column phase selection guide troubleshooting tools ... - Phenomenex

column phase selection guide troubleshooting tools ... - Phenomenex

column phase selection guide troubleshooting tools ... - Phenomenex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Polar<br />

TROUBLESHOOTING TOOLS<br />

• Flow meter<br />

• Leak detector<br />

• New syringe<br />

• Column performance test sample<br />

PRE-INSTALLATION CHECK LIST<br />

• Replace oxygen, moisture and hydrocarbon traps<br />

as necessary.<br />

• Check gas cylinder pressures to ensure that an adequate<br />

supply of carrier, make-up and fuel gases are available.<br />

Carrier gases should be of the highest purity.<br />

Note: It is critical that oxygen and water be removed<br />

from the carrier gas by the appropriate use of filters<br />

and adsorbents.<br />

CRITICAL COLUMN INSTALLATION STEPS<br />

INJECTOR INSTALLATION:<br />

Recommendation:<br />

GC <strong>column</strong>s do not have a specific directional flow when<br />

received from the manufacturer. Upon initial use of your<br />

new Zebron <strong>column</strong>, <strong>Phenomenex</strong> recommends the practice<br />

of dedicating one specific end of the <strong>column</strong> for injector<br />

installation only. This is particularly important when dealing<br />

with active/caustic or contaminating compounds. If these<br />

compounds are routinely injected onto the <strong>column</strong>,<br />

degradation of the <strong>phase</strong> will occur - leading to higher<br />

bleed. A typical first step to remedying (removing) this<br />

bleed would be to trim 10 cm from the front (injector)<br />

end of the <strong>column</strong> and keep trimming this inlet end of the<br />

<strong>column</strong> as necessary. Trying to remedy any bleed issues<br />

by trimming the <strong>column</strong> may not work if both ends have<br />

been interchangeably installed into the inlet.<br />

1. Place a capillary nut and ferrule on the injector end of<br />

the GC <strong>column</strong>, allowing a section of <strong>column</strong> to protrude.<br />

Trim one to two centimeters from the protruding end to<br />

remove ferrule contamination that may have entered the<br />

<strong>column</strong>. Inspect the cut with a magnifier to ensure that a<br />

smooth, clean, square-cut edge has been made - recut<br />

if necessary.<br />

2. Carefully hang the <strong>column</strong> in the GC oven, being<br />

cautious not to scratch or damage the polyimide<br />

coating on the capillary tubing. Rotate the <strong>column</strong> to<br />

avoid sharp bends of the capillary <strong>column</strong> and any<br />

contact of the <strong>column</strong> with oven surfaces.<br />

3. Insert the <strong>column</strong> into the injector exactly the correct<br />

distance specified in the instrument manual. Tighten the<br />

ferrule nut finger-tight then 1/2 turn with a wrench. If the<br />

<strong>column</strong> can still be moved, tighten another 1/4 turn until<br />

the <strong>column</strong> is secure.<br />

4. Adjust the carrier gas to obtain the flow rate listed on the<br />

test chromatogram.<br />

DETECTOR INSTALLATION:<br />

Note: For users with sensitive detectors such as MS and<br />

ECD, <strong>column</strong> conditioning steps should be performed before<br />

installing the <strong>column</strong> to prevent contamination and frequent<br />

maintenance of the detector.<br />

1. Place the <strong>column</strong> nut and ferrule past the end of the<br />

<strong>column</strong> and cut a centimeter or two off the end of the<br />

<strong>column</strong>. Be sure that the ferrule is the right size and<br />

• Methane or other non-retained compound<br />

• Reference <strong>column</strong><br />

• New septa, ferrules and injector liners<br />

• Instrument manuals<br />

• Ensure that the injection port is clean and free<br />

of sample residues, septum, or capillary debris.<br />

• Check and replace as necessary critical injector<br />

components such as seals, liners, and septa.<br />

• Check and replace detector seals as necessary.<br />

• Carefully inspect your <strong>column</strong> for damage or breakage.<br />

pointing in the correct direction. Inspect the cut with<br />

a magnifier and ensure that the cut is square and smooth.<br />

Recut if needed.<br />

2. Insert the outlet end of the <strong>column</strong> into the detector<br />

exactly the distance prescribed in the instrument<br />

manual. Distances will vary between detectors. Tighten<br />

the ferrule nut finger-tight then 1/2 turn with a wrench.<br />

If the <strong>column</strong> can still be moved, tighten another<br />

1/4 turn until the <strong>column</strong> is secure.<br />

3. Inspect the <strong>column</strong> connections for leaks using an<br />

electronic leak detector. Leaks at the inlet end may<br />

introduce oxygen to the <strong>column</strong> that will result in<br />

increased <strong>column</strong> bleed and damage to the <strong>column</strong><br />

<strong>phase</strong>.<br />

Proper & Improperly Cut Capillary<br />

Correct<br />

COLUMN CONDITIONING:<br />

1. Allow sufficient time for the carrier gas to flow through<br />

the <strong>column</strong> to purge any oxygen that may be in the<br />

system.<br />

2. Raise the temperature of the <strong>column</strong> to the maximum<br />

isothermal operating temperature that is listed on the<br />

individual Zebron ® GC Column Test Report. Maintain<br />

this temperature until a constant baseline is achieved.<br />

Conditioning times will depend on the <strong>phase</strong> identity and<br />

thickness, with thicker films taking longer to stabilize.<br />

In order to minimize the downtime of theinstrument,<br />

<strong>column</strong>s can be conditioned overnight at the maximum<br />

isothermal temperature.<br />

INSTALLATION TESTING:<br />

1. Inject a detectable unretained sample, such as methane<br />

for an FID, to determine dead volume time and linear<br />

gas velocity at the desired <strong>column</strong> temperature. Adjust<br />

gas pressure for optimal flow depending on carrier gas<br />

<strong>selection</strong>.<br />

2. The non-retained peak must have ideal peak shape or<br />

installation is faulty and needs to be redone.<br />

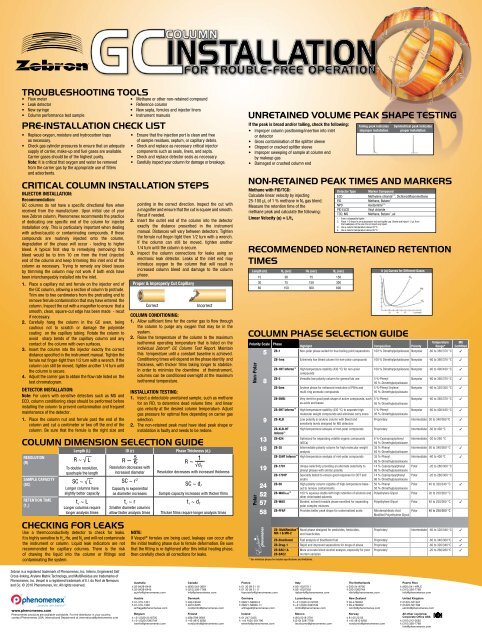

COLUMN DIMENSION SELECTION GUIDE<br />

RESOLUTION<br />

(R)<br />

SAMPLE CAPACITY<br />

(SC)<br />

RETENTION TIME<br />

(t r<br />

)<br />

Incorrect<br />

Length (L) ID (r) Phase Thickness (d f )<br />

R ~ √ — L<br />

To double resolution,<br />

quadruple the length<br />

SC ~ √ — L<br />

Longer <strong>column</strong>s have<br />

slightly better capacity<br />

t r ~ L<br />

Longer <strong>column</strong>s require<br />

longer analysis times<br />

CHECKING FOR LEAKS<br />

Use a thermoconductivity detector to check for leaks.<br />

It is highly sensitive to H 2<br />

, He, and N 2<br />

and will not contaminate<br />

the instrument or <strong>column</strong>. Liquid leak indicators are not<br />

recommended for capillary <strong>column</strong>s. There is the risk<br />

of drawing the liquid into the <strong>column</strong> or fittings and<br />

contaminating the system.<br />

R ~ r<br />

Resolution decreases with<br />

increased diameter<br />

SC ~ r 2<br />

Capacity is exponential<br />

as diameter increases<br />

t r ~ r<br />

Smaller diameter <strong>column</strong>s<br />

allow faster analysis times<br />

R ~ 1<br />

√ — d f<br />

Resolution decreases with increased thickness<br />

SC ~ d f<br />

Sample capacity increases with thicker films<br />

t r ~ d f<br />

Thicker films require longer analysis times<br />

NOTE:<br />

If Vespel ® ferrules are being used, leakage can occur after<br />

the initial heating <strong>phase</strong> due to ferrule deformation. Be sure<br />

that the fitting is re-tightened after this initial heating <strong>phase</strong>,<br />

then carefully check all corrections for leaks.<br />

UNRETAINED VOLUME PEAK SHAPE TESTING<br />

If the peak is broad and/or tailing, check the following:<br />

• Improper <strong>column</strong> positioning/insertion into inlet<br />

or detector<br />

• Gross contamination of the splitter sleeve<br />

• Chipped or cracked splitter sleeve<br />

• Improper sweeping of sample at <strong>column</strong> end<br />

by makeup gas<br />

• Damaged or crushed <strong>column</strong> end<br />

NON-RETAINED PEAK TIMES AND MARKERS<br />

Type Marker Compound<br />

Methane with FID/TCD:<br />

Detector<br />

Calculate linear velocity by injecting<br />

ECD<br />

Linear Velocity (u) = L/t o<br />

25-100 μL of 1 % methane in N 2 gas blend.<br />

Measure the retention time of the<br />

FID<br />

NPD<br />

Methane, Butane 1<br />

Acetonitrile 2, 4<br />

PID ELCD<br />

Vinyl chloride<br />

methane peak and calculate the following:<br />

TCD, MS<br />

COLUMN PHASE SELECTION GUIDE<br />

Polarity Scale<br />

5<br />

8<br />

9<br />

13<br />

18<br />

19<br />

24<br />

52<br />

57<br />

58<br />

Temperature MS<br />

Phase<br />

Highlight Composition Polarity Range* Certiftied<br />

ZB-1 Non-polar <strong>phase</strong> suited for true boiling point separations 100 % Dimethylpolysiloxane Nonpolar -60 to 360/370 °C 3<br />

ZB-1ms Extremely low bleed <strong>column</strong> for non-polar compounds 100 % Dimethylpolysiloxane Nonpolar -60 to 360/370 °C 3<br />

ZB-1HT Inferno High temperature stability (430 °C) for non-polar 100 % Dimethylpolysiloxane Nonpolar -60 to 400/430 °C 3<br />

compounds<br />

ZB-5 Versatile low polarity <strong>column</strong> for general lab use 5 %-Phenyl<br />

95 %-Dimethylpolysiloxane<br />

Nonpolar -60 to 360/370 °C 3<br />

ZB-5ms<br />

ZB-5MSi<br />

ZB-5HT Inferno <br />

ZB-XLB<br />

Arylene <strong>phase</strong> for enhanced resolution of PAHs and<br />

multi-ring aromatic compounds<br />

Very inert for good peak shape of active compounds, such<br />

as acids and bases<br />

High temperature stability (430 °C) to separate high<br />

molecular weight compounds and eliminate carry overs<br />

Low polarity si-arylene <strong>column</strong> with bleed and<br />

sensitivity levels designed for MS detectors<br />

5 %-Phenyl Arylene<br />

95 %-Dimethylpolysiloxane<br />

5 %-Phenyl<br />

95 %-Dimethylpolysiloxane<br />

Nonpolar -60 to 325/350 °C 3<br />

Nonpolar -60 to 360/370 °C 3<br />

5 %-Phenyl<br />

95 %-Dimethylpolysiloxane<br />

Nonpolar -60 to 400/430 °C 3<br />

Proprietary Intermediate 30 to 340/360 ºC 3<br />

ZB-XLB-HT High temperature anlaysis of mid-polar compounds Proprietary Intermediate -60 to 400 ºC 3<br />

Inferno <br />

ZB-624<br />

ZB-35<br />

Optimized for separating volatile organic compounds<br />

(VOCs)<br />

Intermediate polarity <strong>column</strong> for high molecular weight<br />

analysis<br />

6 %-Cyanopropylphenyl<br />

94 %-Dimethylpolysiloxane<br />

35 %-Phenyl<br />

65 %-Dimethylpolysiloxane<br />

ZB-35HT Inferno High temperature analysis of mid-polar compounds 35 %-Phenyl<br />

65 %-Dimethylpolysiloxane<br />

ZB-1701<br />

ZB-1701P<br />

ZB-50<br />

ZB-WAXPLUS <br />

ZB-WAX<br />

Unique selectivity providing an alternate selectivity to<br />

phenyl <strong>phase</strong>s with similar polarity<br />

Specially tested to ensure good response for DDT and<br />

endrin<br />

High polarity <strong>column</strong> capable of high-temperature bakeout<br />

to remove contaminants<br />

100 % aqueous stable with high retention of alcohols and<br />

other chlorinated solvents<br />

Bonded, solvent rinsable <strong>phase</strong> excellent for separating<br />

polar complex mixtures<br />

ZB-FFAP Provides better peak shape for underivatized acids Nitroterephthalic Acid<br />

Modified Polyethylene Glycol<br />

ZB- MultiResidue <br />

MR-1 & MR-2<br />

Novel <strong>phase</strong> designed for pesticides, herbicides,<br />

and insecticides<br />

Intermediate -20 to 260 °C<br />

Intermediate 50 to 340/360 °C 3<br />

Intermediate -60 to 400 ºC 3<br />

14 %-Cyanopropylphenyl<br />

86 %-Dimethylpolysiloxane<br />

Polar -20 to 280/300 °C<br />

14 %-Cyanopropylphenyl Polar -20 to 280/300 °C<br />

86 %-Dimethylpolysiloxane<br />

50 %-Phenyl<br />

Polar 40 to 320/340 °C 3<br />

50 %-Dimethylpolysiloxane<br />

Polyethylene Glycol Polar 20 to 250/260 °C<br />

Polyethylene Glycol Polar 40 to 250/260 °C 3<br />

Polar 40 to 250/260 °C<br />

Proprietary Intermediate -60 to 320/340 °C 3<br />

ZB-Bioethanol Fast analysis of bioethanol fuel Proprietary -60 to 340/360 ºC 3<br />

ZB-Drug-1 Rapid and improved separations for drugs of abuse Proprietary -60 to 320/340 ºC 3<br />

ZB-BAC1 &<br />

ZB-BAC2<br />

More accurate blood alcohol analysis, especially for post<br />

mortem samples<br />

Proprietary -20 to 260/280 ºC 3<br />

* See individual <strong>phase</strong>s for detailed specifications and limitations.<br />

Methylene chloride 2, 3 , Dichlorodifluoromethane<br />

Methane, Butane 1 , air<br />

1. From a disposable lighter<br />

2. Place 1-2 drops in an autosampler vial and tightly cap. Shake and inject 1-2 μL from<br />

the headspace of the vial. Do not inject any liquid.<br />

3. Use a <strong>column</strong> temperature above 55 ºC.<br />

4. Use a <strong>column</strong> temperature above 95 ºC.<br />

RECOMMENDED NON-RETAINED RETENTION<br />

TIMES<br />

Length (m) H 2 (sec) He (sec) N 2 (sec)<br />

Non-Polar<br />

15 38 75 150<br />

30 75 150 300<br />

60 150 300 600<br />

Tailing peak indicates<br />

improper installation<br />

Symmetrical peak indicates<br />

proper installation<br />

h (u) Curves for Different Gases<br />

Zebron is a registered trademark of <strong>Phenomenex</strong>, Inc. Inferno, Engineered Self<br />

Cross-linking, Arylene Matrix Technology, and MultiResidue are trademarks of<br />

<strong>Phenomenex</strong>, Inc. Vespel is a registered trademark of E.I. du Pont de Nemours<br />

and Co. © 2010 <strong>Phenomenex</strong>, Inc. All rights reserved.<br />

Australia<br />

t: 02-9428-6444<br />

f: 02-9428-6445<br />

auinfo@phenomenex.com<br />

Canada<br />

t: (800) 543-3681<br />

f: (310) 328-7768<br />

info@phenomenex.com<br />

France<br />

t: 01 30 09 21 10<br />

f: 01 30 09 21 11<br />

franceinfo@phenomenex.com<br />

Italy<br />

t: 051 6327511<br />

f: 051 6327555<br />

italiainfo@phenomenex.com<br />

The Netherlands<br />

t: 030-2418700<br />

f: 030-2383749<br />

nlinfo@phenomenex.com<br />

Puerto Rico<br />

t: (800) 541-HPLC<br />

f: (310) 328-7768<br />

info@phenomenex.com<br />

www.phenomenex.com<br />

<strong>Phenomenex</strong> products are available worldwide. For the distributor in your country,<br />

contact <strong>Phenomenex</strong> USA, International Department at international@phenomenex.com<br />

Austria<br />

t: 01-319-1301<br />

f: 01-319-1300<br />

anfrage@phenomenex.com<br />

Belgium<br />

t: +31 (0)30-2418700<br />

f: +31 (0)30-2383749<br />

beinfo@phenomenex.com<br />

Denmark<br />

t: 4824 8048<br />

f: 4810 6265<br />

nordicinfo@phenomenex.com<br />

Finland<br />

t: (09)4789 0063<br />

f: +45 4810 6265<br />

nordicinfo@phenomenex.com<br />

Germany<br />

t: 06021-58830-0<br />

f: 06021-58830-11<br />

anfrage@phenomenex.com<br />

Ireland<br />

t: 01 247 5405<br />

f: +44 1625-501796<br />

eireinfo@phenomenex.com<br />

Luxembourg<br />

t: +31 (0)30-2418700<br />

f: +31 (0)30-2383749<br />

nlinfo@phenomenex.com<br />

Mexico<br />

t: (55) 5018 3791<br />

f: (310) 328-7768<br />

tecnicomx@phenomenex.com<br />

New Zealand<br />

t: 09-4780951<br />

f: 09-4780952<br />

nzinfo@phenomenex.com<br />

Norway<br />

t: 81 00 20 05<br />

f: +45 4810 6265<br />

nordicinfo@phenomenex.com<br />

United Kingdom<br />

t: 01625-501367<br />

f: 01625-501796<br />

ukinfo@phenomenex.com<br />

All other countries:<br />

Corporate Office USA<br />

t: (310) 212-0555<br />

f: (310) 328-7768<br />

info@phenomenex.com

PEAKS<br />

NO PEAKS<br />

GHOST PEAKS<br />

TAILING PEAKS<br />

BROAD SOLVENT FRONTS<br />

Possible Cause:<br />

System<br />

• Clogged syringe ............................................................<br />

• Leaks ............................................................................<br />

• No carrier gas ...............................................................<br />

• Detector OFF or not lit ...................................................<br />

• Wrong injection port ......................................................<br />

• Clogged inlet sleeve ......................................................<br />

Column<br />

• Broken <strong>column</strong> ..............................................................<br />

• Plugged <strong>column</strong> ............................................................<br />

Possible Cause:<br />

System<br />

• Septum bleed ................................................................<br />

• Carry over .....................................................................<br />

• Dirty inlet ......................................................................<br />

• Contaminated gas .........................................................<br />

• Outgassing from traps ..................................................<br />

• Contaminated gas lines .................................................<br />

Column<br />

• Sample contaminated ...................................................<br />

Sample<br />

• Contaminated sample ...................................................<br />

• Contaminated flush solvent ...........................................<br />

• Possible sample degradation .........................................<br />

Possible Cause:<br />

• Contaminated or active injector liner or <strong>column</strong> ............<br />

• Dead volume due to poorly installed liner or <strong>column</strong> .....<br />

• Ragged <strong>column</strong> end ......................................................<br />

• A bad match between the polarities of stationary .........<br />

<strong>phase</strong> and the solvent<br />

• A cold region in the sample flow path ...........................<br />

• Debris in the liner or <strong>column</strong> .........................................<br />

• Injection takes too long .................................................<br />

• Split ratio is too low .......................................................<br />

• Overloading the inlet ....................................................<br />

• Some types of compounds such as alcoholic ...............<br />

amines and carboxylic acids tend to tail<br />

Possible Cause:<br />

• Bad <strong>column</strong> installation .................................................<br />

• Injector leak ..................................................................<br />

• Injection volume too large .............................................<br />

• Injection temperature too low ........................................<br />

• Split ratio is too low ......................................................<br />

• Column temperature too low .........................................<br />

• Initial <strong>column</strong> temperature too high ................................<br />

for splitless injection<br />

• Purge time too long (splitless injection) .........................<br />

Suggested Remedy:<br />

Clean or replace syringe.<br />

Check injector for leaks. Make sure <strong>column</strong> is properly installed in detector.<br />

Turn on carrier gas.<br />

Ignite or turn on detector. Reduce sample size or gas flows if solvent blew out detector.<br />

Verify correct injection port.<br />

Replace inlet liner.<br />

Inspect <strong>column</strong> and verify flow at <strong>column</strong> outlet.<br />

Cut off 5-10 cm of <strong>column</strong> ends and reinstall <strong>column</strong>. Verify flow at <strong>column</strong> outlet.<br />

Suggested Remedy:<br />

Replace septum with high-temperature, low-bleed septum.<br />

Increase final temperature and hold. Rinse syringe better.<br />

Replace inlet liner.<br />

Replace filters, scrubbers, or service purifiers. Use higher purity gasses.<br />

Replace traps.<br />

Replace or clean gas lines.<br />

Cut 50-100 cm from injector side of <strong>column</strong>. Perform an extended conditioning step. Solvent<br />

rinse <strong>column</strong>. Use glass wool in liner or decrease injection temperature, or replace <strong>column</strong>.<br />

Remake sample with higher purity/fresh solvents and clean glassware.<br />

Replace syringe flush solvent with fresh/pure solvent.<br />

Make new sample. Store samples using proper procedures. Reduce introduction of catalysts<br />

or reactive analytes in sample. Store samples in opaque or dark containers.<br />

Suggested Remedy:<br />

Clean or replace injector liner. Don’t use glass wool in the liner. Solvent rinse or replace<br />

the <strong>column</strong>.<br />

Confirm by injecting inert peak (methane). If it tails, <strong>column</strong> is not properly installed.<br />

Reinstall liner and <strong>column</strong> as necessary.<br />

Score the tubing lightly with a sapphire scribe or a ceramic scoring wafer before breaking it.<br />

Examine the end. If the break is not clean and the end square, cut the <strong>column</strong> again. Point<br />

the end down while breaking it, and reinstall the <strong>column</strong> while installing a nut and ferrule.<br />

This will prevent fragments from entering the <strong>column</strong>.<br />

Change the stationary <strong>phase</strong>. Usually polar analytes tail on non-polar <strong>column</strong>s,<br />

or dirty <strong>column</strong>s.<br />

Remove any cold zones in the flow path.<br />

Clean or replace the liner. Cut 10 cm off the end of the <strong>column</strong> and reinstall it.<br />

Improve injection technique.<br />

Increase split ratio to at least 20:1.<br />

Decrease the sample volume or dilute sample.<br />

Try a more polar <strong>column</strong>. Make a derivative of the sample.<br />

Suggested Remedy:<br />

Reinstall <strong>column</strong>.<br />

Find and fix leak.<br />

Decrease sample size or dilute 1:10.<br />

Increase injection temperature so the entire sample is vaporized “instantly.” An injection<br />

temperature higher than the temperature limit of the <strong>column</strong> will not damage the <strong>column</strong>.<br />

Increase split ratio.<br />

Increase <strong>column</strong> temperature. Use a lower boiling point solvent.<br />

Decrease the initial <strong>column</strong> temperature. Use a less volatile solvent so the initial <strong>column</strong> temperature<br />

is at least 10 °C below the boiling point of the solvent. Use a shorter purge activation time.<br />

Use a shorter purge activation time.<br />

BASELINE<br />

POSSIBLE CAUSES<br />

FOR BASELINE INSTABILITY<br />

SYSTEM<br />

• Leaks, O 2 influx<br />

• Column bleed<br />

• Septum bleed<br />

• Contaminated gases<br />

• Unequilibrated<br />

• Dirty detector<br />

• Dirty inlet<br />

• Improper flow rates<br />

• Pneumatic temperature change<br />

REFERENCE<br />

PARAMETERS UNIT SYMBOLS<br />

Retention Time of<br />

an Unretained Solute<br />

Retention Time,<br />

Measured from the Start<br />

s t o<br />

Adjusted Retention Time s t ’ R = t R - t o<br />

Peak Width<br />

(Base)<br />

Peak Width<br />

(Half Height)<br />

s<br />

s<br />

s<br />

t R<br />

W<br />

W1/2<br />

t o<br />

COLUMN<br />

• Bleed contamination<br />

• Liquid leak detector<br />

contamination<br />

Capacity Factor<br />

–<br />

(Retention Factor)<br />

k = t ’ R<br />

t o<br />

k<br />

Selectivity Factor – 2 t ’<br />

a = =<br />

R2<br />

k 1 t’ R1<br />

t’<br />

Resolution – R2<br />

-<br />

R s = 2<br />

t, R1<br />

( W 1 + W 2<br />

)<br />

Number of Theoretical Plates – N = 5.54<br />

t R t<br />

(W1/2) 2 R<br />

= 16( W ) 2<br />

t’<br />

Number of Effective Plates – R t’<br />

N eff = 5.54 (W1/2) 2 R<br />

= 16 ( W) 2<br />

Column Length cm L<br />

Height Equivalent of a<br />

Theoretical Plate (Plate Height)<br />

cm H =<br />

Effective Plate Height cm H eff =<br />

Linear Velocity of the<br />

Mobile Phase<br />

Pressure Conversions<br />

cm s -1 U =<br />

L<br />

N<br />

L<br />

N eff<br />

L<br />

t o<br />

1 bar = 100 kPa<br />

1 atm = 101.3 kPa<br />

1 psi = 6.9 kPa<br />

SAMPLE<br />

• Carry over<br />

• Depolymerization agents<br />

(HCl, KOH, etc.)<br />

HOW TO<br />

DECREASE<br />

PEAK WIDTH<br />

1. Use a More<br />

Efficient Column<br />

• Packed -<br />

smaller particles, packed<br />

more tightly<br />

• Capillary -<br />

smaller ID, thinner film<br />

2. Optimize Method<br />

Parameters<br />

• See van Deemter<br />

Plots for optimal flow<br />

rates of carrier gases<br />

• Optimize temperature<br />

profiles<br />

3. Reduce Sample Size<br />

• To avoid <strong>column</strong><br />

overloading<br />

4. Reduce Dead<br />

Volume in System<br />

• Follow manufacturer’s<br />

recommended<br />

Installation Instructions<br />

• Eliminate any leaks<br />

• Optimize detector flows<br />

FRONTING PEAKS<br />

SPLIT PEAKS<br />

Possible Cause:<br />

• Column overloading .......................................................<br />

Possible Cause:<br />

• Poor (jerky or erratic) injections .....................................<br />

• Bad <strong>column</strong> installation .................................................<br />

• Fluctuations in <strong>column</strong> temperature ..............................<br />

• Mixed sample solvent for splitless ................................<br />

or on-<strong>column</strong> injections<br />

• When using injection techniques that ............................<br />

require “solvent effect” refocusing such as splitless<br />

injection, the solvent must form a compact, continuous<br />

flooded zone in the <strong>column</strong>. If the solvent does not wet<br />

the stationary <strong>phase</strong> (<strong>column</strong> lining) sufficiently, as<br />

might be the case for methanol used with a nonpolar<br />

stationary <strong>phase</strong>, the solvent flooded zone may be<br />

several meters long and not of uniform thickness. This<br />

will result in broad and distorted peaks because the<br />

solutes will not be refocused into a narrow band near<br />

the beginning of the <strong>column</strong>.<br />

Suggested Remedy:<br />

Reduce the injection volume (increasing sensitivity, if necessary), increase split<br />

ratio, or use a <strong>column</strong> with greater capacity. Columns with larger diameters<br />

or thicker stationary <strong>phase</strong> coatings generally have larger sample capacities;<br />

however, resolution may be reduced.<br />

Suggested Remedy:<br />

Use smooth, steady plunger depression. Use autosampler.<br />

Reinstall <strong>column</strong>.<br />

Repair temperature control system. Calibrate GC oven.<br />

Use single solvent.<br />

Installing a retention gap (5 meters of uncoated<br />

but deactivated <strong>column</strong>) ahead of the chromatographic<br />

<strong>column</strong> may reduce or eliminate this problem.<br />

NON-REPRODUCIBLE RETENTION TIMES<br />

Possible Cause:<br />

System<br />

• Leaks .............................................................<br />

• Erratic flow controller ......................................<br />

• Unstable oven temperature ..............................<br />

• Pneumatic temperature change ......................<br />

• Line pressure change ......................................<br />

• Injection technique ..........................................<br />

Column<br />

• Polarity changing from contamination ..............<br />

• Adsorption .......................................................<br />

Sample<br />

• Concentration solute/stationary .......................<br />

<strong>phase</strong> insolubility<br />

Suggested Remedy:<br />

Check injector for leaks. Make sure <strong>column</strong> is properly installed in detector.<br />

Verify flows. Fix/replace flow controller if necessary.<br />

Calibrate oven. Possibly replace thermocouple.<br />

Redirect oven exhaust. Regulate room temperature.<br />

Install dual stage regulator.<br />

Standardize a reproducible injection technique.<br />

Cut 50-100 cm from injector side of <strong>column</strong>; perform an extended<br />

conditioning step. Solvent rinse <strong>column</strong>. Use glass wool in liner or decrease<br />

injection temperature; or replace <strong>column</strong>.<br />

Increase final temperature in program with hold time. Remove 50-100 cm<br />

from injector side of <strong>column</strong>.<br />

Use retention gap. Change <strong>column</strong> <strong>phase</strong>.<br />

Contact <strong>Phenomenex</strong> to get your<br />

FREE COPY of our GC Troubleshooting Guide<br />

PO52200710_I<br />

Australia<br />

t: 02-9428-6444<br />

f: 02-9428-6445<br />

auinfo@phenomenex.com<br />

Canada<br />

t: (800) 543-3681<br />

f: (310) 328-7768<br />

info@phenomenex.com<br />

France<br />

t: 01 30 09 21 10<br />

f: 01 30 09 21 11<br />

franceinfo@phenomenex.com<br />

Italy<br />

t: 051 6327511<br />

f: 051 6327555<br />

italiainfo@phenomenex.com<br />

The Netherlands<br />

t: 030-2418700<br />

f: 030-2383749<br />

nlinfo@phenomenex.com<br />

Puerto Rico<br />

t: (800) 541-HPLC<br />

f: (310) 328-7768<br />

info@phenomenex.com<br />

www.phenomenex.com<br />

<strong>Phenomenex</strong> products are available worldwide. For the distributor in your country,<br />

contact <strong>Phenomenex</strong> USA, International Department at international@phenomenex.com<br />

Austria<br />

t: 01-319-1301<br />

f: 01-319-1300<br />

anfrage@phenomenex.com<br />

Belgium<br />

t: +31 (0)30-2418700<br />

f: +31 (0)30-2383749<br />

beinfo@phenomenex.com<br />

Denmark<br />

t: 4824 8048<br />

f: 4810 6265<br />

nordicinfo@phenomenex.com<br />

Finland<br />

t: (09)4789 0063<br />

f: +45 4810 6265<br />

nordicinfo@phenomenex.com<br />

Germany<br />

t: 06021-58830-0<br />

f: 06021-58830-11<br />

anfrage@phenomenex.com<br />

Ireland<br />

t: 01 247 5405<br />

f: +44 1625-501796<br />

eireinfo@phenomenex.com<br />

Luxembourg<br />

t: +31 (0)30-2418700<br />

f: +31 (0)30-2383749<br />

nlinfo@phenomenex.com<br />

Mexico<br />

t: (55) 5018 3791<br />

f: (310) 328-7768<br />

tecnicomx@phenomenex.com<br />

New Zealand<br />

t: 09-4780951<br />

f: 09-4780952<br />

nzinfo@phenomenex.com<br />

Norway<br />

t: 81 00 20 05<br />

f: +45 4810 6265<br />

nordicinfo@phenomenex.com<br />

United Kingdom<br />

t: 01625-501367<br />

f: 01625-501796<br />

ukinfo@phenomenex.com<br />

All other countries:<br />

Corporate Office USA<br />

t: (310) 212-0555<br />

f: (310) 328-7768<br />

info@phenomenex.com