New Perth Bunbury Highway complete Steel or synthetic ... - Realview

New Perth Bunbury Highway complete Steel or synthetic ... - Realview

New Perth Bunbury Highway complete Steel or synthetic ... - Realview

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

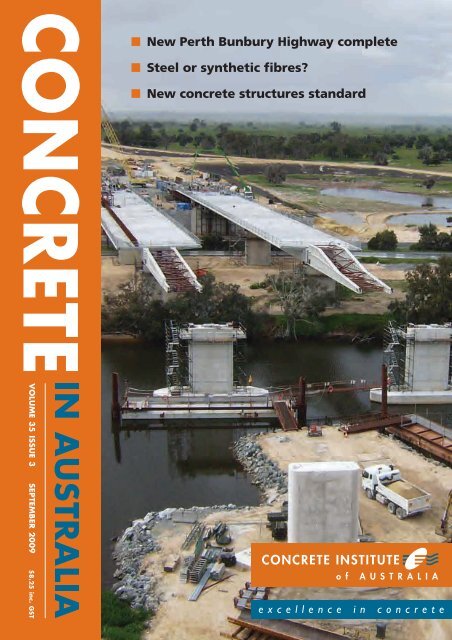

■ <strong>New</strong> <strong>Perth</strong> <strong>Bunbury</strong> <strong>Highway</strong> <strong>complete</strong><br />

■ <strong>Steel</strong> <strong>or</strong> <strong>synthetic</strong> fibres<br />

■ <strong>New</strong> concrete structures standard<br />

VOLUME 35 ISSUE 3 SEPTEMBER 2009 $8.25 inc. GST

FROM THE PRESIDENT<br />

Thankyou to Institute staff and<br />

supp<strong>or</strong>tive members<br />

This issue of Concrete in Australia<br />

is the first to contain peerreviewed<br />

papers. It is also the<br />

first issue to contain a theme <strong>or</strong><br />

main feature - in this case, the<br />

background to the development<br />

of the long awaited revision of AS 3600, with three<br />

peer-reviewed technical papers discussing the significant<br />

engineering design implications of the new standard.<br />

Profess<strong>or</strong> Bob Warner of the University of Adelaide<br />

discusses the background to the new standard. Profess<strong>or</strong> Ian<br />

Gilbert of UNSW examines the changes to development<br />

length and lapped splice length f<strong>or</strong> def<strong>or</strong>med bars in<br />

tension and restrictions on using Class L reinf<strong>or</strong>cement, and<br />

Profess<strong>or</strong> Stephen Foster of UNSW examines the detailing<br />

of high strength concrete columns in the new standard.<br />

The contributions to this special coverage on AS 3600 from<br />

these three eminent academics, in just a sh<strong>or</strong>t space of time,<br />

were made possible by the enthusiasm and dedication of<br />

our Edit<strong>or</strong>ial Committee Conven<strong>or</strong> Jay Sanjayan. Jay also<br />

arranged and managed the peer review process.<br />

The theme around AS 3600 is also timely, as the revised<br />

edition will be one of the three main topics to be discussed<br />

at the Technical F<strong>or</strong>um of Concrete Solutions 09 in Sydney in<br />

September.<br />

This issue of Concrete in Australia also has an interesting<br />

article on the behaviour of steel and <strong>synthetic</strong> fibres in<br />

concrete, sourced from a translation of a paper by French<br />

researcher Pierre Rossi in the March issue of Béton Magazine<br />

and an article on the <strong>New</strong> <strong>Perth</strong> <strong>Bunbury</strong> <strong>Highway</strong> project<br />

in Western Australia.<br />

F<strong>or</strong> the next (December) issue of Concrete in Australia<br />

we intend to include a feature on “Cracking in Concrete”.<br />

Contributions in the f<strong>or</strong>m of technical and project-related<br />

The revised AS 3600 will be a main<br />

topic f<strong>or</strong> discussion at the Concrete<br />

Solutions 09 Technical F<strong>or</strong>um<br />

papers, including new product submissions on this subject<br />

will be welcomed. Please see opposite f<strong>or</strong> details relating to<br />

the submission of papers.<br />

As my term as President comes to a close in September,<br />

may I take this opp<strong>or</strong>tunity to thank our new CEO Graeme<br />

Burns and the Institute’s staff, all Councill<strong>or</strong>s, Branch<br />

Committee members, and the many individuals within<br />

the Institute and the concrete industry in general, f<strong>or</strong> the<br />

supp<strong>or</strong>t and encouragement they have given me over the past<br />

two years. My best wishes are extended to Fred Andrews-<br />

Phaedonos and Liza O’Mo<strong>or</strong>e as they step into the roles of<br />

President and Vice-President respectively.<br />

Tony Kinlay<br />

President, Concrete Institute of Australia<br />

president@concreteinstitute.com.au<br />

Concrete Institute of Australia<br />

Office contact details<br />

National and NSW Branch<br />

Suite 2B, Level 2, 9 Blaxland Road<br />

Rhodes, NSW 2138<br />

PO Box 3157. Rhodes, NSW 2138<br />

Phone: 02 9736 2955<br />

Fax: 02 9736 2639<br />

Email: admin@concreteinstitute.com.au<br />

nsw@concreteinstitute.com.au<br />

Web: www.concreteinstitute.com.au<br />

Queensland Branch<br />

Level 14, 348 Edward Street<br />

Brisbane, Qld 4000<br />

Phone: 07 3227 5204<br />

Fax: 07 3839 6005<br />

Email: qld@concreteinstitute.com.au<br />

Vict<strong>or</strong>ia Branch<br />

2nd Flo<strong>or</strong>, 1 Hobson Street<br />

South Yarra, VIC 3141<br />

Phone: 03 9804 7834<br />

Fax: 03 9827 6346<br />

Email: vic@concreteinstitute.com.au<br />

South Australia Branch<br />

PO Box 559<br />

Marden, SA 5070<br />

Phone: 08 8300 0300<br />

Fax: 08 8341 1591<br />

Email: sa@concreteinstitute.com.au<br />

Western Australia Branch<br />

45 Ventn<strong>or</strong> Avenue<br />

West <strong>Perth</strong>, WA 6005<br />

Phone: 08 9389 4447<br />

Fax: 08 9389 4451<br />

Email: wa@concreteinstitute.com.au<br />

Tasmania Branch<br />

2 Davey Street<br />

Hobart, Tas 7000<br />

Phone: 03 6221 3715<br />

Fax: 03 6224 2325<br />

Email: tas@concreteinstiute.com.au<br />

2 Concrete in Australia Vol 35 No 3

President:<br />

Tony Kinlay<br />

Chief Executive Officer:<br />

Graeme Burns<br />

Concrete Institute of Australia<br />

PO Box 3157<br />

Rhodes NSW 2138<br />

Tel: +61 2 9736 2955<br />

Fax: +61 2 9736 2639<br />

e-mail: admin@concreteinstitute.com.au<br />

web: www.concreteinstitute.com.au<br />

Concrete in Australia<br />

Technical papers on current areas of interest<br />

are invited f<strong>or</strong> peer review, as are m<strong>or</strong>e general<br />

contributions on research and development,<br />

and current <strong>or</strong> recently <strong>complete</strong>d construction<br />

projects. Letters to the Edit<strong>or</strong> and newsw<strong>or</strong>thy<br />

items are also welcome.<br />

Concrete in Australia Edit<strong>or</strong>ial Committee<br />

Conven<strong>or</strong> – Jay Sanjayan<br />

(Jay.Sanjayan@eng.monash.edu.au)<br />

Co-conven<strong>or</strong>s – Fred Andrews-Phaedonos<br />

(Fred.Andrews-Phaedonos@roads.vic.gov.au)<br />

Assoc Prof Rob Wheen (R.Wheen@civil.usyd.edu.au)<br />

James Trezona (TrezonaJ@conwag.com)<br />

Hugh Winslow (hugh.winslow@the precasters.com.au)<br />

Prof Andrew Deeks (deeks@civil.uwa.edu.au)<br />

ISSN 1440-656X, VOL 35 No 3<br />

EDITOR: Bob Jackson<br />

MANAGING EDITOR: Dietrich Ge<strong>or</strong>g<br />

ADVERTISING:<br />

NSW: Maria Mamone and Leanne Ralph<br />

phone 02 9438 1533 fax 02 9438 5934<br />

Vic & Tas: Wyeth Media Services Pty Ltd<br />

10 Keysb<strong>or</strong>ough Close, Keysb<strong>or</strong>ough<br />

Vic 3173. (PO Box 161 Dingley Vic 3172)<br />

phone 03 9701 8844, fax 03 9701 8877<br />

VOLUME 35 ISSUE 3 SEPTEMBER 2009<br />

Contents<br />

2 President’s rep<strong>or</strong>t<br />

4 <strong>New</strong>s<br />

14 Update on Concrete Institute Technical Projects<br />

PROJECTS<br />

<strong>New</strong> <strong>Perth</strong> <strong>Bunbury</strong> <strong>Highway</strong> <strong>complete</strong> 12<br />

<strong>New</strong> mot<strong>or</strong>way opens n<strong>or</strong>th of the Brisbane River 14<br />

P<strong>or</strong>t Botany container terminal expansion 15<br />

PERSPECTIVE<br />

<strong>Steel</strong> fi bres <strong>or</strong> <strong>synthetic</strong> fi bres 16<br />

TECHNICAL PAPERS<br />

2301<br />

October 2008<br />

to March 2009<br />

The new Australian concrete structures standard 18<br />

Development length and lapped splice length f<strong>or</strong> def<strong>or</strong>med bars in tension<br />

– changes to Section 13 of AS3600 23<br />

Restrictions on the use of Class L reinf<strong>or</strong>cement in AS3600-2009 31<br />

Detailing of high strength concrete columns to AS3600-2009 37<br />

ALSO IN THIS ISSUE<br />

National Precaster 47<br />

Pipeline 53<br />

Post-tensioning Institute of Australia 43<br />

Australian Concrete Repair Association 59<br />

Concrete Masonry Association of Australia 60<br />

<strong>Steel</strong> Reinf<strong>or</strong>cement Institute of Australia 62<br />

CCAA Library 63<br />

<strong>New</strong> members 64<br />

Concrete in Australia is produced<br />

f<strong>or</strong> the Concrete Institute of Australia<br />

by Engineers Media<br />

phone 02 9438 1533<br />

fax 02 9438 5934<br />

email bjackson@engineersmedia.com.au<br />

The Murray River Bridge, south of <strong>Perth</strong> on the <strong>New</strong> <strong>Perth</strong> to <strong>Bunbury</strong><br />

<strong>Highway</strong>, is the largest bridge structure on the now <strong>complete</strong>d 70km road.<br />

Shown here is the bridge during incremental launching in September last<br />

year (see project article page 12). PHOTO: SOUTHERN GATEWAY ALLIANCE<br />

The statements made <strong>or</strong> opinions<br />

expressed in this magazine do not<br />

necessarily reflect the views of the<br />

Concrete Institute of Australia n<strong>or</strong> of<br />

Engineers Media.<br />

VOLUME 35 ISSUE 3 SEPTEMBER 2009 $8.25 inc. GST<br />

Concrete in Australia Vol 35 No 3 3

NEWS<br />

Concrete in Australia review<br />

The Institute had a pleasing response to a survey issued to<br />

members in April 2009 in relation to member feedback<br />

on Concrete in Australia. The survey aimed to identify and<br />

highlight key areas of the magazine that are most valued and<br />

areas where improvement may be implemented. The survey<br />

responses aided in a review of the magazine that was carried<br />

out to ensure that the Institute’s c<strong>or</strong>nerstone publication<br />

continues to provide the most relevant, requested and desired<br />

inf<strong>or</strong>mation to issue to the membership.<br />

Many of these changes from the review have been<br />

inc<strong>or</strong>p<strong>or</strong>ated in this issue of the magazine, as highlighted in<br />

the President’s column. The responses to questions relating to<br />

specific technical areas that members feel need to be addressed<br />

will be c<strong>or</strong>related with the results from the recently issued<br />

Technical Needs Survey and will assist in providing a link<br />

in with other Institute initiatives, particularly that of the<br />

Educational Programs.<br />

The survey highlighted the imp<strong>or</strong>tance of the technical papers<br />

included in Concrete in Australia. The magazine’s Conven<strong>or</strong>,<br />

Jay Sanjayan, has focused upon technical content which will<br />

play a vital role in ensuring this membership need is met. The<br />

strong desire from members to ensure that Concrete in Australia<br />

does not become a medium f<strong>or</strong> advert<strong>or</strong>ials and maintains a<br />

non-partisan position has been heeded by the Institute and<br />

subsequent changes to the magazine’s f<strong>or</strong>mat have been made.<br />

The survey also assisted in the Institute obtaining<br />

demographic inf<strong>or</strong>mation that will assist the Institute in further<br />

activities, including a full market segmentation review to<br />

provide direction f<strong>or</strong> membership initiatives. Some key results<br />

from the survey are indicated in the charts provided below:<br />

Recognising Concrete in Australia is a magazine published<br />

quarterly, how many issues have you read (in full/<strong>or</strong> in part)<br />

during the past 12 months<br />

Please rate the imp<strong>or</strong>tance of the following regular<br />

sections of Concrete in Australia.<br />

Not at all<br />

Respondents<br />

Slightly<br />

Moderately<br />

Very<br />

Extremely<br />

Letters to<br />

the Edit<strong>or</strong><br />

<strong>New</strong>s<br />

Items<br />

<strong>New</strong><br />

Products<br />

Institute<br />

Project<br />

Updates<br />

Perspective<br />

Pieces<br />

Project<br />

Rep<strong>or</strong>ts<br />

Technical<br />

Papers<br />

Library<br />

Updates<br />

4 Concrete in Australia Vol 35 No 3

NEWS<br />

Institute council announced<br />

Our Secretary/Treasurer announced the<br />

result of the elections recently conducted<br />

f<strong>or</strong> eight positions on Council at the<br />

Institute’s annual general meeting in<br />

Sydney on 28 May 2009.<br />

Those elected as councill<strong>or</strong>s f<strong>or</strong> the<br />

2009/2011 term appear in the list below.<br />

They join the previously elected executive<br />

team comprised of Fred Andrews-<br />

Phaedonos, Tony Kinlay, Liza O’Mo<strong>or</strong>e<br />

and Craig Heidrich.<br />

The full make up of the Council f<strong>or</strong> the<br />

2009/2011 term is:<br />

• President: Fred Andrews-Phaedonos<br />

• Immediate Past President: Tony Kinlay<br />

• Vice President: Liza O’Mo<strong>or</strong>e<br />

• Secretary/Treasurer: Craig Heidrich.<br />

fib – National Membership Group<br />

The Concrete Institute of Australia has<br />

recently established a new Australian<br />

National Member Group with the<br />

international federation f<strong>or</strong> structural<br />

concrete (fib). The Concrete Institute<br />

will act as the key secretariat f<strong>or</strong> the<br />

Membership Group and has sought<br />

confirmation from other <strong>or</strong>ganisations<br />

who previously expressed a willingness<br />

to join the Membership Group.<br />

The Concrete Institute will<br />

act as the key secretariat f<strong>or</strong><br />

the Membership Group.<br />

The Institute will harness this<br />

opp<strong>or</strong>tunity which will assist in<br />

providing greater technical inf<strong>or</strong>mation<br />

to the membership in regards to what is<br />

occurring on the international scene.<br />

The Institute is appreciative of the<br />

Environmental accreditation f<strong>or</strong><br />

Xypex waterproofing products<br />

Xypex Australia was recently issued<br />

with Licence No XYP-2009 f<strong>or</strong> Xypex<br />

Admix C-1000NF and Xypex Admix<br />

C-5000, by Good Environmental<br />

The eight elected Council<strong>or</strong>s include<br />

Kevin Abrams, Ian Gilbert, Doug Jenkins,<br />

Jay Sanjayan, David Meager, Wolfgang<br />

Merretz, Deb<strong>or</strong>ah Smee and Ian Bishop.<br />

Branch representatives are:<br />

• Queensland: Des Chalmers<br />

• <strong>New</strong> South Wales: Julian B<strong>or</strong>gert<br />

• Vict<strong>or</strong>ia: Gary Wyatt<br />

• Western Australia: Chris Long<br />

• Tasmania: yet to be appointed<br />

• South Australia: yet to be appointed.<br />

The Cement Concrete & Aggregates<br />

Australia representative is Ken Slattery.<br />

The new council will be installed<br />

following the conclusion of the<br />

biennial conference in Sydney in<br />

September 2009.<br />

other <strong>or</strong>ganisations which constitute the<br />

National Member Group, as highlighted<br />

below. The Institute is also appreciative of<br />

Jim F<strong>or</strong>bes and Profess<strong>or</strong> Stephen Foster<br />

who have agreed to be the two delegates<br />

of the National Member Group, with Jim<br />

accepting the role of Head of Delegation.<br />

The Institute also appreciates Ge<strong>or</strong>ge<br />

Cremasco f<strong>or</strong> accepting the role of<br />

deputy of the National Member Group.<br />

The constituted Member Group<br />

includes:<br />

• Concrete Institute of Australia<br />

• Hyder Consulting<br />

• University of <strong>New</strong> South Wales<br />

• Westkon Precast<br />

• Tayl<strong>or</strong> Thomas Whitting (NSW)<br />

Pty Ltd<br />

• Post-Tensioning Institute of Australia<br />

• KBR<br />

• ADG Engineers (Aust) Pty Ltd.<br />

Choice Australia (GECA) as fully<br />

compliant with the GECA 08-2007<br />

Environmentally Innovative Products<br />

Standard.<br />

The certification end<strong>or</strong>ses Xypex<br />

Admix C-1000NF and Admix C-5000 as<br />

environmentally preferable and theref<strong>or</strong>e<br />

suitable f<strong>or</strong> consideration in applications<br />

f<strong>or</strong> buildings with Green Star Ratings<br />

in acc<strong>or</strong>dance with the Green Building<br />

Council of Australia.<br />

Both Xypex certified products have<br />

the ability to generate a non-soluble<br />

crystalline f<strong>or</strong>mation deep within the<br />

p<strong>or</strong>es and capillary tracts of concrete – a<br />

crystalline structure that permanently<br />

seals the concrete against the penetration<br />

of water and other liquids from any<br />

direction.<br />

Good Environmental Choice<br />

Services Pty Ltd (GECS), assessed<br />

the Xypex products to the criteria of<br />

international standard ISO 14 024,<br />

Environmental labels and declarations.<br />

This is f<strong>or</strong> products indicating overall<br />

environmental preferability based<br />

on multiple criteria using life-cycle<br />

considerations.<br />

The key environmental perf<strong>or</strong>mance<br />

criteria against which the Xypex products<br />

were assessed were fitness f<strong>or</strong> purpose<br />

and environmental load reduction, where<br />

the Xypex products were taken through<br />

a Life Cycle Assessment (LCA). The<br />

results calculated by Simapro 7 show that<br />

the Xypex nominated products do have<br />

a minimum 30% environmental load<br />

reduction.<br />

Additional criteria f<strong>or</strong> the assessment<br />

included material requirements,<br />

packaging requirements, environmental<br />

regulations and labour, antidiscrimination<br />

and safety regulations.<br />

Good Environmental Choice Australia,<br />

a not-f<strong>or</strong>-profit <strong>or</strong>ganisation, seeks to<br />

distinguish and reward those producers<br />

and service providers that have improved<br />

their environmental perf<strong>or</strong>mance and<br />

provide an environmentally preferable<br />

product <strong>or</strong> service, from those that do not.<br />

The benefits of an independent<br />

environmental label is that customers<br />

can easily recognise products which are<br />

sensitive to environmental pressures.<br />

In the pursuit of a healthier<br />

environment, Xypex Australia encourages<br />

the industry to consider its GECA<br />

approved products.<br />

F<strong>or</strong> further inf<strong>or</strong>mation visit<br />

www.geca.<strong>or</strong>g.au and www.xypex.com.au<br />

6 Concrete in Australia Vol 35 No 3

concrete solutions 09<br />

17 – 19 September 2009, Luna Park, Sydney<br />

Your future in concrete!<br />

Concrete Solutions 09 comes at<br />

a critical time f<strong>or</strong> all of us in the<br />

concrete industry. Make sure<br />

you are part of it and grab the<br />

opp<strong>or</strong>tunity to position yourself to<br />

lead the industry into the exciting<br />

and challenging times ahead.<br />

Join your industry colleagues in a<br />

program of ideas, knowledge and<br />

solutions which will assist you to<br />

identify opp<strong>or</strong>tunities which will<br />

add value and build a sustainable<br />

future in concrete.<br />

Hear technical presentations of<br />

peer reviewed papers on state<br />

of the art research, design and<br />

application of concrete by local<br />

and international experts.<br />

Debate with industry experts<br />

about critical contemp<strong>or</strong>ary<br />

issues of the day – AS3600 – the<br />

new concrete structures code,<br />

durability and sustainability.<br />

Don’t miss the 2009 Awards f<strong>or</strong><br />

Excellence – recognising some<br />

outstanding contributions to<br />

the development of concrete<br />

technology and practice.<br />

Technical Sessions<br />

A comprehensive technical program<br />

inc<strong>or</strong>p<strong>or</strong>ating 5 plenary sessions and 21<br />

parallel sessions over two days has been<br />

finalised. Papers cover both current and<br />

developing areas of technology and practice<br />

will be presented by leading researchers and<br />

practitioners from Australia and overseas.<br />

This is a critical opp<strong>or</strong>tunity to position<br />

yourself f<strong>or</strong> the exciting future of concrete.<br />

Details of the program are on the web site<br />

www.concrete09.com.au.<br />

Technical F<strong>or</strong>um<br />

On the first day, the Technical F<strong>or</strong>um will<br />

provide a unique opp<strong>or</strong>tunity f<strong>or</strong> delegates<br />

to discuss three critical contemp<strong>or</strong>ary issues<br />

– AS3600, durability and sustainability.<br />

AS3600 – 2009, the new edition of the<br />

Australian Standard f<strong>or</strong> Concrete Structures<br />

has been long awaited. This session will<br />

discuss the implementation and impact of<br />

new inclusions in AS3600 which will affect<br />

us all.<br />

The recent national durability w<strong>or</strong>kshops<br />

<strong>or</strong>ganised by the Institute asked the<br />

question – what do we want from future<br />

durability codes This session will be the first<br />

opp<strong>or</strong>tunity to discuss the initial outcomes<br />

of those w<strong>or</strong>kshops and to provide further<br />

input to this imp<strong>or</strong>tant area.<br />

Sustainability – what does it mean f<strong>or</strong><br />

the concrete industry This session will<br />

provide the opp<strong>or</strong>tunity to discuss the<br />

environmental, social and economic impacts<br />

of sustainability in the concrete industry<br />

and the effectiveness of current tools and<br />

regulations f<strong>or</strong> sustainable design.<br />

The role of R&D<br />

will f<strong>or</strong>m a background theme<br />

to each of these topics. Case studies will be<br />

presented demonstrating how R&D can be<br />

harnessed at both individual and enterprise<br />

level in the technical development process.<br />

2009 Awards f<strong>or</strong> Excellence<br />

32 exciting entries have been received f<strong>or</strong><br />

the 2009 Awards f<strong>or</strong> Excellence, consisting of<br />

9 Building projects, 12 Engineering projects,<br />

2 International projects, and 9 Technology<br />

entries.<br />

Not only will all entries be eligible f<strong>or</strong> the<br />

Institute’s maj<strong>or</strong> award, the Kevin Cavanagh<br />

Medal f<strong>or</strong> Excellence in Concrete, but also<br />

a new award has been introduced this year<br />

f<strong>or</strong> the environmentally sustainable use of<br />

concrete across the Project and Technology<br />

entries.<br />

These awards will be determined by a<br />

prestigious judging panel under the<br />

chairmanship of Jim F<strong>or</strong>bes (Hyder<br />

Consulting), including Ron Bracken (past<br />

President MBA, NSW), Peter Dux (University of<br />

Queensland), Tony Kinlay (GHD and President<br />

CIA) and Adrian Pilton (Johnson Pilton<br />

Walker, Architects). F<strong>or</strong> the environmentally<br />

sustainable use of concrete award, the<br />

judging panel will be guided and advised by<br />

Rob Rouwette (Seni<strong>or</strong> Consultant, Energetics<br />

Pty Ltd).<br />

All entries will be presented at a Gala Cocktail<br />

function on Friday, 18th September 2009<br />

during Concrete Solutions 09, followed by the<br />

presentation of Awards. We are encouraging<br />

all entrants to invite their industry colleagues<br />

and clients to join with us as we celebrate<br />

excellence in concrete. Additional tickets can<br />

be purchased through the web site –<br />

www.concrete09.com.au.<br />

Register NOW online at www.concrete09.com.au

NEWS<br />

Concrete frame choice f<strong>or</strong> Melbourne office building<br />

The new ANZ Centre is under construction by Bovis Lend<br />

Lease at Vict<strong>or</strong>ia Harbour on Melbourne’s Yarra River. It is<br />

Australia’s largest office building and is regarded by Cement<br />

Concrete & Aggregates Australia (CCAA) as an outstanding<br />

exemplar of concrete framed construction.<br />

CCAA said the all-concrete framed solution was selected on<br />

this complex project because it offered construction flexibility,<br />

economy and lower overall construction risk.<br />

The building comprises a 10-st<strong>or</strong>ey section and an adjoining<br />

five-st<strong>or</strong>ey section. Typically, construction of the suspended<br />

flo<strong>or</strong>s takes the f<strong>or</strong>m of post-tensioned band beams spanning the<br />

long direction, and reinf<strong>or</strong>ced concrete (RC) slabs on permanent<br />

Inadequate foundations bring down apartments<br />

In late June this unoccupied building still under construction<br />

in the “Lotus Riverside” residential community in the Minxing<br />

district of Shanghai city toppled over. F<strong>or</strong>tunately, the collapse<br />

occurred in the early m<strong>or</strong>ning, but one w<strong>or</strong>ker was killed. The<br />

photo suggests that the foundations were inadequately anch<strong>or</strong>ed<br />

into the soft ground.<br />

Construction w<strong>or</strong>k on the block appeared to have been<br />

nearly <strong>complete</strong>d, with windows fitted and a tiled facade. Other<br />

identical blocks in the same property development remained<br />

metal deck f<strong>or</strong>mw<strong>or</strong>k in the other direction. The vertical load<br />

bearing structure comprises three RC service c<strong>or</strong>es and circular RC<br />

columns.<br />

The construction solutions adopted f<strong>or</strong> both the h<strong>or</strong>izontal<br />

and vertical elements have resulted in some substantial time<br />

efficiencies.<br />

The ‘whys’ and ‘hows’ of using concrete on this project are<br />

covered in the latest Concrete Concepts case study, published<br />

by CCAA. The Concrete Concepts series is produced by CCAA<br />

to highlight the advantages of concrete framing f<strong>or</strong> multi-rise<br />

projects in Australia. To view case studies in the series, visit<br />

www.concreteconcepts.net.au<br />

standing nearby.<br />

Sub-standard w<strong>or</strong>kmanship has been a maj<strong>or</strong> concern in China’s<br />

building sect<strong>or</strong>, as the country rolls out en<strong>or</strong>mous city expansions<br />

and finishes off vast infrastructure projects. Construction-related<br />

accidents last year included the collapse of a steel arch on a new<br />

railway bridge, which killed several w<strong>or</strong>kers and a crane which fell<br />

on a kindergarten, killing five. The collapse of dozens of schools<br />

during last year’s Sichuan earthquake also led to a wave of public<br />

outrage about c<strong>or</strong>rupt officials and construction firms.<br />

8 Concrete in Australia Vol 35 No 3

Waterfront venue uses recycled concrete<br />

Doltone House at Darling Island Wharf in Sydney’s Pyrmont,<br />

to open in October, is one of the first buildings in Australia to<br />

use structural concrete made from recycled ingredients.<br />

The building is also the first six-star green star rated building<br />

in NSW and offers:<br />

• recycled blackwater f<strong>or</strong> parkland watering and toilet flushing<br />

• trigeneration (gas fired electricity with reuse of the heated<br />

air f<strong>or</strong> abs<strong>or</strong>ption cooling of the building and f<strong>or</strong> heating<br />

hot water)<br />

• heat rejection from the chillers to the harbour<br />

• greater fresh air supply with CO 2<br />

sens<strong>or</strong>s and variable speed<br />

fans and low toxicity materials and finishes to ensure cleaner air<br />

• insulation throughout, with high perf<strong>or</strong>mance glass and<br />

building materials which minimise heat loss.<br />

NEW PRODUCT<br />

The new Doltone House in Pyrmont, Sydney uses structural concrete made<br />

from recycled materials.<br />

PHOTO: BOB JACKSON<br />

3D ultrasonics scanning f<strong>or</strong> identifying concrete defects<br />

A new ultrasonic pulse echo testing machine, developed in<br />

Russia and called MIRA (from the Spanish verb to look and<br />

the English mirr<strong>or</strong>) will be unveiled at the Concrete solutions<br />

09 conference in Sydney.<br />

The device gives an image of the inside of concrete showing<br />

any defects <strong>or</strong> voids, as well as concrete thickness, wide cracking<br />

and honeycombing and voids.<br />

MIRA’s developers have produced a tester which:<br />

• enables dry point contact f<strong>or</strong> the probes<br />

• uses shear waves instead of p-waves in a pulse echo mode,<br />

requiring access to only one face<br />

• has an array of transducers so that each measurement takes<br />

nearly 100 results over an area 400mm x 200mm in a<br />

fraction of a second<br />

• has a built in wireless netw<strong>or</strong>k in the measuring head so data<br />

can be transmitted to a PC<br />

• comes with software that combines multiple measurements,<br />

comprising thousands of results over a large scan area, and<br />

instantly analyses them to give a 3D image <strong>or</strong> multiple<br />

slices through the concrete.<br />

So far it has been used on two projects in Australia to give<br />

PCTE, the Australian distribut<strong>or</strong>, a chance to evaluate it.<br />

On one project it was able to show that there was no loss of<br />

concrete on the inside of a pipe section. Testing was entirely<br />

from the outside face while the pipe was still live. On another it<br />

showed that the defects in a beam were only in the cover zone<br />

and not within the structural concrete.<br />

The heart of the system is the test head, which inc<strong>or</strong>p<strong>or</strong>ates<br />

40 separate transducers that fire and receive during each<br />

measurement. The multitude of readings from each<br />

‘measurement’ gives a snap shot of the concrete below the<br />

measuring head. The measuring head is stepped across the<br />

concrete surface while the software pieces all of the data<br />

together into a seamless image of the entire area. After some<br />

initial calibrations an area 2m high x 400mm wide f<strong>or</strong> example<br />

can be scanned in a few minutes.<br />

F<strong>or</strong> m<strong>or</strong>e inf<strong>or</strong>mation call Reuben Barnes from PCTE on<br />

04 0803 4668 f<strong>or</strong> further inf<strong>or</strong>mation.<br />

Concrete in Australia Vol 35 No 3 9

CONCRETE INSTITUTE PROJECTS<br />

Update on technical projects<br />

The Institute’s Project Manager Technical Services Ben Cosson gives an update on recent progress.<br />

At the time of writing Standards Australia had recently made<br />

a Public Release in response to the global financial crisis. The<br />

release highlighted the impact this has had on their business<br />

operations and their subsequent f<strong>or</strong>ward strategy and the<br />

consequent implications that this will have on stakeholders<br />

and <strong>or</strong>ganisations such as the Concrete Institute. The<br />

implications of the financial crisis have resulted in Standards<br />

identifying underlying resourcing and financial issues.<br />

The Institute had previously identified two potential projects<br />

that may have taken advantage of the Pathway options that were<br />

available through Standards’ <strong>New</strong> Business Model, namely BD-<br />

032: Composite construction and BD-066: Tilt-up construction.<br />

Following the Public Release, the Institute has had discussions<br />

with Standards Australia to identify the implications f<strong>or</strong><br />

undertaking the identified projects. This engagement, lead to an<br />

understanding that future projects undertaken with Standards<br />

Australia will require significant funding investment by industry<br />

in addition to providing committee resources. Until further<br />

clarification is available, the likelihood of BD-032 and BD-066<br />

proceeding appears unlikely.<br />

AS 3600<br />

At the time of writing the Institute had been advised from<br />

Standards Australia that a late August 2009 publication date<br />

was likely f<strong>or</strong> AS 3600. This date will be timely f<strong>or</strong> the issue<br />

of this edition of Concrete In Australia in which AS 3600<br />

is the feature together with the Technical F<strong>or</strong>um at Concrete<br />

Solutions 09, whereby the implementation and impact of new<br />

inclusions in AS 3600 will be a maj<strong>or</strong> topic.<br />

the Committee providing comments and revisions f<strong>or</strong> the<br />

various draft chapters.<br />

• Sustainability W<strong>or</strong>king Group. A draft content of the<br />

publication was in the review process pri<strong>or</strong> to being<br />

circulated to a selected number of people on the Committee<br />

f<strong>or</strong> response.<br />

Professional development<br />

Durability w<strong>or</strong>kshops<br />

The durability w<strong>or</strong>kshops, which were held in June in the<br />

maj<strong>or</strong> states, achieved encouraging participation rates and<br />

valuable feedback. The feedback that was collected, together<br />

with discussions throughout the sessions have provided the<br />

Durability Committee with pertinent inf<strong>or</strong>mation that will be<br />

able to be used in the future, including the revision of Z13:<br />

Perf<strong>or</strong>mance Criteria f<strong>or</strong> Concrete in Marine Environments<br />

and Z7: Durable Concrete Structures. The outcomes of the<br />

w<strong>or</strong>kshops will be provided at the Technical F<strong>or</strong>um of<br />

Concrete Solutions 09. In late July the Durability Committee<br />

was in the process of analysing the State feedback that was<br />

collected on the day.<br />

Publications<br />

The current status of reviewed and initiated publications as of<br />

late July:<br />

• CPN 29: Prestressed Concrete Anch<strong>or</strong>age Zones: Queensland<br />

Branch has been making steady progress.<br />

• Z 15: Cracking in Concrete Structures: The publication was at<br />

the stage of obtaining industry feedback pri<strong>or</strong> to additional<br />

editing f<strong>or</strong> peer review.<br />

• Z 48: Precast Concrete Handbook: The release of this<br />

publication was imminent.<br />

• Z13: Perf<strong>or</strong>mance Criteria f<strong>or</strong> Concrete in Marine<br />

Environments. Feedback from the recently conducted<br />

Durability W<strong>or</strong>kshops will provide valuable inf<strong>or</strong>mation<br />

that will be necessary f<strong>or</strong> the review team of Z13. The<br />

inf<strong>or</strong>mation will be of use in both technical content and the<br />

f<strong>or</strong>mat in which the publication will take.<br />

• A Current Practice Note on Geopolymer Concrete. The<br />

draft writing of the publication was being finalised pri<strong>or</strong> to<br />

Durability Committee presenters at the QLD W<strong>or</strong>kshop [l-r: Tony Thomas,<br />

Shengjun Zhou, Godfrey Smith, David Mahaffey, Frank Papw<strong>or</strong>th (Committee<br />

Chair) and Rodney Paul].<br />

The Institute and the Durability Committee are highly<br />

appreciative of the response feedback obtained and the lively<br />

interactive discussions that took place at the various state<br />

w<strong>or</strong>kshops.<br />

A follow up survey that was issued to all registrants has<br />

provided a positive response with some sound suggestions f<strong>or</strong><br />

future w<strong>or</strong>kshops that the Institute will hold. Some encouraging<br />

responses were particularly noticed in relation to the interaction<br />

10 Concrete in Australia Vol 35 No 3

Establishing Clients’<br />

Durability<br />

Requirements<br />

Achieving Durability<br />

in Design<br />

Achieving Durability<br />

in Construction<br />

that occurred between various stakeholders of the industry<br />

and the opp<strong>or</strong>tunity that the w<strong>or</strong>kshops provided to stimulate<br />

greater awareness about the topic in the registrants own<br />

<strong>or</strong>ganisations as indicated in the two figures above:<br />

Technical<br />

Members technical needs survey<br />

In late July the Institute had drafted the Technical Needs<br />

Survey and was in the process of finalisation pri<strong>or</strong> to<br />

distribution to the membership. The survey will aim to again<br />

identify technical areas of high imp<strong>or</strong>tance to members where<br />

further inf<strong>or</strong>mation is sought.<br />

…the p<strong>or</strong>tal will be an inf<strong>or</strong>mation hub<br />

The results of the survey will be collated and together with results<br />

of other initiatives undertaken will assist in providing a framew<strong>or</strong>k<br />

f<strong>or</strong> key educational programs that may be delivered throughout<br />

the course of 2010. In addition the results will also provide further<br />

inf<strong>or</strong>mation that can be distributed to the Branch committees that<br />

will help in the development of Branch programs.<br />

Development of knowledge p<strong>or</strong>tal<br />

A medium term goal of the Institute is the development of<br />

a Technical Knowledge P<strong>or</strong>tal that will act as an inf<strong>or</strong>mation<br />

hub of resources in all aspects of concrete technology, design<br />

and construction. This will be a maj<strong>or</strong> development and<br />

investment f<strong>or</strong> the Institute that will be provided to add<br />

significant membership value. The initiation of this w<strong>or</strong>k<br />

has begun with sound input from the Institute’s Technical<br />

and Knowledge Development Committees. The Committees<br />

have engaged with Institute staff and consultants from the<br />

inf<strong>or</strong>mation technology industry to ensure member needs are<br />

met and that the execution of the hub delivers results that use<br />

the most efficient f<strong>or</strong>ms of the available technology.<br />

F<strong>or</strong> further inf<strong>or</strong>mation on these activities, contact Ben Cosson<br />

at the Institute’s national office on (02) 9736 2955 <strong>or</strong> by email to<br />

technical@concreteinstitute.com.au.<br />

Concrete in Australia Vol 35 No 3 11

PROJECTS<br />

<strong>New</strong> <strong>Perth</strong> <strong>Bunbury</strong> <strong>Highway</strong> now <strong>complete</strong><br />

The <strong>New</strong> <strong>Perth</strong> <strong>Bunbury</strong> <strong>Highway</strong> (NPBH), one of the biggest infrastructure projects in Western Australia’s hist<strong>or</strong>y,<br />

will be officially opened this month, about three months ahead of schedule.<br />

The project was delivered f<strong>or</strong> Main Roads Western Australia<br />

by the Southern Gateway Alliance (SGA), which was f<strong>or</strong>med<br />

in 2006 to design construct and deliver the NPBH. SGA is<br />

comprised of Leighton Contract<strong>or</strong>s, WA Limestone and GHD.<br />

The construction included 70.5km of dual carriageway, 19<br />

bridges, five interchanges and nine intersections as well as 32km<br />

of shared pedestrian and cycle path, five pedestrian underpasses<br />

and nine fauna underpasses.<br />

The total quantities used included:<br />

• over 55,000m 3 of concrete<br />

• 821 piles and 146 beams f<strong>or</strong> the bridges<br />

• m<strong>or</strong>e than 33km of drainage structures<br />

• about 21km of noise walls.<br />

A central feature of the project was the fast tracked design<br />

of the bridge structures.<br />

Fifteen bridges were built using precast pretensioned Tee Roff<br />

concrete beams, which were manufactured off-site by Delta<br />

C<strong>or</strong>p<strong>or</strong>ation. Just two sizes of beam depth were used, with<br />

consideration given to beam length, beam widths and bridge<br />

skew.<br />

Incremental launching was used f<strong>or</strong> the bridges over the<br />

two river estuaries on the route – the Murray River and the<br />

Serpentine River. The spans were configured to enable the<br />

piers to be placed away from the banks, to help preserve the<br />

riparian environment and maximise navigation clearance.<br />

At both bridge sites, minimising environmental impact and<br />

protecting Ab<strong>or</strong>iginal heritage zones were very imp<strong>or</strong>tant design<br />

considerations.<br />

The bridge designs were fast tracked with construction<br />

starting bef<strong>or</strong>e design completion. Some special considerations<br />

relating to the bridge designs included:<br />

• maintaining the aesthetics of the pier shape while allowing<br />

width f<strong>or</strong> launch bearings, height of pier and varying skew<br />

between bridge locations<br />

• avoiding the use of temp<strong>or</strong>ary piers by judicious design<br />

modifications<br />

• detailing the abutments and retaining walls to abs<strong>or</strong>b<br />

differential settlement<br />

• using the same f<strong>or</strong>ms and launch girder connections f<strong>or</strong> both<br />

bridge locations<br />

• concentrating initial prestress in lower slabs to optimise<br />

The Paganoni Road Interchange on the <strong>New</strong> <strong>Perth</strong> <strong>Bunbury</strong> <strong>Highway</strong>.<br />

12 Concrete in Australia Vol 35 No 3

prestress and simplify segment construction and final<br />

supplementary stressing<br />

• using a new prestress system with lightweight and compact<br />

circular anch<strong>or</strong>ages and a m<strong>or</strong>e efficient single unit coupling<br />

system, instead of multiple components<br />

• launching the bridges in pairs, with one crew w<strong>or</strong>king<br />

between two cast beds at each site. This optimised labour<br />

efficiency and achieved average launch cycles of one a week<br />

• using rolling falsew<strong>or</strong>k instead of the traditional rolling f<strong>or</strong>m<br />

to supp<strong>or</strong>t the Condek f<strong>or</strong>mw<strong>or</strong>k on the internal upper<br />

f<strong>or</strong>ms<br />

• using a brake saddle in front of the abutments during<br />

launching of deck segments.<br />

The Murray River bridge is 272m long (with maximum<br />

spans of 46m) and uses separate structures f<strong>or</strong> n<strong>or</strong>th and<br />

southbound traffic. The southbound bridge carries two lanes of<br />

traffic and a slip lane and the n<strong>or</strong>thbound bridge carries two<br />

lanes and a 3m wide shared pedestrian/ cycle path. The bridge<br />

passes over Pinjarra Road with a 9.5m clearance over the<br />

Murray River, allowing f<strong>or</strong> sufficient freeboard during a one<br />

in 100 flood event. The bridges’ foundations are on 762mm<br />

diameter tubular steel piles, filled with reinf<strong>or</strong>ced concrete.<br />

The Serpentine River bridge also consists of two separate<br />

structures f<strong>or</strong> n<strong>or</strong>thbound and southbound traffic and was built<br />

to a design similar to the larger Murray River crossing.<br />

Each of the Serpentine bridges is 112m long and has three<br />

spans with a maximum span length of 39.5m. They have similar<br />

lane configurations to the Murray River bridges.<br />

To address the aggressive environmental conditions across the<br />

many bridge locations, the Alliance engaged GHD’s Materials<br />

Technology Group to review all durability issues and to prepare<br />

a durability assessment rep<strong>or</strong>t (DAR) to classify the c<strong>or</strong>rosivity<br />

and aggressivity of expected exposure conditions, including<br />

actual acid sulphate soils (AASSs), potential acid sulphate soils<br />

(PASSs) and sea salt chl<strong>or</strong>ides.<br />

The preparation of the DAR culminated in the development<br />

and design of a range of protective measures to minimise<br />

degradation of the structural elements. Examples of such<br />

measures include the epoxy coating of precast concrete piles<br />

used at sites containing AASSs and PASSs and coatings and<br />

isolation membranes f<strong>or</strong> pile caps at the riverine sites containing<br />

saline ground water.<br />

The Pinjarra Road Interchange and Murray River Bridge on the <strong>New</strong> <strong>Perth</strong> <strong>Bunbury</strong> <strong>Highway</strong>.<br />

Concrete in Australia Vol 35 No 3 13

PROJECTS<br />

N<strong>or</strong>thern section of Gateway Mot<strong>or</strong>way opens<br />

A new 7km section of the Gateway Mot<strong>or</strong>way, n<strong>or</strong>th of the<br />

Brisbane River, between the Gateway bridges and just south of<br />

Nudgee Road, opened on 19 July.<br />

The new mot<strong>or</strong>way:<br />

• provides a m<strong>or</strong>e direct route between the Gateway Bridge<br />

and Nudgee Road<br />

• offers enhanced access to the City, Eagle Farm and Pinkenba<br />

areas f<strong>or</strong> mot<strong>or</strong>ists travelling n<strong>or</strong>thbound via a new off-ramp<br />

to Kingsf<strong>or</strong>d Smith Drive<br />

• helps alleviate traffic congestion on the old Gateway<br />

Mot<strong>or</strong>way.<br />

From late this year the mot<strong>or</strong>way will also connect with<br />

Brisbane Airp<strong>or</strong>t C<strong>or</strong>p<strong>or</strong>ation’s new access road and by the<br />

middle of next year it will connect with a <strong>complete</strong>d duplicate<br />

Gateway Bridge.<br />

Maj<strong>or</strong> structures on the n<strong>or</strong>thern part of the mot<strong>or</strong>way<br />

include new n<strong>or</strong>thbound and southbound off ramps where the<br />

mot<strong>or</strong>way intersects with Kingsf<strong>or</strong>d Smith Drive (providing<br />

access to the CBD) and the new airp<strong>or</strong>t interchange.<br />

The entire Gateway Mot<strong>or</strong>way project is being delivered by<br />

Queensland Mot<strong>or</strong>ways f<strong>or</strong> the state government.<br />

Design and construction is by the Leighton Abigroup<br />

Joint Venture. SMEC and Maunsell are the principal design<br />

consultants.<br />

The n<strong>or</strong>thern 7km section of the Gateway Mot<strong>or</strong>way in Brisbane opened to traffic in July. This view is to the south where the new duplicate Gateway Bridge<br />

is currently being constructed.<br />

PHOTO: LEIGHTON ABIGROUP JOINT VENTURE<br />

14 Concrete in Australia Vol 35 No 3

The P<strong>or</strong>t Botany expansion is now well advanced.<br />

PHOTO: BOB JACKSON<br />

P<strong>or</strong>t Botany expansion well under way<br />

Construction of a new 63ha container terminal at P<strong>or</strong>t Botany<br />

f<strong>or</strong> Sydney P<strong>or</strong>ts is now well underway. The expanded p<strong>or</strong>t<br />

area is on the n<strong>or</strong>thern side of Botany Bay to the west of the<br />

present terminal and about 800m east of the third runway at<br />

Sydney Airp<strong>or</strong>t.<br />

Design and construct contract<strong>or</strong>s Baulderstone and Belgian<br />

dredging specialist Jan de Nul, commenced construction just<br />

over a year ago. Dredging, reclamation and wharf and terminal<br />

structures, along with associated road and bridge w<strong>or</strong>ks are<br />

expected to be <strong>complete</strong>d by the end of next year with final<br />

terminal fitout earmarked f<strong>or</strong> 2012. Parsons Brinckerhoff is the<br />

independent verifier to the project.<br />

The p<strong>or</strong>t expansion will involve:<br />

• Creating an additional 2km of wharf face f<strong>or</strong> five extra<br />

shipping berths<br />

• Reclaiming 60ha of land<br />

• Dredging deep water berths to 16.5m<br />

• Dredging 7.8 million cubic metres of fill to create shipping<br />

channels and berth boxes<br />

• Creating a new dedicated road access to the terminal<br />

• Providing additional rail sidings f<strong>or</strong> the terminal<br />

• Providing additional tug berths and facilities.<br />

Concrete in Australia Vol 35 No 3 15

PERSPECTIVE<br />

<strong>Steel</strong> fibres <strong>or</strong> <strong>synthetic</strong> fibres<br />

by Pierre Rossi<br />

Civil engineering and construction professionals no longer<br />

consider fibre reinf<strong>or</strong>ced concrete as exotic. This is after over<br />

30 years of technical research and development. This positive<br />

assessment is the result of several fact<strong>or</strong>s including:<br />

• the benefit of conclusive experience (especially f<strong>or</strong> steel fibre<br />

concretes which have been used since the 1970s)<br />

• very good technical understanding of these materials<br />

(f<strong>or</strong>mulation, use, physical, chemical and mechanical<br />

properties etc)<br />

• the existence of national and international recommendations<br />

on the sizing of the structures <strong>or</strong> structural elements made<br />

up of these materials (today perfectly validated f<strong>or</strong> steel fibre<br />

concretes).<br />

Some objective comparisons<br />

There are now two types of fibre available on the markets:<br />

steel fibres and <strong>synthetic</strong> fibres. When confronted by a pair of<br />

whisky connoisseurs we want to make sure they don’t turn into<br />

alcoholics and drink the whole bottle. Indeed, when relying on<br />

the scientific <strong>or</strong> technical literature concerning the comparative<br />

perf<strong>or</strong>mances (attractions) of the two kinds of fibre, to our<br />

dismay we find that the “thirst” often justifies the means. In<br />

other w<strong>or</strong>ds, we find approximations, err<strong>or</strong>s and unf<strong>or</strong>tunately<br />

even bad faith (<strong>or</strong> w<strong>or</strong>se) sprinkled in these learned texts. The<br />

objective is not to play to the fibre court but to offer some of<br />

the most objective elements possible (at least that is what we<br />

hope) so that the users of the famous fibre can come to the<br />

market without compromising quality. In <strong>or</strong>der to get to this<br />

point we have not chosen to make an exhaustive comparative<br />

analysis between the two competit<strong>or</strong>s, but to focus this<br />

analysis on two imp<strong>or</strong>tant problem areas where they are clearly<br />

differentiated. These two problems are mechanical perf<strong>or</strong>mance<br />

and durability.<br />

Mechanical perf<strong>or</strong>mance<br />

Firstly it is useful to remember the two indispensable basic<br />

points about fibre reinf<strong>or</strong>ced concrete. A fibre reinf<strong>or</strong>ced<br />

concrete is a composite material made up of a matrix – the<br />

concrete, and the reinf<strong>or</strong>cement – the fibre. In a fibre reinf<strong>or</strong>ced<br />

concrete the fibres spread the strain across the cracks created in<br />

the matrix. In other w<strong>or</strong>ds, the fibres are only useful if there are<br />

potential cracks in the material. No cracks, no fibres.<br />

When faced with cracks, one mechanical characteristic of the<br />

fibre is paramount. The Young’s modulus defines the rigidity of<br />

the fibre.<br />

Indeed, the higher the Young’s modulus of the fibre, the better<br />

the control of the cracks created in terms of length and opening.<br />

These values diminish as the Young’s modulus of the fibre<br />

increases.<br />

This principle is essential as long as the anch<strong>or</strong>ing of the fibre<br />

in the concrete is assured. The cracks in the concrete appear<br />

at different times in the life of the material; from the first<br />

moments (plastic shrinkage) up to a very advanced age. As a<br />

result these cracks appear at times in the concrete c<strong>or</strong>responding<br />

to structural characteristics (eg: density) and mechanical<br />

characteristics (resistance in compression, Young’s modulus)<br />

which progressively develop.<br />

During the first three hours the resistance of the concrete and<br />

its Young’s modulus are very low. The compression resistance<br />

is lower than 3MPa; traction resistance is below 0.3MPa and<br />

Young’s modulus is below 5GPa; these figures being all <strong>or</strong>ders of<br />

magnitude.<br />

If the concrete cracks during this period, loads to be taken<br />

by the fibre and crack openings will be low. After 24 hours<br />

and m<strong>or</strong>e the mechanical properties of the concrete increase<br />

considerably. Compression resistance is higher than 10MPa;<br />

traction resistance is above 1MPa and Young’s modulus is above<br />

15GPa. These are still <strong>or</strong>ders of magnitude.<br />

During this maturation period if the concrete is f<strong>or</strong>ced<br />

again to crack, the loads taken again by the fibres as well as the<br />

openings of the crack will be much m<strong>or</strong>e significant.<br />

How will the two types of fibre<br />

behave when the concrete cracks<br />

<strong>Steel</strong> fibres, most often have a high Young’s modulus<br />

(200GPa) and a high resistance in traction (between 800 and<br />

2500MPa). At a very young age, since small openings in the<br />

cracks may appear and because of the po<strong>or</strong> anch<strong>or</strong>ing of the<br />

fibre in the not very compact matrix, these steel fibres are not<br />

very effective against the cracks. The matrix does not pull on<br />

the fibres perpendicularly to the cracks so the cracks also do<br />

not react very much. The m<strong>or</strong>e the concrete ages, the m<strong>or</strong>e<br />

the steel fibres are needed by the cracks. They respond very<br />

effectively.<br />

The <strong>synthetic</strong> fibres used on the concrete are mainly<br />

polypropylene fibres. They have quite a low Young’s modulus<br />

varying between 3GPa and 5GPa. They are offered on the<br />

market in very small sizes (in length and diameter).<br />

M<strong>or</strong>e recently another type of <strong>synthetic</strong> fibre has appeared on<br />

the market; called polymer fibre, <strong>or</strong> macro-<strong>synthetic</strong> fibre. It is<br />

“offered” f<strong>or</strong> structural applications.<br />

Its size is significant and macro-<strong>synthetic</strong>s also have a higher<br />

Young’s modulus than those of polypropylene fibres, varying<br />

between 5GPa and 10GPa approximately.<br />

Finally, two other types of <strong>synthetic</strong> fibres are also used in<br />

concrete, but on a much lower level. These are PVA fibres<br />

and aramid fibres with Young’s Moduli of 30GPa and 70GPa<br />

respectively. These fibres are now used in very high and ultra<br />

high perf<strong>or</strong>mance fibre reinf<strong>or</strong>ced concretes.<br />

The following remarks concern polypropylene fibres and<br />

macro-<strong>synthetic</strong> fibres.<br />

Because of their low Young’s modulus these fibres are very<br />

reactive to potential cracks at a very young age, in particular<br />

16 Concrete in Australia Vol 35 No 3

polypropylene microfibres. Indeed, slight displacements on<br />

the fibres linked to small openings of the cracks in these fibres<br />

generate sufficient loads to combat the propagation of cracks.<br />

This effectiveness is increased because certain polypropylene<br />

fibres are fibrillated and theref<strong>or</strong>e very well anch<strong>or</strong>ed. This is also<br />

the case in a not very compact and adherent matrix such as very<br />

young concrete.<br />

Conversely, as the concrete becomes m<strong>or</strong>e mature, <strong>synthetic</strong><br />

fibres become less significant. Indeed, because of their low Young’s<br />

modulus <strong>synthetic</strong> fibres must undergo large displacements,<br />

c<strong>or</strong>responding to the large openings of the cracks, to generate<br />

appropriate seams in the cracks. Theref<strong>or</strong>e, in aged and cracked<br />

structures in concrete with macro-<strong>synthetic</strong> fibres, cracks are<br />

much m<strong>or</strong>e open than with steel fibres and the def<strong>or</strong>mation of<br />

these structures may be (too) significant.<br />

Another point to consider concerns the mechanical aspects. It<br />

concerns the problems of creep of the fibres.<br />

The creep of a material describes how it def<strong>or</strong>ms in time<br />

even under constant strains. <strong>Steel</strong> fibres at the levels of strain<br />

in concrete do not creep <strong>or</strong> hardly ever. This is not the case<br />

f<strong>or</strong> <strong>synthetic</strong> fibres. In this case the creep is insignificant.<br />

This may have negative effects. Indeed, one may encounter a<br />

situation where in a given situation the concrete with <strong>synthetic</strong><br />

fibres responds c<strong>or</strong>rectly to the specifications of the structure<br />

(mechanical stability, def<strong>or</strong>mation, openings of cracks) and the<br />

creep of fibres (between cracks) makes the structure “sway” in a<br />

situation which is not acceptable with def<strong>or</strong>mation (good use of<br />

the structure) and crack openings which become too significant<br />

(durability problems).<br />

Durability<br />

When people talk about the durability of fibre reinf<strong>or</strong>ced<br />

concretes there are two fact<strong>or</strong>s involved: the material and the<br />

structure.<br />

The first aspect concerns the problem of c<strong>or</strong>rosion of the fibres<br />

(material). Regarding <strong>synthetic</strong> fibres, apart from some aramid<br />

fibres, there is no durability problem in the fibre in the concrete.<br />

Regarding steel fibres, c<strong>or</strong>rosion of the fibres may obviously<br />

occur. Experience and research conclude that:<br />

• superficial c<strong>or</strong>rosion of the fibres may cause discol<strong>or</strong>ations on<br />

the surface of the exposed structures<br />

• surface c<strong>or</strong>rosion of the fibres does not cause any fault <strong>or</strong><br />

disturbance in the mechanical operation of the structures<br />

using it.<br />

The potential c<strong>or</strong>rosion of steel fibres may be minimised in<br />

practice by:<br />

• optimising the f<strong>or</strong>mulation of the fibre reinf<strong>or</strong>ced concrete<br />

• using non-steel framew<strong>or</strong>ks <strong>or</strong> ones with an “internal skin”<br />

(<strong>synthetic</strong> tissue f<strong>or</strong> example)<br />

• using galvanised fibres.<br />

The second aspect regarding the durability of fibre reinf<strong>or</strong>ced<br />

concretes concerns the fire resistance of structures. <strong>Steel</strong> fibres<br />

are not a determining fact<strong>or</strong> in the fire resistance of structures.<br />

What we can underline is that a structure in fibre reinf<strong>or</strong>ced<br />

concrete behaves rather better in the presence of fire than a<br />

n<strong>or</strong>mal reinf<strong>or</strong>ced concrete structure (fewer breaks).<br />

Conversely, some <strong>synthetic</strong> fibres, particularly polypropylene<br />

microfibres have a significantly positive impact on this problem.<br />

This effectiveness is due to a very simple phenomenon: in the<br />

case of a fire, polypropylene fibres disappear (they have reached<br />

their fusion point) to leave in place a significant netw<strong>or</strong>k of<br />

fine canalisations (capillaries) shared through the volume of the<br />

structure. These canalisations act as expansion vessels f<strong>or</strong> the<br />

water vapour generated under pressure by the fire (evap<strong>or</strong>ation of<br />

the water present in the concrete).<br />

Regarding the durability of the fibre reinf<strong>or</strong>ced concrete<br />

structures, a last imp<strong>or</strong>tant point concerns maintaining a function<br />

required f<strong>or</strong> a given structure over time. Like any covering in fibre<br />

reinf<strong>or</strong>ced concrete which has to ensure a seal (eg: in presence<br />

of water infiltrations). Because of the creep of <strong>synthetic</strong> fibres,<br />

mentioned above, this function, currently ensured by a concrete<br />

structure in <strong>synthetic</strong> fibres, may not be so some time afterwards.<br />

This is a problem which does not concern steel fibre concretes.<br />

<strong>Steel</strong> and <strong>synthetic</strong> fibres are<br />

nowhere near as incompatible<br />

as many people think.<br />

Finally, in the case of prefabricated p<strong>or</strong>table elements, <strong>or</strong><br />

structures which may come into direct contact with users,<br />

safety problems may arise if these are steel fibre concretes. This<br />

phenomenon mainly concerns fibre reinf<strong>or</strong>ced concretes with<br />

small diameter fibres, that is under <strong>or</strong> equal to 0.25mm. Indeed,<br />

one can never guarantee 100% that any steel fibre will not show<br />

on the surface of the structure, which may cause injuries.<br />

Technical solutions exist to mitigate this inconvenience,<br />

solutions which should not be skipped. The problem of injury<br />

caused by the fibres does not occur with <strong>synthetic</strong> fibres.<br />

Summarising the above, it can be<br />

said that:<br />

• steel fibre concretes do not perf<strong>or</strong>m well with regard to young<br />

age cracking, but they are very effective f<strong>or</strong> the cracking in<br />

concrete structures which have reached maturity<br />

• polypropylene micro fibre concretes are effective in young age<br />

cracking (plastic shrinkage)<br />

• macro-<strong>synthetic</strong> concretes are technically less significant<br />

than steel fibre concretes (with a problem of keeping certain<br />

functions over time) in relatively stressed structures<br />

• polypropylene microfibres are recommended to improve the<br />

fire resistance of concrete structures<br />

• care is needed regarding p<strong>or</strong>table structures <strong>or</strong> in contact with<br />

the user when they contain micro steel fibres. These micro<br />

steel fibres can cause cuts if no technical solution is adopted.<br />

To conclude, those who have assessed the respective<br />

perf<strong>or</strong>mances of the two fibres and who have left sectarianism<br />

and bad faith at the do<strong>or</strong>, may chose, in some cases to combine<br />

the two types of reinf<strong>or</strong>cing. They are no where near as<br />

incompatible as you may think.<br />

Pierre Rossi is from the Lab<strong>or</strong>atoire Central des Ponts et<br />

Chaussées Université Paris Est (East Paris university central<br />

lab<strong>or</strong>at<strong>or</strong>y f<strong>or</strong> bridges and roads) This is a translation of a paper by<br />

Pierre Rossi, published in Béton Magazine in March 2009.<br />

Concrete in Australia Vol 35 No 3 17

TECHNICAL<br />

The new Australian concrete structures<br />

standard – delays, problems and lessons<br />

R F Warner<br />

The University of Adelaide<br />

After some years of delay, the fourth edition of the Australian<br />

Concrete Structures Standard is now expected to appear by<br />

the end of 2009 <strong>or</strong> at the beginning of 2010. Committee<br />

BD-002 of Standards Australia is responsible f<strong>or</strong> AS 3600,<br />

and it commenced w<strong>or</strong>k on the fourth edition just after the<br />

appearance of the third edition in 2001. Progress was initially<br />

rapid and a draft f<strong>or</strong> public comment was released in 2005.<br />

The release of the draft f<strong>or</strong> public comment is an imp<strong>or</strong>tant<br />

milestone which usually occurs near the end of the preparation<br />

process, with the new standard appearing sh<strong>or</strong>tly thereafter.<br />

The ongoing delays in the appearance of the new AS 3600 led<br />

to concern and bemusement in the construction industry, with<br />

speculation on the reasons f<strong>or</strong> the delays. Individual members of<br />

BD-002 have frequently been asked to explain the situation and<br />

why there has been such a delay.<br />

The decisions that are made within BD-002, together with<br />

the underlying debates, are of course confidential and will not<br />

be discussed here. Nevertheless, industry questions concerning<br />

the delays are legitimate and deserve answers. The broad reasons<br />

f<strong>or</strong> the delays also need to be addressed, not in <strong>or</strong>der to find<br />

scapegoats, but in <strong>or</strong>der to learn lessons f<strong>or</strong> the future. It would<br />

indeed be unf<strong>or</strong>tunate if the problems experienced by BD-<br />

002 were to reappear when it undertakes future w<strong>or</strong>k. It is<br />

thus imp<strong>or</strong>tant to identify any ongoing issues that need to be<br />

addressed, not only by BD-002 but also by Standards Australia.<br />

As a starting point f<strong>or</strong> the present discussion it will be useful<br />

to look briefly at the committees responsible f<strong>or</strong> the concrete<br />

structures standard, the steps needed to produce a new standard,<br />

and the nature of the committee processes.<br />

Committees and Processes<br />

Committee BD-002 consists of around twenty members<br />

who are experienced in various areas of concrete design and<br />

construction. Most represent Australian <strong>or</strong>ganisations which<br />

are actively involved in the construction industry, and in<br />

particular in the design and construction of concrete structures.<br />

Organisations presently represented on BD-002 include:<br />

AUSTROADS; the Association of Consulting Engineers; the<br />

Bureau of <strong>Steel</strong> Manufacturers Australia; Cement Concrete<br />

and Aggregates Australia; the Concrete Institute of Australia;<br />

Engineers Australia; the Master Builders; the National Precast<br />

Concrete Association; the <strong>Steel</strong> Reinf<strong>or</strong>cement Institute.<br />

Standards Australia is represented by a Projects Manager who<br />

acts as committee secretary. The Australian Buildings Code<br />

Board also has a representative on BD-002. A further five <strong>or</strong><br />

so members are academics <strong>or</strong> researchers who are not chosen<br />

primarily to represent specific institutions, but rather on the<br />

basis of their knowledge and expertise, and their ability to<br />

contribute to the w<strong>or</strong>k of Committee BD-002.<br />

The detailed w<strong>or</strong>k of preparing a new standard is undertaken<br />

in small w<strong>or</strong>king sub-committees of BD-002, which deal with<br />

specialised topic areas such as strength, serviceability, durability,<br />

etc. Sub-committee w<strong>or</strong>k involves reviewing and evaluating<br />

new technical inf<strong>or</strong>mation, deciding on which inf<strong>or</strong>mation is<br />

to be included in the standard, drafting the various clauses and<br />

sections, and comparing draft clauses with comparable clauses<br />

in other overseas codes and standards. The sub-committees<br />

include co-opted outside members as well as BD-002 members,<br />

so that the expertise of specialists can be drawn on when needed.<br />

All decisions and draft clauses prepared in sub-committee are<br />

reviewed and accepted <strong>or</strong> modified by the main committee.<br />

An ongoing policy of Standards Australia is that committee<br />

decisions have to be consensus based. It is fairly obvious that<br />

a process based on consensus can only w<strong>or</strong>k if considerable<br />

goodwill is exercised, both by individual committee members<br />

and by the <strong>or</strong>ganisations represented. Nevertheless, and perhaps<br />

surprisingly, previous concrete structures standards in Australia<br />

have been successfully produced on the basis of committee<br />

consensus f<strong>or</strong> many years.<br />

A final imp<strong>or</strong>tant step in the introduction of a new edition of<br />

an Australian standard is taken by the Australian Building Code<br />

Board. The new document has to be accepted by the ABCB<br />

bef<strong>or</strong>e it is referenced in the Australian Building Code (Australian<br />

Building Codes Board, 2006). Referencing in the Building Code<br />

means that the standard becomes a legal document applicable in<br />

all states and territ<strong>or</strong>ies.<br />

The preparation of the new standard<br />

Generally speaking, preliminary w<strong>or</strong>k is first undertaken to see<br />

whether a new standard is in fact needed. In the case of BD-<br />

002, however, w<strong>or</strong>k typically commences on the next edition<br />

of AS 3600 as soon as a new edition appears. This is made<br />

necessary by the continuing and rapid increase in knowledge<br />

in the field of concrete structures and the continuing changes<br />

in the industry, coupled with the time required to <strong>complete</strong><br />

the en<strong>or</strong>mous amount of w<strong>or</strong>k involved in preparing such a<br />

document. Initial planning w<strong>or</strong>k f<strong>or</strong> the fourth edition of AS<br />

3600 was thus initiated in 2001 and intense sub-committee<br />

w<strong>or</strong>k followed sh<strong>or</strong>tly thereafter. The detailed w<strong>or</strong>k has resulted<br />

in a number of needed changes coming into the fourth edition,<br />

including:<br />

• an increase in the maximum concrete strength treated in the<br />

design rules, from 65 MPa to 100 MPa<br />

• an extension of the design methods f<strong>or</strong> columns to cover<br />

elements made with high strength concrete<br />

• a change in the treatment of loads, actions, action effects<br />

and other design concepts, with different nomenclature and<br />

18 Concrete in Australia Vol 35 No 3

terminology, to align with the new suite of Standards, AS/<br />

NZS 1170, Parts 0 to 4, in which the general requirements<br />

and design methods f<strong>or</strong> all materials are spelled out<br />

• the introduction of <strong>complete</strong>ly new strength design check<br />

procedures to allow the use of sophisticated analytic methods,<br />

such as linear and non-linear finite elements, in the strength<br />

design of members and structures<br />

• an extensive redraft of the strut-and-tie provisions within its<br />

own section<br />

• a revised treatment of the design of walls<br />

• new, updated treatments of fire resistance and durability<br />

• updated inf<strong>or</strong>mation on the structural properties of steel and<br />

concrete.<br />

These and other imp<strong>or</strong>tant changes were introduced into a first<br />

draft document which was reviewed, edited and modified by the<br />

main committee. The draft was then edited by Standards Australia<br />

and issued f<strong>or</strong> public comment in 2005 as Document DR–05252<br />

(Standards Australia Committee BD-002, 2005). The contents of<br />

the document are discussed in some detail in Warner et al, 2007.<br />

The final phase in the preparation of a new edition of AS 3600<br />

begins with a careful consideration of the public comments. These<br />

are acted on, as appropriate, and a “near-final” voting draft is<br />

prepared and edited. All members of BD-002 vote on whether <strong>or</strong><br />

not to accept this document as the new standard. The expectation<br />

is that members, having been closely involved at all stages in both<br />

the preparation of the draft and the underlying consensus-based<br />

decisions, will vote in the positive. A member who casts a negative<br />