AS-700, AS-710

AS-700, AS-710

AS-700, AS-710

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

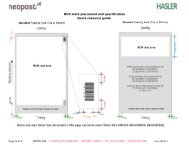

For known print object thicknesses<br />

Scale value<br />

Max. Print object<br />

thickness<br />

Print object<br />

Print object<br />

thickness<br />

0 0.4 mm Standard paper 80g/m²<br />

Empty envelope<br />

1 0.8 mm Envelope filled with<br />

standard paper, folded<br />

3 times<br />

0.1 mm<br />

0.4 mm<br />

0.7 mm<br />

2 2.0 mm<br />

3 3.5 mm<br />

4 5.0 mm<br />

5 6.0 mm<br />

5.4.1.2 Setting the Media Width for the Sheet Separating System<br />

1. Turn both knurled knobs (1), each about 1-half turn away from the stop in<br />

the middle position (see HIllustration 5-25).<br />

2. Unlock the knurled knob by turning counter-clockwise (2), lift it up and lock<br />

it again by turning clockwise in a lifted position (see arrows).<br />

1 2 1<br />

1.<br />

2.<br />

3.<br />

Illustration 5-25: Setting the paper feed<br />

3. Place a piece of the medium to be processed (3) under the lifted separating<br />

fingers; two pieces, in the case of thin media. If the medium is so thin that it<br />

possibly will not be reached by two separating fingers, then under the free<br />

separating finger should also be placed a medium of the same thickness.<br />

Non-compliance with these steps can lead to premature wear<br />

(grooves) of the separation roller.<br />

35