Instruction Manual - Nature Coast Hobby Shop

Instruction Manual - Nature Coast Hobby Shop

Instruction Manual - Nature Coast Hobby Shop

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

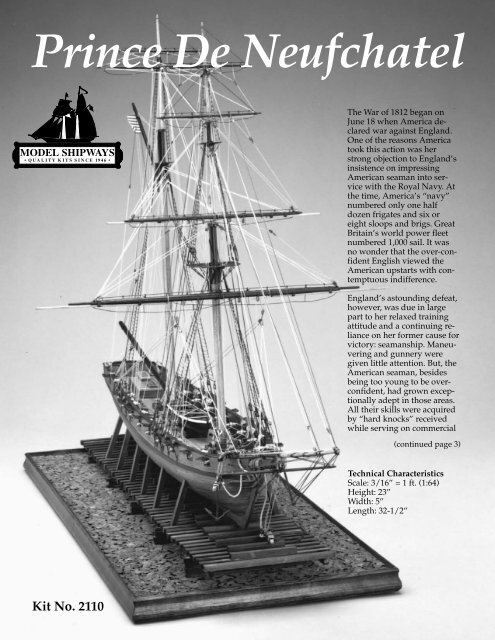

Prince De Neufchatel<br />

The War of 1812 began on<br />

June 18 when America declared<br />

war against England.<br />

One of the reasons America<br />

took this action was her<br />

strong objection to England’s<br />

insistence on impressing<br />

American seaman into service<br />

with the Royal Navy. At<br />

the time, America’s “navy”<br />

numbered only one half<br />

dozen frigates and six or<br />

eight sloops and brigs. Great<br />

Britain’s world power fleet<br />

numbered 1,000 sail. It was<br />

no wonder that the over-confident<br />

English viewed the<br />

American upstarts with contemptuous<br />

indifference.<br />

England’s astounding defeat,<br />

however, was due in large<br />

part to her relaxed training<br />

attitude and a continuing reliance<br />

on her former cause for<br />

victory: seamanship. Maneuvering<br />

and gunnery were<br />

given little attention. But, the<br />

American seaman, besides<br />

being too young to be overconfident,<br />

had grown exceptionally<br />

adept in those areas.<br />

All their skills were acquired<br />

by “hard knocks” received<br />

while serving on commercial<br />

(continued page 3)<br />

Technical Characteristics<br />

Scale: 3/16” = 1 ft. (1:64)<br />

Height: 23”<br />

Width: 5”<br />

Length: 32-1/2”<br />

Kit No. 2110

<strong>Instruction</strong> <strong>Manual</strong><br />

9th Century Privateer Hermaphrodite-Schooner<br />

Prince De Neufchatel<br />

1812-15<br />

By Robert L. Evans<br />

©Copyright 2005<br />

Model Shipways, Inc.<br />

3850 N 29th Terrace • Hollywood, FL 33020<br />

2

(continued from page 1)<br />

ships that were drawn into petty<br />

skirmishes with French frigates, the<br />

Moors of Tripoli and the many pirates<br />

or privateers that sailed the<br />

waters looking for easy wealth.<br />

And, while England rested on her<br />

laurels, America’s resilient, intelligent<br />

young men were being trained<br />

to the maximum.<br />

Credit for America’s success in<br />

winning the War of 1812 belongs<br />

in part to the many privateers who<br />

signed on to do battle against the<br />

might of England. According to<br />

Falconer’s Dictionary of the Marine<br />

(1768), “Privateers are vessels of<br />

war armed and equipped by particular<br />

merchants, and furnished with<br />

commissions from the State to<br />

cruise against and annoy the<br />

enemy by taking, sinking, or burning<br />

their shipping.” The commission,<br />

authorized by a letter-of-marque,<br />

empowered merchants to appropriate<br />

to their own use whatever<br />

prize (actual capture of a vessel)<br />

they made, as well as receive monetary<br />

allowance for each prisoner<br />

taken.<br />

While on the whole the privateers,<br />

as irregular forces, were certainly<br />

no match for the the British regular<br />

cruisers, they inflicted enormous<br />

damage on the foe. Among four of<br />

the privateers that were most creditable<br />

was the speedy brigantine<br />

Prince de Neufchatel captained by<br />

J. Ordronaux of New York. A superbly<br />

built vessel of 310 tons, she<br />

mounted 18 guns and originally<br />

possessed a crew of 150 men.<br />

Her most awesome battle occurred<br />

on October 11th just after having<br />

made a very successful cruise. She<br />

had on board 37 prisoners and<br />

$300,000 in goods, but had manned<br />

and sent in so many prizes that<br />

only 40 of her crew remained. With<br />

little warning, the crew found<br />

themselves pursued by the British<br />

frigate Endymion which, during a<br />

calm, dispatched 5 boats containing<br />

111 men. The Neufchatel opened fire<br />

on the boats but they were soon<br />

alongside, and the British clamored<br />

aboard the hopelessly undermanned<br />

brigantine. A desperate<br />

battle ensued. The slaughter was<br />

frightful. The British lost with 28<br />

killed, 37 wounded and 10 taken<br />

prisoner. American losses were 7<br />

killed, 15 badly and 9 slightly<br />

wounded, with only 9 men untouched!<br />

This incredible battle with<br />

its miraculous outcome reflected<br />

the highest honor on the American<br />

captain and his crew.<br />

After returning to Boston with her<br />

prize, she was issued a new letterof-marque<br />

and sailed in December<br />

of 1814 under the command of<br />

Nicholas Millin. On the 26th, she<br />

was spotted and chased by three<br />

British frigates; Leander, Newcastle<br />

and Acasta. Prince de Neufchatel<br />

would have escaped, if not for the<br />

fact that she lost spars by carrying<br />

too much sail. The commodore of<br />

the frigate squadron was so impressed<br />

by the schooner’s speed<br />

that rather than having her condemned<br />

in Halifax, he had her sent<br />

to the Deptford Dockyard to be<br />

surveyed. Her lines were taken, but<br />

in handling, her back was broken<br />

on the dock gate sill. This accident<br />

prevented her from being taken<br />

into Royal Navy service and she<br />

was sold off.<br />

One of the most notorious of the<br />

American privateers during the<br />

War of 1812, Prince de Neufchatel<br />

was supposedly built by Christian<br />

Bergh at New York in 1812-13 and<br />

was named for Berthier, one of<br />

Napoleon’s marshalls of the period.<br />

One of the larger privateers. she<br />

measured 107’ 6” at the waterline,<br />

and possessed a speed equal to design<br />

speeds of clipper ships built 40<br />

years later. Because she had a size<br />

and shape that could attain high<br />

speeds and hold more firepower,<br />

her shape was given to a whole<br />

fleet of opium clippers.<br />

Armament for the privateers was<br />

usually sixteen 12-pounder carronades<br />

and two long 18’s as chase<br />

guns. All were carriage mounted to<br />

allow more positioning freedom,<br />

and to accommodate the higher<br />

bulwarks found on the privateers.<br />

3

Construction Stages and Table of Contents<br />

Brief History Cover, pg 3<br />

Credits Pg 2<br />

Before You Begin Pg 5<br />

How to Work With the Plans and Parts Pg 6<br />

Sail Option (Read before beginning construction) Pg 6<br />

What You’ll Need to Start Construction Pg 6<br />

Painting & Staining the Model Pg 7<br />

Stage A: Building the Hull Assembly Pg 8<br />

1. Bulkhead & False Keel Preparation Pg 8<br />

2. Frame Assembly Pg 8<br />

3. Deck Plate Mounting Pg 8<br />

4. Bow and Stern Blocks Pg 9<br />

5. Bulkhead Edge Chamfering Pg 9<br />

6. Bulwark Plate Fitting & Mounting Pg 9<br />

7. Transom Pg 10<br />

8. Inner Bulwark Preparation Pg 11<br />

Stage B: Surfacing the Hull Assembly Pg 12<br />

1. Lower Hull Under-planking Pg 12<br />

2. Applying Filler to the Under-planking Pg 12<br />

3. Inboard Bulwarks Pg 13<br />

4. Outer Final Planking Pg 13<br />

5. Planking the Inner Bulwarks Pg 13<br />

6. Outboard Final Planking Pg 13<br />

7. Stern Final Planking Pg 13<br />

8. Lower Hull Final Planking Pg 14<br />

9. Creating Batten Lines on the Lower Hull Pg 14<br />

10. Plank Tapering For the Hull<br />

11. Deck Final Planking<br />

12. The Cap Rail<br />

Pg 14<br />

Pg 15<br />

Pg 15<br />

Stage C: Mounting the Hull Pg 16<br />

1. Mounting Board with Two Pedestals Pg 16<br />

2. Launching Ways Pg 16<br />

Stage D: Deck Furniture Pg 16<br />

1. Bowsprit & Bitts Pg 17<br />

2. Forward Companionway Pg 17<br />

3. Windlass Bitts (Fore & Main) Pg 17<br />

4. Hatches (Galley, Main & Aft) Pg 17<br />

5. Main Cabin Pg 17<br />

6. Rudder, Mast Openings, Pump Assemblies Pg 17<br />

7. Belaying Pin Racks & Channels Pg 18<br />

8. Gunport Lids Pg 18<br />

9. Bow Pg 18<br />

10. Railing Bitts & Knightheads<br />

11. Armament<br />

Pg 18<br />

Pg 18<br />

Stage E: Mast & Spar Construction Pg 20<br />

1. Assembling the Masts Pg 20<br />

2. Spars & Booms Pg 20<br />

3. Fittings Pg 20<br />

4. Bowsprit Assembly Pg 21<br />

5. Mounting Spars & Booms Pg 21<br />

6. Mounting the Masts & Bowsprit Pg 21<br />

Stage F: Standing Rigging Pg 22<br />

1. Bowsprit Rigging Pg 22<br />

2. Fore-stays Pg 22<br />

3. Shrouds Pg 23<br />

4. Back-stays Pg 23<br />

5. Lifts Pg 23<br />

Stage G: Running Rigging Pg 24<br />

1. Jib Sails Pg 24<br />

2. Stay-Sails Pg 25<br />

3. Gaffs Pg 25<br />

4. Driver Boom Pg 25<br />

5. Spars Pg 25<br />

6. Ground Tackle Pg 26<br />

7. Flag Halyard Pg 26<br />

8. Ship’s Boat Pg 26<br />

Key to Rigging Plan Pg 29<br />

Bibliography Pg 30

BEFORE YOU BEGIN<br />

Great attention has been given to compiling<br />

these instructions so the less experienced<br />

modeler will have a more complete<br />

understanding of the design intent<br />

of the prefabricated parts and fittings in<br />

the kit. Alternately, the more experienced<br />

modeler will find that parts provisions<br />

are flexible enough to allow application<br />

of individual building techniques and sequences<br />

other than those suggested in<br />

this manual.<br />

An attempt has been made in the kit design<br />

to provide materials which lessen<br />

the time and skill required to produce the<br />

finished model. Laser cut parts are used<br />

extensively, particularly for the bulwarks.<br />

This will allow a more accurate<br />

placement of the gun and oar ports. The<br />

laser cut false keel and bulwarks also<br />

give a more accurate shape to the hull.<br />

These prefabricated parts do not, however,<br />

eliminate the individual fitting and<br />

adjustments that must be made during<br />

construction, due to variances in manufacturing<br />

tolerances and the modeler’s<br />

care in construction.<br />

For those familiar with Model Shipway’s<br />

kit of the Fair American, you’ll find construction<br />

of this kit to be somewhat similar.<br />

The topsail schooner rig will be less<br />

involved, but size will present more difficulty.<br />

The hull shape, however, lends itself<br />

to ease of planking. Anyone who<br />

builds this Baltimore Clipper should find<br />

it a satisfying step toward more involved<br />

modeling experiences.<br />

Those of you wanting to expand the details<br />

of your model will find all of the required<br />

additional specifications in the<br />

publications listed in the Bibliography.<br />

Happy modeling!<br />

5

6<br />

HOW TO WORK WITH THE<br />

PLANS AND PARTS<br />

The plans for the Prince de Neufchatel are<br />

drawn to full 3/16” (1:64) scale. This<br />

makes it easy for the modeler to take<br />

parts dimensions directly from the plans,<br />

as well as check each finished assembly<br />

portion for accuracy. To transfer information<br />

from instructions and plans to actual<br />

parts and materials, the following measuring<br />

tools are almost a must:<br />

1. 6” or 12” Scale calibrated in both English<br />

and Metric measures. (The English<br />

should be divided to 1/64” and also provide<br />

decimal calibrations to .01.” The<br />

Metric should be divided into millimeters.)<br />

To work with the surfaces of the<br />

model, choose a scale made of thin plastic<br />

so it may be bent along the curves.<br />

2. 6” Dividers which will allow one of<br />

the needlepoints to be converted to a<br />

pencil point. A Compass will fill this<br />

need if it has replaceable tips.<br />

3. 6” Vernier Caliper calibrated in both<br />

English and Metric would be a useful addition<br />

to the above tools.<br />

Five Plans are provided:<br />

1. P-001: Fabricated Components listed<br />

and shown in detail<br />

2. P-002: Hull Assembly<br />

3. P-003: Masts and Spars<br />

4. P-004: Rigging Detail– shrouds, ratlines,<br />

stays, lifts, halliards, downhauls,<br />

braces & boom rigging<br />

5. P-005: Rigging Detail– Clew lines,<br />

sheets, tacks, square sail outline, bow<br />

sprit rigging<br />

Sequential drawings and photos, not necessarily<br />

to scale, will be found throughout<br />

the instruction manual to help describe<br />

the assembly. In addition, a List of<br />

Parts can be found on a separate sheet included<br />

in the kit.<br />

It is strongly suggested that before starting<br />

construction, the modeler go through<br />

these instructions and the contents of the<br />

kit. Examining the kit will serve two purposes.<br />

First, the modeler will become familiar<br />

with the kit contents, and second;<br />

he will be able to determine that all has<br />

been supplied as listed on the enclosed<br />

List of Parts sheet. It is also suggested<br />

that all small fittings and hardware be<br />

sorted into labeled parts boxes or compartments<br />

to avoid loss during the building<br />

process. It’s surprising how familiar<br />

the modeler can become with the kit requirements<br />

by just handling the parts!<br />

Important: If you are planning to mount<br />

sails, read the Sail Option section now so<br />

you’ll be prepared for that final stage.<br />

SAIL OPTION<br />

If you are planning to rig sails on the<br />

model, preparation must be made early<br />

on. Additional blocks will be required for<br />

the bunt lines. Belaying plans should be<br />

layed out for leech lines, stay-sails and jib<br />

sheets. As will be mentioned in the two<br />

sections on rigging, the spares will be<br />

used up and some shifting of the belaying<br />

points may be required. The rigging<br />

of the square sail clews and sheets will<br />

also have to be done as the sails are bent.<br />

Study of the books listed in the bibliography<br />

will aid in building accuracy.<br />

Preparing the Sails: Using the Rigging<br />

Plans as a guide, make paper patterns of<br />

the sails first to be sure that your final<br />

sails will fit properly (see also figures<br />

73a, 73b, 81a and 81c). Also be certain<br />

that the spars are set at their raised position<br />

as shown on the plans. With the patterns<br />

established, you can cut oversized<br />

pieces of cotton balloon cloth. These<br />

should be tinted with wood stain. Min-<br />

Wax “Driftwood” is a good choice, but<br />

stay away from stains with any red in<br />

them, such as mahogany, maple or walnut.<br />

The stained cloth can then be sized<br />

with clear lacquer and ironed flat. Next,<br />

draw panel lines on the sails. Hemming<br />

can be created simply by folding and gluing<br />

the edges. (While the pencil lines will<br />

define the sail structure, stitching the<br />

panel lines and the hems will add more<br />

detail in this scale.)<br />

There are many approaches to making<br />

sails and they have been well described<br />

in various publications. Your choice of<br />

method may be determined by the tools<br />

you have on hand.<br />

WHAT YOU’LL NEED<br />

TO START CONSTRUCTION<br />

The following tools and supplies are recommended<br />

for the construction process.<br />

Modelers who have built before may<br />

have their own favorites.<br />

A. Knives:<br />

1. Set of hobby knives with a quantity<br />

of #ll blades and square and skew<br />

chisel blades<br />

2. Box of single edge razor blades<br />

B. Files:<br />

1. Set of medium needle files<br />

2. Combination medium/coarse<br />

& round/flat rasp<br />

C. Saws:<br />

Razor saw set<br />

D. Clamps:<br />

1. 6 Small C-clamps<br />

2. 12 Wooden, spring clothespins<br />

E. Sandpaper:<br />

Assortment of grits from 100 to 240<br />

F. Boring Tools:<br />

1. Set of miniature drills, sizes 61-80<br />

2. A pin vise<br />

3. Set of miniature reamers<br />

G. Miscellaneous:<br />

1. Small hammer<br />

2. Tweezers<br />

3. Small fine scissors<br />

4. Miniature pliers<br />

a. round nose<br />

b. square<br />

c. diagonal cutters<br />

d. tapered, half-round<br />

5. 1/2” or 3/4” masking tape<br />

H. Finishing:<br />

1. Brushes<br />

a. fine with round and square ends<br />

b. medium with round<br />

and square ends<br />

I. Supplies:<br />

(will be covered in detail in “Finishing<br />

the Model” section and throughout<br />

instructions)<br />

1. Paint<br />

2. Wood stains<br />

3. White glue<br />

4. Super glue<br />

5. Glazes and stains<br />

Note: Miniature power tools such as<br />

drills, sanders and scroll saws will speed<br />

up some work, but are not necessary to<br />

construct this kit.

PAINTING & STAINING<br />

THE MODEL<br />

It may seem strange to begin an instruction<br />

manual with directions on applying<br />

the finishes to the model. Not so! Much<br />

time and effort can be saved, and a more<br />

professional result can be obtained, if the<br />

finishing process is carried out during<br />

construction. Painting of various small<br />

parts, masts and spars should be accomplished<br />

before they are installed on the<br />

model. Painting sequence must be a well<br />

thought out procedure, otherwise you<br />

may have difficulty as you proceed with<br />

assembly. For example, it is easier to<br />

paint a deckhouse or hatch coaming before<br />

it is glued to the deck. Put the parts<br />

aside until they are ready to be installed.<br />

Proper timing in the application of finishes<br />

and the use of masking tape to define<br />

painted edges should eliminate unsightly<br />

glue marks and splotchy stained surfaces.<br />

In the end, following these general<br />

suggestions will be to your advantage.<br />

Your first decision should be to determine<br />

how “finished” you want the model<br />

to be. A more authentic scheme will require<br />

the finishing of internal bulwarks,<br />

railings, transom, mast tops and doublings<br />

and deck furniture. This would entail<br />

using the following color scheme:<br />

1. Red: internal bulwarks, gunport<br />

edges, oarport edges, hatch coamings,<br />

companionway coamings, gun carriages,<br />

pumps, windlass supports, bitts, inside<br />

gunport lids.<br />

2. Black: mast tops, mast doublings, cap<br />

rail, main wale, outside ship’s boat, transom,<br />

bowsprit to doubling, spars, gaffs,<br />

booms and outside gunport lids. Metal<br />

parts such as gun barrels, anchors, cleats<br />

and rings can be finished with metal<br />

blackener or painted.<br />

3. Yellow or gold: beak supports and<br />

structure, name lettering<br />

4. Stains: Oak – deck planking, cabins<br />

and companionways;<br />

Dark Walnut – external hull, keel, stem,<br />

sternpost, inside ship’s boat, rudder;<br />

Natural Pine – unpainted mast sections<br />

To achieve an “all natural look” finish<br />

would require that most parts of the<br />

model be stained Dark Walnut, except<br />

for the deck, which should be stained in<br />

Oak. But even with this natural type<br />

look, a more attractive finish could be obtained<br />

by painting the cap rail and wale<br />

black. This would accent the lines of the<br />

hull. The hardware, guns, etc. could be<br />

left bright or blackened. Hatch coamings<br />

could revert to the Dark Walnut stain.<br />

Remember, each captain had his preferences<br />

and painted accordingly. You will<br />

be the captain of your ship and can do<br />

the same.<br />

Staining & Painting Techniques<br />

The following techniques will improve<br />

whichever finish you choose:<br />

1. Stains should be applied to the part before<br />

mounting. This will eliminate any<br />

interference by glues that may be present<br />

on the surface. It will also prevent the<br />

bleeding of one stain color into another<br />

on an adjacent surface.<br />

2. Paints should be applied to any part<br />

that will abut a surface which is to be a<br />

different color or stain. This will be particularly<br />

useful when joining the inner<br />

bulwark planking and the waterways<br />

with decking surface, and when mounting<br />

wales and the cap rail which are a<br />

different color than the hull or bulwarks.<br />

This step completely eliminates the need<br />

for masking or carefully painting a line.<br />

Some touch-up may be required, but it<br />

will be much easier than cutting an entire<br />

line. Beyond the parts or strakes that define<br />

different finishes, the painting<br />

can be done on the model.<br />

If the parts are pre-finished as suggested,<br />

any differences in gloss or glue marks<br />

will be eliminated by the application of a<br />

final overcoat of glaze or varnish. Whenever<br />

possible, surfaces to be painted<br />

should be placed horizontally to eliminate<br />

“runs” which will ruin the finish.<br />

Pointed brushes are best used for detail<br />

work and the flats will work best on the<br />

larger areas. Do not “build up” paint as it<br />

will hide structural details and could<br />

possibly chip while handling during construction.<br />

Detailed painting is best accomplished<br />

by steadying the hand<br />

against the work or other surface and<br />

only using the finger movements to<br />

apply the brush strokes.<br />

Only paints developed for model work<br />

should be used as they have the finer pigments<br />

which will not take away from<br />

surface details. Whenever possible, use<br />

standard colors as mixed by the manufacturer.<br />

This will allow a better match of<br />

color when going from one container to<br />

another.<br />

General finishing techniques require that<br />

any finish should set at least 24 hours before<br />

applying an additional coat or other<br />

treatment. (Each manufacturer will have<br />

a recommendation on drying and setting<br />

times for their products.)<br />

7

FIG. 1<br />

FIG. 3 FIG. 5<br />

A bulkhead marked and ready for assembly to the<br />

false keel.<br />

FIG. 2<br />

Deck plate mounting held with clothespins.<br />

FIG. 4<br />

Bow blocks shaped. Black line is black tape defining<br />

chamfered width of false keel.<br />

FIG. 6<br />

Bulkhead and false keel assembly.<br />

Bow blocks mounted.<br />

Stern blocks mounted.<br />

8<br />

STAGE A<br />

BUILDING THE HULL ASSEMBLY<br />

The Hull Assembly of any model represents<br />

75% of the job. Besides serving as<br />

the support platform for the masts and<br />

rigging, most attention given by the observer<br />

will be directed toward the hull<br />

lines and deck details. For these reasons,<br />

the hull framework should be constructed<br />

with precision, creating a sturdy, true<br />

and perfectly symmetrical showpiece.<br />

The Prince de Neufchatel hull frame is<br />

made up of 22 bulkheads, a one-piece<br />

false keel and a deck plate. They are all<br />

laser cut to close tolerances, allowing a fit<br />

that should not require any additional<br />

fixtures for alignment when properly assembled.<br />

Extensive use of horizontal waterlines<br />

and vertical centerlines on these<br />

parts are a great help in establishing<br />

what will be the basis for all subsequent<br />

construction.<br />

1. Bulkhead & False Keel<br />

Preparation:<br />

The bulkheads are cut from 1/8”-thick<br />

plywood and are sequentially identified<br />

“A” to “V” from bow to stern (see figure<br />

1). Each of them has shaped extensions<br />

above the deck line to define the height<br />

of the bulwarks and they are grooved to<br />

fit over the 3/16”-thick false keel piece.<br />

(Bulkhead “O” does not extend above the<br />

deck so as to prevent interference with<br />

the gunport openings.) The pre-cut bulkheads<br />

have the deck camber cut in.<br />

Check the keel grooves for an accurate fit<br />

over the false keel. If too small, they<br />

should be widened equally about the<br />

centerline. Before mounting to the keel,<br />

label and mark each bulkhead with a vertical<br />

centerline and a horizontal line perpendicular<br />

to the centerline and through<br />

the deck crown at the bulwarks.<br />

Next, check all bulkhead grooves of the<br />

3/16”-thick plywood false keel to ascertain<br />

that they will accept the 1/8”-thick<br />

bulkheads. The depth of the grooves<br />

should allow each bulkhead to sit with its<br />

center flush with the top of the false keel<br />

piece (see figure 2). Vertical lines should<br />

be drawn to establish bulkhead alignment<br />

on the keel piece at the forward<br />

side of each bulkhead groove.<br />

Note: all groove fits should be close, but<br />

not bind or allow excess movement.<br />

2. Frame Assembly:<br />

Starting from either the bow or stern, sequentially<br />

glue the bulkheads into place<br />

(see figure 2). The center of each bulkhead<br />

should be aligned with the center of<br />

the keel piece, and the horizontal line on<br />

each bulkhead must be set perpendicular<br />

to the vertical side of the keel piece. This<br />

can be checked with a small square. The<br />

bulkhead should also be at a 90-degree<br />

angle to the keel piece. Sequential mounting<br />

is necessary to allow use of the<br />

square for each bulkhead alignment.<br />

Bulkheads can be held with white glue<br />

and clamped with clothespins. When<br />

properly aligned, the joint can be set by<br />

wicking in slow-set cyanoacrylate glue.<br />

A note on glues: White glues are slower<br />

setting and tolerant to parts adjustments.<br />

They tend to fill wood porosity, and this,<br />

along with their moisture content, provides<br />

a stronger bond when an additional<br />

application of cyanoacrylate glue is<br />

combined (for joints that need it). For<br />

more delicate assembly work, this combination<br />

of glues is not recommended,<br />

since some filleting may occur and the<br />

white glue does not always dry clear.<br />

A note on hull symmetry: Eyeballing–<br />

Even though you have carefully marked<br />

and set each bulkhead square on the false<br />

keel, keep eyeing the entire assembly<br />

from stern to bow to assure that no twist<br />

has set in that would result in a warped<br />

deck or cocked transom mounting.<br />

3. Deck Plate Mounting:<br />

The sub-deck plate of 1/32”-thick laser<br />

cut aircraft grade plywood is the next<br />

item to be installed to the hull framework<br />

(see figure 3). Draw a centerline on the

FIG. 7a<br />

FIG. 7b<br />

Good<br />

Plank<br />

BHDS<br />

Bevel too great could<br />

leave as is but better to<br />

add wedge and re-sand<br />

Hump–sand<br />

to dotted line<br />

and recheck<br />

Good<br />

Stern blocks shaped.<br />

Chamfering of the bulkhead edges.<br />

FIG. 8 FIG. 9<br />

Shows after-end of stern blocks which are left<br />

square until transom is installed.<br />

First strake of under-planking at deckplate level.<br />

deck plate from bow to stern. The bulkhead<br />

slots should also have lines drawn<br />

across the deck plate connecting them<br />

from port to starboard. These notches are<br />

deep enough to clear the bulkhead extension<br />

above the deck line. Check their<br />

widths for an accurate fit of the bulkhead<br />

thickness. Widen if too tight, but DON’T<br />

OVERWIDEN THESE SLOTS!!! They accurately<br />

position the bulkheads and<br />

straighten any curvature that may be present<br />

in the false keel piece. The fit of<br />

these slots should be equal to the snug fit<br />

of the keel to bulkhead joints.<br />

The deck plate can be held down to the<br />

deck camber by using clothespins at the<br />

edges of the bulkheads. Be sure the deck<br />

plate centerline is on the center of the<br />

false keel and the mast holes are over the<br />

mast grooves in bulkheads “E” and “N.”<br />

Small nails can be used to hold the plate<br />

in place on the top of the false keel.<br />

White or cyanoacrylate glue is then<br />

wicked into the joint of the bulkheads<br />

and the underside of the deck plate.<br />

4. Bow & Stern Blocks:<br />

When the deck plate is set, bow and stern<br />

blocks of medium grade balsa are fitted<br />

(see figures 4 and 6). As sized, the grain<br />

of the bow blocks must run fore and aft,<br />

and the grain of the stern blocks must<br />

run vertically. Surfaces of these blocks<br />

have to be chamfered* (see figures 5 and<br />

7a). This will allow a snug fit into the corners<br />

formed by the deck plate, false keel<br />

and bulkhead “A” at the bow; and bulkhead<br />

“V” at the stern.<br />

*Note: Chamfering means to cut or bevel<br />

the corner at an inclined angle for working<br />

the wood to a particular shape.<br />

5. Bulkhead Edge Chamfering:<br />

The bulkhead edges have to be chamfered<br />

to properly accept the under planking<br />

and give a true look to the hull (see figure<br />

7b). The Prince de Neufchatel hull does not<br />

require extensive work in this area. The<br />

bulkheads that require the most chamfering<br />

are “A, B, C, D, E, & F” at the bow<br />

and “P, Q, R, S, T, U & V” at the stern.<br />

The ten amidships from “G” to “O” can<br />

have square edges. To maintain the hull<br />

shape, the after corners of the bow bulkheads<br />

and the forward corners of the<br />

stern bulkheads to be chamfered should<br />

be marked with a pen or pencil. When<br />

chamfering, these corners should never<br />

disappear. The bulkhead thickness of<br />

1/8” was selected to allow ease of chamfering,<br />

as well as provide a greater number<br />

of bulkheads for a better hull line.<br />

The best tools for chamfering this model<br />

are files. Flats can be used on the convex<br />

edges and rounds are the better choice for<br />

the concave edges at the stern. For these<br />

narrower bulkheads, knife cuts should<br />

not be required. When proceeding with<br />

the chamfering, you will find that the<br />

bow and stern blocks will be altered to<br />

maintain a true hull line all the way to the<br />

stem and stern post lines. This work will<br />

test your ability to set a fair curve line on<br />

the hull. It can only be done well with patience.<br />

Practice helps, but this may be<br />

your first try ... so, easy does it!<br />

The last chamfering to be done is the<br />

shaping of the false keel piece from bulkhead<br />

“D” to the bow and bulkhead “P”<br />

to the stern (see figures 5 and 8). Chamfer<br />

the false keel from its original 3/16”<br />

thickness to 1/8” thickness all the way to<br />

the deck plate at the bow and to the stern<br />

block at the stern. This tapering will accommodate<br />

the walnut stem, keel and<br />

sternpost pieces which will be added before<br />

applying the final hull planking.<br />

6. Bulwark Plate Fitting<br />

& Mounting:<br />

The frame is now ready for the first strake<br />

of under-planking that is required to properly<br />

fit the bulwark plates (see figure 9).<br />

It is 1/16” x 3/16” basswood that will also<br />

be used for the under-planking of the lower<br />

hull. Mount it even with the top edge of<br />

the deck plate from bow to stern. It can be<br />

held in place at each bulwark with small<br />

nails and glue. Spring clamps will work<br />

best at the bow. (Wet forward ends of<br />

these strips to ease bending at the bow.)<br />

9

FIG. 10<br />

FIG. 12 FIG. 14<br />

Bulwark plate clamped in position to determine<br />

bottom edge line.<br />

FIG. 11<br />

Clamping at stern showing variety of clamps that<br />

can be used to hold hull flair curvature.<br />

FIG. 13<br />

The transom plate looking inboard aft.<br />

Bulwark plate clamped during gluing.<br />

Starboard bulwark plate mounted.<br />

10<br />

The bulwark plates are laser cut from<br />

1/32” plywood. These pieces have the<br />

gunport and oarport openings cut into<br />

them (see figure 10). The bow, stern and<br />

bottom sides have been left oversized to<br />

allow fitting to the framework you have<br />

built. The top edge has been accurately<br />

shaped to the top bulwark line. The gunport<br />

openings are cut slightly undersize<br />

to allow proper sizing to the gunport<br />

frames which will be mounted later. The<br />

first thing to do is establish which are the<br />

lower edges of the bulwark plates.<br />

The gunport openings will help. They are<br />

numbered 1 through 11 from bow to<br />

stern. Gunports 5 and 11 should be centered<br />

vertically between bulkhead extensions<br />

“I” and “J” and “T” and “U” respectively.<br />

The top edge of the bulwark<br />

plate has to be 25/32” from the top of the<br />

deck plate at bulkhead “T” and 31/32” at<br />

bulkhead “I.” An additional height check<br />

can be made at bulkhead “A.” It should<br />

be 13/16.” With the bulwark plates set at<br />

these dimensions and clamped in place, a<br />

line should be drawn inboard along the<br />

bulwark plate at the top of the deck plate.<br />

The bulwark plate can be removed and<br />

cut to this line, which establishes its bottom<br />

edge for assembly.<br />

The plates are then remounted to the bulkhead<br />

extensions with clamps at the proper<br />

fore and aft, and vertical settings and<br />

glued in place with slow-set Super glue<br />

(see figure 11). They should be clamped at<br />

each bulkhead to be sure they conform to<br />

the tumblehome and flair curvatures along<br />

the hull (see figure 12). It can be advantageous<br />

to glue in the bottom edges before<br />

clamping to the bulkhead shapes above<br />

deck. To aid in positioning these bulwark<br />

plates, you should refer to the plans and<br />

use the following table as a guide (Also ...<br />

the bow ends tend to flair upward and<br />

should be held firmly in place):<br />

Bulkhead Top edge above deck plate<br />

A................................13/16”<br />

B....................................“<br />

C................................27/32”<br />

D..................................7/8”<br />

E................................ 31/32”<br />

F.....................................“<br />

G....................................“<br />

H....................................“<br />

I......................................“<br />

J......................................“<br />

K................................15/16”<br />

L.....................................“<br />

M...............................29/32”<br />

N............................... 27/32”<br />

O..................................7/8”<br />

P.....................................“<br />

Q................................27/32”<br />

R....................................“<br />

S.................................13/16”<br />

T................................ 25/32”<br />

U..................................3/4”<br />

V................................11/32”<br />

Note: These dimensions are taken along<br />

the outer curved surfaces of the bulwark<br />

extensions which are longer than<br />

the vertical height from the edge of the<br />

deck plate.<br />

These dimensions are for reference only<br />

and depend upon the accuracy of the<br />

deck plate level. A true line is more important<br />

than an actual conformation to<br />

any reference dimension. In addition,<br />

the bulkhead extensions should be<br />

aligned externally to give a true line to<br />

the bulwarks (see figure 13). If some are<br />

below a true line, they should be<br />

shimmed with 1/8” wide basswood<br />

stock. Those that may be too “fat”<br />

should be trimmed down. The 3/16”<br />

width of these extensions will accommodate<br />

any trimming easily. Gross<br />

bumps or indentations are not the intent<br />

of the ship designer, builder, historian,<br />

kit designer or modeler.<br />

7. Transom<br />

The transom piece is also laser cut from<br />

1/32” plywood. Its top is cut to the design<br />

curvature and the gunports are also<br />

cut as they were in the bulwark plates<br />

(see figure 14). The bottom and side<br />

edges have been left longer to allow fitting<br />

to your assembly. This piece should<br />

have a vertical centerline drawn on it between<br />

the gunports.

FIG. 15<br />

FIG. 17<br />

Stern blocks filed to the slope of transom.<br />

Gun and oar port frames amidships.<br />

FIG. 16 FIG. 18<br />

Gunport frame clamped at bow.<br />

1/16” square filler strips amidships.<br />

Align the transom center with the deck<br />

centerline and the top edge with the aft<br />

top corners of the bulwark plates. A line<br />

drawn across the deck plate will define<br />

the bottom edge of the transom piece.<br />

When cut to this line, it can be realigned,<br />

held with tape and glued in place along<br />

the bulwark and deck plates. The port<br />

and starboard edges can then be trimmed<br />

down flush with the after ends of the bulwark<br />

plates (see figure 15).<br />

If your frame assembly is square and<br />

level from bow to stern, the transom<br />

will be square if properly aligned. Its<br />

shape may have to be altered to give<br />

this squareness and alignment with the<br />

bulwark plates. If the shape needs to be<br />

altered, be sure to keep the transom<br />

symmetrical from port to starboard, as<br />

nothing shows up with more stigma<br />

than the transom if it is tilted.<br />

8. Inner Bulwark Preparation<br />

Giving the bulwarks the proper thickness<br />

for support and the framing for any<br />

openings is the last bulwark detail chore<br />

to be done before starting the hull surfacing.<br />

Frames for the gunports and oarports<br />

have been laser cut from 1/16” plywood.<br />

The gunport frames are opened to<br />

the proper size and must be centered<br />

over the openings cut in the bulwark<br />

plates. They should be clamped when the<br />

glue is setting to hold them to the curva-<br />

ture of the bulwarks (see figure 16). The<br />

oarport frames are also cut to an accurate<br />

size and should be glued over their<br />

matching openings in the bulwark plates.<br />

The bulwark gunport openings can be<br />

cut to the inner edges of the gunport<br />

frames with a #11 blade. The oarport<br />

openings can be filed to even edges with<br />

a square miniature file (see figure 17).<br />

The transom gunports are treated in the<br />

same manner as the bulwark gunports.<br />

Any framing that may extend over the<br />

top of the bulwarks or butt into a bulwark<br />

extension can be cut to a proper fit.<br />

These frames establish the bulwark thickness<br />

but do not control thickness at the<br />

top and bottom edges.<br />

For any long top or bottom edge opening<br />

between the frames, the support for the<br />

railing and the inner bulwark planking is<br />

supplied by 1/16” square basswood strip<br />

stock (see figures 18 and 19). The strips<br />

mounted at the deck level also provide a<br />

supporting gusset to the bulwark plates<br />

when the bulkhead extensions have been<br />

cut down to the 1/16” thickness at a later<br />

stage of construction.<br />

At the bow are additional strips to support<br />

the inner planking around the curve.<br />

And at the forward lower end, 1/16”-<br />

thick plates are added in the area where<br />

the hawse holes should be drilled 1/8” in<br />

diameter (see figure 20 and plans).<br />

FIG. 19<br />

Filler strips and gunport frames on transom.<br />

FIG. 20<br />

Filler strips and hawse pipe plate at bow.<br />

11

FIG. 21<br />

FIG. 23 FIG. 25<br />

Bow under-planking below bulwarks. Bow completely covered with under-planking. Under-planking at stern clamped to false keel.<br />

FIG. 22<br />

FIG. 24<br />

FIG. 26<br />

Bow under-planking ready for stealers.<br />

Under-planking faired to false keel.<br />

Stern under-planking below bulwarks.<br />

12<br />

STAGE B<br />

SURFACING THE HULL ASSEMBLY<br />

What follows are the steps explaining<br />

how to properly plank the various areas<br />

of the hull from the keel up to the bulwarks<br />

and its railing. This will include<br />

various finishing requirements for those<br />

parts of the hull assembly and planking<br />

which will make finishing a lot less difficult.<br />

Each step will advise the type of finish<br />

required for either the painted or “all<br />

natural look” options. This particular<br />

hull shape is one of the easiest to plank<br />

and should cause little difficulty.<br />

1. Lower Hull Under-Planking<br />

The first surface to be covered is the<br />

lower hull below the first planking strake<br />

and below the bulwark plates (see figures<br />

21-Bow and 26-Stern). All strakes are<br />

1/16” x 3/16” basswood and require no<br />

finish before mounting. The only purpose<br />

for this planking is to provide a surface<br />

for the second and final layer of<br />

planking. For this reason, you can save<br />

time by not worrying about tapering<br />

planks toward the bow unless you want<br />

the practice. All initial applications of<br />

planking are left full width and allowed<br />

to take a natural line along the lower hull<br />

starting initially at the top.<br />

Other strakes can be laid along the false<br />

keel bottom even with the 1/8” width<br />

that was chamfered when the hull frame<br />

assembly was built (see figure 25-Stern).<br />

As you work up from the bottom and<br />

down from the top, there will be tapered<br />

openings left in the hull areas. These<br />

openings should be filled with “stealers”<br />

(“short lengths of plank worked in<br />

among other strakes to facilitate rounding<br />

off in parts of great curvature”).<br />

Stealers were and are still used in the<br />

planking of life-size ships. These stealers<br />

can be made as required from the planking<br />

material (see figures 22-Bow and 27-<br />

Stern). Doing this step affords the modeler<br />

additional practice that will be helpful<br />

when it comes time to apply the final<br />

planking surface.<br />

2. Applying Filler<br />

to the Under-Planking<br />

When finished with the under-planking,<br />

apply filler to any small cracks that may<br />

exist. This will give a uniform surface for<br />

the next layer (see figure 23-Bow).<br />

When the glue and filler have set, usually<br />

overnight, shape the under-hull by filing<br />

and sanding. Flat files can be used on the<br />

convex surfaces and rounded files will<br />

work best on the concave areas. The planking<br />

must be faired into the 1/8” width of<br />

the false keel edge (see figures 24-Bow, 28-<br />

FIG. 27<br />

Stern under-planking ready for stealers.<br />

FIG. 28<br />

Under-planking faired to false keel.

FIG. 29<br />

FIG. 31 FIG. 33<br />

Under-planking at amidships, ready for keel and<br />

final planking.<br />

Inner final planks clamped into place on bulwarks.<br />

The inner planks painted on the bulwarks.<br />

FIG. 30 FIG. 32<br />

Inner under-planking across transom. Cut-down<br />

bulkhead extensions can be seen on bulwarks.<br />

Amidships inner final planking before trimming to gunport openings.<br />

Stern and 29-Amidships). It should also be<br />

leveled with the bulwark plates along the<br />

deck edge. Any nails that have been used<br />

to hold the planking should be filed off as<br />

you shape the hull. If not, they can be dug<br />

out with a pair of fine side-cutters. This<br />

final shaping should ready the hull for the<br />

external planking.<br />

3. Inboard Bulwarks<br />

The bulwarks located inboard can now<br />

be prepared for planking. The bulkhead<br />

extensions above-deck are all 3/16”<br />

wide. They must be cut down to the gunport<br />

and oarport thickness of 1/16” (see<br />

figure 30). This will allow the inboard<br />

bulwark planking to set properly against<br />

the various port frames along the inside<br />

of the bulwark plates. These extensions<br />

also should be cut flush to the deck plate.<br />

4. Outer Final Planking<br />

All outer planking, except for the deck, is<br />

.021” x 5/32” (.5 x 4 mm) walnut. The<br />

deck planking is 1/32” x 1/8” basswood.<br />

To avoid glue marks, all of these strips<br />

should be finished first before mounting.<br />

Stain the walnut planking “walnut” and<br />

the basswood deck strips “oak.” The<br />

wale is made from 1/16” x 3/16” (1.5 x 5<br />

mm) walnut and also should be stained<br />

“walnut.” This prepares all of the external<br />

planking for mounting regardless of<br />

your choice of finishes.<br />

5. Planking the Inner Bulwarks<br />

Because of the optional choice of painting,<br />

the inner bulwarks must be planked first.<br />

Planking strakes are applied from the<br />

deck plate upwards (see figure 31). Planking<br />

should be sized to the edges of the<br />

gunports, but can be run across the oarports,<br />

which are better opened after<br />

planking is completed (see figure 32).<br />

When the inner planking is done, open all<br />

ports and even up the edges (see figure<br />

33). The inner bulwarks and port edges<br />

should be painted now before the outer<br />

bulwark planking is started. If using the<br />

“all natural look” finish, the port edges<br />

should be stained at this point.<br />

6. Outboard Final Planking<br />

Outboard planking begins with the wale<br />

(see figure 34). It should be mounted<br />

with its top edge even with the bottom of<br />

the bulwark plate. If you are going to<br />

paint, the wale should be painted in<br />

place on the hull before continuing with<br />

the final planking. The wale is carried<br />

across the stern at deck level and this also<br />

should be painted if desired.<br />

7. Stern Final Planking<br />

Final planking starts at the stern, beginning<br />

first with the wale and continuing<br />

up to the top of the bulwarks (see figure<br />

35). Cut all strakes at the gunports, but<br />

FIG. 34<br />

The wale painted black. Inner bulwarks paint can<br />

be seen around edges of gunports.<br />

FIG. 35<br />

Outer transom final planking.<br />

13

FIG. 36<br />

FIG. 39<br />

Final planking of bulwarks amidships above wale.<br />

FIG. 37<br />

FIG. 38<br />

The keel amidships with one of the strengthening<br />

finishing nails showing.<br />

FIG. 40<br />

14<br />

Three laser-cut stem pieces.<br />

cover the oarports (see figure 36). The<br />

oarports are to be opened after final<br />

planking is complete, just as they were<br />

after the first layer of planking.<br />

8. Lower Hull Final Planking<br />

Before beginning the final planking of the<br />

lower hull, mount the keel, stern post<br />

and stem pieces to the false keel (see figures<br />

37 and 38). They are wider than the<br />

keel pieces, which will provide the rabbet<br />

(groove to receive plank edges) needed<br />

for planking at the bow and stern. These<br />

parts should be stained “walnut” before<br />

mounting. The keel piece should be<br />

nailed to the bottom of the false keel in<br />

addition to using glue (see figures 39 and<br />

40). Larger finishing nails can be used<br />

here, but to prevent the keel from splitting,<br />

drill holes for the nails before driving<br />

them into the wood.<br />

The stem mounted to the false keel.<br />

9. Creating Batten Lines<br />

on the Lower Hull<br />

For the hull below the wale to achieve a<br />

scale-like appearance, that area should be<br />

divided into three sections by battens before<br />

laying the final planking (see figure<br />

41). This procedure is described in the<br />

Planking <strong>Manual</strong> (included in the kit).<br />

Since there is already a hull surface provided<br />

by the first layer of planking, narrow<br />

strips of chart tape can be substituted<br />

for wooden battens. They will be easier<br />

to work around. After creating the batten<br />

divisions, plank the upper and lower<br />

sections first, then finish with the center<br />

section (see figure 42).<br />

10. Plank Tapering For the Hull<br />

The Neufchatel hull allows the simplest<br />

plank tapering. From amidships to the<br />

bow, each strake is tapered from its full<br />

width down to 1/16” (see figure 43). It is<br />

best to do this tapering off the ship on full<br />

length strips. From amidships aft, all<br />

planks are left full width, and stealers will<br />

be required (see figures 44, 45 and 46).<br />

All planking can be attached with a thin<br />

layer of white glue to hold the tougher<br />

areas. Those planks which curve around<br />

the bow should be soaked in water and<br />

held to a form, such as a jar lid, until they<br />

dry. This makes the bow planking proceed<br />

much faster.<br />

To further improve the scale look, each<br />

strake should be divided into scalelengths<br />

of 4” representing approximately<br />

21 feet. These divisions are best cut after<br />

each strake is applied, and before the<br />

next is set into place. In total, there<br />

should be 21 strakes from keel to wale.<br />

Refer to the Planking <strong>Manual</strong> for the<br />

proper spacing of plank “ends” from<br />

strake to strake. Strake ends tucked into<br />

the rabbet at bow and stern will give a<br />

The stern post and the shape of the after-end<br />

of the keel.<br />

FIG. 41<br />

Batten lines created on the lower hull with tape.<br />

FIG. 42<br />

Final planking on the lower hull.

FIG. 43<br />

FIG. 45 FIG. 47<br />

Final planking on bow showing tapering.<br />

Final planking on stern nearly completed.<br />

Start of deck final planking showing guide strip<br />

on centerline.<br />

FIG. 44 FIG. 46<br />

FIG. 48<br />

Final planking on the lower stern showing the first<br />

stealer position.<br />

Final planking amidships.<br />

A method of forming cap rail strips.<br />

very realistic appearance. For those with<br />

more ambition, treenails* can be added to<br />

the butt ends of the planks.<br />

When hull final planking is completed,<br />

another coat of stain will even out the<br />

finish.<br />

*Treenails are easily made from round tapered<br />

toothpicks which can be glued into<br />

any size hole and clipped off. Smoothing<br />

of the surface may require refinishing.<br />

11. Deck Final Planking<br />

Returning to above deck, the oak stained<br />

basswood strips will be used to cover the<br />

deck base plate. A first strake should be<br />

laid full length down the center line of<br />

the hull (see figure 47). Be sure to drill<br />

small holes at the mast openings or they<br />

will be lost as the planking continues.<br />

The next planks will fill the areas between<br />

hatch and cabin openings in the<br />

deck plate. The remainder of the plank<br />

strips can be cut into 4” lengths to be laid<br />

in a three-step pattern. Save some strips<br />

to make those planks which may require<br />

a little longer length to fill an area. (No<br />

real deck would ever have a one or two<br />

foot long plank. Once again, you eager<br />

beavers can add treenails if desired.) The<br />

deck should be planked right out to the<br />

bulwarks, but does not require an exact<br />

fit at the edges, since this joint will be<br />

covered by the waterway.<br />

The waterway is made of 1/4-round<br />

stock and should be painted red or<br />

stained “walnut” before mounting. It<br />

should be soaked and curved at the bow<br />

end before finishing and mounting. It<br />

will run the length of the bulwarks and<br />

across the stern.<br />

12. The Cap Rail<br />

To maintain a smooth curvature, the cap<br />

rail around the top of the bulwarks is<br />

made from 5/64” x 5/64” ( 2 x 2 mm)<br />

walnut strip stock. The cap rail is three<br />

strips wide with the middle centered on<br />

the bulwark top.<br />

Those portions of the rail stripping that<br />

cover the bow should be soaked and set<br />

around a form to dry (see figure 48). All<br />

strips should be finished before mounting<br />

(see figure 49). The painted version<br />

should be done in black and the “all natural<br />

look” stained “walnut.”<br />

The first rail strip to be mounted is the<br />

center strip. To it, the inner and outer<br />

strips are applied (see figure 50a). Top<br />

corner edges should be rounded and the<br />

top smoothed. Next, refinish the cap rail<br />

in the areas that were sanded. For detail,<br />

you can cut scarf lines every twenty<br />

scale-feet or so. (For those who are using<br />

the “all natural look” finish, pick rail<br />

strips that are alike in color.)<br />

This completes the Basic Hull Assembly.<br />

FIG. 49<br />

Bow cap rail strips ready for mounting.<br />

FIG. 50a<br />

Outer cap rail strips clamped for gluing.<br />

15

FIG. 50B<br />

The model on launching ways shown at a more completed stage of construction.<br />

16<br />

STAGE C<br />

MOUNTING THE HULL<br />

Before proceeding with additional work<br />

it is best to mount the hull. This step will<br />

help prevent details from becoming damaged<br />

during handling and will allow you<br />

to make any alignments that require a<br />

true waterline. Proper mounting of the<br />

hull is very important and will allow the<br />

accurate building and aligning of the remainder<br />

of the model. While any modeler<br />

can devise his own mounting, there<br />

are two commercial types of mounting<br />

available to you.<br />

1. Mounting Board with<br />

Two Pedestals (not included)<br />

The first is the traditional mounting<br />

board with two brass pedestals. This requires<br />

that holes be drilled through the<br />

keel into the false keel. The first hole<br />

drilled for the Prince de Neufchatel should<br />

be 5 1/2” from the aft end of the keel.<br />

The second hole should be spaced 8”<br />

from the first. This spacing, along with<br />

same sized pedestals, will give a proper<br />

set to the waterline. A 20” x 4 1/2” walnut<br />

baseboard will give adequate support.<br />

Screw holes in the baseboard also<br />

should be spaced 8” apart on the centerline<br />

and 6” from either end.<br />

When drilling the keel for the pedestal<br />

mounting screws, it is best to clamp<br />

wood strips on either side of the keel to<br />

prevent it from breaking out during<br />

drilling. Any thin walls will be supported<br />

by the pedestals when they are mounted<br />

between the keel and the baseboard. The<br />

screw heads at the bottom of the baseboard<br />

should be countersunk so they<br />

won’t protrude, but will instead provide<br />

a flush surface.<br />

Be sure to drill the screw holes vertically<br />

(port to starboard) as they will determine<br />

the level of the hull abeam. When inserting<br />

the screws, apply a coating of glue to<br />

help their holding power in the plywood<br />

false keel.<br />

2. Launching Ways<br />

(included in the kit)<br />

The second type of mounting that can be<br />

employed is the launching ways, which<br />

are most suitable for a model without<br />

sails (see photo 50b). It is supplied in kit<br />

form with instructions. Drilling of the<br />

keel is still required to apply the rods<br />

that anchor the model to the ways. In addition,<br />

there have to be hull props for a<br />

model the size of the Prince de Neufchatel.<br />

The launching ways are easily assembled<br />

and should be mounted on a minimal<br />

board size of 24” x 6.” (Expanding the<br />

size of the board will allow you to create<br />

a mini-diorama comprised of boat yard<br />

ground activity.) To achieve the proper<br />

waterline level the ways should rise 3/4”<br />

from stern to bow end over the 24.”<br />

Note: It is recommended that either<br />

choice mounting piece be finished before<br />

mounting the Hull Assembly into place.<br />

During mounting, be sure that the rails of<br />

the hull are level with the mount. Future<br />

alignments, especially the masting, will<br />

be gauged from this base.<br />

STAGE D<br />

DECK FURNITURE<br />

The Baltimore Clippers of the War of 1812<br />

were rather hastily built and had only a<br />

single weather deck. Because of this<br />

arrangement, only the most essential<br />

structures were incorporated in order to<br />

create the least interference with armament<br />

and larger crews. From bow to<br />

stern, the Prince de Neufchatel provided a<br />

fore grid platform with belaying pins aft<br />

at rail level, cat heads for ground tackle,<br />

bowsprit bitts, a focs’l (pronounced<br />

fokes’l which is the forecastle or forward<br />

deck popularly known as the space below<br />

cabin for crew) companionway, a simple<br />

anchor windlass with support bitts, galley<br />

hatch, amidships cargo hatch and a smaller<br />

winch forward of the mainmast (see

FIG. 51<br />

FIG. 53 FIG. 55<br />

Basic blocks created for deck furniture, hatches<br />

and cabins.<br />

FIG. 52 FIG. 54<br />

Galley hatch with stack on forward deck.<br />

Completed cabin and tiller aft. Open gunport lids<br />

can be seen.<br />

Forward companionway in place.<br />

Main hatch, pumps, aft hatch and basic cabin assembly (from right to left).<br />

figure 51). Aft of the main mast are the<br />

bilge pumps, a smaller loading and ventilating<br />

hatch and a main cabin with a companionway<br />

forward of the tiller.<br />

This section will also include fabrication<br />

of the gunport lids, channels with deadeyes<br />

and chain plates, and the belaying<br />

pin racks inboard abeam the fore and<br />

main masts.<br />

When assembling and mounting these details<br />

all finishing, paint or stain, should be<br />

applied before any glue touches the wood.<br />

1. Bowsprit & Bitts<br />

At the very bow an opening must be cut<br />

to accept the bowsprit which is nominally<br />

1/2” in diameter. The bitts should be<br />

assembled and mounted aft of it (Figures<br />

56 and 60 show these details at more<br />

completed stages of construction). These<br />

bitts, as well as others, should be pinned<br />

into the deck using the small brass nails<br />

provided. Insert the nails into the feet of<br />

the bitts, cut off the nail heads, leaving a<br />

portion of the shaft, and mount them into<br />

holes which have been drilled into the<br />

deck. The bowsprit may be mounted at<br />

this time.<br />

2. Forward Companionway<br />

The forward companionway is created<br />

with a balsa block set into the most forward<br />

opening of the deck (see figure 52). It<br />

should be planked with the .021” x 5/32”<br />

walnut planks. Trim the vertical corners<br />

with the 3/32” basswood angle and the<br />

base with 5/64” square walnut. Fashion<br />

the top out of two strips of walnut using<br />

brass strips to represent the hinges.<br />

3. Windlass Bitts (Fore & Main)<br />

Mount these upright supports in the<br />

same manner as the bowsprit bitts (see<br />

figure 56 for fore windlass bitts, and figure<br />

60 which shows catheads and rail<br />

bitts at the bow).<br />

4. Hatches (Galley, Main & Aft)<br />

All three deck hatches are constructed in<br />

the same manner (see figures 53 and 54).<br />

Cut 1/8”-thick basswood to fit each<br />

hatch opening in the deck. Paint them<br />

black and assemble grid strips to fit and<br />

glue onto the plate. This assembly should<br />

then be set, leveled and glued into the<br />

appropriate deck opening. The stained<br />

grid with the black backing gives a look<br />

of depth. Surround each of the deck<br />

hatches with a coaming of 1/16” x 1/4”<br />

basswood; either stained or painted.<br />

Note: The galley hatch is located aft of<br />

the foremast and has added detail in the<br />

form of a galley stack (see figure 53).<br />

Cover the hatch’s forward end with a<br />

solid plank as indicated in the plans and<br />

mount the stack on it.<br />

Note: An oddball hatch is located forward<br />

where the port and starboard rails<br />

meet. Use the grid as before and cut the<br />

hatch to shape. Mount 9 belaying pins in<br />

the after side and glue into place (see<br />

figure 56).<br />

5. Main Cabin<br />

Shape the main cabin from the larger<br />

balsa block to fit the deck opening. Plank<br />

it, as well as the sides of the companionway<br />

and the skylight, with the .021” x<br />

5/32” walnut (see figure 55). The cabin<br />

and companionway tops should then be<br />

covered with the scored sheet. Next,<br />

paint the top of the skylight black and<br />

then apply the 1/32” square framing.<br />

This assembly should then be set into the<br />

deck and the corners trimmed with angle<br />

stock. Then place 5/64” square molding<br />

around the bottom of the cabin at deck<br />

level. Finally, assemble the companionway<br />

door using boards slipped into a<br />

vertical frame with a latch at the top.<br />

6. Rudder, Mast openings,<br />

Pump Assemblies<br />

At the rudder post and mast openings,<br />

plates of 3/64” (l mm) walnut should be<br />

mounted (see figures 56 and 57). Mount<br />

the two pump assemblies at the rear corners<br />

of the mainmast plate (see figure 54).<br />

After shaping its post, insert the rudder<br />

17

FIG. 56 FIG. 57<br />

Rudder and fittings. “Rivets” are white glue dots<br />

that were painted black when dry.<br />

FIG. 58<br />

Completed outfitted bow with carronades, forward bitts, bow grid and fore windlass.<br />

Starboard main mast belaying pin rack. Breech<br />

ropes can be seen on carronades.<br />

18<br />

into the opening as indicated. Rudder<br />

hinges can be made from the 3/32” wide<br />

brass strip. Form the tiller from the basswood<br />

strip and mount it to the top of the<br />

rudder post (see figure 55).<br />

7. Belaying Pin Racks<br />

& Channels<br />

While not actually part of the deck furniture,<br />

the belaying pin racks and channels<br />

with their fittings can be mounted at this<br />

time. The belaying pin racks lay inboard<br />

beside each of the masts (see figure 58).<br />

Mount them at the bottom edge of the inboard<br />

rail overhang. Drill the belaying<br />

pin holes after mounting the racks. Next,<br />

position and mount the channels evenly<br />

with the belaying pin racks on the outboard<br />

rail overhang. Drill the openings in<br />

the channels that will eventually accept<br />

the deadeye/chain plate assemblies.<br />

Glue the belaying pins into the racks.<br />

Next, insert the deadeye assemblies<br />

through the channels (see figure 59).<br />

They will be pinned to the hull sides, but<br />

have to be aligned with the mast tops<br />

first. To simulate this, set false masts into<br />

the deck and align the chain plates with<br />

string attached to the proper height on<br />

the false mast. The chain plates must then<br />

be anchored with brass nails. Nail these<br />

into the hull.<br />

8. Gunport Lids<br />

Because the hull is securely mounted for<br />

safe handling, you can now introduce the<br />

gunport lids without fear of breaking<br />

them (see figure 59). The gunport lids<br />

and frames are laser cut pieces with the<br />

lids located juxtaposed inside the frames.<br />

Paint the lids red or stain them. Next,<br />

plank them horizontally with the outer<br />

hull walnut strip material. Then remove<br />

the loops from the tops of the brass<br />

hinges and blacken them. Glue them to<br />

the lids and paint the outside of the lids<br />

black. (If you’re doing the “all natural<br />

look” finish, black hinges only with the<br />

natural wood is preferred.)<br />

The aft two port lids may be positioned<br />

closed, but the remainder forward should<br />

be left open. Each opened lid is fitted into<br />

the gunport against the top edge and<br />

glued perpendicular to the hull surface.<br />

(Opened gunport lids can be seen in figures<br />

55 and 56.)<br />

9. Bow<br />

The stem is supported by two gussets.<br />

These are made from 3/64” thick walnut<br />

shaped to fit the stem and hull. Notice<br />

how they curve upward toward the end<br />

of the stem. Next, the catheads are made<br />

from 5/32” (4 mm) square walnut stock.<br />

They represent double blocks for the<br />

ground tackle and should be drilled.<br />

When at sea, the Prince de Neufchatel did<br />

not mount a bow decoration, therefore,<br />

the only trim is the stem framing which<br />

is made of basswood strip stock. Paint it<br />

yellow. Finally, the hawse pipes should<br />

be set into holes drilled into the forward<br />

bulwark. These will lead the anchor rope<br />

back to the forward windlass and then<br />

aft to the same openings in the deck beside<br />

the forward end of the main hatch<br />

(see figure 60).<br />

10. Railing Bitts & Knightheads<br />

These can be mounted now and the additional<br />

eyebolts that will be required in<br />

the rigging will be covered in the rigging<br />

section (see figure 60).<br />

11. Armament<br />

All 16 carronades and 2 long gun assemblies<br />

should be built, mounted and<br />

rigged at this time (see figures 61, 62a,<br />

62b, 62c, 62d and 62e). Carriages should<br />

be either stained or painted red. The<br />

Rigging <strong>Manual</strong> shows complete rigging<br />

details. Kit supplies only provide eyebolts<br />

and line for breech ropes. The eyebolts<br />

should be inserted into drilled<br />

holes 1/4” outside the edges of each<br />

gunport. Additional rigging of the guns<br />

will demonstrate the crowded condition<br />

of the deck of this ship which was built<br />

as a fighting machine.

FIG. 59<br />

FIG. 62b<br />

Trunnion &<br />

trunnion cap<br />

1/4”<br />

LONG GUN – 2 REQUIRED<br />

Barrel trunnion 7/16” lg–2 req, 1/16” dia. brass<br />

Wheel axle 3/4” lg–4 req, 1/16” dia brass<br />

Carriage side spacers 1/16” x 1/4” x 1/4” lg, basswood– 4 req<br />

Carriage side<br />

Axles<br />

CARRONADE – 16 REQUIRED<br />

Barrel trunnion 9/16” lg–16 req, 1/16” dia. brass<br />

Rear wheel axle 1” lg–16 req, 1/16” dia brass<br />

Front axle 13/16” lg–16 req, 1/16” dia brass<br />

Carriage side spacers 1/16” x 1/4” basswood–<br />

shape as shown, 16 each required<br />

Channel with lower deadeyes and chainplates.<br />

Gunports are closed. White glue dots are simulated<br />

“rivets” to be painted.<br />

5/16”<br />

1/2”<br />

GUN CARRIAGE ASSEMBLY<br />

1. Paint or stain assembled carriage<br />

2. Barrel with trunnion is set on assembly of carriage<br />

3. Wheel axle assemblies are mounted<br />

4. Mount trunnion caps<br />

FIG. 60<br />

FIG. 62c<br />

Rigging placement<br />

on the carronade<br />

carriage.<br />

Breech rope<br />

Outhaul<br />

tackle<br />

Bow detail showing knightheads, catheads, stem<br />

gussets, rail bitts and hawse pipe.<br />

Inhaul tackle<br />

FIG. 61<br />

FIG. 62d<br />

Rigging placement<br />

on the long gun<br />

carriage.<br />

Breech line<br />

Outhaul<br />

tackle<br />

Carronade assembly parts. The long gun is similar.<br />

Inhaul<br />

tackle<br />

FIG. 62a<br />

FIG. 62e<br />

Assembled carronade carriage.<br />

Long guns at bow showing crowding of the deck at more completed stage of construction.<br />

19

FIG. 63a<br />

FIG. 63b<br />

1<br />

Start<br />

2 3 4<br />

Rotate 180° Rotate 90° Rotate 180°<br />

Use a coarse or medium flat file<br />

Fore mast top assembly with platform.<br />

FIG. 64<br />

5 6 7<br />

8-sided 16-sided Round<br />

PROPORTIONS FOR TAPERING<br />

Yard<br />

Mast<br />

Gaff and Boom<br />

1/3 2/3<br />

Tapering spars and progression of flats.<br />

Fore top gallant with doubling and cross trees.<br />

20<br />

STAGE E<br />

MAST & SPAR CONSTRUCTION<br />

All of the parts that make up the masts<br />

and spars are drawn to full scale with dimensions.<br />

Each of the individual pieces<br />

should be cut to length and shaped (see<br />

figure 63a). They can be easily tapered by<br />

filing lengthwise, beginning with coarse<br />

files and progressing to fine files, and<br />

then sandpaper. Any minor tool marks<br />

that remain will be in keeping with the<br />

look of the actual masting which was<br />

usually hand-shaped along its length.<br />

When all pieces are shaped they should<br />

be stained “Natural Pine” before proceeding<br />

with the assembly.<br />

1. Assembling the Masts<br />

When completed, both mast assemblies<br />

must be built in line from port to starboard<br />

to allow proper rigging set-up:<br />

Fore mast: This mast is built up in three<br />

sections: lower, top and top gallant. They<br />

should be connected at the doublings by<br />

mast caps and trestle trees. Cross trees<br />

also should be added between the top<br />

and top gallant (see figures 63b, 64 and<br />

66a). Assemble and position a top platform<br />

between the lower and top mast.<br />

This top should be at a 10-degree angle to<br />

the mast so that it will sit level when the<br />

mast is mounted to the hull. Both masts<br />

have a 10-degree rake.<br />

Main mast: This mast is built up in two<br />

sections: lower and top mast poles. Connect<br />

them at the doubling with mast cap<br />

and trestle trees. Add cross trees to the<br />

trestle trees.<br />

When the mast assemblies are completed,<br />

position and mount the support cheeks<br />

into place at the doublings as shown in<br />