA-43-NGL-062 TNMC-43NGL-062 72827 72302 72826 72301 72828 72303 .500 .187 .203 .062 .156<br />

TNMA-43-NGL-094 TNMC-43NGL-094 72831 72306 72830 72305 72832 72307 .500 .187 .203 .094 .215<br />

TNMA-43-NGL-125 TNMC-43NGL-125 72835 72310 72834 72309 72836 72311 .500 .187 .203 .125 .215<br />

TNMA-43-NGL-156 TNMC-43NGL-156 72839 72314 72838 72313 72840 72315 .500 .187 .203 .156 .215<br />

TNMA-44-NG-250 TNMC-44NG-250 72843 72318 72842 72317 72844 72319 .500 .250 .203 .250 .215<br />

TNMA-54-NG-125 TNMC-54NG-125 72847 72322 72846 72321 72848 72323 .625 .250 .250 .125 .275<br />

TNMA-54-NG-187 TNMC-54NG-187 72851 72326 72850 72325 72852 72327 .625 .250 .250 .187 .275<br />

TNMA-54-NG-250 TNMC-54NG-250 72855 72330 72854 72329 72856 72331 .625 .250 .250 .250 .275<br />

TNMA-54-NGR-125 TNMC-54NGR-125 72859 72334 72858 72333 72860 72335 .625 .250 .250 .125 .275<br />

TNMA-54-NGR-187 TNMC-54NGR-187 72863 72338 72862 72337 72864 72339 .625 .250 .250 .187 .275<br />

TNMA-54-NGL-125 TNMC-54NGL-125 72867 72342 72866 72341 72868 72343 .625 .250 .250 .125 .275<br />

TNMA-54-NGL-187 TNMC-54NGL-187 72871 72346 72870 72345 72872 72347 .625 .250 .250 .187 .275<br />

TNMA-55-NG-312 TNMC-55NG-312 72875 72350 72874 72349 72876 72351 .625 .312 .250 .312 .275<br />

TNMA-64-NG-250 TNMC-64NG-250 72879 72354 72878 72353 72880 72355 .750 .250 .312 .250 .335<br />

TNMA-66-NG-375 TNMC-66NG-375 72883 72358 72882 72357 72884 72359 .750 .375 .312 .375 .335<br />

TNMA-67-NG-437 TNMC-67NG-437 72887 72362 72886 72361 72888 72363 .750 .437 .312 .437 .335<br />

TNMA-69-NG-562 TNMC-69NG-562 72891 72366 72890 72365 72892 72367 .750 .562 .312 .562 .335<br />

18 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

On Edge Inserts<br />

Please call to check availability of Inserts.<br />

On Edge<br />

TPMA-TPMC<br />

First Choice General Purpose General Purpose High Performance<br />

Material Application<br />

Non Ferrous Ferrous Ferrous & Non Ferrous<br />

Stainless Steel,<br />

Cast Iron,<br />

Aluminum & H.T.A.<br />

Carbon Steel,<br />

Alloy Steel &<br />

Stainless Steel<br />

Carbon Steel,<br />

Alloy Steel & Stainless Steel ,<br />

Cast Iron, Aluminum & H.T.A.<br />

<strong>Dorian</strong> Insert Grade DVK10 DVP656 DASK25B<br />

Description UPC No 733101- Insert Dimensions<br />

NV 60º TPMA TPMC TPMA TPMC TPMA TPMC TPMA TPMC I.C. Thick<br />

Threading<br />

5º Positive Rake<br />

TPMA-32NV TPMC-32NV 73394 73056 73393 73055 73395 73057 .375 .125 .150<br />

TPMA-43NV TPMC-43NV 73401 73063 73400 73062 73402 73064 .500 .187 .203<br />

TPMA-44NV TPMC-44NV 73408 73070 73407 73069 73409 73071 .500 .250 .203<br />

TPMA-54NV TPMC-54NV 73415 73077 73414 73076 73416 73078 .625 .250 .250 .010 4-20<br />

TPMA-64NV TPMC-64NV 73422 73084 73421 73083 73423 73085 .750 .250 .312<br />

TPMA-66NV TPMC-66NV 73429 73091 73428 73090 73430 73092 .750 .375 .312<br />

NT ACME 29º TPMA TPMC TPMA TPMC TPMA TPMC TPMA TPMC I.C. Thick<br />

Threading<br />

Positive Rake<br />

TPMA-32NT-6P TPMC-32NT-6P 73433 73095 73432 73094 73434 73096 .375 .125 .150 .0566 6<br />

TPMA-32NT-8P TPMC-32NT-8P 73437 73099 73436 73098 73438 73100 .375 .125 .150 .0411 8<br />

TPMA-32NT-10P TPMC-32NT-10P 73441 73103 73440 73102 73442 73104 .375 .125 .150 .0319 10<br />

TPMA-32NT-12P TPMC-32NT-12P 73445 73107 73444 73106 73446 73108 .375 .125 .150 .0283 12<br />

TPMA-32NT-14P TPMC-32NT-14P 73449 73111 73448 73110 73450 73112 .375 .125 .150 .0239 14<br />

TPMA-32NT-16P TPMC-32NT-16P 73453 73115 73452 73114 73454 73116 .375 .125 .150 .0206 16<br />

TPMA-43NT-4P TPMC-43NT-4P 73457 73119 73456 73118 73458 73120 .500 .187 .203 .0875 4<br />

TPMA-43NT-5P TPMC-43NT-5P 73461 73123 73460 73122 73462 73124 .500 .187 .203 .0689 5<br />

TPMA-43NT-6P TPMC-43NT-6P 73465 73127 73464 73126 73466 73128 .500 .187 .203 .0566 6<br />

TPMA-43NT-8P TPMC-43NT-8P 73469 73131 73468 73130 73470 73132 .500 .187 .203 .0411 8<br />

TPMA-43NT-10P TPMC-43NT-10P 73473 73135 73472 73134 73474 73136 .500 .187 .203 .0319 10<br />

TPMA-43NT-12P TPMC-43NT-12P 73477 73139 73476 73138 73478 73140 .500 .187 .203 .0283 12<br />

TPMA-43NT-14P TPMC-43NT-14P 73481 73143 73480 73142 73482 73144 .500 .187 .203 .0239 14<br />

TPMA-43NT-16P TPMC-43NT-16P 73485 73147 73484 73146 73486 73148 .500 .187 .203 .0206 16<br />

TPMA-54NT-3P TPMC-54NT-3P 73489 73151 73488 73150 73490 73152 .625 .250 .250 .1184 3<br />

TPMA-54NT-4P TPMC-54NT-4P 73493 73155 73492 73154 73494 73156 .625 .250 .250 .0875 4<br />

TPMA-54NT-5P TPMC-54NT-5P 73497 73159 73496 73158 73498 73160 .625 .250 .250 .0689 5<br />

TPMA-55NT-2.5P TPMC-55NT-2.5P 73501 73163 73500 73162 73502 73164 .625 .312 .250 .1431 2.5<br />

TPMA-66NT-2P TPMC-66NT-2P 73505 73167 73504 73166 73506 73168 .750 .375 .312 .1802 2<br />

NT Stub ACME 29º TPMA TPMC TPMA TPMC TPMA TPMC TPMA TPMC I.C. Thick<br />

Threading<br />

Positive Rake<br />

T<br />

T<br />

T<br />

I.C.<br />

I.C.<br />

I.C.<br />

60°<br />

W 29°<br />

W 29°<br />

TPMA-32NT-6P-S TPMC-32NT-6P-S 73509 73171 73508 73170 73510 73172 .375 .125 .150 .0652 6<br />

TPMA-32NT-8P-S TPMC-32NT-8P-S 73513 73175 73512 73174 73514 73176 .375 .125 .150 .0476 8<br />

TPMA-32NT-10P-S TPMC-32NT-10P-S 73517 73179 73516 73178 73518 73180 .375 .125 .150 .0370 10<br />

TPMA-32NT-12P-S TPMC-32NT-12P-S 73521 73183 73520 73182 73522 73184 .375 .125 .150 .0326 12<br />

TPMA-32NT-14P-S TPMC-32NT-14P-S 73525 73187 73524 73186 73526 73188 .375 .125 .150 .0276 14<br />

TPMA-32NT-16P-S TPMC-32NT-16P-S 73529 73191 73528 73190 73530 73192 .375 .125 .150 .0238 16<br />

TPMA-43NT-4P-S TPMC-43NT-4P-S 73533 73195 73532 73194 73534 73196 .500 .187 .203 .1004 4<br />

TPMA-43NT-5P-S TPMC-43NT-5P-S 73537 73199 73536 73198 73538 73200 .500 .187 .203 .0793 5<br />

TPMA-43NT-6P-S TPMC-43NT-6P-S 73541 73203 73540 73202 73542 73204 .500 .187 .203 .0652 6<br />

TPMA-43NT-8P-S TPMC-43NT-8P-S 73545 73207 73544 73206 73546 73208 .500 .187 .203 .0476 8<br />

TPMA-43NT-10P-S TPMC-43NT-10P-S 73549 73211 73548 73210 73550 73212 .500 .187 .203 .0370 10<br />

TPMA-43NT-12P-S TPMC-43NT-12P-S 73553 73215 73552 73214 73554 73216 .500 .187 .203 .0326 12<br />

TPMA-43NT-14P-S TPMC-43NT-14P-S 73557 73219 73556 73218 73558 73220 .500 .187 .203 .0276 14<br />

TPMA-43NT-16P-S TPMC-43NT-16P-S 73561 73223 73560 73222 73562 73224 .500 .187 .203 .0238 16<br />

TPMA-54NT-3P-S TPMC-54NT-3P-S 73565 73227 73564 73226 73566 73228 .625 .250 .250 .1356 3<br />

TPMA-54NT-4P-S TPMC-54NT-4P-S 73569 73231 73568 73230 73570 73232 .625 .250 .250 .1004 4<br />

TPMA-54NT-5P-S TPMC-54NT-5P-S 73573 73235 73572 73234 73574 73236 .625 .250 .250 .0793 5<br />

TPMA-55NT-2.5P-S TPMC-55NT-2.5P-S 73577 73239 73576 73238 73578 73240 .625 .312 .250 .1638 2.5<br />

TPMA-66NT-2P-S TPMC-66NT-2P-S 73581 73243 73580 73242 73582 73244 .750 .375 .312 .2060 2<br />

Hole<br />

Dia.<br />

Hole<br />

Dia.<br />

Hole<br />

Dia.<br />

Rad.<br />

.003<br />

.005<br />

.003<br />

.005<br />

.010<br />

.008<br />

.008<br />

.010<br />

.008<br />

.010<br />

W<br />

W<br />

TPI<br />

8-36<br />

5-24<br />

5-24<br />

4-20<br />

3-12<br />

TPI<br />

TPI<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 19

On Edge Inserts<br />

Please call to check availability of Inserts.<br />

On Edge<br />

TPMA-TPMC<br />

First Choice General Purpose General Purpose High Performance<br />

Material Application<br />

Non Ferrous Ferrous Ferrous & Non Ferrous<br />

Stainless Steel,<br />

Cast Iron,<br />

Aluminum & H.T.A.<br />

Carbon Steel,<br />

Alloy Steel &<br />

Stainless Steel<br />

Carbon Steel,<br />

Alloy Steel & Stainless Steel ,<br />

Cast Iron, Aluminum & H.T.A.<br />

<strong>Dorian</strong> Insert Grade DVK10 DVP656 DASK25B<br />

Description UPC No 733101- Insert Dimensions<br />

NG TPMA TPMC TPMA TPMC TPMA TPMC TPMA TPMC I.C. Thick<br />

<strong>Grooving</strong><br />

5º Positive Rake<br />

Hole<br />

Dia. W Depth<br />

TPMA-32NG-031 TPMC-32NG-031 73585 73247 73584 73246 73586 73248 .375 .125 .150 .031 0.75<br />

TPMA-32NG-062 TPMC-32NG-062 73589 73251 73588 73250 73590 73252 .375 .125 .150 .062 .150<br />

TPMA-32NG-094 TPMC-32NG-094 73593 73255 73592 73254 73594 73256 .375 .125 .150 .094 .150<br />

TPMA-32NG-125 TPMC-32NG-125 73597 73259 73596 73258 73598 73260 .375 .125 .150 .125 .150<br />

TPMA-32NGR-031 TPMC-32NGR-031 73601 73263 73600 73262 73602 73264 .375 .125 .150 .031 .075<br />

I.C.<br />

TPMA-32NGR-062 TPMC-32NGR-062 73605 73267 73604 73266 73606 73268 .375 .125 .150 .062 .150<br />

TPMA-32NGR-094 TPMC-32NGR-094 73609 73271 73608 73270 73610 73272 .375 .125 .150 .094 .150<br />

NG<br />

TPMA-32NGL-031 TPMC-32NGL-031 73613 73275 73612 73274 73614 73276 .375 .125 .150 .031 .075<br />

TPMA-32NGL-062 TPMC-32NGL-062 73617 73279 73616 73278 73618 73280 .375 .125 .150 .062 .150<br />

TPMA-32NGL-094 TPMC-32NGL-094 73621 73283 73620 73282 73622 73284 .375 .125 .150 .094 .150<br />

NGL<br />

TPMA-43NG-062 TPMC-43NG-062 73625 73287 73624 73286 73626 73288 .500 .187 .203 .062 .156<br />

TPMA-43NG-094 TPMC-43NG-094 73629 73291 73628 73290 73630 73292 .500 .187 .203 .094 .215<br />

TPMA-43NG-125 TPMC-43NG-125 73633 73295 73632 73294 73634 73296 .500 .187 .203 .125 .215<br />

TPMA-43NG-156 TPMC-43NG-156 73637 73299 73636 73298 73638 73300 .500 .187 .203 .156 .215<br />

NGR<br />

TPMA-43NG-187 TPMC-43NG-187 73641 73303 73640 73302 73642 73304 .500 .187 .203 .187 .215<br />

TPMA-43NGR-062 TPMC-43NGR-062 73645 73307 73644 73306 73646 73308 .500 .187 .203 .062 .156<br />

TPMA-43NGR-094 TPMC-43NGR-094 73649 73311 73648 73310 73650 73312 .500 .187 .203 .094 .215<br />

TPMA-43-NGR-125 TPMC-43NGR-125 73653 73315 73652 73314 73654 73316 .500 .187 .203 .125 .215<br />

TPMA-43NGR-156 TPMC-43NGR-156 73657 73319 73656 73318 73658 73320 .500 .187 .203 .156 .215<br />

TPMA-43NGL-062 TPMC-43NGL-062 73661 73323 73660 73322 73662 73324 .500 .187 .203 .062 .156<br />

TPMA-43NGL-094 TPMC-43NGL-094 73665 73327 73664 73326 73666 73328 .500 .187 .203 .094 .215<br />

TPMA-43NGL-125 TPMC-43NGL-125 73669 73331 73668 73330 73670 73332 .500 .187 .203 .125 .215<br />

TPMA-43NGL-156 TPMC-43NGL-156 73673 73335 73672 73334 73674 73336 .500 .187 .203 .156 .215<br />

TPMA-44NG-250 TPMC-44NG-250 73677 73339 73676 73338 73678 73340 .500 .250 .203 .250 .215<br />

TPMA-54NG-125 TPMC- 54NG-125 73681 73343 73680 73342 73682 73344 .625 .250 .250 .125 .275<br />

TPMA-54NG-187 TPMC-54NG-187 73685 73347 73684 73346 73686 73348 .625 .250 .250 .187 .275<br />

TPMA-54NG-250 TPMC-54NG-250 73689 73351 73688 73350 73690 73352 .625 .250 .250 .250 .275<br />

TPMA-54NGR-125 TPMC-54NGR-125 73693 73355 73692 73354 73694 73356 .625 .250 .250 .125 .275<br />

TPMA-54NGR-187 TPMC-54NGR-187 73697 73359 73696 73358 73698 73360 .625 .250 .250 .187 .275<br />

TPMA-54NGL-125 TPMC-54NGL-125 73701 73363 73700 73362 73702 73364 .625 .250 .250 .125 .275<br />

TPMA-54NGL-187 TPMC-54NGL-187 73705 73367 73704 73366 73706 73368 .625 .250 .250 .187 .275<br />

TPMA-55NG-312 TPMC-55NG-312 73709 73371 73708 73370 73710 73372 .625 .312 .250 .312 .275<br />

TPMA-64NG-250 TPMC-64NG-250 73713 73375 73712 73374 73714 73376 .750 .250 .312 .250 .335<br />

TPMA-66NG-375 TPMC-66NG-375 73717 73379 73716 73378 73718 73380 .750 .375 .312 .375 .335<br />

TPMA-67NG-437 TPMC-67NG-437 73721 73383 73720 73382 73722 73384 .750 .437 .312 .437 .335<br />

TPMA-69NG-562 TPMC-69NG-562 73725 73387 73724 73386 73726 73388 .750 .562 .312 .562 .335<br />

20 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

On Edge <strong>Tool</strong>holder Identification System<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 21

On Edge Threading <strong>Tool</strong>holders<br />

MTVO-A R/L Threading <strong>Tool</strong>holder- Style V - O.D. Threading and Shallow <strong>Grooving</strong> for triangle TNMA inserts<br />

Right Hand Shown, Left Hand Opposite<br />

Description<br />

Part No.<br />

733101-<br />

R.H.<br />

L.H.<br />

A B C E F G<br />

Max.<br />

GRV Depth<br />

V<br />

MTVOR/L08-3A-A 58122 58123 0.500 0.500 4.000 1.020 0.625 0.250 0.150<br />

MTVOR/L08-3B-A 58126 58127 0.500 0.500 4.500 1.020 0.625 0.250 0.150<br />

MTVOR/L10-3B-A 58130 58131 0.625 0.625 4.500 1.020 0.750 0.250 0.150<br />

MTVOR/L12-3B-A 58134 58135 0.750 0.750 4.500 1.020 0.875 0.250 0.150<br />

MTVOR/L16-3D-A 58138 58139 1.000 1.000 6.000 1.155 1.250 0.250 0.150<br />

MTVOR/L12-4B-A 58142 58143 0.750 0.750 4.500 1.250 0.875 0.250 0.230<br />

MTVOR/L16-4D-A 58146 58147 1.000 1.000 6.000 1.250 1.250 0.250 0.230<br />

MTVOR/L20-4D-A 58150 58151 1.250 1.250 6.000 1.250 1.500 0.250 0.230<br />

MTVOR/L24-4E-A 58154 58155 1.500 1.500 7.000 1.250 1.750 0.250 0.230<br />

MTVOR/L16-5D-A 58158 58159 1.000 1.000 6.000 1.500 1.250 0.250 0.292<br />

MTVOR/L20-5D-A 58162 58163 1.250 1.250 6.000 1.500 1.500 0.250 0.292<br />

TNMA<br />

Gage<br />

Insert<br />

Lock<br />

Pin Clamp<br />

Clamp<br />

Screw<br />

322 NL-33 CL-6 XNS-36<br />

432 NL-44 CL-6 XNS-36<br />

543 NL-56 CL-6 XNS-36<br />

MTVOR/L20-64D-A 58166 58167 1.250 1.250 6.000 1.750 1.500 0.316 0.360 643 NL-66 CL-12 XNS-59<br />

MTVOR/L20-66D-A 58170 58171 1.250 1.250 6.000 1.750 1.500 0.316 0.360 663 NL-66L CL-12 XNS-59<br />

For inserts see pages 17-20. For spare part see page 79.<br />

MTHO-A R/L Threading <strong>Tool</strong>holder- Style H - Gang <strong>Tool</strong>holder for Shallow <strong>Grooving</strong> or I.D. Threading for triangle TNMA inserts<br />

Right Hand Shown, Left Hand Opposite<br />

Description<br />

Part No.<br />

733101-<br />

R.H.<br />

L.H.<br />

A B C E F G X L<br />

MTHOR/L10-3B 58176 58177 0.625 0.625 4.500 0.875 1.000 0.375 0.250 -<br />

MTHOR/L12-3B 58178 58179 0.750 0.750 4.500 0.875 1.125 0.375 0.250 1.50<br />

MTHOR/L12-4B 58180 58181 0.750 0.750 4.500 0.875 1.250 0.500 0.250 -<br />

Min.<br />

Bore<br />

M<br />

Max.<br />

GRV Depth<br />

V<br />

Min.<br />

I.D.<br />

O.D.<br />

TNMA<br />

Gage<br />

Insert<br />

Lock<br />

Pin<br />

Clamp<br />

Clamp<br />

Screw<br />

2.0 .100 .125 322 NL-33 CL-5 XNS-35<br />

MTHOR/L16-4D 58182 58183 1.000 1.000 6.000 0.875 1.500 0.500 0.250 2.00 3.0 .125 .194 432 NL-44 CL-6 XNS-36<br />

MTHOR/L20-4D 58184 58185* 1.250 1.250 6.000 0.875 1.750 0.500 0.250 2.00<br />

MTHOR/L16-5D 58186 58187 1.000 1.000 6.000 1.000 1.500 0.625 0.250 2.50<br />

MTHOR/L20-5D 58188 58189 1.250 1.250 6.000 1.000 1.750 0.625 0.250 2.50<br />

* Not standard stock item, call for lead time. For inserts see pages 17-20. For spare part see page 79.<br />

3.0 .170 .242 543 NL-56 CL-6 XNS-36<br />

MTZO R/L Threading <strong>Tool</strong>holder- Style Z - Reverse Hand Threading for triangle TNMA inserts<br />

Right Hand Shown, Left Hand Opposite<br />

Description<br />

Part No.<br />

733101-<br />

R.H.<br />

L.H.<br />

A B C E F G<br />

Max.<br />

GRV Depth<br />

V<br />

MTZOR/L12-3B 58260 58261 0.750 0.750 4.500 1.000 1.000 0.250 0.150<br />

MTZOR/L16-3D 58264* 58265* 1.000 1.000 6.000 1.000 1.250 0.250 0.150<br />

MTZOR/L16-4D 58268 58269 1.000 1.000 6.000 1.320 1.250 0.250 0.230<br />

MTZOR/L20-4D 58272 58273 1.250 1.250 6.000 1.320 1.500 0.250 0.230<br />

MTZOR/L16-5D 58276* 58277* 1.000 1.000 6.000 1.500 1.250 0.250 0.292<br />

MTZOR/L20-5D 58280* 58281* 1.250 1.250 6.000 1.500 1.500 0.250 0.292<br />

MTZOR/L20-66D 58284 58285 1.250 1.250 6.000 1.750 1.500 0.250 0.360<br />

MTZOR/L24-66E 58288 58289 1.500 1.500 7.000 1.750 2.000 0.500 0.360<br />

* Not standard stock item, call for lead time. For inserts see pages 17-20. For spare part see page 79.<br />

TNMA<br />

Gage<br />

Insert<br />

Lock<br />

Pin Clamp<br />

Clamp<br />

Screw<br />

322 NL-33 CL-6 XNS-36<br />

432 NL-44 CL-7 XNS-36<br />

543 NL-56 CL-7 XNS-36<br />

663 NL-66L CL-30 XNS-510<br />

22 Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com

On Edge Threading <strong>Tool</strong>holders<br />

MTVO-CN R/L Threading <strong>Tool</strong>holder- Style V - O.D. Threading and Shallow <strong>Grooving</strong> for triangle TNMC inserts<br />

Right Hand Shown, Left Hand Opposite<br />

Description<br />

Part No.<br />

733101-<br />

R.H.<br />

L.H.<br />

A B C E F G<br />

Max.<br />

GRV Depth<br />

V<br />

MTVOR/L08-3A-CN 58012 58013 0.500 0.500 4.000 1.020 0.625 0.125 0.150<br />

MTVOR/L08-3B-CN 58016 58017 0.500 0.500 4.500 1.020 0.625 0.125 0.150<br />

MTVOR/L10-3B-CN 58020 58021 0.625 0.625 4.500 1.020 0.750 0.125 0.150<br />

MTVOR/L12-3B-CN 58024 58025 0.750 0.750 4.500 1.020 0.875 0.125 0.150<br />

MTVOR/L16-3D-CN 58028 58029 1.000 1.000 6.000 1.155 1.250 0.250 0.150<br />

MTVOR/L12-4B-CN 58032 58033 0.750 0.750 4.500 1.250 0.875 0.125 0.230<br />

MTVOR/L16-4D-CN 58036 58037 1.000 1.000 6.000 1.250 1.250 0.250 0.230<br />

MTVOR/L20-4D-CN 58040 58041 1.250 1.250 6.000 1.250 1.500 0.250 0.230<br />

MTVOR/L24-4E-CN 58044 58045* 1.500 1.500 7.000 1.250 1.750 0.250 0.230<br />

MTVOR/L16-5D-CN 58048 58049 1.000 1.000 6.000 1.500 1.250 0.250 0.292<br />

MTVOR/L20-5D-CN 58052 58053 1.250 1.250 6.000 1.500 1.500 0.250 0.292<br />

* Not standard stock item, call for lead time. For inserts see pages 17-20. For spare part see page 79.<br />

TNMC<br />

Gage<br />

Insert<br />

Insert<br />

Torx<br />

Screw<br />

Torx<br />

key<br />

Clamp<br />

Clamp<br />

Clip<br />

Clamp<br />

Screw<br />

322 GTS-1M T-10 HC-9 CL-9 CS-96<br />

432 GTS-2 T-20 HC-12 CL-12 CS-126<br />

543 GTS-3 T-20 HC-12 CL-12 CS-126<br />

STVO R/L Threading <strong>Tool</strong>holder- Style V - O.D. Threading and Shallow <strong>Grooving</strong> for triangle TNMC inserts<br />

Right Hand Shown, Left Hand Opposite<br />

Description<br />

Part No.<br />

733101-<br />

R.H.<br />

L.H.<br />

A B C E F G<br />

Max.<br />

GRV Depth<br />

V<br />

STVOR/L08-3A 58070 58071 0.500 0.500 4.000 1.000 0.625 0.125 0.150<br />

STVOR/L10-3B 58074 58075 0.625 0.625 4.500 1.000 0.750 0.125 0.150<br />

STVOR/L12-3B 58078 58079 0.750 0.750 4.500 1.000 0.875 0.125 0.150<br />

STVOR/L16-3D 58082 58083 1.000 1.000 6.000 1.250 1.250 0.250 0.150<br />

STVOR/L12-4B 58086 58087 0.750 0.750 4.500 1.250 0.875 0.125 0.230<br />

STVOR/L16-4D 58090 58091 1.000 1.000 6.000 1.430 1.250 0.250 0.230<br />

STVOR/L20-4D 58094 58095 1.250 1.250 6.000 1.250 1.500 0.250 0.230<br />

STVOR/L24-4E 58098 58099 1.500 1.500 7.000 1.250 1.750 0.250 0.230<br />

STVOR/L16-5D 58102 58103 1.000 1.000 6.000 1.500 1.250 0.250 0.292<br />

STVOR/L20-5D 58106 58107 1.250 1.250 6.000 1.500 1.500 0.250 0.292<br />

TNMC<br />

Gage<br />

Insert<br />

Insert<br />

Torx<br />

Screw<br />

Torx<br />

key<br />

322 GTS-1M T-10<br />

432 GTS-2 T-20<br />

543 GTS-3 T-20<br />

STVOR/L20-64D 58110 58111 1.250 1.250 6.000 1.750 1.500 0.250 0.360 643 GTS-4 T-30<br />

STVOR/L20-66D 58114 58115 1.250 1.250 6.000 1.750 1.500 0.250 0.360 663 GTS-4 T-30<br />

For inserts see pages 17-20. For spare part see page 79.<br />

STHO R/L Threading <strong>Tool</strong>holder- Style H - Gang <strong>Tool</strong>holder for Shallow <strong>Grooving</strong> for I.D. Threading for triangle TNMC inserts<br />

For Both Internal and External Operations<br />

Right Hand Shown, Left Hand Opposite<br />

Description<br />

Part No.<br />

733101-<br />

R.H.<br />

L.H.<br />

A B C E F G L<br />

STHOR/L08-3B 58192 58193 0.500 0.500 4.500 0.875 0.875 0.375 -<br />

STHOR/L10-3B 58196 58197 0.625 0.625 4.500 0.875 1.000 0.375 -<br />

STHOR/L12-3B 58200 58201 0.750 0.750 4.500 0.875 1.125 0.375 1.500<br />

STHOR/L12-4B 58204 58205 0.750 0.750 4.500 0.875 1.250 0.500 -<br />

STHOR/L16-4D 58208 58209* 1.000 1.000 6.000 0.875 1.500 0.500 2.000<br />

STHOR/L20-4D 58212 58213 1.250 1.250 6.000 0.875 1.750 0.500 2.000<br />

STHOR/L16-5D 58216 58217 1.000 1.000 6.000 1.000 1.750 0.625 2.500<br />

STHOR/L20-5D 58220 58221 1.250 1.250 6.000 1.000 1.750 0.625 2.500<br />

Min.<br />

Bore<br />

M<br />

* Not standard stock item, call for lead time. For inserts see pages 17-20. For spare part see page 79.<br />

Max.<br />

GRV Depth<br />

V<br />

Min.<br />

I.D.<br />

O.D.<br />

TNMC<br />

Gage<br />

Insert<br />

Insert<br />

Torx<br />

Screw<br />

Torx<br />

key<br />

2.0 0.100 0.125 322 GTS-1M T-10<br />

3.0 0.125 0.194 432 GTS-2 T-20<br />

3.0 0.170 0.242 543 GTS-3 T-20<br />

Call: 979-282-2861 Fax: 979-282-2951 Visit:www.doriantool.com E-mail:sales@doriantool.com 23

On Edge Threading <strong>Tool</strong>holders<br />

STZO R/L Threading <strong>Tool</strong>holder-Style Z - Reverse Hand Threading for triangle TNMC inserts<br />

Right Hand Shown, Left Hand Opposite<br />

Description<br />

Part No.<br />

733101-<br />

R.H.<br />

L.H.<br />

A B C E F G<br />

Max.<br />

GRV Depth<br />

V<br />

STZOR/L12-3B 58230 58231* 0.750 0.750 4.500 1.000 1.000 0.250 0.150<br />

STZOR/L16-3D 58234 58235 1.000 1.000 6.000 1.000 1.250 0.250 0.150<br />

STZOR/L16-4D 58238 58239 1.000 1.000 6.000 1.320 1.250 0.250 0.230<br />

STZOR/L20-4D 58242 58243 1.250 1.250 6.000 1.320 1.500 0.250 0.230<br />

STZOR/L16-5D 58246 58247* 1.000 1.000 6.000 1.500 1.250 0.250 0.292<br />

STZOR/L20-5D 58250* 58251 1.250 1.250 6.000 1.500 1.500 0.250 0.292<br />

* Not standard stock item, call for lead time. For inserts see pages 17-20. For spare part see page 79.<br />

TNMC<br />

Gage<br />

Insert<br />

Insert<br />

Torx<br />

Screw<br />

Torx<br />

key<br />

322 GTS-1M T-10<br />

432 GTS-2 T-20<br />

543 GTS-3 T-20<br />

S-MTHO-A R/L Threading Bar- Style H - I.D. Threading and Shallow <strong>Grooving</strong> for triangle TNMA inserts<br />

Description<br />

Part No.<br />

733101- Min.<br />

R.H. L.H.<br />

Bore<br />

B C D F<br />

Right Hand Shown, Left Hand Opposite<br />

Max.<br />

GRV<br />

Depth<br />

V<br />

S16T-MTHOR/L-3-A 58346 58347 1.388 12.00 1.000 0.687 0.120 0.250<br />

S20U-MTHOR/L-3-A 58350 58351 1.656 14.00 1.250 0.828 0.120 0.250<br />

S20U-MTHOR/L-4-A 58354 58355 1.812 14.00 1.250 0.875 0.190 0.250<br />

S24U-MTHOR/L-4-A 58358 58359 2.250 14.00 1.500 1.000 0.190 0.250<br />

S32V-MTHOR/L-4-A 58362 58363 3.000 16.00 2.000 1.328 0.190 0.250<br />

S32V-MTHOR/L-5-A 58366 58367 3.500 16.00 2.000 1.375 0.250 0.250<br />

S40V-MTHOR/L-5-A 58370 58371 3.750 16.00 2.500 1.687 0.250 0.250<br />

S48Y-MTHOR/L-5-A 58374 58375 4.000 18.00 3.000 1.891 0.250 0.250<br />

S40V-MTHOR/L-66-A 58378 58379 4.000 16.00 2.500 1.750 0.312 0.312<br />

S48Y-MTHOR/L-66-A 58382 58383 4.500 18.00 3.000 2.000 0.312 0.312<br />

For inserts see pages 17-20. For spare part see page 79.<br />

X<br />

TNMA<br />

Gage<br />

Insert<br />

Lock<br />

Pin Clamp<br />

Clamp<br />

Screw<br />

322 NL-33 CL-5 XNS-36<br />

432 NL-44 CL-6 XNS-37<br />

543 NL-56 CL-6 XNS-37<br />

663 NL-66L CL-12 XNS-59<br />

S-MTHO-C R/L Threading Bar- Style H - I.D. Threading and Shallow <strong>Grooving</strong> for triangle TNMC inserts<br />

Description<br />

Part No.<br />

733101- Min.<br />

R.H. L.H.<br />

Bore<br />

B C D F<br />

Right Hand Shown, Left Hand Opposite<br />

Max.<br />

GRV<br />

Depth<br />

V<br />

S16T-MTHOR/L-3-C 58300 58301 1.388 12.00 1.000 0.687 0.120 0.250<br />

S20U-MTHOR/L-3-C 58304 58305 1.656 14.00 1.250 0.828 0.120 0.250<br />

S20U-MTHOR/L-4-C 58308 58309 1.812 14.00 1.250 0.875 0.190 0.250<br />

S24U-MTHOR/L-4-C 58312 58313 2.250 14.00 1.500 1.000 0.190 0.250<br />

S32V-MTHOR/L-4-C 58316 58317 3.000 16.00 2.000 1.328 0.190 0.250<br />

S32V-MTHOR/L-5-C 58320 58321 3.500 16.00 2.000 1.375 0.250 0.250<br />

S40V-MTHOR/L-5-C 58324 58325 3.750 16.00 2.500 1.687 0.250 0.250<br />

S48Y-MTHOR/L-5-C 58328* 58329* 4.000 18.00 3.000 1.891 0.250 0.250<br />

S40V-MTHOR/L-66-C 58332 58333 4.000 16.00 2.500 1.750 0.312 0.312<br />

S48Y-MTHOR/L-66-C 58336* 58337* 4.500 18.00 3.000 2.000 0.312 0.312<br />

X<br />

TNMC<br />

Gage<br />

Insert<br />

* Not standard stock item, call for lead time. For inserts see pages 17-20. For spare part see page 79.<br />

Insert<br />