Effect of Thermal Cycles on Compressive Strength of Different ...

Effect of Thermal Cycles on Compressive Strength of Different ...

Effect of Thermal Cycles on Compressive Strength of Different ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Thermal</str<strong>on</strong>g> <str<strong>on</strong>g>Cycles</str<strong>on</strong>g> <strong>on</strong> <strong>Compressive</strong> <strong>Strength</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Different</strong><br />

Grades <str<strong>on</strong>g>of</str<strong>on</strong>g> C<strong>on</strong>crete<br />

K . Chandramouli 1 , P. Srinivasa Rao 2 , T. Seshadri Sekhar 3 , N. Pannirselvam 4 and P. Sravana 2<br />

1 NRI Institute <str<strong>on</strong>g>of</str<strong>on</strong>g> Technology, Visadala, Guntur, Andhra Pradesh, 2 Jawaharlal Nehru Technological University, College <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Engineering, Hyderabad, Andhra Pradesh, 3 Principal Chirala Engineering College, Chirala, Prakasam District, Andhra Pradesh<br />

4 Vellore Institute <str<strong>on</strong>g>of</str<strong>on</strong>g> Technology University, Vellore, Tamilnadu<br />

ss.tirumala@gmail.com<br />

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------.<br />

Abstract -- C<strong>on</strong>crete in structures when exposed to high Objectives <str<strong>on</strong>g>of</str<strong>on</strong>g> the Study: The objectives <str<strong>on</strong>g>of</str<strong>on</strong>g> the current research<br />

temperature gets stressed. This paper reports <strong>on</strong> the work is to study the compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete for<br />

experimental study <strong>on</strong> the compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary different grades <str<strong>on</strong>g>of</str<strong>on</strong>g> M20, M30, M40 and M50 with zero<br />

grade <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete such as M20, M30, M40 and M50 subjected to<br />

thermal cycles <str<strong>on</strong>g>of</str<strong>on</strong>g> 28, 56, 90, and 180 for 50° C.<br />

thermal cycles at a temperature <str<strong>on</strong>g>of</str<strong>on</strong>g> 50º C. The experimental<br />

program <strong>on</strong> c<strong>on</strong>crete specimens <str<strong>on</strong>g>of</str<strong>on</strong>g> size 100 x 100 x 100 mm cubes<br />

were cast for testing compressive strength. The test specimens<br />

II. MATERIALS AND METHODS<br />

were demoulded after 24 hours <str<strong>on</strong>g>of</str<strong>on</strong>g> air cooling and kept for water Cement: Ordinary Portland cement available in local market<br />

curing for 28 days. The decrease in compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> standard brand was used in the investigati<strong>on</strong>. Cement used<br />

ordinary c<strong>on</strong>crete mixes in comparis<strong>on</strong> with zero thermal cycles has been tested for various proporti<strong>on</strong>s as per IS 4031-1988<br />

for 50° C are observed to be varied from 14 to 23 % for 28, 56, and found to be c<strong>on</strong>firming to various specificati<strong>on</strong>s are IS<br />

90, and 180 thermal cycles.<br />

12269-1987. The specific gravity was 2.96 and fineness was<br />

3200 cm 2 /gm. The cement c<strong>on</strong>firms to 53 Grade.<br />

Keywords: C<strong>on</strong>crete, Grade <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete, <str<strong>on</strong>g>Thermal</str<strong>on</strong>g> cycle.<br />

I. INTRODUCTION<br />

CONCRETE is an organic material than the high temperature<br />

and its durati<strong>on</strong> decreases the c<strong>on</strong>crete strength and its<br />

durability. Fire resistance <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete is affected by factors<br />

like temperatures, durati<strong>on</strong> and c<strong>on</strong>diti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the fire. The type<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> materials used in the c<strong>on</strong>structi<strong>on</strong> has porosity and moisture<br />

c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete, its thermal properties and the size <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

structural member and the type <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>structi<strong>on</strong> determines the<br />

fire resistivity <str<strong>on</strong>g>of</str<strong>on</strong>g> the material and increase in the size <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

structural member increase the fire resistance. To determine<br />

the resistance <str<strong>on</strong>g>of</str<strong>on</strong>g> the c<strong>on</strong>crete samples exposed to high<br />

temperatures and in order to determine the compressive<br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete at elevated temperatures. The unstressed,<br />

property test method is to provide property data <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete at<br />

room temperature after exposed to elevated temperatures<br />

[1, 2].<br />

Coarse aggregate: Crushed angular granite metal <str<strong>on</strong>g>of</str<strong>on</strong>g> 20 mm<br />

size from a local source was used as coarse aggregate. The<br />

specific gravity <str<strong>on</strong>g>of</str<strong>on</strong>g> 2.61 and fineness modulus 7.13 was used.<br />

Fine aggregate: River sand was used as fine aggregate. The<br />

specific gravity <str<strong>on</strong>g>of</str<strong>on</strong>g> 2.58 and fineness modulus 3.25 .<br />

Preparati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Specimens: The present investigati<strong>on</strong> is a study<br />

<strong>on</strong> the compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete specimens<br />

subjected to thermal cycles at a temperature <str<strong>on</strong>g>of</str<strong>on</strong>g> 50º C. This<br />

was planned to be carried out through an experimental<br />

program <strong>on</strong> c<strong>on</strong>crete specimens <str<strong>on</strong>g>of</str<strong>on</strong>g> size 100 x 100 x 100 mm<br />

cubes for compressive strength. The test specimens were<br />

demoulded after 24 hours <str<strong>on</strong>g>of</str<strong>on</strong>g> air cooling and kept for water<br />

curing for 28 days. The design mix proporti<strong>on</strong>s are given in<br />

Table 1.<br />

At high temperatures, Portland cement c<strong>on</strong>cretes undergo<br />

important changes in their properties, due to the degradati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> its internal structure. The c<strong>on</strong>crete structures could be<br />

exposed to high temperatures due to different reas<strong>on</strong>s. Mainly<br />

during exposure to fire; another <strong>on</strong>e could be when the<br />

structure or its elements are a part <str<strong>on</strong>g>of</str<strong>on</strong>g> industrial installati<strong>on</strong>s [3,<br />

4]. The adverse effects <str<strong>on</strong>g>of</str<strong>on</strong>g> l<strong>on</strong>g-term exposure <str<strong>on</strong>g>of</str<strong>on</strong>g> plain cement<br />

mortars and c<strong>on</strong>crete to hot weather c<strong>on</strong>diti<strong>on</strong>s [5].<br />

<str<strong>on</strong>g>Thermal</str<strong>on</strong>g> Cycle Procedure: One thermal cycle c<strong>on</strong>stitute a<br />

heating period <str<strong>on</strong>g>of</str<strong>on</strong>g> 8 hours and subsequent cooling (in air<br />

room temperature) period <str<strong>on</strong>g>of</str<strong>on</strong>g> 16 hours. The standard<br />

specimens after curing period were placed in electric<br />

ovens at 50º C for 0, 28, 56, 90 and 180 thermal cycles.<br />

The specimens were removed from ovens and then<br />

allowed to cool in air for 2 hours after specified time.<br />

56

COMPRESSIVE STRENGTH OF CONCRETE<br />

Then the specimens were tested for compressive strength<br />

and the details are tabulated in Table 2.<br />

III. RESULTS AND DISCUSSION<br />

<strong>Compressive</strong> <strong>Strength</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ordinary C<strong>on</strong>crete at Zero <str<strong>on</strong>g>Thermal</str<strong>on</strong>g><br />

<str<strong>on</strong>g>Cycles</str<strong>on</strong>g>: Table 2 gives a comparative study <strong>on</strong> compressive<br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> various grades <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete mixes <str<strong>on</strong>g>of</str<strong>on</strong>g> M20,<br />

M30, M40 and M50 investigated at zero thermal cycles at 50º<br />

C. The values are observed to be varied from 36.6 to 54.2<br />

N/mm 2 .<br />

<strong>Compressive</strong> <strong>Strength</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ordinary C<strong>on</strong>crete Mixes at 28<br />

<str<strong>on</strong>g>Thermal</str<strong>on</strong>g> <str<strong>on</strong>g>Cycles</str<strong>on</strong>g>: Table 2 gives a comparative study <strong>on</strong><br />

compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> various grades <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete<br />

mixes <str<strong>on</strong>g>of</str<strong>on</strong>g> M20, M30, M40 and M50 investigated at 28 thermal<br />

cycles at 50º C. These values are observed to be varied from<br />

31.1 to 46.1 N/mm 2 .<br />

<strong>Compressive</strong> <strong>Strength</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ordinary C<strong>on</strong>crete Mixes at 56<br />

<str<strong>on</strong>g>Thermal</str<strong>on</strong>g> <str<strong>on</strong>g>Cycles</str<strong>on</strong>g>: Table 2 gives a comparative study <strong>on</strong><br />

compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> various grades <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete<br />

mixes <str<strong>on</strong>g>of</str<strong>on</strong>g> M20, M30, M40 and M50 investigated at 56 thermal<br />

cycles at 50º C. The values are observed to be varied from<br />

30.0 to 44.4 N/mm 2 .<br />

<strong>Compressive</strong> <strong>Strength</strong> Properties <str<strong>on</strong>g>of</str<strong>on</strong>g> Ordinary C<strong>on</strong>crete Mixes<br />

at 90 <str<strong>on</strong>g>Thermal</str<strong>on</strong>g> <str<strong>on</strong>g>Cycles</str<strong>on</strong>g>: Table 2 gives a comparative study <strong>on</strong><br />

compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> various grades <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete<br />

mixes <str<strong>on</strong>g>of</str<strong>on</strong>g> M20, M30, M40 and M50 investigated at 90 thermal<br />

cycles at 50º C. These values are observed to be varied from<br />

28.9 to 42.8 N/mm 2 .<br />

<strong>Compressive</strong> <strong>Strength</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ordinary C<strong>on</strong>crete Mixes at 180<br />

<str<strong>on</strong>g>Thermal</str<strong>on</strong>g> <str<strong>on</strong>g>Cycles</str<strong>on</strong>g>: Table 2 gives a comparative study <strong>on</strong><br />

compressive strength <strong>on</strong> various grades <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete<br />

mixes <str<strong>on</strong>g>of</str<strong>on</strong>g> M20, M30, M40 and M50 investigated at 180<br />

thermal cycles at 50º C. The values are observed to be varied<br />

from 28.5 to 42.3 N/mm 2 . The variati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> compressive<br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete at 0, 28, 56, 90 and 180 thermal<br />

cycles are presented in Fig.1.<br />

Variati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>Compressive</strong> <strong>Strength</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ordinary C<strong>on</strong>crete<br />

Mixes Compared With Zero <str<strong>on</strong>g>Thermal</str<strong>on</strong>g> <str<strong>on</strong>g>Cycles</str<strong>on</strong>g>: Table 3 gives<br />

percentage decrease in compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> various grades<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete mixes in comparis<strong>on</strong> with zero thermal<br />

cycles for 50° C is observed to be varied from 14 to 23 % for<br />

28, 56, 90, and 180 thermal cycles.<br />

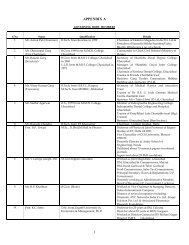

TABLE 1 DESIGN MIX PROPORTIONS OF ORDINARY CONCRETE MIXES<br />

Grade <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

c<strong>on</strong>crete<br />

Cement<br />

Fine<br />

aggregate<br />

Coarse<br />

aggregate<br />

w/c<br />

M 20 1 2.30 3.52 0.55<br />

M 30 1 1.96 3.25 0.50<br />

M 40 1 1.51 2.93 0.40<br />

M 50 1 1.31 2.54 0.36<br />

TABLE 2 THERMAL EFFECTS ON COMPRESSIVE STRENGTH OF ORDINARY CONCRETE AT 50 ° C AT VARIOUS THERMAL CYCLES<br />

Grade <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete No <str<strong>on</strong>g>of</str<strong>on</strong>g> thermal<br />

cycles<br />

<strong>Compressive</strong> strength at 50 ° C<br />

<strong>Compressive</strong> strength<br />

(MPa)<br />

M 20 M 30 M 40 M 50<br />

0 36.6 41.5 47.9 54.2<br />

28 31.1 35.3 40.7 46.1<br />

56 30.0 34.0 39.3 44.4<br />

90 28.9 32.8 37.8 42.8<br />

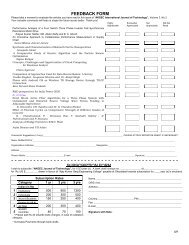

TABLE 3<br />

AT 50 ° C<br />

PERCENTAGE OF VARIATION IN COMPRESSIVE STRENGTH OF ORDINARY CONCRETE COMPARED WITH ZERO THERMAL CYCLES<br />

Grade <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete<br />

No. <str<strong>on</strong>g>of</str<strong>on</strong>g> thermal cycles<br />

<strong>Compressive</strong> strength at 50 ° C<br />

(Decrease)<br />

M 20<br />

0 -<br />

28 15.02<br />

56 18.03<br />

57

<strong>Compressive</strong><br />

Strewngtrh ( MPa)<br />

M 30<br />

M 40<br />

M 50<br />

90 21.03<br />

180 22.13<br />

0 -<br />

28 14.94<br />

56 18.07<br />

90 20.96<br />

180 21.93<br />

0 -<br />

28 15.03<br />

56 17.95<br />

90 21.08<br />

180 21.92<br />

0 -<br />

28 14.94<br />

56 18.08<br />

90 20.80<br />

180 21.96<br />

Fig.1 Variati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Compressive</strong> <strong>Strength</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ordinary C<strong>on</strong>crete at <strong>Different</strong><br />

<str<strong>on</strong>g>Thermal</str<strong>on</strong>g> <str<strong>on</strong>g>Cycles</str<strong>on</strong>g> at 50º C<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

28 56 90 180<br />

No <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Thermal</str<strong>on</strong>g> <str<strong>on</strong>g>Cycles</str<strong>on</strong>g><br />

M 20<br />

M 30<br />

M 40<br />

M 50<br />

IV. CONCLUSION<br />

C<strong>on</strong>crete specimens c<strong>on</strong>taining ordinary Portland cement<br />

undergo deteriorati<strong>on</strong> in term <str<strong>on</strong>g>of</str<strong>on</strong>g> compressive strength and<br />

exposed to air temperatures higher than 25º C for a l<strong>on</strong>ger<br />

period.<br />

The effect <str<strong>on</strong>g>of</str<strong>on</strong>g> temperatures is related to either the weaker<br />

formati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> cement paste hydrates are the differential thermal<br />

expansi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> matrix comp<strong>on</strong>ents.<br />

The decrease in compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> ordinary c<strong>on</strong>crete<br />

mixes in comparis<strong>on</strong> with zero thermal cycles for 50° C is<br />

observed to be varied from 14 to 23 % for 28, 56, 90, and<br />

180 thermal cycles.<br />

V. REFERENCES<br />

1. Phan LT, Carino NJ., 2003, Code Provisi<strong>on</strong>s for High<br />

<strong>Strength</strong> C<strong>on</strong>crete <strong>Strength</strong> Temperature Relati<strong>on</strong>ship at<br />

Elevated Temperatures, Material Structure, 36(256): 91–<br />

98.<br />

2. Husem M., 2006, The <str<strong>on</strong>g>Effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> High Temperature<br />

<strong>on</strong> <strong>Compressive</strong> and Flexural <strong>Strength</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> Ordinary and<br />

High-Performance C<strong>on</strong>crete, Fire Safety Journal, 41:<br />

155–63.<br />

58

COMPRESSIVE STRENGTH OF CONCRETE<br />

3. Bazant, Z. and Kaplan, M., 1996, C<strong>on</strong>crete at High<br />

Temperatures, L<strong>on</strong>gman Group Limited, UK.<br />

4. Smith, P., 1994, Resistance to Fire and High Temperature<br />

Significance <str<strong>on</strong>g>of</str<strong>on</strong>g> Tests and Properties <str<strong>on</strong>g>of</str<strong>on</strong>g> C<strong>on</strong>crete and<br />

C<strong>on</strong>crete-Making Materials, STP 169C, ASTM Internati<strong>on</strong>al,<br />

West C<strong>on</strong>shohocken, PA, 282–295.<br />

5. Mirza, W. H. & A1-Noury, S. I., 1985, Mortar in an<br />

Adverse Climate, C<strong>on</strong>crete Internati<strong>on</strong>al Design and<br />

C<strong>on</strong>structi<strong>on</strong>, ACI, 7 (8), 56-64.<br />

Dr. Seshadri Sekhar.T graduated from KSRM<br />

college <str<strong>on</strong>g>of</str<strong>on</strong>g> Engineering affiliated to S.V.<br />

University, Tirupati in Civil Engineering, and<br />

Completed M.Tech with specializati<strong>on</strong> in<br />

Structural Engineering from JNTU College <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Engineering Hyderabad.<br />

Completed M.S.(S<str<strong>on</strong>g>of</str<strong>on</strong>g>tware Systems ) from BITS<br />

Pilani. His research areas <str<strong>on</strong>g>of</str<strong>on</strong>g> interest are Special<br />

C<strong>on</strong>cretes. Has published over 60 research<br />

papers.<br />

He was associated with nearly 25 M. Tech projects. He is Member <str<strong>on</strong>g>of</str<strong>on</strong>g> ISTE,<br />

IEEE and Fellow <str<strong>on</strong>g>of</str<strong>on</strong>g> IETE.<br />

Dr P. Srinivasa Rao specialized in<br />

structural engineering. His Research<br />

interests are C<strong>on</strong>crete Technology,<br />

Structural Design, High Performance<br />

C<strong>on</strong>crete, Prefabricating Structures, Special<br />

C<strong>on</strong>cretes and use <str<strong>on</strong>g>of</str<strong>on</strong>g> Micro Silica, Fly Ash<br />

in Building Materials. He has been<br />

associated with a number <str<strong>on</strong>g>of</str<strong>on</strong>g> Design<br />

projects, for number <str<strong>on</strong>g>of</str<strong>on</strong>g> organizati<strong>on</strong>s and<br />

involved as a key pers<strong>on</strong> in Quality<br />

c<strong>on</strong>trol and Mix Designs.<br />

Dr . P. Sravana is an Associate Pr<str<strong>on</strong>g>of</str<strong>on</strong>g>essor<br />

at J.N.T.University , Kukatpally ,<br />

Hyderabad. Specialized in transportati<strong>on</strong><br />

engineering . Research interests are Special<br />

c<strong>on</strong>cretes , Pavement Design. She has been<br />

associated with a number <str<strong>on</strong>g>of</str<strong>on</strong>g> design<br />

projects for number <str<strong>on</strong>g>of</str<strong>on</strong>g> organizati<strong>on</strong>s and<br />

involved as a key pers<strong>on</strong> in Quality<br />

c<strong>on</strong>trol, Mix Designs and Bitumen<br />

Evaluati<strong>on</strong> Tests. .Has 12 years <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

academic, research and industrial<br />

experience and published over 30 research<br />

papers.<br />

59