Instruction Manual - Nature Coast Hobby Shop

Instruction Manual - Nature Coast Hobby Shop

Instruction Manual - Nature Coast Hobby Shop

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

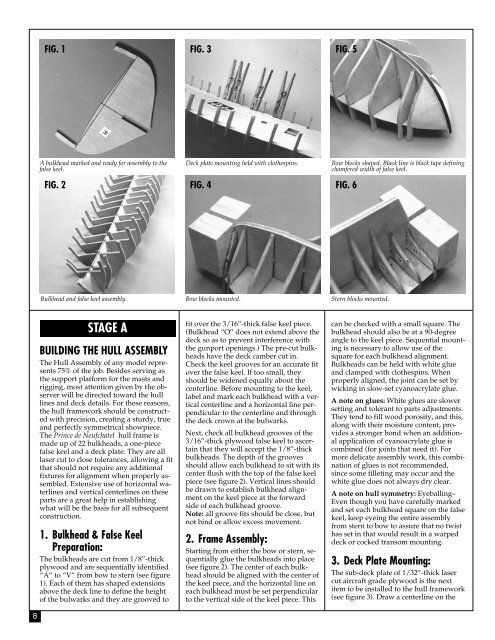

FIG. 1<br />

FIG. 3 FIG. 5<br />

A bulkhead marked and ready for assembly to the<br />

false keel.<br />

FIG. 2<br />

Deck plate mounting held with clothespins.<br />

FIG. 4<br />

Bow blocks shaped. Black line is black tape defining<br />

chamfered width of false keel.<br />

FIG. 6<br />

Bulkhead and false keel assembly.<br />

Bow blocks mounted.<br />

Stern blocks mounted.<br />

8<br />

STAGE A<br />

BUILDING THE HULL ASSEMBLY<br />

The Hull Assembly of any model represents<br />

75% of the job. Besides serving as<br />

the support platform for the masts and<br />

rigging, most attention given by the observer<br />

will be directed toward the hull<br />

lines and deck details. For these reasons,<br />

the hull framework should be constructed<br />

with precision, creating a sturdy, true<br />

and perfectly symmetrical showpiece.<br />

The Prince de Neufchatel hull frame is<br />

made up of 22 bulkheads, a one-piece<br />

false keel and a deck plate. They are all<br />

laser cut to close tolerances, allowing a fit<br />

that should not require any additional<br />

fixtures for alignment when properly assembled.<br />

Extensive use of horizontal waterlines<br />

and vertical centerlines on these<br />

parts are a great help in establishing<br />

what will be the basis for all subsequent<br />

construction.<br />

1. Bulkhead & False Keel<br />

Preparation:<br />

The bulkheads are cut from 1/8”-thick<br />

plywood and are sequentially identified<br />

“A” to “V” from bow to stern (see figure<br />

1). Each of them has shaped extensions<br />

above the deck line to define the height<br />

of the bulwarks and they are grooved to<br />

fit over the 3/16”-thick false keel piece.<br />

(Bulkhead “O” does not extend above the<br />

deck so as to prevent interference with<br />

the gunport openings.) The pre-cut bulkheads<br />

have the deck camber cut in.<br />

Check the keel grooves for an accurate fit<br />

over the false keel. If too small, they<br />

should be widened equally about the<br />

centerline. Before mounting to the keel,<br />

label and mark each bulkhead with a vertical<br />

centerline and a horizontal line perpendicular<br />

to the centerline and through<br />

the deck crown at the bulwarks.<br />

Next, check all bulkhead grooves of the<br />

3/16”-thick plywood false keel to ascertain<br />

that they will accept the 1/8”-thick<br />

bulkheads. The depth of the grooves<br />

should allow each bulkhead to sit with its<br />

center flush with the top of the false keel<br />

piece (see figure 2). Vertical lines should<br />

be drawn to establish bulkhead alignment<br />

on the keel piece at the forward<br />

side of each bulkhead groove.<br />

Note: all groove fits should be close, but<br />

not bind or allow excess movement.<br />

2. Frame Assembly:<br />

Starting from either the bow or stern, sequentially<br />

glue the bulkheads into place<br />

(see figure 2). The center of each bulkhead<br />

should be aligned with the center of<br />

the keel piece, and the horizontal line on<br />

each bulkhead must be set perpendicular<br />

to the vertical side of the keel piece. This<br />

can be checked with a small square. The<br />

bulkhead should also be at a 90-degree<br />

angle to the keel piece. Sequential mounting<br />

is necessary to allow use of the<br />

square for each bulkhead alignment.<br />

Bulkheads can be held with white glue<br />

and clamped with clothespins. When<br />

properly aligned, the joint can be set by<br />

wicking in slow-set cyanoacrylate glue.<br />

A note on glues: White glues are slower<br />

setting and tolerant to parts adjustments.<br />

They tend to fill wood porosity, and this,<br />

along with their moisture content, provides<br />

a stronger bond when an additional<br />

application of cyanoacrylate glue is<br />

combined (for joints that need it). For<br />

more delicate assembly work, this combination<br />

of glues is not recommended,<br />

since some filleting may occur and the<br />

white glue does not always dry clear.<br />

A note on hull symmetry: Eyeballing–<br />

Even though you have carefully marked<br />

and set each bulkhead square on the false<br />

keel, keep eyeing the entire assembly<br />

from stern to bow to assure that no twist<br />

has set in that would result in a warped<br />

deck or cocked transom mounting.<br />

3. Deck Plate Mounting:<br />

The sub-deck plate of 1/32”-thick laser<br />

cut aircraft grade plywood is the next<br />

item to be installed to the hull framework<br />

(see figure 3). Draw a centerline on the