PowerCool HB 500 - MTU Detroit Diesel Australia

PowerCool HB 500 - MTU Detroit Diesel Australia

PowerCool HB 500 - MTU Detroit Diesel Australia

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRODUCT DATA SHEET<br />

<strong>HB</strong><strong>500</strong>-NF 50/50 Premix Coolant<br />

Power Cool <strong>HB</strong><strong>500</strong>-NF Premix Coolant is a superior, fully formulated Hybrid<br />

technology engine coolant. This Hybrid technology coolant has the advantage of<br />

being more robust than conventional engine coolants. This low silicate, phosphate,<br />

nitrite and amine free product is recommended for use in construction and<br />

industrial, mining, power generation, rail, truck, bus and agricultural applications.<br />

It provides excellent high temperature protection for aluminium and cast iron<br />

surfaces.<br />

Power Cool <strong>HB</strong><strong>500</strong>-NF Premix Coolant is mixed at 50% concentration. It does<br />

not require the addition of supplemental coolant additives (SCAs) as the product<br />

is specially formulated to protect heavy duty diesel wet sleeve liners. It is<br />

recommended that the coolant be topped up as necessary with Power Cool<br />

<strong>HB</strong><strong>500</strong>-NF Premix Coolant. In addition Power Cool <strong>HB</strong><strong>500</strong>-NF Premix Coolant<br />

offers the following advantages:<br />

• Extended life – With proper cooling system maintainance Power Cool <strong>HB</strong><strong>500</strong>-NF Premix Coolant has an<br />

expected service life of up to 4 years or 1,000,000 km or 12,000 hours whichever occurs first<br />

• Power Cool is compatible with standard SCA’s and coolant extenders. However SCA’s are not required<br />

in this coolant formulation.<br />

• Low silicate<br />

• Phosphate, nitrite and amine free<br />

• Universal use, meets or exceeds standard industry requirements for , light and heavy duty diesel<br />

applications<br />

• Product is compatible with both conventional and OAT coolants. To maximise performance [regarding<br />

issues such as extended life] it is best to flush the old coolant and replace with Power Cool <strong>HB</strong><strong>500</strong>-NF<br />

Premix Coolant at your next service interval

PRODUCT DATA SHEET<br />

Power Cool <strong>HB</strong><strong>500</strong> NF Premix Coolant is recommended for use with the following industry<br />

specifications and applications:<br />

• ASTM D-3306, D-4985<br />

• SAE J1034/J1941<br />

• Caterpillar EC1 • Mercedes Benz DBL 325<br />

• Cummins 14603 • <strong>MTU</strong> MTL 5048<br />

• <strong>Detroit</strong> <strong>Diesel</strong> 7SE 298<br />

• New Holland WSN-M97B18-D<br />

• DaimlerChrysler MS 7170, MS 9769<br />

• PACCAR<br />

• Ford ESE-M97B44A, ESE-M97B18-C, Ford WSS-M97B51-A1 • Peterbilt 8502.002<br />

• Freightliner 48-2288D<br />

• Perkins<br />

• GM 1825M, 1899M, GM Heavy Truck • Saab-Scania 6901<br />

• Hyundai<br />

• SAE J1034, J1941<br />

• JIS K2234 • TMC RP 329<br />

• Kenworth RO26-170-97<br />

• Suitable for Toyota<br />

• Landrover<br />

• White Star<br />

• MACK Trucks<br />

• US Federal A-A-870-A<br />

• DAF<br />

• JCB<br />

• Iveco<br />

• Scania TB1451<br />

• John Deere<br />

Power Cool <strong>HB</strong><strong>500</strong> NF Premix Coolant Performance Testing<br />

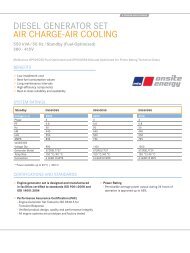

Coupon ASTM D-1384<br />

Glassware Corrosion<br />

ASTM D-2570<br />

Simulated Service<br />

Type 1 Test Results 1 Max. Spec. 1 Test Results 1,2 Max. Spec. 1<br />

Copper 1.5 10 1.4 20<br />

Solder 3 2.5 15 3.2 60<br />

Brass 1.5 10 1.8 20<br />

Steel 1.0 10 0.4 20<br />

Cast Iron 1.0 10 0.8 20<br />

Aluminium 1.0 15 1.1 60<br />

1. Wt./loss coupon in mg. 2. Copper/brass radiator results. 3. Regular 70/30 lead on copper/brass<br />

coupons.<br />

Power Cool <strong>HB</strong><strong>500</strong> NF Premix Coolant Performance Testing<br />

ASTM Test Procedure Test Results Specification<br />

D4340 Heat Rejecting Aluminium Corrosion 0.27 mg/cm 2 /week 1.0 maximum<br />

D2809 Aluminium Water Pump Cavitation-<br />

9 - 10 8 minimum<br />

Erosion Corrosion (rating from 1 to 10)<br />

Shelf-life stability: minimum 2 years from date of manufacture

PRODUCT DATA SHEET<br />

Power Cool <strong>HB</strong><strong>500</strong> NF Premix Coolant Physical & Chemical Properties<br />

Test Performance Test Method<br />

pH 7.5 – 8.5 ASTM D-1287<br />

Reserve Alkalinity (ml) 6 min. ASTM D-1121<br />

Specific Gravity (15.6ºC/60ºF) 1.065 - 1.075 ASTM D-1122<br />

Freeze Point -37ºC ASTM D-1177<br />

Foam Volume (ml) 50 max. ASTM D-1881<br />

Break Time (sec) 5 max. ASTM D-1881<br />

Flash Point 116ºC ASTM D-92<br />

Fire Point 120ºC<br />

Ash Content (wt. %) 2.5 max. ASTM D-1119<br />

Odour<br />

Colour<br />

Total Glycols (Weight %)<br />

Inhibitors and dye (Weight %)<br />

Characteristic<br />

Green<br />

50.0 min.<br />

2.5 max.<br />

Chloride ppm 25 max. ASTM D-3634<br />

Silicon (ppm) 93 max. ICP<br />

The performance and physical property data described for this product are typical results not sale specifications except where maximum or<br />

minimum is indicated.<br />

Power Cool <strong>HB</strong><strong>500</strong>-NF Premix Coolant provides exceptional value as an aluminium and cast iron<br />

compatible, long life engine coolant. For coolant top up use Power Cool <strong>HB</strong><strong>500</strong>-NF Premix coolant,<br />

DO NOT add just water as this will dilute the corrosion inhibitor package.<br />

For more information on Power Cool for your application please contact<br />

<strong>MTU</strong> <strong>Detroit</strong> <strong>Diesel</strong> <strong>Australia</strong> on 1300 <strong>MTU</strong> <strong>Detroit</strong> (1300 688 338)<br />

Notice: Because use conditions and applicable laws may differ from one location to another and may change with time, the customer is responsible<br />

for determining whether products and the information in this document is appropriate for their use and for ensuring that their workplace and disposal<br />

practices are in compliance with applicable laws and other governmental enactments. Power Cool’s warranty is limited to the claims of product meeting<br />

stated specifications. It is the responsibility of the end user to determine product suitability as recommended in the Owner’s Manual and to follow engine<br />

manufacturer’s instructions.