Download LED Status Indicators White Paper (PDF) - Proflow Systems

Download LED Status Indicators White Paper (PDF) - Proflow Systems

Download LED Status Indicators White Paper (PDF) - Proflow Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>LED</strong> <strong>Status</strong> <strong>Indicators</strong><br />

Use in Fuse Terminals and Modules<br />

Fuse holders used in industrial applications, whether fuse terminal blocks<br />

or modules, often include a status <strong>LED</strong>. These may indicate the fuse is healthy<br />

or may energize if the fuse fails and thus indicate a blown fuse.<br />

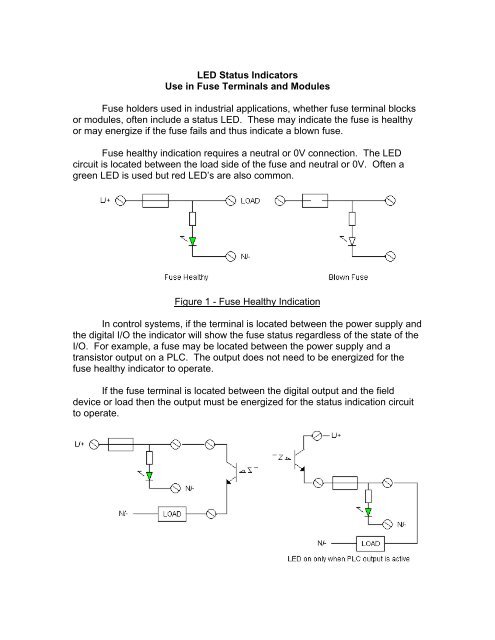

Fuse healthy indication requires a neutral or 0V connection. The <strong>LED</strong><br />

circuit is located between the load side of the fuse and neutral or 0V. Often a<br />

green <strong>LED</strong> is used but red <strong>LED</strong>’s are also common.<br />

Figure 1 - Fuse Healthy Indication<br />

In control systems, if the terminal is located between the power supply and<br />

the digital I/O the indicator will show the fuse status regardless of the state of the<br />

I/O. For example, a fuse may be located between the power supply and a<br />

transistor output on a PLC. The output does not need to be energized for the<br />

fuse healthy indicator to operate.<br />

If the fuse terminal is located between the digital output and the field<br />

device or load then the output must be energized for the status indication circuit<br />

to operate.

Figure 2 - Connection to PLC Digital Output<br />

When the fuse fails the indicator turns off so there is no indicator current<br />

produced in a blown fuse situation. Fuse modules, i.e. a printed circuit board in a<br />

DIN rail mounted housing, can include the neutral / 0V connection so fuse<br />

healthy indication is easily achieved. However, most fuse terminals do not<br />

include terminations for the neutral / 0V so this type of status indication is less<br />

common than blown fuse indication.<br />

In the case of blown fuse indication, the <strong>LED</strong> circuit is located in parallel<br />

with the fuse. When the fuse is healthy the voltage drop across the indicator<br />

circuit is insufficient to energize the <strong>LED</strong>. If the fuse blows the supply voltage is<br />

now applied to the indicator circuit and the <strong>LED</strong> illuminates. As the impedance of<br />

the <strong>LED</strong> circuit is generally much higher than the load the majority of the supply<br />

voltage is applied to the <strong>LED</strong> circuit.<br />

Figure 3 - Blown Fuse Indication<br />

Figure 4 - Connection to PLC Digital Output

No terminations for the neutral / 0V are required. The drawback is the<br />

<strong>LED</strong> circuit produces a current flow through the load when the fuse is blown.<br />

This “leakage current” is undesirable and should be kept to a minimum so that it<br />

does not pose a safety hazard. <strong>LED</strong> currents as high as 2.5-3mA are not<br />

uncommon. At least one DIN rail fuse terminal supplier offers blown fuse<br />

indication that draws 0.25-0.5mA and still provides highly visible <strong>LED</strong>’s.<br />

Another drawback with blown fuse indication is that the indicator only<br />

functions when the PLC output is energized.<br />

Figure 5 - Leakage Current<br />

Emphatec’s new DEPRO - CLSI offers the best of both worlds - no<br />

leakage current fuse healthy indication with no need to provide a neutral / 0V<br />

connection. This is achieved by installing current sensing in series with the fuse.<br />

If the fuse is powered and healthy and the load is connected (and not open<br />

circuit) then the indicating <strong>LED</strong> energizes. Like blown fuse indication the<br />

indicator circuit only works when the PLC output is energized.<br />

Figure 6 - DEPRO - CLSI Fuse Healthy Indication<br />

The current sensing circuit must be compact (current transformers would<br />

be too large) and introduce minimal voltage drop. Emphatec’s circuit drops the<br />

voltage by approximately 0.8V regardless of the current flow so to keep power

dissipation to a minimum the maximum fuse rating is 500mA. This is more than<br />

sufficient for the majority of PLC I/O and control loop applications.<br />

The DEPRO - CLSI is designed for both AC and DC voltages and<br />

operates from 12V to 230V - one fuse module will work in a wide range of<br />

applications. The <strong>LED</strong> intensity is not dependant on the supply voltage but is<br />

optimal at a load current of 10mA of higher. At lower load currents it may be<br />

difficult to see the <strong>LED</strong> when illuminated.<br />

Key Features of the DEPRO - CLSI:<br />

- Wide operating voltage range: 12-230Vac/dc<br />

- Fuse healthy indication without the need for a neutral or 0V connection<br />

- No leakage current<br />

- Indicates control loop wiring is intact, fuse is healthy and load is drawing current<br />

- Requires just 11.2mm of DIN rail<br />

- Mounts on 32mm and 35mm DIN rails<br />

- Class 1 Division 2 certified for use in hazardous locations