Hangers - USP Connectors

Hangers - USP Connectors Hangers - USP Connectors

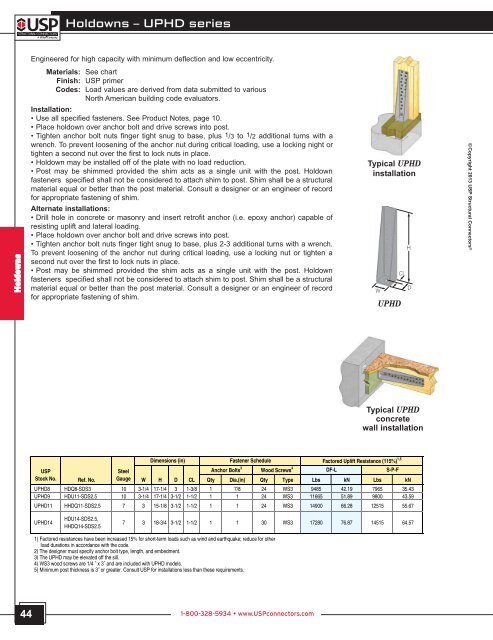

Holdowns – UPHD series Engineered for high capacity with minimum deflection and low eccentricity. Holdowns Materials: See chart Finish: USP primer Codes: Load values are derived from data submitted to various North American building code evaluators. Installation: • Use all specified fasteners. See Product Notes, page 10. • Place holdown over anchor bolt and drive screws into post. • Tighten anchor bolt nuts finger tight snug to base, plus 1/3 to 1/2 additional turns with a wrench. To prevent loosening of the anchor nut during critical loading, use a locking night or tighten a second nut over the first to lock nuts in place. • Holdown may be installed off of the plate with no load reduction. • Post may be shimmed provided the shim acts as a single unit with the post. Holdown fasteners specified shall not be considered to attach shim to post. Shim shall be a structural material equal or better than the post material. Consult a designer or an engineer of record for appropriate fastening of shim. Alternate installations: • Drill hole in concrete or masonry and insert retrofit anchor (i.e. epoxy anchor) capable of resisting uplift and lateral loading. • Place holdown over anchor bolt and drive screws into post. • Tighten anchor bolt nuts finger tight snug to base, plus 2-3 additional turns with a wrench. To prevent loosening of the anchor nut during critical loading, use a locking nut or tighten a second nut over the first to lock nuts in place. • Post may be shimmed provided the shim acts as a single unit with the post. Holdown fasteners specified shall not be considered to attach shim to post. Shim shall be a structural material equal or better than the post material. Consult a designer or an engineer of record for appropriate fastening of shim. Typical UPHD installation W UPHD CL H D © Copyright 2013 USP Structural Connectors ® Typical UPHD concrete wall installation USP Stock No. Dimensions (in) Fastener Schedule Factored Uplift Resistance (115%) 1,5 Steel Anchor Bolts 3 Wood Screws 4 DF-L S-P-F Ref. No. Gauge W H D CL Qty Dia.(in) Qty Type Lbs kN Lbs kN UPHD8 HDQ8-SDS3 10 3-1/4 17-1/4 3 1-3/8 1 7/8 24 WS3 9485 42.19 7965 35.43 UPHD9 HDU11-SDS2.5 10 3-1/4 17-1/4 3-1/2 1-1/2 1 1 24 WS3 11665 51.89 9800 43.59 UPHD11 HHDQ11-SDS2.5 7 3 15-1/8 3-1/2 1-1/2 1 1 24 WS3 14900 66.28 12515 55.67 UPHD14 HDU14-SDS2.5, HHDQ14-SDS2.5 7 3 18-3/4 3-1/2 1-1/2 1 1 30 WS3 17280 76.87 14515 64.57 1) Factored resistances have been increased 15% for short-term loads such as wind and earthquake; reduce for other load durations in accordance with the code. 2) The designer must specify anchor bolt type, length, and embedment. 3) The UPHD may be elevated off the sill. 44 1-800-328-5934 • www.USPconnectors.com

Tension Ties – HTT, LTS series & LTTI31 HTT series – Secures multi-ply studs or posts to mudsills or foundation. Nail fastening makes for a convenient connection to studs or posts in cramped retrofit installations. LTS series – The LTS19 is designed for nail-on installation to 2x joists or studs, and the LTS20B provides a nail or bolt fastening option. The LTS20B will accommodate wood I-Joists if 10d x 1 1 ⁄ 2˝ nails are used instead of the specified 16d nails. LTTI31 – An open web joist tension tie designed for use with masonry or concrete construction. © Copyright 2013 USP Structural Connectors ® Materials: See chart Finish: G90 galvanizing Codes: Load values are derived from data submitted to various North American building code evaluators. Installation: • Use all specified fasteners. See Product Notes, page 10. • Use all specified fasteners to attach the strap portion of the connector to the side of stud, post, joist, purlin, or beam. Secure the base to the concrete or masonry wall with specified anchor bolt. A design professional shall specify the type, length, and embedment of the anchor bolt. No washers required. • HTT45 Min – Fill all round holes. • HTT45 Max – Fill all round and diamond holes. • LTTI31 & LTS connectors must be mounted flush to the surface of the mudsill. • Factored resistances are based on either nail or bolt fastening; nail and bolt values cannot be combined. • Washers are not required on transfer plates that fit over the anchor bolt. • Tighten anchor bolt nuts finger tight snug to base plus, 1/3 to 1/2 additional turns with a wrench. To prevent loosening of the anchor nut during critical loading, use a locking nut or tighten a second nut over the first to lock nuts in place. • Field bending is not required provided minimum fastener edge distance of 3/8" is maintained. W L W L NEW W 3 3/4˝ 6 1/4˝ L CL Typical LTTI31 installation W D 3/8˝ Typ. 6˝ LTTI31 W L 11/16˝ 2 3 /8˝ 6 3 /16˝ Holdowns 1 3/4˝ Typical LTS CL HTT16 (HTT22 similar) D CL D HTT4 (HTT5 similar) Typical HTT4 installation HTT45 Typical HTT45 installation 1/4˝ transfer plate CL D LTS20B 2 1 /2˝ L Steel Gauge Dimensions (in) Fastener Schedule Strap 2,5 Nail Anchor DF-L S-P-F USP Spacing Bolt 3 Stock No. Ref. No. Strap Plate W L D CL (in) Qty Dia. (in) Qty Type Lbs kN Lbs kN 10d 5700 25.35 4905 21.82 HTT45 (Min) 18 HTT4, 16d x 2-1/2 6710 29.85 5780 25.71 10 -- -- 2-1/2 16 2 1-3/8 1-3/4 1 5/8 HTT5 10d 7515 33.43 6465 28.76 HTT45 (Max) 26 16d x 2-1/2 8505 37.83 7315 32.54 10d x 1-1/2 4695 20.89 4025 17.91 HTT4 HTT4 12 -- -- 3 10-7/16 2-3/4 1-3/8 1-3/4 1 5/8 20 10d 5690 25.33 4880 21.71 16d x 2-1/2 6025 26.81 5165 22.98 10d x 1-1/2 5625 25.02 4820 21.45 HTT5 HTT5 12 -- -- 3 13-15/16 2-3/4 1-3/8 1-3/4 1 5/8 28 10d 7980 35.50 6840 30.43 16d x 2-1/2 7390 32.88 6335 28.18 HTT16 -- -- 10 -- -- 2-1/2 15-5/8 2 1-3/8 1-3/4 1 5/8 18 10d 5355 23.82 3800 16.90 HTT22 -- -- 10 -- -- 2-1/2 21-1/2 2 1-3/8 1-3/4 1 5/8 32 10d 5180 23.04 3680 16.37 LTTI31 4 LTTI31 18 3 3-3/4 31 2-5/8 1-3/8 3 1 5/8 18 10d x 1-1/2 2905 12.92 2440 10.85 LTS19 4 LTT19 16 3 1-3/4 22-1/4 3 1-1/2 2-1/2 1 3/4 8 10d 1245 5.54 1045 4.65 10 10d x 1-1/2 1140 5.07 960 4.27 LTS20B LTT20B 12 3 2 20 3 1-1/2 3-3/4 1 3/4 10 16d 1145 5.09 960 4.27 2 1/2 1215 5.40 1020 4.54 1) Factored resistances have been increased 15% for short-term loads such as wind and earthquake; no further increase allowed. 2) 16d sinkers may be substituted for the specified 10d common nails with no load reduction. 3) The designer must specify anchor bolt type, length and embedment depth. 4) LTTI and LTS holdowns shall be installed tight to the sill plate. 5) NAILS: New products or updated product information are designated in red font. Factored Tensile Resistance (115%) 1 1/4˝ transfer plate LTS19 Hanger not shown 1-800-328-5934 • www.USPconnectors.com 45 USP2240-131 CL D Installation

- Page 1 and 2: Product Catalog 57 th Edition

- Page 3 and 4: The Original Connector Company! HA

- Page 5 and 6: USP Index © Copyright 2013 USP Str

- Page 7 and 8: Corrosion Information © Copyright

- Page 9 and 10: Product Information U.S. Standard S

- Page 11 and 12: Design Notes © Copyright 2013 USP

- Page 13 and 14: Fasteners © Copyright 2013 USP Str

- Page 15 and 16: Nails - N & NA series continued NA1

- Page 17 and 18: Wood Screw Applications - WS series

- Page 19 and 20: Wood Screw Applications - WS series

- Page 21 and 22: Concrete & Masonry © Copyright 201

- Page 23 and 24: ADHESIVE ANCHORING SYSTEMS CIA-GEL

- Page 25 and 26: Undercut Anchoring Systems - DUC Du

- Page 27 and 28: Steel Angle Lintels - SAL series St

- Page 29 and 30: Threaded Rods - THR series USP has

- Page 31 and 32: Anchor Bolts - STB & STBL series Em

- Page 33 and 34: Anchor Bolts - AB & ABP series Anch

- Page 35 and 36: Foundation Anchors - ST series ST1-

- Page 37 and 38: Adjustable Support Posts - JP serie

- Page 39 and 40: Type 2 Top Plates - T2TP Series ©

- Page 41 and 42: Predeflected Holdowns - PHD & PHDA

- Page 43: Holdowns - TD & TDX series continue

- Page 47 and 48: Foundation Straps - LSTAD & STAD Se

- Page 49 and 50: Foundation Straps - HPAHD & PAHD42

- Page 51 and 52: Caps & Bases Post Anchors . . . . .

- Page 53 and 54: Wet Post Anchors - WAS & WE series

- Page 55 and 56: © Copyright 2013 USP Structural Co

- Page 57 and 58: Post Caps - EPCM & PCM series © Co

- Page 59 and 60: Post Beam Corner - PBC series The P

- Page 61 and 62: Column Caps - KCCQ & KECCQ series c

- Page 63 and 64: Column Caps - KCCQ & KECCQ series c

- Page 65 and 66: Angles & Straps Coiled Strapping .

- Page 67 and 68: Multi-Purpose Framing Angles - MP34

- Page 69 and 70: Framing Angles - A3, AC, JA, & MP s

- Page 71 and 72: Stud Plate Ties - RSPT, SPT, & SPTH

- Page 73 and 74: Corner Reinforcements - B & BL seri

- Page 75 and 76: Framing Clips - SFC6 Framing clips

- Page 77 and 78: Strap Ties - HRS, HTP, KST, KSTI, L

- Page 79 and 80: Strap Ties - HRS, HTP, KST, KSTI, L

- Page 81 and 82: Twist Straps - HTW, KTS, LFTA6, LTW

- Page 83 and 84: Permanent Wood Foundation Strap - P

- Page 85 and 86: Masonry Twist Straps - HTWM series

- Page 87 and 88: Hangers Panel & Purlin Hangers . .

- Page 89 and 90: Slant Nail Joist Hangers - HUS, JUS

- Page 91 and 92: Face Mount Hanger Charts © Copyrig

- Page 93 and 94: Face Mount Hanger Charts continued

Holdowns – UPHD series<br />

Engineered for high capacity with minimum deflection and low eccentricity.<br />

Holdowns<br />

Materials: See chart<br />

Finish: <strong>USP</strong> primer<br />

Codes: Load values are derived from data submitted to various<br />

North American building code evaluators.<br />

Installation:<br />

• Use all specified fasteners. See Product Notes, page 10.<br />

• Place holdown over anchor bolt and drive screws into post.<br />

• Tighten anchor bolt nuts finger tight snug to base, plus 1/3 to 1/2 additional turns with a<br />

wrench. To prevent loosening of the anchor nut during critical loading, use a locking night or<br />

tighten a second nut over the first to lock nuts in place.<br />

• Holdown may be installed off of the plate with no load reduction.<br />

• Post may be shimmed provided the shim acts as a single unit with the post. Holdown<br />

fasteners specified shall not be considered to attach shim to post. Shim shall be a structural<br />

material equal or better than the post material. Consult a designer or an engineer of record<br />

for appropriate fastening of shim.<br />

Alternate installations:<br />

• Drill hole in concrete or masonry and insert retrofit anchor (i.e. epoxy anchor) capable of<br />

resisting uplift and lateral loading.<br />

• Place holdown over anchor bolt and drive screws into post.<br />

• Tighten anchor bolt nuts finger tight snug to base, plus 2-3 additional turns with a wrench.<br />

To prevent loosening of the anchor nut during critical loading, use a locking nut or tighten a<br />

second nut over the first to lock nuts in place.<br />

• Post may be shimmed provided the shim acts as a single unit with the post. Holdown<br />

fasteners specified shall not be considered to attach shim to post. Shim shall be a structural<br />

material equal or better than the post material. Consult a designer or an engineer of record<br />

for appropriate fastening of shim.<br />

Typical UPHD<br />

installation<br />

W<br />

UPHD<br />

CL<br />

H<br />

D<br />

© Copyright 2013 <strong>USP</strong> Structural <strong>Connectors</strong> ®<br />

Typical UPHD<br />

concrete<br />

wall installation<br />

<strong>USP</strong><br />

Stock No.<br />

Dimensions (in)<br />

Fastener Schedule<br />

Factored Uplift Resistance (115%) 1,5<br />

Steel<br />

Anchor Bolts 3 Wood Screws 4<br />

DF-L<br />

S-P-F<br />

Ref. No. Gauge W H D CL Qty Dia.(in) Qty Type Lbs kN Lbs kN<br />

UPHD8 HDQ8-SDS3 10 3-1/4 17-1/4 3 1-3/8 1 7/8 24 WS3 9485 42.19 7965 35.43<br />

UPHD9 HDU11-SDS2.5 10 3-1/4 17-1/4 3-1/2 1-1/2 1 1 24 WS3 11665 51.89 9800 43.59<br />

UPHD11 HHDQ11-SDS2.5 7 3 15-1/8 3-1/2 1-1/2 1 1 24 WS3 14900 66.28 12515 55.67<br />

UPHD14<br />

HDU14-SDS2.5,<br />

HHDQ14-SDS2.5<br />

7 3 18-3/4 3-1/2 1-1/2 1 1 30 WS3 17280 76.87 14515 64.57<br />

1) Factored resistances have been increased 15% for short-term loads such as wind and earthquake; reduce for other<br />

load durations in accordance with the code.<br />

2) The designer must specify anchor bolt type, length, and embedment.<br />

3) The UPHD may be elevated off the sill.<br />

<br />

<br />

44<br />

1-800-328-5934 • www.<strong>USP</strong>connectors.com