Adept SmartAxis User's Guide - Adept Technology, Inc.

Adept SmartAxis User's Guide - Adept Technology, Inc.

Adept SmartAxis User's Guide - Adept Technology, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

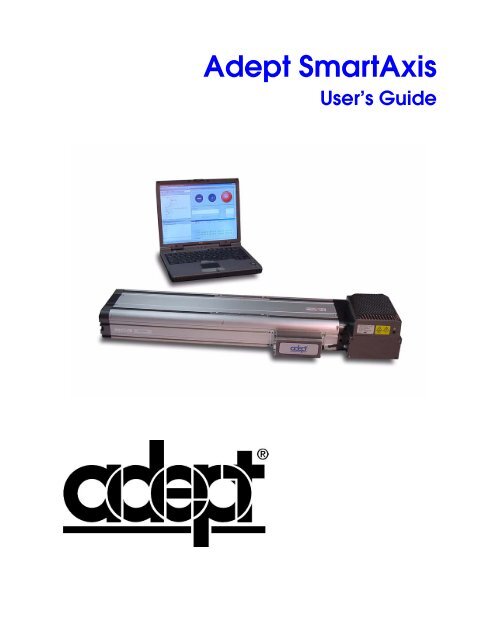

<strong>Adept</strong> <strong>SmartAxis</strong><br />

User’s <strong>Guide</strong>

<strong>Adept</strong> <strong>SmartAxis</strong><br />

User’s <strong>Guide</strong><br />

00332-000, Rev. C<br />

July 2005<br />

3011 Triad Drive • Livermore, CA 94551 • USA • Phone 925.245.3400 • Fax 925.960.0452<br />

Otto-Hahn-Strasse 23 • 44227 Dortmund • Germany • Phone 49.231.75.89.40 • Fax 49.231.75.89.450<br />

41, rue du Saule Trapu • 91300 • Massy • France • Phone 33.1.69.19.16.16 • Fax 33.1.69.32.04.62

The information contained herein is the property of <strong>Adept</strong> <strong>Technology</strong>, <strong>Inc</strong>., and shall not be reproduced<br />

in whole or in part without prior written approval of <strong>Adept</strong> <strong>Technology</strong>, <strong>Inc</strong>. The information herein is<br />

subject to change without notice and should not be construed as a commitment by <strong>Adept</strong> <strong>Technology</strong>, <strong>Inc</strong>.<br />

This manual is periodically reviewed and revised.<br />

<strong>Adept</strong> <strong>Technology</strong>, <strong>Inc</strong>., assumes no responsibility for any errors or omissions in this document. Critical<br />

evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future<br />

documentation. Please submit your comments by e-mail to: techpubs@adept.com<br />

Copyright ©2002, 2005 by <strong>Adept</strong> <strong>Technology</strong>, <strong>Inc</strong>. All rights reserved.<br />

The <strong>Adept</strong> logo, <strong>Adept</strong>Vision, AIM, HexSight, and HexaVision<br />

are registered trademarks of <strong>Adept</strong> <strong>Technology</strong>, <strong>Inc</strong>.<br />

ActiveV, <strong>Adept</strong>, <strong>Adept</strong> 1060, <strong>Adept</strong> 1060+, <strong>Adept</strong> 1850, <strong>Adept</strong> 1850 XP, <strong>Adept</strong> 540, <strong>Adept</strong> 560, <strong>Adept</strong> C40,<br />

<strong>Adept</strong> C60, <strong>Adept</strong> CC, <strong>Adept</strong> Cobra 550, <strong>Adept</strong> Cobra 550 CleanRoom, <strong>Adept</strong> Cobra 600, <strong>Adept</strong> Cobra 800,<br />

<strong>Adept</strong> Cobra i600, <strong>Adept</strong> Cobra i800, <strong>Adept</strong> Cobra s600, <strong>Adept</strong> Cobra s800, <strong>Adept</strong> DeskTop, <strong>Adept</strong> Digital<br />

Workcell, <strong>Adept</strong> FFE, <strong>Adept</strong> FlexFeeder 250, <strong>Adept</strong> IC, <strong>Adept</strong> Impulse Feeder, <strong>Adept</strong> LineVision, <strong>Adept</strong><br />

MC, <strong>Adept</strong> MV, <strong>Adept</strong> MV-10, <strong>Adept</strong> MV-19, <strong>Adept</strong> MV4, <strong>Adept</strong> MV-5, <strong>Adept</strong> MV-8, <strong>Adept</strong> NanoBonder<br />

EBS, <strong>Adept</strong> NanoBonder LWS, <strong>Adept</strong> NanoCell, <strong>Adept</strong> NanoStage L1P2, <strong>Adept</strong> NanoStage L3, <strong>Adept</strong><br />

NanoStage L3P2, <strong>Adept</strong> OC, <strong>Adept</strong> SmartAmp, <strong>Adept</strong> <strong>SmartAxis</strong>, <strong>Adept</strong> SmartController CS, <strong>Adept</strong><br />

SmartController CX, <strong>Adept</strong> SmartModule, <strong>Adept</strong> SmartMotion, <strong>Adept</strong> SmartServo, <strong>Adept</strong> sDIO, <strong>Adept</strong><br />

Servo Kit, <strong>Adept</strong> sMI6, <strong>Adept</strong> SMIF-EZ, <strong>Adept</strong>Align 650, <strong>Adept</strong>Atlas, <strong>Adept</strong>Cartesian, <strong>Adept</strong>Force,<br />

<strong>Adept</strong>FTP, <strong>Adept</strong>GEM, <strong>Adept</strong>Modules, <strong>Adept</strong>Motion, <strong>Adept</strong>Motion Servo, <strong>Adept</strong>Motion VME,<br />

<strong>Adept</strong>Net, <strong>Adept</strong>NFS, <strong>Adept</strong>One, <strong>Adept</strong>One-MV, <strong>Adept</strong>One-XL, <strong>Adept</strong>RAPID, <strong>Adept</strong>Six 300, <strong>Adept</strong>Six<br />

300CL, <strong>Adept</strong>Six 600, <strong>Adept</strong>TCP/IP, <strong>Adept</strong>Three, <strong>Adept</strong>Three-MV, <strong>Adept</strong>Three-XL, <strong>Adept</strong>Two,<br />

<strong>Adept</strong>Vicron, <strong>Adept</strong>Vicron 300S, <strong>Adept</strong>Vicron 310D, <strong>Adept</strong>Vision AVI, <strong>Adept</strong>Vision AGS, <strong>Adept</strong>Vision<br />

GV, <strong>Adept</strong>Vision I, <strong>Adept</strong>Vision II, <strong>Adept</strong>Vision VME, <strong>Adept</strong>Vision VXL, <strong>Adept</strong>Vision XGS, <strong>Adept</strong>Vision<br />

XGS II, <strong>Adept</strong>Windows, <strong>Adept</strong>Windows Controller, <strong>Adept</strong>Windows DDE, <strong>Adept</strong>Windows Offline Editor,<br />

<strong>Adept</strong>Windows PC, AIM Command Server, AIM Dispense, AIM PCB, AIM VisionWare, A-Series,<br />

AutoCal, AutoTune, AutoWidth, CCM, CCMII, CGM, FlexFeedWare, HyperDrive, Microenvironment,<br />

MicroV + , MotionWare, ObjectFinder, ObjectFinder 2000, PackOne, PalletWare, SMIF-C, SMIF-EZX,<br />

SMIF-Z, SMIF-ZX, S-Series, UltraOne, V, V + , and VisionTeach are trademarks of <strong>Adept</strong> <strong>Technology</strong>, <strong>Inc</strong>.<br />

Any trademarks from other companies used in this publication<br />

are the property of those respective companies.<br />

Printed in the United States of America

Table of Contents<br />

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

1.1 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Mechanism Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Multiple Axis Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Axis Coordination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

1.2 How Can I Get Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

1.3 Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

<strong>Adept</strong> Document Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

2.1 <strong>SmartAxis</strong> Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

2.2 System Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

2.3 Mounting Screw Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

2.4 R-Series Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

R-H Module Component Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16<br />

R-M Module Component Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17<br />

R-Sz Module Component Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18<br />

2.5 Installing the PDU2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

E-Stop Supply Select Switch S1 On PDU2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

2.6 Installing the <strong>Adept</strong> Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

2.7 Attaching Digital I/O to the RIO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

2.8 Installing the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

Connecting the Serial Cable from RIO to PC. . . . . . . . . . . . . . . . . . . . . . . . 22<br />

PC System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

Overview of Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23<br />

Installing <strong>Adept</strong> DeskTop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23<br />

3 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

3.2 Programming and Operating the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

Starting <strong>Adept</strong> DeskTop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

Verifying System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

Programming the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

Using the MicroV+ Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 5

Table of Contents<br />

3.3 Autostarting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27<br />

3.4 SmartAmp Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

Indicator LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

Brake Release Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

4 Remote I/O Device (RIO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

4.1 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Remote IO Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

4.2 DC Power for RIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

4.3 RIO Input Signal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

Removing the Outer Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

Jumper Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31<br />

Sensor Type Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33<br />

4.4 RIO Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34<br />

SW1 - Local or External Power Source for Output Signals . . . . . . . . . . . . . . . 34<br />

Providing External Power For RIO Output Drivers . . . . . . . . . . . . . . . . . . . . . . 34<br />

4.5 RS-232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35<br />

4.6 RIO LED Functions and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36<br />

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37<br />

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37<br />

Parts Not Requiring Any Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37<br />

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37<br />

5.2 Other Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38<br />

6 Technical Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39<br />

6.1 Module Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39<br />

6.2 <strong>Adept</strong> SmartAmp Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41<br />

SmartAmp Connector Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42<br />

6.3 RIO Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45<br />

RIO Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45<br />

RIO Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46<br />

RIO Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48<br />

6.4 PDU2 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49<br />

PDU2 Connectors and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49<br />

PDU2 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50<br />

PDU2 E-Stop Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51<br />

PDU2 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52<br />

6 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Table of Contents<br />

PDU2 Mounting Bracket Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53<br />

PDU2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54<br />

PDU2 Connector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55<br />

6.5 Transportable Moment Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56<br />

Transportable Moment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56<br />

Transportable Load of a Moving Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59<br />

A Reconfiguring a System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61<br />

A.1 Reconfiguring Hardware and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61<br />

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61<br />

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61<br />

A.2 Installing a RIO in the Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62<br />

Install the SPI Board on the SmartAmp Bracket . . . . . . . . . . . . . . . . . . . . . . 62<br />

RIO Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63<br />

A.3 Upgrading the MicroV+ Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64<br />

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67<br />

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 7

Introduction 1<br />

1.1 Product Description<br />

Hardware<br />

The <strong>Adept</strong> <strong>SmartAxis</strong> system is a self-contained, single-axis linear actuator system. It is a<br />

complete motion system made up of three hardware components:<br />

1. A linear module comprising an integrated AC servo motor-driven ball screw<br />

mechanism with linear bearings.<br />

2. An <strong>Adept</strong> SmartAmp which integrates a servo controller, servo amplifier, and<br />

power controller in one compact unit. The SmartAmp mounts to the linear<br />

module.<br />

3. A Remote I/O device (RIO) that provides a programming and control interface to<br />

the SmartAmp.<br />

NOTE: A SmartModule becomes a <strong>SmartAxis</strong> when the MicroV +<br />

operating system is running on the SmartAmp.<br />

R-Series Modules<br />

The R-Series modules are equipped with sealed belt covers to protect against harsh<br />

environments.<br />

• R-H Module (90405 - 10XXX) (See Figure 2-2 on page 16.)<br />

The R-H module is designed for heavy payloads, up to 80 kg horizontal and 40 kg<br />

vertical. R-H modules are equipped with 400W motors.<br />

NOTE: The part number listed above represents the module without an<br />

<strong>Adept</strong> SmartAmp attached. The assembly part number (module with<br />

SmartAmp) will be different. If the part number prefix is 90406, it is a<br />

cleanroom version of the module. This applies to all R- Series module<br />

types.<br />

• R-M Module (90405 - 20XXX) (See Figure 2-3 on page 17.)<br />

The R-M module is designed for horizontal and vertical medium payloads up to<br />

40 kg. R-M modules are equipped with 400W motors.<br />

• R-Sz Module (90405 - 40XXX) (See Figure 2-4 on page 18.)<br />

The R-Sz module is designed for horizontal and vertical light payloads up to 20<br />

kg. R-Sz modules are equipped with 200W motors for heavy-duty vertical<br />

cycling.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 9

Chapter 1 - Introduction<br />

Remote I/O Device<br />

The Remote I/O Device (RIO) provides 12 digital input signals and 8 digital output<br />

signals. This device also contains an RS-232 serial port which is used to communicate with<br />

the <strong>SmartAxis</strong>.<br />

PDU2<br />

The Power Distribution Unit-2 (PDU2) provides electrical power to the <strong>SmartAxis</strong>. The<br />

functions include:<br />

• switched AC power for the SmartAmp<br />

• 24 VDC power for the SmartAmp and the RIO<br />

• connections for E-Stop circuits<br />

NOTE: A <strong>SmartAxis</strong> system could include a PDU3, which has all the same<br />

functionality as the PDU2, but the PDU3 has a DC output current of<br />

3 amps total, instead of 2 amps for the PDU2.<br />

The optional <strong>SmartAxis</strong> Front Panel provides an emergency stop switch and High Power<br />

switch.<br />

Software<br />

The <strong>SmartAxis</strong> system is shipped with the following software:<br />

1. <strong>Adept</strong> DeskTop 1.0: provides programming and control interface.<br />

2. MicroV + : O.S. and programming language used to program and control the<br />

system. MicroV + resides and runs in the SmartAmp.<br />

3. SA_SPEC: used to configure the SmartAmp for specific modules, and to set up<br />

the calibration and tuning parameters for the module.<br />

NOTE: Additional software and programming information can be found<br />

in Chapter 3.<br />

Mechanism Control<br />

The <strong>Adept</strong> <strong>SmartAxis</strong> can be implemented using several control strategies. Typically, the<br />

desired control strategy is determined by the control hardware and software available in<br />

the work cell. This could range from stand-alone (<strong>SmartAxis</strong> only) installations to PC- or<br />

PLC based-installations. Listed below are several strategies. Additional strategies not<br />

described here might be practical.<br />

1. Standard MicroV + Application: This is a stand-alone strategy in which the <strong>Adept</strong><br />

<strong>SmartAxis</strong> module is controlled from MicroV + programs running onboard the<br />

<strong>Adept</strong> SmartAmp. The <strong>SmartAxis</strong> modules ships with example MicroV +<br />

programs installed. Additional example programs are available online.<br />

10 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

How Can I Get Help<br />

2. Discrete I/O Control from PLC or PC: This is a remote control strategy in which<br />

the <strong>Adept</strong> <strong>SmartAxis</strong> module is controlled from a PLC or a PC via discrete I/O<br />

signals. A MicroV + application resides on the <strong>Adept</strong> SmartAmp and interprets the<br />

discrete signals into MicroV + functions. The MicroV + application programs can be<br />

modified and expanded for use in a wide variety of applications. The PLC or PC<br />

may also handle the cell control functions.<br />

3. Serial Communications from PLC or PC: This is a remote control strategy, in<br />

which the <strong>Adept</strong> <strong>SmartAxis</strong> module is controlled from a PLC or a PC via serial<br />

communication. MicroV + commands are sent to the <strong>Adept</strong> SmartAmp via the<br />

RS232 port on the Remote I/O device (RIO). All application code may reside on<br />

the PLC or the PC. The PLC or PC may also handle the cell control functions. For<br />

more information on this control strategy contact your local Applications Support<br />

office.<br />

Multiple Axis Configurations<br />

While the <strong>SmartAxis</strong> system was initially designed for single-axis applications, it may be<br />

desirable to combine multiple <strong>SmartAxis</strong> modules into an X/Y and X/Y/Z mechanism.<br />

For information about installation of multiple axis mechanisms, see the <strong>Adept</strong><br />

SmartModules Instruction Handbook Volume 2 (available on the Knowledge Express<br />

CD-ROM).<br />

Axis Coordination<br />

NOTE: The <strong>SmartAxis</strong> modules do not require the 1394 cables as<br />

described in the SmartModules documentation.<br />

End-point coordination of multiple <strong>SmartAxis</strong> modules can be performed using the<br />

strategies outlined above, but linear or circular interpolation is not currently supported. If<br />

an application requires interpolation, use of a SmartController should be considered.<br />

1.2 How Can I Get Help<br />

Refer to the How to Get Help Resource <strong>Guide</strong> (<strong>Adept</strong> P/N 00961-00700) for details on<br />

getting assistance with your <strong>Adept</strong> software and hardware. Additionally, you can access<br />

information sources on <strong>Adept</strong>’s corporate web site:<br />

http://www.adept.com<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 11

Related Manuals<br />

1.3 Related Manuals<br />

This manual covers the installation and setup of an <strong>Adept</strong> <strong>SmartAxis</strong> system. There are<br />

additional manuals that cover programming the system, reconfiguring installed<br />

components, and adding other optional components; see Table 1-1. These manuals are<br />

available on the <strong>Adept</strong> Document Library CD-ROM shipped with each system.<br />

Table 1-1. Related Manuals<br />

Manual Title<br />

<strong>Adept</strong> DeskTop Online Help<br />

SA_SPEC Utility Online<br />

Help<br />

MicroV+ Online Help<br />

<strong>Adept</strong> SmartModules<br />

Instruction Handbook<br />

Volume 1<br />

<strong>Adept</strong> SmartModules<br />

Instruction Handbook<br />

Volume 2<br />

<strong>Adept</strong> SmartController<br />

User’s <strong>Guide</strong><br />

<strong>Adept</strong> SmartModules Quick<br />

Setup <strong>Guide</strong><br />

Description<br />

Describes how to use the <strong>Adept</strong> DeskTop software.<br />

Describes how to use the SA_SPEC Utility program.<br />

Describes how to use the MicroV + programming language.<br />

Describes how to install the <strong>Adept</strong> MV Controller in an <strong>Adept</strong><br />

SmartModules system.<br />

Describes how to assemble and install an <strong>Adept</strong> SmartModules<br />

system.<br />

Describes the installation and configuration of the <strong>Adept</strong><br />

SmartController. It contains information on the <strong>Adept</strong> Front<br />

Panel.<br />

Describes how to quickly set up the <strong>Adept</strong> SmartModules robot<br />

and connect it to the controller. There is a separate guide for<br />

each SmartModule configuration.<br />

<strong>Adept</strong> Document Library<br />

The <strong>Adept</strong> Document Library (ADL) contains documentation for <strong>Adept</strong> products. You<br />

can access a local copy of the ADL from the <strong>Adept</strong> Software CD shipped with your<br />

system, or from the separate ADL CD. Additionally, an Internet version of the ADL can be<br />

accessed by going to the <strong>Adept</strong> Web site and selecting Document Library from the home<br />

page. To go directly to the <strong>Adept</strong> Document Library, type the following URL into your<br />

browser:<br />

http://www.adept.com/Main/KE/DATA/adept_search.htm<br />

To locate information on a specific topic, use the Document Library search engine on the<br />

ADL main page. To view a list of available product documentation, select the Document<br />

Titles option.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 12

Installation 2<br />

This chapter covers the components needed for a complete system installation, including<br />

details for the <strong>Adept</strong> R-Series <strong>SmartAxis</strong> modules and system cabling.<br />

2.1 <strong>SmartAxis</strong> Installation Procedure<br />

The installation and setup of any <strong>SmartAxis</strong> system involves the completion of the<br />

following steps. During completion of the steps, other sections of this manual will be<br />

referenced. See Figure 2-1 on page 14 for a diagram of the system components and<br />

cabling.<br />

Table 2-1. <strong>SmartAxis</strong> Installation Procedure<br />

Action to Perform<br />

1. Mount the linear module to the<br />

work surface.<br />

2. Install the PDU2 and wire the<br />

user-supplied external E-Stop<br />

circuit.<br />

3. Install the optional <strong>Adept</strong> Front<br />

Panel.<br />

4. Connect the RIO to your PC, using<br />

an RS-232 serial cable.<br />

5. Install <strong>Adept</strong> DeskTop (ADT) or<br />

<strong>Adept</strong> Desktop Lite (ADTL) on the<br />

PC.<br />

For Details<br />

See Section 2.4 for R-Series modules.<br />

See Section 2.5 on page 19.<br />

See Section 2.6 on page 21. If the Front Panel is<br />

not used, the user must supply this<br />

functionality to the system (see Figure 6-3 on<br />

page 51).<br />

See “Connecting the Serial Cable from RIO to<br />

PC” on page 22.<br />

See “Installing <strong>Adept</strong> DeskTop” on page 23.<br />

Note: The SA_SPEC utility is automatically<br />

installed during this process.<br />

6. Turn on the AC power switch on<br />

the PDU2.<br />

7. Verify that the system is<br />

functioning properly.<br />

See Section 3.2 on page 25. Also look at the<br />

section on Example MicroV + Programs.<br />

8. Learn about the Autostart feature. See Section 3.3 on page 27.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 13

C B<br />

I R<br />

R E<br />

C A<br />

U K<br />

I E<br />

T R<br />

R<br />

Chapter 2 - Installation<br />

2.2 System Cable Diagram<br />

SmartAmp<br />

24VDC Cable<br />

Switched<br />

AC Cable<br />

<strong>Adept</strong> PDU2<br />

PDU2 to Front Panel<br />

Adapter<br />

PDU2<br />

24V<br />

STOP<br />

SA<br />

AUX<br />

CH1 CH2<br />

ES1 ES2<br />

SA DC RESET<br />

AUX DC RESET<br />

RIO Interface<br />

Cable<br />

Terminator<br />

Installed<br />

1<br />

AC<br />

PWR<br />

SA<br />

XDCS<br />

2<br />

XSLV1/<br />

XSLV2<br />

PDU2 to<br />

Front Panel<br />

Cable<br />

<strong>Adept</strong> Front Panel -<br />

Optional<br />

<strong>Adept</strong> RIO<br />

AC<br />

PWR<br />

IN<br />

RS-232 Cable<br />

AC In<br />

100-240 VAC<br />

Desktop or Laptop PC<br />

Typical <strong>Adept</strong> SmartModule<br />

Figure 2-1. <strong>SmartAxis</strong> System Cable Diagram with PDU2 and Front Panel<br />

Precautions<br />

Observe the following precautions when configuring any module:<br />

1. When assembling cables, avoid applying unreasonable force to cables.<br />

2. Before applying power, ensure that all cables have been connected correctly.<br />

WARNING: Improper connection may result in damage to<br />

the <strong>SmartAxis</strong> or the Power Distribution Unit.<br />

14 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Mounting Screw Torques<br />

2.3 Mounting Screw Torques<br />

When securing screws used to install modules, mounting brackets, and other<br />

components, apply the amount of torque specified in Table 2-2 and Table 2-3.<br />

Table 2-2 applies to the following:<br />

• Mounting brackets attached to modules<br />

• Mounting brackets attached to the work surface<br />

• Customer equipment attached to the end caps of R-Series modules<br />

Table 2-2. Modules and Mounting Brackets Screw and Bolt Torque Specifications<br />

Module Screw Diameter Tightening Torque<br />

R-H M8 33.3 N•m<br />

R-M M6 14.7 N•m<br />

R-Sz M5 5.7 N•m<br />

Table 2-3 applies to any equipment attached to the module carriage.<br />

Table 2-3. Module Carriage Torque Specifications<br />

Module Screw Diameter Tightening Torque<br />

R-H M8 33.3 N•m<br />

R-M M6 14.7 N•m<br />

R-Sz M5 11.7 N•m<br />

NOTE: Refer to the Technical Specifications chapter in the <strong>Adept</strong><br />

SmartModules Instruction Handbook Volume 2 for dimension drawings<br />

of the modules and mounting brackets. This manual is located on the<br />

<strong>Adept</strong> Knowledge Express CD-ROM, and on the <strong>Adept</strong> web site.<br />

2.4 R-Series Module Installation<br />

This section describes the process of installing R-Series modules. The R-H, R-M, and R-Sz<br />

modules have a factory installed SmartAmp, a SmartAmp mounting bracket, and RIO<br />

device. See Figure 2-2, Figure 2-3, and Figure 2-4 for an overview of the system<br />

components for each module type. To properly mount a module:<br />

1. Prepare the work surface by drilling and tapping four appropriately sized holes<br />

for each module mounting bracket used. The number of brackets used will vary<br />

based on the size of the module. See Table 2-2 for the appropriate hole size for the<br />

bracket being used.<br />

2. Mount the module to the work surface using four screws per bracket.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 15

Chapter 2 - Installation<br />

R-H Module Component Overview<br />

R-H Module<br />

R-H Module Mounting Bracket<br />

(optional)<br />

SmartAmp<br />

RIO Device<br />

SmartAmp Mounting<br />

Bracket<br />

Figure 2-2. R-H: System Component Overview<br />

Table 2-4. R-H Parts List<br />

Description Part Number Qty<br />

R-H module assembly (including factory installed 4051x-xxx<br />

1<br />

SmartAmp)<br />

Mounting bracket, RH (optional, factory installed) 90400-01100 2 a<br />

PDU to Amp Cables<br />

AC power cable<br />

24V DC cable (factory installed)<br />

OR<br />

Amp to Amp Cables (for combining multiple axes)<br />

AC power cable<br />

24V DC cable<br />

10410-009xx<br />

10410-010xx<br />

10410-006xx<br />

10410-007xx<br />

Remote I/O kit (factory installed) 90410-20050 1<br />

a Quantity may vary according to module lengths. R-H modules with 300 to 600 mm stroke use two<br />

mounting brackets; 800 mm and longer stroke modules require three mounting brackets.<br />

1<br />

1<br />

16 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

R-Series Module Installation<br />

R-M Module Component Overview<br />

R-M Module<br />

SmartAmp<br />

R-M Module Mounting<br />

Bracket (optional)<br />

RIO Device<br />

SmartAmp Mounting<br />

Bracket<br />

Figure 2-3. R-M: System Component Overview<br />

Table 2-5. R-M Parts List<br />

Description Part Number Qty<br />

R-M module assembly (including factory installed 4052x-xxx<br />

1<br />

SmartAmp)<br />

Mounting bracket, RM (optional, factory installed) 90400-01200 2 a<br />

PDU to Amp Cables<br />

AC power cable<br />

24V DC cable (factory installed)<br />

OR<br />

Amp to Amp Cables (for combining multiple axes)<br />

AC power cable<br />

24V DC cable<br />

10410-009xx<br />

10410-010xx<br />

10410-006xx<br />

10410-007xx<br />

Remote I/O kit (factory installed) 90410-20050 1<br />

a Quantity may vary according to module lengths. R-M modules with strokes less than 750 mm require<br />

two mounting brackets; R-M modules with strokes greater than 750 mm require three mounting<br />

brackets.<br />

1<br />

1<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 17

Chapter 2 - Installation<br />

R-Sz Module Component Overview<br />

SmartAmp<br />

R-Sz Module<br />

Mounting Bracket<br />

(optional)<br />

R-Sz Module<br />

RIO Device<br />

Figure 2-4. R-Sz: System Component Overview<br />

Table 2-6. R-Sz Parts List<br />

Description Part Number Qty<br />

R-Sz module assembly (including factory installed 4054x-xxx<br />

1<br />

SmartAmp)<br />

Mounting bracket, RSz (optional, factory installed) 90400-01300 2 a<br />

PDU to Amp Cables<br />

AC power cable<br />

24V DC cable (factory installed)<br />

OR<br />

Amp to Amp Cables (for combining multiple axes)<br />

AC power cable<br />

24V DC cable<br />

10410-009xx<br />

10410-010xx<br />

10410-006xx<br />

10410-007xx<br />

Remote I/O kit (factory installed) 90410-20050 1<br />

a Quantity may vary according to module lengths. R-Sz modules with strokes less than 300 mm require<br />

two mounting brackets; R-Sz modules with strokes greater than 400 mm require three mounting<br />

brackets.<br />

1<br />

1<br />

18 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Installing the PDU2<br />

2.5 Installing the PDU2<br />

NOTE: A <strong>SmartAxis</strong> system could include a PDU3, which has all the same<br />

functionality as the PDU2, but the PDU3 has a DC output current of 3<br />

amps total, instead of 2 amps for the PDU2.<br />

The PDU2 performs the following functions in an <strong>Adept</strong> <strong>SmartAxis</strong> system:<br />

• supplies switched AC power to the SmartAmp<br />

• provides AC power filtering and surge protection<br />

• supplies 24 VDC power to the SmartAmp and RIO<br />

• provides CAT-3 E-Stop function<br />

See page 49 for the details of the connectors and indicators on the PDU2.<br />

1. Mount the PDU2 in an appropriate location. Interface cables from the SmartAmp<br />

to the PDU2 are 4.5 meters, so the PDU2 must be within that distance. Mounting<br />

brackets are supplied with the PDU2 (see Figure 2-5). For dimensions of the<br />

mounting brackets, see Figure 6-5 on page 53.<br />

CAUTION: To allow for proper cooling, mount the PDU2<br />

with 50 mm clearance at the top and bottom of the unit.<br />

Figure 2-5. PDU2 with Mounting Brackets Installed<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 19

Chapter 2 - Installation<br />

2. Connect the 24 VDC cable coming from the SmartAmp to the XDCS connector on<br />

the PDU2.<br />

3. Connect the AC power cable coming from the SmartAmp to the AC PWR SA<br />

connector on the PDU2.<br />

4. Connect user-supplied external E-Stop and safety circuits to the XSLV1 connector<br />

on the PDU2. See Figure 6-3 on page 51 for a schematic on user-supplied safety<br />

circuits. If an external E-Stop circuit is not supplied by the user, the <strong>Adept</strong> Front<br />

Panel must be connected to the XSLV1 or XSLV2 connector. See Section 2.6 on<br />

page 21 for details.<br />

The unused XSLV connector must be terminated using the <strong>Adept</strong>-supplied<br />

terminating jumper.<br />

5. Make sure the S1 switch inside the PDU2 is set to the Internal position if you are<br />

using an <strong>Adept</strong> Front Panel. See the next section for information.<br />

6. Connect the user-supplied AC power source (100-240 VAC) to the AC PWR IN<br />

connector on the PDU2.<br />

E-Stop Supply Select Switch S1 On PDU2<br />

The PDU2 E-Stop system can be powered by its own internal 24VDC power supply, or it<br />

can be configured to be powered by an external source. The E-Stop Supply Select Switch<br />

S1, located inside the PDU2, controls this function. To access the switch, remove the<br />

snap-in cover, see Figure 2-6.<br />

WARNING: Only skilled or instructed personnel should<br />

attempt to change PDU2 power source. Always disconnect<br />

AC power to the PDU2 prior to changing the S1 switch<br />

position.<br />

• The factory default position is EXTERNAL.<br />

• If you use an <strong>Adept</strong> Front Panel, S1 must be set to INTERNAL.<br />

• If you have a user-supplied front panel, S1 can be set to either INTERNAL or<br />

EXTERNAL, depending on how the E-Stop circuit is designed.<br />

See Figure 6-3 on page 51.<br />

Remove cover to<br />

access switch S1<br />

S1 selects Internal<br />

or External E-Stop<br />

power<br />

Figure 2-6. Location of Switch S1<br />

20 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Installing the <strong>Adept</strong> Front Panel<br />

2.6 Installing the <strong>Adept</strong> Front Panel<br />

The optional <strong>Adept</strong> Front Panel provides an Emergency Stop switch and a High Power<br />

enable switch. See Figure 2-1 on page 14 for the system cable diagram.<br />

NOTE: The Auto/Manual switch on the Front Panel is not functional in an<br />

<strong>Adept</strong> <strong>SmartAxis</strong> system.<br />

1. Locate the Front Panel adaptor plug and install it in the XFP connector on the side<br />

of the Front Panel.<br />

2. Locate the PDU-to-Front Panel cable. Connect one end to the XSLV2 connector on<br />

the PDU2. Connect the other end to the adapter plug on the side of the Front<br />

Panel.<br />

3. Verify that switch S1 in the PDU2 is set to Internal. See page 20 for details.<br />

NOTE: If you do not use the <strong>Adept</strong> Front Panel, you must supply the<br />

E-Stop and High Power enable functionality to the system. See Figure 6-3<br />

on page 51.<br />

2.7 Attaching Digital I/O to the RIO<br />

If you are planning to connect discrete digital I/O signals to the RIO, you should do that<br />

now. Refer to Chapter 4 for complete information on the RIO device.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 21

Chapter 2 - Installation<br />

2.8 Installing the Software<br />

Connecting the Serial Cable from RIO to PC<br />

1. Locate the serial cable that is shipped with the system.<br />

2. Connect one end of the serial cable to the RS-232 connector on the RIO.<br />

3. Connect the other end of the serial cable to a serial port on the PC. See the next<br />

section for PC requirements.<br />

PC System Requirements<br />

Running the <strong>SmartAxis</strong> system using <strong>Adept</strong> DeskTop and MicroV + requires following PC<br />

setup:<br />

• IBM-compatible PC with a processor capable of running Windows 98 SE, Windows<br />

2000, or WindowsNT<br />

• Windows 98 SE, Windows 2000, or WindowsNT running service pack 4 or later<br />

• Hard Disk Space: 750 MB; 15MB to install the software, 500 MB to install the online<br />

documentation (optional - can be accessed from CD-ROM drive), and the rest for<br />

swap space and temporary files<br />

• 16 MB RAM minimum<br />

• one RS-232 serial port (settings are configured automatically by ADT)<br />

•CD-ROM drive<br />

•SVGA monitor<br />

If you use an optional terminal emulator (for example, Windows HyperTerminal) to<br />

communicate with the system, configure the RS-232 serial port with the following<br />

settings:<br />

• baud rate = 9600, data bits = 8, parity = none, stop bits = 1<br />

• flow control = DTS/CTS (hardware flow control)<br />

• Local echo = enabled<br />

• [ENTER] key sends CRLF (or LF)<br />

• Emulation = ANSI or VT100<br />

22 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Installing the Software<br />

Overview of Software<br />

The <strong>SmartAxis</strong> is supplied with the following software programs used for configuring,<br />

calibrating, programming, and operating the system.<br />

Table 2-7. System Supplied Software<br />

<strong>Adept</strong> DeskTop 1.0<br />

MicroV +<br />

SA_SPEC<br />

Provides programming and control interface for the <strong>SmartAxis</strong><br />

system.<br />

Operating system and programming language used to control<br />

and program the system. MicroV + resides and runs in the<br />

firmware of the SmartAmp.<br />

Used to configure the amplifier for the module, and set up the<br />

calibration (set zero position) and motion tuning parameters of<br />

the module.<br />

Installing <strong>Adept</strong> DeskTop<br />

The SA_SPEC and <strong>Adept</strong> Desktop 1.0 (ADT) software is supplied on a CD-ROM that is<br />

shipped with your <strong>SmartAxis</strong> system.<br />

1. To install the software, place the CD-ROM in the CD drive on your PC. If<br />

AutoPlay is enabled on your CD drive, the CD-ROM autostarts and displays the<br />

screen shown in Figure 2-7. If AutoPlay is not enabled, you will need to start the<br />

CD manually. You can double-click on the autorun.exe file, or go to:<br />

Start => Run => [CDROM}:\autorun.exe<br />

Figure 2-7. ADT Main Menu<br />

2. Select Read Important Information to open the text file with recent details that<br />

could affect the installation.<br />

3. Select Install <strong>Adept</strong> DeskTop to start the installation process. This will install the<br />

<strong>Adept</strong> DeskTop and the SA_SPEC programs. You will need the serial number<br />

from the label on your ADT CD-ROM package to complete the installation.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 23

Chapter 2 - Installation<br />

4. Follow the instructions on-screen during the installation process. For more details<br />

on installing the software, refer to the <strong>Adept</strong> DeskTop Online Help and the<br />

SA_SPEC Utility Online Help.<br />

5. After the software is installed, go to Chapter 3 to learn more about operating the<br />

<strong>SmartAxis</strong> system.<br />

NOTE: If you need to reconfigure anything in your system, refer to<br />

Appendix A.<br />

24 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

System Operation 3<br />

3.1 Introduction<br />

This chapter provides an overview of system operation. Before proceeding with<br />

developing the application it is important to verify that the system is operating correctly.<br />

3.2 Programming and Operating the System<br />

<strong>Adept</strong> DeskTop is used as an interface to operate the system and to develop MicroV+<br />

programs. <strong>Adept</strong> DeskTop provides a suite of tools to communicate with, program, and<br />

control the <strong>SmartAxis</strong> system.<br />

Starting <strong>Adept</strong> DeskTop<br />

1. To start <strong>Adept</strong> DeskTop from the Windows task bar, select:<br />

Start => Programs => <strong>Adept</strong> => <strong>Adept</strong> DeskTop<br />

The <strong>Adept</strong> DeskTop program initializes and displays the Startup Sequence<br />

window.<br />

2. Select Default MicroV + desktop and connect and click OK.<br />

The default MicroV + desktop opens and establishes communication with the<br />

SmartAmp.<br />

3. See the <strong>Adept</strong> DeskTop Online Help for complete information on using ADT.<br />

Verifying System Operation<br />

After establishing communication with the <strong>SmartAxis</strong> system, verify system operation by<br />

entering the following commands.<br />

1. From the <strong>Adept</strong> DeskTop menu bar, select:<br />

Tools => Monitor Terminal Emulator<br />

This opens the green Monitor window.<br />

2. Set the speed to a slow motion, at the dot prompt enter:<br />

SPEED 10<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 25

Chapter 3 - System Operation<br />

CAUTION: Make sure the motion is unobstructed and be<br />

ready to press the ESTOP if necessary.<br />

3. Press the High Power button on the <strong>Adept</strong> Front Panel. If you are using a<br />

user-supplied enabling device, instead of the Front Panel, enable high power at<br />

this time.<br />

4. Turn on High Power to the SmartAmp by entering:<br />

enable power<br />

The green LED on the SmartAmp will start blinking quickly.<br />

5. Perform the initial runtime calibration, enter:<br />

calibrate<br />

On modules equipped with brakes, a click during calibration indicates the brakes<br />

releasing. After calibration is complete, the system returns to dot prompt. You are<br />

now ready to operate and program the system.<br />

NOTE: You can also enable power and calibrate the module from the<br />

Robot Control Panel in <strong>Adept</strong> DeskTop by clicking the POWER and<br />

CALIB buttons.<br />

6. Move the <strong>SmartAxis</strong> system to an absolute position. For example, to move to a<br />

position 25 mm from the zero position, enter:<br />

DO @0 JMOVE 25<br />

7. The <strong>SmartAxis</strong> system will move to the position requested. This confirms that the<br />

system is communicating and working properly.<br />

Programming the System<br />

NOTE: MicroV + is a subset of the V + programming language. Not all V +<br />

commands are available in MicroV + , and several new commands have<br />

been added. Refer to the MicroV+ Online Help for details.<br />

<strong>Adept</strong> DeskTop provides a program editor to create and edit MicroV + programs for the<br />

<strong>Adept</strong> <strong>SmartAxis</strong> system. To access the program editor, select:<br />

Tools => Editor/Debugger<br />

The Program Editor window displays. The Program Editor contains an array of tools<br />

(represented by icons) for creating new programs, opening saved programs, copying and<br />

pasting lines of code, inserting common program commands, etc. See the <strong>Adept</strong> DeskTop<br />

Online Help for details.<br />

The MicroV + operating system can also be accessed using a terminal emulator such as<br />

Windows HyperTerminal. The line editor can also be used to create MicroV + programs.<br />

See Editing Programs Using a Terminal Emulator in the MicroV + online help for details.<br />

26 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Autostarting the System<br />

Using the MicroV + Examples<br />

<strong>Inc</strong>luded in the online help are Example MicroV+ Programs available for use with the<br />

<strong>SmartAxis</strong> system. These example programs illustrate the following:<br />

•autostart<br />

• basic motion and signal usage<br />

• autostart with error recovery<br />

• command request and execution<br />

• supervisor and worker programs<br />

In addition, a comprehensive sample application is included on the software CD in a<br />

directory named MicroV + Example. Before loading the sample application, be sure to read<br />

the README-APP.TXT file also located in that directory.<br />

3.3 Autostarting the System<br />

In addition to manually loading and running programs on the <strong>SmartAxis</strong> system, the<br />

system can also be set to automatically load and execute programs upon power up. This<br />

feature enables the system to be operated without having a PC connected.<br />

To autostart the system, the following must take place:<br />

1. The autostart system switch must be enabled by the monitor command ENABLE<br />

AUTOSTART or by the program instruction SWITCH AUTOSTART = -1.<br />

2. A program named AUTO must reside on NVRAM. (Other MicroV + programs can<br />

be stored on NVRAM.)<br />

When the <strong>SmartAxis</strong> system is powered up, the operating system loads and the following<br />

commands are issued automatically:<br />

LOAD (loads all programs in NVRAM to RAM)<br />

EXECUTE 3 AUTO (executes the program named auto in task 3.<br />

Note that this is not a monitor command program).<br />

The auto program can execute other programs on tasks 0, 1, and 2.<br />

The MicroV+ Online Help includes an example of how to create an autostart program.<br />

NOTE: You can interrupt the autostart process by typing Control-C during<br />

the first ten seconds after powering up the system. This feature is<br />

available in MicroV + version 1.2a1 and later only.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 27

Chapter 3 - System Operation<br />

3.4 SmartAmp Operation<br />

Indicator LED<br />

The Indicator LED on the SmartAmp is a green/red bicolor LED that indicates specific<br />

conditions depending on its status.<br />

Table 3-1. SmartAmp Indicator LED Conditions<br />

LED Status<br />

LED Off<br />

LED green, blinking slow<br />

LED green, blinking fast<br />

LED blinking alternately green and red<br />

LED red, blinking fast<br />

LED green or red, not blinking<br />

Condition<br />

24VDC not present<br />

24VDC present, High Power disabled<br />

24VDC present, High Power enabled<br />

To identify an axis during configuration<br />

SmartAmp Fault, 24VDC present<br />

SmartAmp logic failure<br />

Brake Release Button<br />

The brake release button is the recessed push-button located below the Indicator LED.<br />

• the brake release circuit requires 24 VDC at the SmartAmp to function.<br />

• pressing the brake release button releases the brakes on any module equipped<br />

with brakes, typically a module mounted in a vertical orientation.<br />

• pressing the brake release button while the system is running causes a software<br />

E-Stop, disables high power, and brings the mechanisms to an uncontrolled stop.<br />

• pressing brake release disables high power, but does not disable PDU2 AC to<br />

SmartAmps. Both ES1 and ES2 LEDs on the PDU2 remain on, if they were already<br />

on.<br />

28 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Remote I/O Device (RIO) 4<br />

4.1 Product Description<br />

The Remote Input/Output Device (RIO) provides 12 input and 8 output signals near the<br />

SmartAmp. The RIO also provides RS-232 communications for the <strong>SmartAxis</strong>. A RIO can<br />

be connected to each SmartAmp in the system. See Section 6.3 on page 45 for RIO<br />

specifications and additional technical details.<br />

Remote IO Components<br />

The RIO is made up of the following components:<br />

Connectors<br />

• Remote IO device<br />

• SPI Interface printed circuit board (provides interface to SmartAmp)<br />

• Cable to connect RIO to SPI<br />

The RIO has four connectors:<br />

• RS-232: communications port for <strong>SmartAxis</strong> product (not used with<br />

SmartModules)<br />

• I/O Group A: connection for 6 input signals, 4 output signals and external 24VDC<br />

• I/O Group B: connection for 6 input signals, 4 output signals and external 24VDC<br />

• SmartAmp Int: connection for interface to <strong>Adept</strong> SmartAmp<br />

Default Configuration<br />

The RIO is installed on the <strong>SmartAxis</strong> at the factory. The factory default configuration is:<br />

• Local 24VDC for RIO and Outputs (Switch 1 on RIO) from the PDU2<br />

• Local 24VDC for Inputs<br />

• NPN polarity for input signals<br />

If this is the desired configuration for your application, you do not have to change the<br />

internal jumper settings inside the RIO. If the above settings need to be changed, the RIO<br />

cover must be removed. See “Removing the Outer Cover” on page 30.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 29

Chapter 4 - Remote I/O Device (RIO)<br />

4.2 DC Power for RIO<br />

The RIO requires a 24 VDC power source. The power source is selected by switch SW1<br />

inside the RIO. SW1 also selects the power source for the output signals. See Figure 4-2 on<br />

page 32. When SW1 is set to Local, the 24 VDC is supplied by the PDU (default setting).<br />

When SW1 is set to External, then the user must supply 24 VDC to operate the RIO. The<br />

external 24VDC is supplied via the I/O Group A and I/O Group B connectors (see Figure<br />

4-5 on page 34).<br />

4.3 RIO Input Signal Configuration<br />

The RIO has internal jumpers that configure input signals to work with NPN or PNP<br />

devices. Internal jumpers also allow for local or external 24VDC and ground for the<br />

inputs.<br />

While each signal can be configured as NPN (default) or PNP independently, the 12 input<br />

signals are grouped in three blocks of 4 signals as shown below<br />

• Block 1: inputs 1001, 1002, 1003 and 1004<br />

• Block 2: input 1005, 1006, 1007 and 1008<br />

• Block 3: input 1009, 1010, 1011 and 1012<br />

The 24VDC source and ground can be configured independently for each of the three<br />

blocks. Jumpers J3, J4, and J5 are used to select the 24VDC source. Jumpers J18, J19, and<br />

J20 are used to select the ground. See Figure 4-2 on page 32.<br />

Removing the Outer Cover<br />

To gain access to the jumpers, the outer cover must be removed.<br />

1. Remove the RIO from the module by loosening the four screws that attach it to<br />

the module and disconnect the cable from the RIO to the SmartAmp.<br />

2. Remove four corner screws from the I/O Group A endcap. See Figure 4-1 on page<br />

31.<br />

3. Remove two hex screws from the opposite endcap.<br />

4. Pull the internal assembly out as shown.<br />

5. Turn the assembly over to see the jumper switches. See Figure 4-2 on page 32.<br />

CAUTION: You must observe precautions for ESD when<br />

handling the RIO internal assembly. Use a grounding<br />

wrist strap or other measures to protect against exposure<br />

to ESD.<br />

30 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

RIO Input Signal Configuration<br />

Hex screws from<br />

D-Sub connector<br />

Figure 4-1. Removing the Cover<br />

Jumper Locations<br />

To set jumpers, refer to the following places for information:<br />

•see Figure 4-2 on page 32 for the layout of the jumpers<br />

•see Table 4-1 on page 32 for the listing of input signal and jumper numbers<br />

•see Table 6-11 on page 46 and Table 6-12 on page 47 for the complete pinout of the<br />

signals on the Group A and Group B connectors.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 31

Chapter 4 - Remote I/O Device (RIO)<br />

LOCAL<br />

SW1<br />

EXTERNAL<br />

NPN<br />

+24V<br />

PNP<br />

SOURCE<br />

SELECT<br />

J18<br />

J15<br />

J12<br />

J9<br />

J6<br />

J3<br />

LOCAL<br />

EXT<br />

GND SELECT<br />

J19<br />

J20<br />

J16<br />

J17<br />

J13<br />

J10<br />

J11<br />

J7<br />

J8<br />

J4<br />

J5<br />

PWR SELECT LOCAL<br />

EXT<br />

POLARITY SELECT<br />

LOCAL<br />

SW1<br />

EXTERNAL<br />

Ground Select<br />

Jumpers<br />

Input Polarity Select Jumpers<br />

PNP<br />

NPN<br />

Power Select<br />

Jumpers<br />

J18<br />

J15<br />

J12<br />

J9<br />

J6<br />

J3<br />

LOCAL<br />

EXT<br />

GND SELECT<br />

J19<br />

J20<br />

J16<br />

J17<br />

J13<br />

J10<br />

J11<br />

J7<br />

J8<br />

J4<br />

J5<br />

PWR SELECT LOCAL<br />

EXT<br />

POLARITY SELECT<br />

Figure 4-2. Input Signal Jumpers<br />

Table 4-1. Input Signal and Jumper Number<br />

Input Signal Name Jumper Number Input Signal Name Jumper Number<br />

1001 J6 1007 J13<br />

1002 J9 1008 J16<br />

1003 J12 1009 J8<br />

1004 J15 1010 J11<br />

1005 J7 1011 J14<br />

1006 J10 1012 J17<br />

32 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

RIO Input Signal Configuration<br />

Sensor Type Selection<br />

Each input signal can be configured as either NPN or PNP by setting a jumper to the<br />

appropriate position. Figure 4-3 illustrates connecting an NPN device to input signal 1001<br />

with local 24V. This is the default setting.<br />

Local 24V<br />

(Via PDU)<br />

Remote I/O<br />

Device<br />

User Circuits<br />

To Processor<br />

I<br />

NPN<br />

PNP<br />

To Processor<br />

J1- pin 21<br />

Input 1001<br />

I<br />

J1- pin 35<br />

NPN<br />

Collector<br />

NPN<br />

Emitter<br />

Local Ground<br />

NPN Connection<br />

Figure 4-3. Connecting NPN device to Signal 1001 with Local 24V<br />

Figure 4-4 illustrates connecting a PNP device to input signal 1005 with external 24V.<br />

Remote I/O<br />

Device<br />

User Circuits<br />

Local 24V<br />

(Via PDU)<br />

External<br />

24V<br />

J1-pin 12<br />

NPN<br />

PNP<br />

I<br />

To<br />

Processor<br />

To Processor<br />

I<br />

I<br />

J1-pin 9<br />

PNP<br />

Emitter<br />

J1-pin 25<br />

Input 1005<br />

PNP<br />

Collector<br />

Local Ground<br />

PNP Connection<br />

J1-pin 41<br />

External Ground<br />

Figure 4-4. Connecting NPN device to Signal 1005 with External 24V<br />

For the complete pinout locations see Table 6-11 and Table 6-12 on page 47.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 33

Chapter 4 - Remote I/O Device (RIO)<br />

4.4 RIO Output Signals<br />

SW1 - Local or External Power Source for Output Signals<br />

The RIO can be configured to operate on the local 24 VDC supplied by the PDU2, or on an<br />

external 24VDC source supplied by the user. Switch SW1 inside the RIO selects the local<br />

or external 24 VDC, the default setting is for local 24 VDC. The local 24VDC power source<br />

is capable of delivering a maximum 2.0 amps total for all outputs.<br />

Providing External Power For RIO Output Drivers<br />

While the local 24V power source is capable of driving up to 2A total on the 8 output<br />

signals, each single output driver is capable of 500 mA. To achieve 500 mA on each output<br />

signal, external 24VDC must be provided as illustrated in Figure 4-5. Each pin shown in<br />

Figure 4-5 is capable of delivering 1.0A. SW1 is set to the External 24V/Gnd position. See<br />

Figure 4-6 on page 35 for an example out signal circuit.<br />

See Figure 4-1 on page 31 and Figure 4-2 on page 32 for details on removing the cover and<br />

accessing SW1. See Table 6-11 on page 46 and Table 6-12 on page 47 for complete<br />

connector pinout details.<br />

RIO<br />

J1-12<br />

J1-13<br />

J1-14<br />

J1-15<br />

J1-41<br />

J1-42<br />

J1-43<br />

J1-44<br />

User-Supplied<br />

External +24VDC<br />

User-Supplied<br />

External Ground<br />

+24VDC<br />

Ground<br />

J21-12<br />

J21-13<br />

J21-14<br />

J21-15<br />

J21-41<br />

J21-42<br />

J21-43<br />

J21-44<br />

User-Supplied<br />

External +24VDC<br />

User-Supplied<br />

External Ground<br />

J21 = Group A I/O connector<br />

J1 = Group B I/O connector<br />

Figure 4-5. External Power and Ground Pins<br />

34 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

RS-232 Connector<br />

Remote I/O<br />

Device<br />

User Circuits<br />

+24VDV<br />

Output 1<br />

Control<br />

J1-pin 1<br />

Ground<br />

J1-pin 16<br />

Figure 4-6. Example Output Signal Circuit (1 of 8 Outputs)<br />

For the complete pinout locations see Table 6-11 and Table 6-12 on page 47.<br />

4.5 RS-232 Connector<br />

NOTE: The RS-232 communication is functional only with <strong>Adept</strong><br />

<strong>SmartAxis</strong> Modules. It is not functional with <strong>Adept</strong> SmartModules.<br />

Table 4-2. RIO RS-232 Pin Assignments<br />

Pin<br />

Signal Name<br />

1 NC<br />

2 TX<br />

3 RX<br />

4 NC<br />

5 Ground<br />

6 NC<br />

7 RTS<br />

8 CTS<br />

9 NC<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 35

Chapter 4 - Remote I/O Device (RIO)<br />

4.6 RIO LED Functions and Troubleshooting<br />

COMM<br />

(green)<br />

FAULT<br />

(red)<br />

FAULT<br />

When power is applied to the <strong>Adept</strong> <strong>SmartAxis</strong> system, the FAULT LED (red) blinks for a<br />

few seconds. After communication is established with the SmartAmp, the FAULT LED<br />

turns off and the COMM LED (green) starts blinking. See Table 4-3 for other conditions.<br />

Table 4-3. RIO LED Functions<br />

LED State Description<br />

COMM and<br />

FAULT<br />

Blinking after power up and communication<br />

with SmartAmp established<br />

Blinking for a few seconds before<br />

communication with SmartAmp established<br />

(occurs upon power up)<br />

Blinking after attempting to establish<br />

communication with SmartAmp<br />

Both LEDs off<br />

Normal<br />

Normal<br />

Problem with communication<br />

to SmartAmp. Check the cable<br />

and connections between RIO<br />

and SmartAmp.<br />

RIO not receiving 24VDC from<br />

SmartAmp. Verify SW1 is set to<br />

Local, unless user is supplying<br />

External 24VDC.<br />

36 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Maintenance 5<br />

5.1 Maintenance<br />

To prevent accidents, observe the following precautions when inspecting or maintaining<br />

the unit.<br />

WARNING: Turn off the power to the PDU2/SmartAmp<br />

when personnel or tools are in the vicinity of the robot<br />

work area.<br />

WARNING: Do not disassemble or modify the unit except<br />

as instructed in this manual.<br />

WARNING: The V-Series modules are not sealed. Prevent<br />

foreign objects and liquids from entering the module body<br />

because these materials may damage the module.<br />

NOTE: <strong>SmartAxis</strong> modules are self-lubricating and do not require<br />

lubrication.<br />

Parts Not Requiring Any Maintenance<br />

The linear bearings and ball screw have lifetime lubrication and do not require periodic<br />

maintenance.<br />

Daily Maintenance<br />

Perform daily checks as shown in Table 5-1.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 37

Chapter 5 - Maintenance<br />

Table 5-1. Daily Maintenance Checks<br />

Check Points<br />

SmartAmp heatsink<br />

Base fixing bolts (bolts used to attach<br />

mounting plates to work surface)<br />

Work fixing bolts (bolts used to attach<br />

equipment to module sliders)<br />

Procedures and Specifications<br />

Check to see that it is free of dust and debris<br />

Check for looseness; tighten as necessary.<br />

See Table 2-2 on page 15 and Table 2-3 on page 15 for<br />

tightening torque.<br />

NOTE: No brush replacement is required because AC servo motors are<br />

used in this product.<br />

5.2 Other Periodic Maintenance<br />

Table 5-2 gives a summary of other preventive maintenance procedures and guidelines on<br />

frequency.<br />

Table 5-2. Inspection and Maintenance<br />

Item Period Reference<br />

Ball screw and linear guide 3 months Visually inspect and look for unusual<br />

wear.<br />

Cable connections 1 month Visually inspect to ensure that all<br />

connections are secure.<br />

SmartAmp 1 month Visually inspect to ensure that this<br />

component is securely mounted.<br />

Seal belts on R-series modules 1 month Visually inspect for unusual wear<br />

and/or debris near these components.<br />

NOTE: The frequency of these procedures depends on the particular<br />

system, its operating environment, and amount of usage. Use the times in<br />

Table 5-1 and Table 5-2 as guidelines and modify the schedule as needed.<br />

In general, look for any unusual wear on components.<br />

38 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

Technical Reference 6<br />

6.1 Module Performance Specifications<br />

Table 6-1. Specifications for Standard R-Series Modules<br />

R-H<br />

(Horizontal)<br />

R-Hz<br />

(Vertical)<br />

R-M<br />

(Horizontal)<br />

R-Mz<br />

(Vertical)<br />

R-Sz<br />

(Vertical)<br />

Stroke (mm) 300, 400, 500,<br />

600, 800,<br />

1000 a<br />

250, 350, 450,<br />

300, 600 250, 350, 450,<br />

950 a<br />

550, 750, 550<br />

100, 200, 300,<br />

400, 500<br />

Maximum speed (mm/s) 1200 600 1200 600 600<br />

Transportable load (kg) 80 40 40 40 20<br />

Rated thrust force (N) 400 800 400 800 400<br />

Repeatability (mm) ±0.010 ±0.010 ±0.010 ±0.010 ±0.010<br />

Transportable moment Rolling (N ² m)<br />

Pitching (N ² m)<br />

Yawing (N ² m)<br />

(See Section 6.5 on page 56)<br />

600 600 70 70 32<br />

450 450 120 120 24<br />

400 400 120 120 24<br />

Motor output (W) 400 400 (w/brake) 400 400 (w/brake) 200 (w/brake)<br />

Ball screw lead (mm) 20 10 20 10 10<br />

Motor mount position<br />

Direct<br />

mount<br />

Direct<br />

mount<br />

Direct<br />

mount<br />

Direct<br />

mount<br />

Left side<br />

Operating temperature<br />

0-40ºC<br />

Operating humidity<br />

20-85% (Non condensing)<br />

a R-H and R-M modules are available in extended strokes up to 2000mm and 1550mm respectively.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 39

Chapter 6 - Technical Reference<br />

Table 6-2. Specifications for Extended R-Series Modules<br />

R-H<br />

(Horizontal)<br />

R-M<br />

(Horizontal)<br />

Stroke (mm) 1200, 1400, 2000 1150, 1350, 1550<br />

Maximum speed<br />

R-H 1200 = 1200 mm/sec<br />

R-H 1400 = 1080 mm/sec<br />

R-H 2000 = 560 mm/sec<br />

R-M 1150 = 1200 mm/sec<br />

R-M 1350 = 1080 mm/sec<br />

R-M 1550 = 840 mm/sec<br />

Transportable load (kg) 80 40<br />

Rated thrust force (N) 400 400<br />

Repeatability (mm) ±0.010 ±0.010<br />

Transportable moment Rolling (N ² m)<br />

Pitching (N ² m)<br />

Yawing (N ² m)<br />

(See Section 6.5 on page 56)<br />

600 70<br />

450 120<br />

400 120<br />

Motor output (W) 400 400<br />

Ball screw lead (mm) 20 20<br />

Motor mount position Left side mount Left side mount<br />

Operating temperature<br />

Operating humidity<br />

0-40ºC<br />

20-85% (Non condensing)<br />

40 <strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C

<strong>Adept</strong> SmartAmp Specifications<br />

6.2 <strong>Adept</strong> SmartAmp Specifications<br />

Input Power Requirements<br />

Table 6-3. <strong>Adept</strong> SmartAmp Specifications<br />

AC input voltage<br />

AC input frequency<br />

Max AC input current<br />

nominal 100-240 VAC, single phase<br />

maximum range 85-264 VAC<br />

nominal 50-60 Hz, 47-63 Hz maximum<br />

6 Amps<br />

DC input voltage 24 V, +20%, -15%<br />

Inverter Output<br />

Bus Voltage<br />

Switching Frequency<br />

Sinewave Commutation (max frequency)<br />

Max Output Current (per phase)<br />

Max Output Power (continuous) a<br />

Max Output Power (momentary peak) a<br />

435 VDC<br />

8 kHz<br />

400 Hz<br />

10 A (rms), 15 A (peak)<br />

400 W<br />

1200 W<br />

Communication<br />

Servo network communication standard<br />

Maximum data communication rate<br />

IEEE 1394a<br />

400Mb/s<br />

Environmental<br />

Ambient temperature<br />

Humidity<br />

Altitude<br />

Maximum case temperature<br />

Dimensions<br />

Weight<br />

5°C to 40°C (41 to 104°F)<br />

5 to 90%, noncondensing<br />

less then 2000 m (6500 ft.)<br />

85° C<br />

50mm X 120mm X 150mm<br />

1.5 kg<br />

a Peak and continuous power figures are rated at 208 VAC input voltage. These figures vary<br />

with input voltage and must be de-rated accordingly.<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 41

<strong>Adept</strong> SmartAmp Specifications<br />

SmartAmp Connector Specifications<br />

Table 6-4. Motor Connector<br />

Pin # Description Pin Location<br />

1 PHASE U<br />

2 PHASE V<br />

2<br />

1<br />

3 PHASE W<br />

4 FGND<br />

4 3<br />

Motor Connector<br />

as viewed on SmartAmp<br />

Mating Connector:<br />

AMP/Tyco #172167-1, 4-pin Mini-Universal Mate-N-Lock<br />

AMP/Tyco #170362-2, Socket Contact, Mini-Univ. Mate-N-Lock<br />

Table 6-5. Encoder Connector<br />

Pin # Description Pin # Description Pin Location<br />

1 PHASE A+ 9 N/C<br />

2 PHASE A- 10 PHASE Z2+<br />

3 PHASE B+ 11 PHASE Z2-<br />

4 PHASE B- 12 PHASE B1+<br />

5 PHASE Z+ 13 RESET<br />

6 PHASE Z- 14 PHASE B1-<br />

7 GND 15 +3.6 V BAT<br />

8 +5V<br />

11 15<br />

6<br />

10<br />

1<br />

5<br />

Encoder Connector<br />

as viewed on SmartAmp<br />

Mating Connector:<br />

AMP/Tyco #748468-1, 15-pin HDP-22 Plug Kit<br />

AMP/Tyco #748333-2, Pin Contact, Size 22DF, 22-28 AWG<br />

AMP/Tyco #747579-8, Ferrule, Sizes 1-3<br />

Table 6-6. Brake Connector<br />

Pin # Description Pin Location<br />

1 Brake_24V<br />

2 Brake_GND<br />

1<br />

2<br />

Brake Connector<br />

as viewed on SmartAmp<br />

Mating Connector:<br />

AMP/Tyco #172165-1, 2-pin Mini-Universal Mate-N-Lock<br />

AMP/Tyco #170362-2, Socket Contact, Mini-Univ. Mate-N-Lock<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 42

<strong>Adept</strong> SmartAmp Specifications<br />

Table 6-7. +24V Connector (2 per SmartAmp)<br />

Pin # Description Pin Location<br />

1 AUTO2<br />

2 AUTO1<br />

3 GND<br />

4 +24 VDC<br />

Note: the two +24V connectors on the<br />

SmartAmp are interchangeable.<br />

1<br />

2<br />

3<br />

4<br />

Mating Connector:<br />

AMP/Tyco #104257-3, 4-pin AMPMODU Receptacle Housing<br />

AMP/Tyco #104480-9, Contact Pin, AMPMODU, 22-26 AWG<br />

+24V Connector<br />

as viewed on SmartAmp<br />

Table 6-8. AC Connector (2 per SmartAmp)<br />

Pin # Description Pin Location<br />

1 Hot (L1)<br />

2 Neutral (L2)<br />

1 2<br />

Note: the two AC connectors on the<br />

SmartAmp are interchangeable.<br />

AC Connector<br />

as viewed on SmartAmp<br />

Mating Connector:<br />

MOLEX #39-01-2025, 2-pin Mini-Fit Junior Receptacle Assembly<br />

MOLEX #39-00-0039, Contact Terminal, Mini-Fit Family<br />

Table 6-9. IEEE 1394 Connector (2 per SmartAmp)<br />

Pin #<br />

Description<br />

1 VP<br />

2 VG<br />

3 TPB-<br />

4 TPB+<br />

5 TPA-<br />

6 TPA+<br />

7 Shield (FGND)<br />

8 Shield (FGND)<br />

Note: the two IEEE 1394 connectors on the SmartAmp are<br />

interchangeable.<br />

Mating Connector:<br />

Use approved IEEE 1394 Cable<br />

<strong>Adept</strong> <strong>SmartAxis</strong> User’s <strong>Guide</strong>, Rev. C 43

Chapter 6 - Technical Reference<br />

SmartAmp Connectors<br />

Brake<br />

Connector<br />