Comparison of Friction Stir Welding, Friction Surfacing and other ...

Comparison of Friction Stir Welding, Friction Surfacing and other ...

Comparison of Friction Stir Welding, Friction Surfacing and other ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AKGEC INTERNATIONAL JOURNAL OF TECHNOLOGY, Vol. 4, No. 1<br />

<strong>Comparison</strong> <strong>of</strong> <strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong>, <strong>Friction</strong> <strong>Surfacing</strong> <strong>and</strong><br />

<strong>other</strong> <strong>Welding</strong> Processes<br />

Dr. M. Lakshmana Rao 1 , P. Suresh Babu 2 , Y. Seenaiah 3 <strong>and</strong> T. Rammohan 4<br />

1<br />

Department <strong>of</strong> Mechanical Engineering, Prakasam Engineering College, K<strong>and</strong>ukur 523105 AP.<br />

2<br />

Department <strong>of</strong> Mechanical Engineering, Rao & Naidu Engineering College, Ongole 523001 AP.<br />

3<br />

Department <strong>of</strong> Mechanical Engineering, RISE Prakasam School <strong>of</strong> Engineering, Vallur 523272 AP.<br />

4<br />

Department <strong>of</strong> Mechanical Engineering, Brilliant College <strong>of</strong> Engineering, Hyderabad AP.<br />

1<br />

lakshmanrao5@yahoo.com , 2 Sureshbabudevi.p@gmail.com, 3 seenaiah_yanamala@yahoo.co.in, 4 tocrm123@gmail.com<br />

Abstract -- <strong>Friction</strong> stir <strong>Welding</strong> Process (FSW) is a solid state<br />

welding method developed by The <strong>Welding</strong> Institute (TWI), <strong>and</strong><br />

now being increasingly used in the welding <strong>of</strong> Aluminum<br />

including steels. FSW has now extended to variety <strong>of</strong> materials<br />

including steels <strong>and</strong> polymers. Research towards the further<br />

extension <strong>of</strong> the process to join dissimilar metal combinations<br />

like Fe-Al <strong>and</strong> Al-Cu is currently underway. This paper highlights<br />

the comparative study between FSW <strong>and</strong> <strong>Friction</strong> surfacing,<strong>other</strong><br />

joining processes. Hence this study may be helpful for enhancing<br />

the welding quality. This study to be helpful for those who are<br />

engaged in this area.<br />

Keywords: <strong>Friction</strong>, <strong>Welding</strong>, <strong>Comparison</strong>, FSW, Quality, Properties,<br />

<strong>Surfacing</strong>.<br />

I. INTRODUCTION<br />

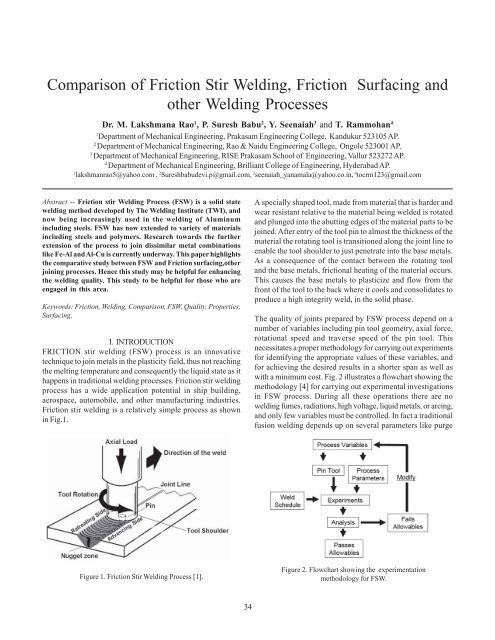

FRICTION stir welding (FSW) process is an innovative<br />

technique to join metals in the plasticity field, thus not reaching<br />

the melting temperature <strong>and</strong> consequently the liquid state as it<br />

happens in traditional welding processes. <strong>Friction</strong> stir welding<br />

process has a wide application potential in ship building,<br />

aerospace, automobile, <strong>and</strong> <strong>other</strong> manufacturing industries.<br />

<strong>Friction</strong> stir welding is a relatively simple process as shown<br />

in Fig.1.<br />

A specially shaped tool, made from material that is harder <strong>and</strong><br />

wear resistant relative to the material being welded is rotated<br />

<strong>and</strong> plunged into the abutting edges <strong>of</strong> the material parts to be<br />

joined. After entry <strong>of</strong> the tool pin to almost the thickness <strong>of</strong> the<br />

material the rotating tool is transitioned along the joint line to<br />

enable the tool shoulder to just penetrate into the base metals.<br />

As a consequence <strong>of</strong> the contact between the rotating tool<br />

<strong>and</strong> the base metals, frictional heating <strong>of</strong> the material occurs.<br />

This causes the base metals to plasticize <strong>and</strong> flow from the<br />

front <strong>of</strong> the tool to the back where it cools <strong>and</strong> consolidates to<br />

produce a high integrity weld, in the solid phase.<br />

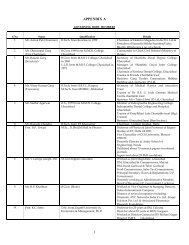

The quality <strong>of</strong> joints prepared by FSW process depend on a<br />

number <strong>of</strong> variables including pin tool geometry, axial force,<br />

rotational speed <strong>and</strong> traverse speed <strong>of</strong> the pin tool. This<br />

necessitates a proper methodology for carrying out experiments<br />

for identifying the appropriate values <strong>of</strong> these variables, <strong>and</strong><br />

for achieving the desired results in a shorter span as well as<br />

with a minimum cost. Fig. 2 illustrates a flowchart showing the<br />

methodology [4] for carrying out experimental investigations<br />

in FSW process. During all these operations there are no<br />

welding fumes, radiations, high voltage, liquid metals, or arcing,<br />

<strong>and</strong> only few variables must be controlled. In fact a traditional<br />

fusion welding depends up on several parameters like purge<br />

Figure 1. <strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong> Process [1].<br />

Figure 2. Flowchart showing the experimentation<br />

methodology for FSW.<br />

34

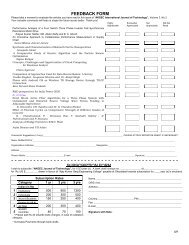

COMPARISON OF WELDING PROCESSES<br />

gas, voltage, amperage, wire feed, travel speed, shield gas <strong>and</strong><br />

arc gap, while the FSW process can be controlled with the<br />

rotation speed, travel speed, pin tool pressure <strong>and</strong> eventually<br />

<strong>other</strong> minor variables<br />

II. COMPARISONS BETWEEN FSW & TIG<br />

1) The formation <strong>of</strong> fine, equi-axed grains <strong>and</strong> uniformly<br />

distributed very fine strengthening precipitates in the<br />

weld region is the reason for superior tensile properties<br />

<strong>of</strong> FSW joints compared to TIG joints [3].<br />

2) The fractography <strong>of</strong> FSW joint revealed fine dimples<br />

<strong>and</strong> TIG joint reveled course dimples, which shows that<br />

FSW joints have higher ductility compared to TIG<br />

joints[3].<br />

the material is melted using conventional welding<br />

techniques [4].<br />

III. COMPARISION OF MATERIAL PROPERTIES<br />

BETWEEN FSW AND OTHER PROCESSES<br />

The tensile strength <strong>of</strong> the FSW joint is stronger than the MIG<br />

joint, but lower than the base metal as seen in fig.3.The impact<br />

strength <strong>of</strong> the FSW have more than the base metal <strong>and</strong> MIG<br />

joint as seen in fig.4. The relative cost <strong>of</strong> the FSW joint is less<br />

than the MIG joint shown in fig.5. Elongation <strong>of</strong> the FSW joint<br />

is more than the MIG joint, but lower than the base metal as<br />

seen in fig.6. The FSW process gives a fine microstructure,<br />

while MIG welds have carse structure. Higher performance in<br />

3) FSW joint exhibited higher strength values (51% <strong>of</strong> base<br />

material) compared to TIG joint (44.5%) [3].<br />

4) Micro hardness tests confirm the general decay <strong>of</strong><br />

mechanical properties induced by higher temperature<br />

experienced by material in case <strong>of</strong> TIG joint [3].<br />

5) Micro hardness tests performed in case <strong>of</strong> FSW joint<br />

shows great differences among four different zones,<br />

nugget zone, TMAZ (Thermo Mechanically Affected<br />

Zone), HAZ (Heat Affected Zone) <strong>and</strong> base metal. The<br />

first two zones are characterized by a general drop <strong>of</strong><br />

mechanical properties, even though nugget zone showed<br />

a slight recovery due to fine grain structure [3].<br />

Figure 3. UTS <strong>of</strong> Base Metal, FSW <strong>and</strong> MIG [4].<br />

6) From industrial prospective, FSW is very competitive<br />

because it saves energy due to less heat input, prevents<br />

joints from fusion related defects, is cost effective <strong>and</strong><br />

has better strength than TIG joint [3].<br />

7) FSW is an exciting process for welding pieces <strong>of</strong> material<br />

together as receives little (or) no weld preparations,<br />

operates at relatively low temperatures. So gives <strong>of</strong>f no<br />

fumes, is environmentally friendly, energy efficient <strong>and</strong><br />

can be used by only semi-skilled personnel to produce a<br />

satisfactory weld. This process is suitable for welding<br />

plate, pipe (or) fabrications <strong>and</strong> has been used to built<br />

up components <strong>of</strong> complex shape [4].<br />

Figure 4. <strong>Comparison</strong> <strong>of</strong> strength between<br />

Base Metal, FSW <strong>and</strong> MIG [4].<br />

8) As TIG <strong>and</strong> MIG welding processes replaced most <strong>of</strong> the<br />

original stick welding operations in the past, it is<br />

envisaged that FSW will displace many <strong>of</strong> the current<br />

TIG (or) MIG welding applications with reduced costs<br />

<strong>and</strong> superior weld quality [4].<br />

9) As the welding is carried out below the melting point <strong>of</strong><br />

the material there is minimum heat affected zone with the<br />

reduced ductility as observed with conventional<br />

techniques. This can be particularly advantageous with<br />

some aluminum alloys as segregation can occur when<br />

Figure 5. Relative cost <strong>of</strong> FSW <strong>and</strong> MIG [4].<br />

35

AKGEC INTERNATIONAL JOURNAL OF TECHNOLOGY, Vol. 4, No. 1<br />

The mechanism <strong>of</strong> bonding when mild steel is coated with<br />

aluminum alloy as well as MMC is the formation <strong>of</strong><br />

intermettallics. Stainless steel coating <strong>of</strong> mild steel leads to<br />

the formation <strong>of</strong> carbides in the stainless steel adjacent to the<br />

interface as a result <strong>of</strong> carbon migration from mild steel towards<br />

stainless steel [11].<br />

Figure 6. Elongation <strong>of</strong> Base Metal, FSW <strong>and</strong> MIG [4].<br />

production rate <strong>and</strong> quality as well as decreasing production<br />

costs, can be obtained by FSW welding. They required preoperations<br />

before the welding process are very limited in FSW.<br />

This feature <strong>of</strong> the FSW process saves consumable material,<br />

time cost <strong>and</strong> improves the quality <strong>of</strong> the welds [5].<br />

IV. FRICTION SURFACING<br />

<strong>Friction</strong> surfacing <strong>of</strong> the alloy was carried out using a<br />

commercially available friction surfacing machine was<br />

employed.The consumable was mounted on a holder that was<br />

attached to the arbor <strong>of</strong> the machine.The substrate plate was<br />

designed,cleaned <strong>and</strong> held in the vice,which is fixed on the<br />

table <strong>of</strong> the drilling machine.Arbor is moved to the position <strong>of</strong><br />

the starting plate <strong>and</strong> is lowered down into position to deposit<br />

the material on the starting plate.Once the loaded end <strong>of</strong> the<br />

consumable is suffeciently hot(red hot),the arbor is moved<br />

into position to deposit the materail on the substrate.The radial<br />

drilling machine was set at a certain speed <strong>of</strong> rpm .The<br />

translatory motion was manual .Once, the consumable was<br />

suffeciently hot (red hot), <strong>and</strong> then the traverse feed was given<br />

to the surfacing consuamble.The hot consumable material<br />

flows plastically over the substrate to form a thick coating<br />

process shown in Fig.7 [11].<br />

Figure 7. <strong>Friction</strong> <strong>Surfacing</strong>.<br />

IV. INDUSTRIAL SIGNIFICANCE<br />

The potential significance <strong>of</strong> technology lies in its superiority<br />

<strong>of</strong> retaining excellent mechanical <strong>and</strong> structural integrity <strong>of</strong> the<br />

welds <strong>and</strong> its capability <strong>of</strong> being able to weld previously difficult<br />

to weld materials, as well as welding <strong>of</strong> dissimilar metals.<br />

An<strong>other</strong> emerging trend <strong>of</strong> this technology is the repair <strong>of</strong><br />

structural surfaces or repair <strong>of</strong> weldments, one <strong>of</strong> which is the<br />

<strong>Friction</strong> <strong>Stir</strong> Processing (FSP) <strong>of</strong> materials as to enhance surface<br />

characteristics <strong>and</strong> its mechanical properties [9].<br />

V. CONCLUSION<br />

1) <strong>Comparison</strong>s are shown between FSW <strong>and</strong> <strong>other</strong><br />

processes like TIG, MIG<br />

2) From industrial prospective, FSW is very competitive<br />

because it saves energy due to less heat input, prevents<br />

joints from fusion related defects, is cost effective <strong>and</strong><br />

has better strength than TIG joint<br />

3) Material properties are compared <strong>and</strong> shown between<br />

FSW <strong>and</strong> Other processes.<br />

4) <strong>Friction</strong> surface process is discussed<br />

5) The potential significance <strong>of</strong> the technology lies in its<br />

superiority <strong>of</strong> retaining excellent mechanical <strong>and</strong><br />

structural integrity <strong>of</strong> the welds <strong>and</strong> its capability <strong>of</strong> being<br />

able to weld previously difficult to weld materials, as<br />

well as welding dissimilar metals.<br />

VI. REFERENCES<br />

[1] A. Hartawan, T.B. Thoe, S.T. Ng, H. Wu <strong>and</strong> K.Liu, “Initial<br />

Investigation in to <strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong>”, SIMTech Technical<br />

Reports (STR_V10_N1-02-MTG) Vol. 10, No. 1, Jan-Mar<br />

2009.<br />

[2] V. Soundarrajan, M. Valant <strong>and</strong> R. Kovacevic, “An Overview<br />

<strong>of</strong> R&D work in <strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong> at SMU”, Association<br />

<strong>of</strong> Metallurgical Engineers <strong>of</strong> Serbia AMES,<br />

UDC:669.141243.046.516-20.<br />

[3] Ratnesh K. Shukla <strong>and</strong> Pavin K.Shah, “Comparative study <strong>of</strong><br />

<strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong> <strong>and</strong> Tungsten inert gas welding process”<br />

Indian Journal <strong>of</strong> Science <strong>and</strong> Technology, Vol.3, No.6, June<br />

2010.<br />

[4] C.E.D Rowe et al. “Advances in Tooling Matreials for <strong>Friction</strong><br />

<strong>Stir</strong> <strong>Welding</strong>”, TWI <strong>and</strong> Cedar Metals Ltd. pp 1-11.<br />

[5] Mustafa.K.K, Erdinc. Kaluc,Aydin Sic, “ Experimental<br />

Investigation <strong>of</strong> MIG <strong>and</strong> <strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong> process <strong>of</strong><br />

Al(6061) alloy” The Arabian Journal for Science <strong>and</strong><br />

Engineering Vol. 35, No.1B, Apr 2010.<br />

[6] J.A. Querin, H.A. Rubis<strong>of</strong>f <strong>and</strong> J.A. Schneider, “Pin Tool<br />

Geometry Effects in <strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong>”. TWI (The <strong>Welding</strong><br />

36

COMPARISON OF WELDING PROCESSES<br />

Institute), pp 1-5.<br />

[7] John Martin, “Materials for Engineering”, Second Edition,<br />

WPL, Cambridge, Engl<strong>and</strong>, 2002.<br />

[8] Stefano Ferretti, DIEM, University <strong>of</strong> Bologona, “<strong>Friction</strong><br />

<strong>Stir</strong> <strong>Welding</strong> Process Optimization: Experimental Methods”,<br />

International conference 2009, Bologona, pp 210-214.<br />

[9] A.Hartawan, T.B.Thoe, S.T.Ng, H.Wu, <strong>and</strong> K.Liu “ Intitial<br />

Investigation Into <strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong>” SIMTech Technical<br />

Reports (STR_V10_N1_02_MTG) Jan-Mar 2009.<br />

[10] Stefano Ferretti, “<strong>Friction</strong> <strong>Stir</strong> <strong>Welding</strong> process optimization:<br />

Experimental methods” DIEM, University <strong>of</strong> Bologna Via<br />

Risorgimento, 2-40136 Bologna.<br />

[11] G. Madhusudan Reddy, ”<strong>Friction</strong> <strong>Surfacing</strong> <strong>of</strong> Metallic coatings<br />

on steels”, Proc. Workshop on <strong>Friction</strong> <strong>Welding</strong> & <strong>Friction</strong><br />

<strong>Stir</strong> <strong>Welding</strong>, Nov.24-25, 2011. pp 5.1 -5.9<br />

Pr<strong>of</strong> Dr. M. Lakshman Rao is currently<br />

Principal, Prakasam Engineering College,<br />

K<strong>and</strong>ukur. Obtained BTech degree in<br />

Mechanical engineering form S.K. University-<br />

Ananthapur in 1994 <strong>and</strong> ME degree in<br />

Production Engineering from MNNIT,<br />

Allahabad in 1997. Conferred Doctorate (PhD<br />

Mech.) by Osmania University, Hyderabad in<br />

2010.<br />

Seenaiah Yanamalam<strong>and</strong>a obtained BTech<br />

degree in Mechanical Engineering from RVRJC<br />

College <strong>of</strong> Engineering <strong>and</strong> MTech in<br />

Production Engineering from SVU College <strong>of</strong><br />

Engineering.<br />

Presently pursuing PhD research work at JNTU<br />

Kakinada.<br />

Published articles on welding in conferences<br />

<strong>and</strong> journals. Has over 10 years experience in teaching.<br />

C. Rama Moihana Rao studied graduation<br />

(AMIE) from the Institution <strong>of</strong> Engineers <strong>and</strong><br />

Masters from JNTU, Hyderabad. His<br />

specialization is Advanced Manufacturing<br />

Systems.<br />

He is currently working as an Associate<br />

pr<strong>of</strong>essor in Brilliant College <strong>of</strong> Engineering,<br />

Hyderabad.<br />

Pursuing PhD at JNTU, Hyderabad. Possesses teaching experience <strong>of</strong><br />

over 12 years.<br />

Also completed Post Graduation in Computer<br />

Science from JNTU, Kakinada in 2008. Specialized in the areas <strong>of</strong><br />

metal forming, welding, nano technology <strong>and</strong> composite materials.<br />

Published 35 technical papers. Guiding 3 PhD scholars. He has abiding<br />

passion for teaching <strong>and</strong> research. Received “Eminent Engineer Award”<br />

on Sept 15th Engineers day for the year 2012 from the Institution <strong>of</strong><br />

Engineers India ,Vijayawada Chapter, A.P. Authored the book Operations<br />

Research for Engineering Students. He is a life member <strong>of</strong> the Indian<br />

Society for Technical Education.<br />

P. Suresh Babu received his AMIE degree in<br />

Mechanical Engineering from The Institution<br />

<strong>of</strong> Engineers (India) in 1996, ME degree in<br />

Metallurgical Engineering from PSG College<br />

<strong>of</strong> Technology, affiliated to Bharathiar<br />

University, Coimbatore, in 1998.<br />

Currently pursuing PhD in Mechanical<br />

Engineering at K.L. University, Vaddeswaram,<br />

Guntur.<br />

He has rich industrial <strong>and</strong> teaching experience <strong>of</strong> around 15 years in the<br />

field <strong>of</strong> Mechanical <strong>and</strong> Metallurgical Engineering.<br />

Published five technical papers. Currently working as Associate Pr<strong>of</strong>essor<br />

in Rao & Naidu Engineering College, Ongole, AP. His research interests<br />

are in the areas <strong>of</strong> welding technology <strong>and</strong> metallurgy.<br />

37