MeasureIT Scanning Platform Troubleshooting Procedures Manual

MeasureIT Scanning Platform Troubleshooting Procedures Manual

MeasureIT Scanning Platform Troubleshooting Procedures Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Measure IT<br />

<strong>Scanning</strong> <strong>Platform</strong><br />

<strong>Troubleshooting</strong> <strong>Procedures</strong> <strong>Manual</strong>

PROPRIETARY DATA<br />

This document contains proprietary data of ABB Inc.<br />

No disclosure, distribution (electronic or otherwise), reproduction,<br />

or other means of dissemination may be made without written permission.<br />

Produced by QCS Product Development.<br />

Writers: Bill Houston, Pamela Murray<br />

Illustrators: Melinda Hoyle, Todd Theodore<br />

Technical Contributor: Mort Jensen<br />

© 1992, 1994-1999, 2002-2003 by ABB Inc. All rights reserved.<br />

1180 MICRO, 1190, Smart <strong>Platform</strong>, and ACE are trademarks of ABB Inc.<br />

UNIX® is a registered trademark of AT&T.<br />

DESQview is a registered trademark of Quarter Deck Office Systems.<br />

® AccuRay is a registered trademark and service mark of ABB Inc.<br />

March 2003<br />

3BUS 208 055 R1101<br />

(formerly 101761-001)

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Document Version History<br />

Measure IT<br />

<strong>Scanning</strong> <strong>Platform</strong><br />

<strong>Troubleshooting</strong> <strong>Procedures</strong> <strong>Manual</strong><br />

Version<br />

Level<br />

Effective<br />

Date<br />

Sections Changed<br />

by Revision<br />

Sections Added<br />

by Revision<br />

Sections Deleted<br />

by Revision<br />

A April 1992 Original Release<br />

B March 1994 Entire <strong>Manual</strong><br />

C December 1995 Entire <strong>Manual</strong><br />

D April 1996 Profile Development in the<br />

<strong>Scanning</strong> <strong>Platform</strong>, 24<br />

ABB 1190<br />

Measurement Analysis<br />

Using On-Line Utilities,<br />

28-36<br />

Startup Messages, 75-76<br />

AEOS Setup Problems, 94<br />

E October 1996 Entire <strong>Manual</strong><br />

F March 1997 Servo and Scanner Diagnostic<br />

Instance Variables, 87<br />

<strong>Troubleshooting</strong> Flow Charts,<br />

61, 69<br />

G<br />

September<br />

1997<br />

Entire <strong>Manual</strong><br />

H August 1998 Entire <strong>Manual</strong><br />

I August 1999 “Power Down and DC Power<br />

Analysis” on page 149<br />

“Micro-Controller DC Power<br />

Log” on page 152<br />

J January 2002 cover art, header, product<br />

names<br />

K February 2002 Exercising the Reflection IR<br />

Flag, 237<br />

11 March 2003 <strong>Manual</strong> Part Numbers<br />

3BUS 208 055 R1101<br />

Document Version History

Blank Page

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Preface<br />

The Measure IT <strong>Scanning</strong> <strong>Platform</strong> <strong>Troubleshooting</strong> <strong>Procedures</strong> <strong>Manual</strong>, 3BUS 208 055 R1101, is<br />

a reference guide to troubleshooting the SP 1200 and the SP 700. This manual contains information<br />

for the trained diagnostician on the theory of <strong>Scanning</strong> <strong>Platform</strong> operation and advanced<br />

troubleshooting tools.<br />

3BUS 208 055 R1101<br />

Preface<br />

i

Blank Page

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Table of Contents<br />

Preface ........................................................................................... i<br />

List of Figures ............................................................................. xi<br />

1 Selected Theories of Operation.............................................. 1<br />

Positioning System Overview......................................................................2<br />

Head Package Dimensions Setup ...............................................................3<br />

Definition of Head Package Dimensions ..............................................................4<br />

How Head Position is Determined...............................................................5<br />

Motion Theory ...............................................................................................7<br />

Servo Theory of Operation....................................................................................7<br />

ACCELERATION Phase Operation..............................................................9<br />

CRUISING Phase Operation..........................................................................9<br />

DECELERATION Phase Operation ............................................................10<br />

HOMING Phase Operation ..........................................................................11<br />

Motion Control Theory .......................................................................................12<br />

System Response to Some Position Parameters..................................................13<br />

Moving from Off–Sheet to On–Sheet ..........................................................17<br />

Detecting Edges While <strong>Scanning</strong>.................................................................18<br />

Profile Development for 1190 Systems.....................................................19<br />

Time Based Measurement ...................................................................................19<br />

Profile Development in the <strong>Scanning</strong> <strong>Platform</strong>...................................................21<br />

Profile Transmission to the Host Computer ........................................................25<br />

Profile Development in the 1190 Host Computer ...............................................26<br />

1190 Measurement Analysis using On-Line Utilities ...............................27<br />

Introductory Comments.......................................................................................27<br />

ABB Measurement Analysis Using the tbmcu Utility ........................................27<br />

Using tbmcu Utility in Stand-alone.....................................................................31<br />

Converting tbmcu Files for Spreadsheet Analysis ..............................................32<br />

Examining Floating Point TBM Arrays ..............................................................34<br />

1190 Measurement Analysis Using sentest Utility .............................................35<br />

Profile Data ..................................................................................................36<br />

Single Point Drift Data.................................................................................37<br />

Profile Development for 1180 Systems.....................................................38<br />

Profile Transmission and Development ..............................................................38<br />

Profile Development in the <strong>Scanning</strong> <strong>Platform</strong>...................................................39<br />

Accessing 1180 MICRO Profile Data Inside the <strong>Scanning</strong> <strong>Platform</strong>..................42<br />

Displaying the Mini-Access Profile Array...................................................44<br />

Profile Transmission to a Host Computer ...........................................................45<br />

Profile Development within the Host Computer..........................................46<br />

Data Box Collection Calculation..................................................................47<br />

Logical Zone Calculations...................................................................................48<br />

3BUS 208 055 R1101<br />

Table of Contents<br />

iii

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Sensor Theory .............................................................................................49<br />

Sensor Processing Overview ...............................................................................49<br />

Filtering ........................................................................................................49<br />

Normalization...............................................................................................49<br />

Linearization.................................................................................................50<br />

Correction.....................................................................................................50<br />

Conversion ...................................................................................................50<br />

Compensation...............................................................................................50<br />

Fine Tuning ..................................................................................................50<br />

Sensor Input Signal Processing ...........................................................................51<br />

Sensor Output Signal Processing ........................................................................55<br />

2 General <strong>Troubleshooting</strong> Instructions................................. 59<br />

Data Required for Problem Escalation......................................................60<br />

<strong>Troubleshooting</strong> Flow Charts ....................................................................63<br />

Host Computer Coldstart Data File Overview ..........................................76<br />

Startup Messages .......................................................................................77<br />

Changing the Host/SP BAUD Rate and the Station ID.............................85<br />

Radiological Safety Features and Alarms ................................................86<br />

Broken Grid Alarm..............................................................................................86<br />

Inherent Sheet Break (ISB) Alarm ......................................................................86<br />

Head Tracking Error............................................................................................87<br />

Shutter Closed During Prepare to Move .............................................................87<br />

Shutter Closed When Host Computer is Down...................................................87<br />

Invalid Shutter Open Alarm ................................................................................87<br />

3 Position and Motion Problems ............................................. 89<br />

Preliminary <strong>Troubleshooting</strong> Activity .......................................................90<br />

Positioning Events Historical Diagnostic .................................................91<br />

Mechanical Influence on Motion Problems ..............................................94<br />

Comments About the Motor Controller.....................................................95<br />

Diagnosis of <strong>Platform</strong> and Servo Problems .............................................96<br />

Hang Up Problems ..............................................................................................96<br />

vmin Too Small............................................................................................96<br />

Motor Controller Slope Too Small...............................................................97<br />

servo01 Request Complete...........................................................................97<br />

Overcontrol Problems..........................................................................................97<br />

vmin Too Large (or activeVmin) .................................................................97<br />

Motor Controller Slope and Offset Too Large.............................................98<br />

xdb Too Small ..............................................................................................98<br />

Miscellaneous...............................................................................................98<br />

Servo & Scanner Diagnostic Instance Variables .....................................99<br />

servo01 object......................................................................................................99<br />

xdb................................................................................................................99<br />

iv<br />

Table of Contents<br />

3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

vdb................................................................................................................99<br />

avdb ..............................................................................................................99<br />

advdb ............................................................................................................99<br />

vmin/activeVmin..........................................................................................99<br />

vmax...........................................................................................................100<br />

vminFilterFactor.........................................................................................100<br />

ddcExcessiveErrorPercent..........................................................................100<br />

ddcRestrictedMotionPercent ......................................................................100<br />

Accel...........................................................................................................100<br />

Kp...............................................................................................................100<br />

Ki................................................................................................................101<br />

slopep .........................................................................................................101<br />

slopen .........................................................................................................101<br />

biasp ...........................................................................................................101<br />

biasn ...........................................................................................................101<br />

vminTune ...................................................................................................101<br />

sampleInterval ............................................................................................101<br />

xfinal[3]......................................................................................................101<br />

vfinal[3]......................................................................................................101<br />

increment[3] ...............................................................................................101<br />

duration[3]..................................................................................................102<br />

homingError ...............................................................................................102<br />

farEdge .......................................................................................................102<br />

homeEdge...................................................................................................102<br />

scanner01 object ................................................................................................102<br />

maxEdgeChange.........................................................................................102<br />

dbWidth......................................................................................................102<br />

dbAvgTime.................................................................................................102<br />

healthRequest .............................................................................................103<br />

maxSpeed ...................................................................................................103<br />

positioningSafetyMargin............................................................................103<br />

target...........................................................................................................103<br />

autoEOS .....................................................................................................103<br />

farEOSUnknown/homeEOSUnknown.......................................................103<br />

inTransit .....................................................................................................103<br />

scanning......................................................................................................103<br />

sheetBreakPresent ......................................................................................104<br />

stdzPending ................................................................................................104<br />

offSheetTimer.............................................................................................104<br />

onSheetTimer .............................................................................................104<br />

Servo Diagnostic <strong>Troubleshooting</strong> Utility ........................................................104<br />

Selected Servo Diagnostics Definition of Terms: .............................................105<br />

delx.............................................................................................................105<br />

STOP_PAST ..............................................................................................105<br />

CONTINUE HOMING..............................................................................105<br />

FINISHED HOMING ................................................................................105<br />

3BUS 208 055 R1101<br />

Table of Contents<br />

v

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

AEOS Setup Problems..............................................................................107<br />

Frame Tuning and Diagnostic Tool, ft.....................................................110<br />

Enter ft Utility ............................................................................................112<br />

4 ABB Smart Processing Center (ASPC) Hardware............. 113<br />

Host/Workstation Interface to the ASPC.................................................114<br />

Inspecting and Repairing BRAM .............................................................116<br />

Digital I/O Utility ........................................................................................118<br />

dim Main Menu .................................................................................................118<br />

Procedure for Using the dim Utility ..................................................................118<br />

dim Reports .......................................................................................................119<br />

I/O Selection..............................................................................................119<br />

Printout of I/O Configuration.....................................................................119<br />

Digital Input/Output Signal Verification and Tracing.............................120<br />

Analog Input Monitor Utility .....................................................................121<br />

aim Main Menu .................................................................................................121<br />

Procedure for Using the aim Utility ..................................................................121<br />

aim Reports........................................................................................................122<br />

I/O Device Selection Report ......................................................................122<br />

AI Signal Report (Statistics) ......................................................................123<br />

AI Channel Gains Report ...........................................................................124<br />

AI Channel Slopes and Offsets Report ......................................................124<br />

Analog Input Signal Verification and Tracing ........................................125<br />

Using the Diagnostic Card Adapter.........................................................126<br />

Diagnostic Cards ...............................................................................................130<br />

Replacement Parts .............................................................................................138<br />

LED Interpretation.....................................................................................139<br />

Power Supply LEDs ..........................................................................................139<br />

ECF, ECS, and ECC LEDs ...............................................................................140<br />

ECF and ECC Boards (Only).....................................................................140<br />

MPRC LEDs......................................................................................................141<br />

Analog and Digital I/O Documentation....................................................146<br />

Power Down Analysis...............................................................................147<br />

Safety Interrupt Alert.........................................................................................147<br />

Power Down and DC Power Analysis...............................................................149<br />

Micro-Controller DC Power Log...............................................................152<br />

5 Software Diagnostic Tools.................................................. 155<br />

Software Diagnosis...................................................................................156<br />

General Software <strong>Troubleshooting</strong> Techniques ................................................156<br />

Resource ............................................................................................................156<br />

Operating System ..............................................................................................157<br />

Application ........................................................................................................157<br />

vi<br />

Table of Contents<br />

3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

AVOS and Application Utilities........................................................................158<br />

General AVOS Utilities .............................................................................158<br />

The inspect Utility .............................................................................................160<br />

The gstore Utility...............................................................................................162<br />

Identifying Sensor Configuration ............................................................164<br />

Identifying Software Release Levels .......................................................165<br />

Finding System Release Levels.........................................................................165<br />

Finding Subsystem Release Levels ...................................................................165<br />

Release Level Check of Diskettes .....................................................................166<br />

Signal/Measurement Processing Analysis and Reporting (smr)..........168<br />

Summary of smr Capabilities ............................................................................168<br />

Operation Overview ..........................................................................................169<br />

Triggers..............................................................................................................171<br />

Outputs ..............................................................................................................173<br />

Automatic Reporting and Retriggering .............................................................175<br />

Global Access....................................................................................................176<br />

Starting and Stopping Data Collection..............................................................176<br />

Overview of Menu Selection.............................................................................176<br />

General Procedure......................................................................................176<br />

Practical Application..................................................................................177<br />

Example......................................................................................................177<br />

Trigger Setup..............................................................................................177<br />

Collect Data On:.........................................................................................178<br />

smr Work Sheet .................................................................................................178<br />

Resource Checks ......................................................................................180<br />

Obtaining the monitor Report............................................................................180<br />

Obtaining derr, bfchk, and dfree Data...............................................................183<br />

How to Start the <strong>Scanning</strong> <strong>Platform</strong>........................................................185<br />

Displaying Reports within inspect ..........................................................187<br />

Standardize Report ............................................................................................187<br />

Sample Check Report........................................................................................188<br />

Calibrate Sample Report....................................................................................189<br />

Preparing On–Site Documentation..........................................................190<br />

Operation of the Sensor Health Pages....................................................191<br />

Off-Line Debug ..........................................................................................195<br />

6 Sensor <strong>Troubleshooting</strong>...................................................... 197<br />

Sensor Compensation - Operation and Setup .......................................198<br />

Definition of Terms ...........................................................................................198<br />

Operation ...........................................................................................................199<br />

Compensation Flag Setup..................................................................................201<br />

Air Column Compensation for Smart Sensors.......................................202<br />

Procedure to Disable Gap Compensation..........................................................202<br />

3BUS 208 055 R1101<br />

Table of Contents<br />

vii

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Changing the Measurement Resolution .................................................203<br />

Sensor Measurement Validity Codes ......................................................205<br />

Sensor Local Modes of Operation...........................................................206<br />

Basis Weight Sensor (TLK, TLP, and TLS) .............................................209<br />

<strong>Troubleshooting</strong> Flow Chart .............................................................................209<br />

Basis Weight Hardware Diagnostics.................................................................211<br />

To Open or Close Shutter:..........................................................................211<br />

To Unclamp or Clamp Electrometer ..........................................................211<br />

Infrared Moisture Sensor..........................................................................213<br />

Sensor Alarm Codes..........................................................................................213<br />

Alarms 4619/4719 and 4624/4724 .............................................................214<br />

Alarms 4615/4715, 4616/4716, 4617/4717, 4618/4718, & 4622/4722 .....215<br />

Alarm 4603/4703........................................................................................216<br />

Alarm 4608/4708........................................................................................217<br />

Alarm 4602/4702........................................................................................217<br />

Alarm 4621/4721........................................................................................217<br />

Alarms 4609/4709, 4611/4711, 4612/4712, 4613/4713, 4614/4714, and<br />

4679/4779............................................................................................217<br />

Correlation Problems.........................................................................................218<br />

General Correlation Scatter........................................................................218<br />

Rewet..........................................................................................................218<br />

Dirt Buildup on the Sensor Window..........................................................218<br />

Step-Outs in the Trend ...............................................................................219<br />

Composition Effects on Infrared Sensors...................................................219<br />

Operation at Design Limits ........................................................................219<br />

Insufficient Cooling....................................................................................220<br />

<strong>Troubleshooting</strong> Flow Charts............................................................................220<br />

Exercising the Gain Using Software Commands ..............................................237<br />

Using inspect..............................................................................................237<br />

Using the Health Page Pulse Monitor ........................................................237<br />

Exercising the Reflection IR Flag .....................................................................237<br />

Discontinuity Counter .......................................................................................238<br />

Ash Sensors (TLXR) .................................................................................239<br />

Ash Sensor Standardize Results ........................................................................240<br />

Ash Sensor Hardware Diagnostics ....................................................................242<br />

To Open or Close Shutter...........................................................................242<br />

To Unclamp or Clamp the Electrometer ....................................................242<br />

Ash Correlation Problems ...............................................................................244<br />

Air Bearing, Contacting, and Non-Contacting Caliper Sensors ...........246<br />

Exercising the Caliper Sensor ...........................................................................246<br />

<strong>Troubleshooting</strong> Alarms....................................................................................247<br />

Alarm Code Classification ................................................................................249<br />

Sensor Validity Codes .......................................................................................250<br />

viii<br />

Table of Contents<br />

3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Appendix A: Quick Reference Guide ..................................... 251<br />

<strong>Scanning</strong> <strong>Platform</strong> Utilities ......................................................................252<br />

Line Prompts .....................................................................................................252<br />

Special Functions ..............................................................................................252<br />

Utility Command Response to a File ................................................................252<br />

Utility Commands......................................................................................253<br />

File Commands..................................................................................................253<br />

Maintenance and Debugging.............................................................................253<br />

Performing a gstore ..................................................................................254<br />

Object Inspector........................................................................................255<br />

Display Object...................................................................................................255<br />

Modify Object ...................................................................................................256<br />

Special Characters .............................................................................................257<br />

Inspect Messages...............................................................................................257<br />

Command Format.......................................................................................257<br />

Examples:...................................................................................................258<br />

Using the Editor.................................................................................................258<br />

Enter Editor ................................................................................................258<br />

Editor Commands.......................................................................................258<br />

Editor Example...........................................................................................258<br />

Function Keys ...........................................................................................259<br />

DESQview Operations ..............................................................................260<br />

Open Window....................................................................................................260<br />

Close Window ...................................................................................................260<br />

Switch Window .................................................................................................260<br />

Rearrange...........................................................................................................260<br />

Move..................................................................................................................261<br />

Resize ................................................................................................................261<br />

Creating a Hot Key............................................................................................261<br />

Display Scripts ..................................................................................................262<br />

Off-Line Debug ..........................................................................................263<br />

Inspect Messages .....................................................................................264<br />

Application Tools ......................................................................................265<br />

Index ......................................................................................... 267<br />

3BUS 208 055 R1101<br />

Table of Contents<br />

ix

Blank Page

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

List of Figures<br />

Figure .............................................................................................................Page<br />

Figure 1-1 Diagram of Positioning Subsystem ..................................................... 2<br />

Figure 1-2 Sensor Head Positions & their Relationship to the Scanner ............... 14<br />

Figure 1-3 Frame Scan Limits Aligned about the Center of the Process ............. 15<br />

Figure 1-4 Position Relationships of Various Sheet Width Parameters ............... 20<br />

Figure 1-5 TBM Profiling Parameters (Sensor Measurement Using LO RES 1) 23<br />

Figure 1-6 Data Box Relationships for Different Resolutions ............................. 24<br />

Figure 1-7 Sheet Width and Profile Relationships ............................................... 40<br />

Figure 1-8 profiler object display ......................................................................... 43<br />

Figure 1-9 <strong>Scanning</strong> <strong>Platform</strong> Algorithm Processing ........................................... 49<br />

Figure 1-10 Sensor Input/Output Signal Relationship ........................................... 51<br />

Figure 1-11 Example Printout of Input Signal Array ............................................. 52<br />

Figure 1-12 Locating A2D Data in a Logical Channel .......................................... 54<br />

Figure 1-13 outputSignals as Inputs to Other Sensors ........................................... 56<br />

Figure 1-14 Example Printout of Output Signal Array .......................................... 57<br />

Figure 2-1 <strong>Troubleshooting</strong> Flow Chart A ........................................................... 64<br />

Figure 2-2 <strong>Troubleshooting</strong> Flow Chart B ........................................................... 65<br />

Figure 2-3 <strong>Troubleshooting</strong> Flow Chart C ........................................................... 66<br />

Figure 2-4 <strong>Troubleshooting</strong> Flow Chart D ........................................................... 67<br />

Figure 2-5 <strong>Troubleshooting</strong> Flow Chart E ........................................................... 68<br />

Figure 2-6 <strong>Troubleshooting</strong> Flow Chart F ............................................................ 69<br />

Figure 2-7 <strong>Troubleshooting</strong> Flow Chart G ........................................................... 70<br />

Figure 2-8 <strong>Troubleshooting</strong> Flow Chart H ........................................................... 71<br />

Figure 2-9 <strong>Troubleshooting</strong> Flow Chart I ............................................................. 72<br />

Figure 2-10 <strong>Troubleshooting</strong> Flow Chart J ............................................................ 73<br />

Figure 2-11 <strong>Troubleshooting</strong> Flow Chart K ........................................................... 74<br />

Figure 2-12 <strong>Troubleshooting</strong> Flow Chart L ........................................................... 75<br />

Figure 3-1 Servo Diagnostics Report ................................................................... 105<br />

Figure 3-2 Frame Tuning Utility Menu Tree ........................................................ 111<br />

Figure 3-3 Description of ft Menu Options .......................................................... 112<br />

Figure 4-1 Debug Port on the <strong>Scanning</strong> <strong>Platform</strong> ................................................ 115<br />

Figure 4-2 Example of Diskette Repair Activity .................................................. 116<br />

Figure 4-3 Main Menu for the Digital I/O Utility ................................................ 118<br />

Figure 4-4 I/O Selection Menu ............................................................................. 119<br />

Figure 4-5 Digital I/O Monitor ............................................................................. 119<br />

Figure 4-6 Partial Example of an I/O Configuration Printout .............................. 119<br />

Figure 4-7 aim Main Menu ................................................................................... 121<br />

3BUS 208 055 R1101<br />

List of Figures<br />

xi

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Figure 4-8 I/O Selections from the aim Report .................................................... 122<br />

Figure 4-9 Device Selected ................................................................................... 122<br />

Figure 4-10 aim Input Values ................................................................................. 123<br />

Figure 4-11 aim Statistics Display Page ................................................................. 123<br />

Figure 4-12 aim Software Gains Report ................................................................. 124<br />

Figure 4-13 aim Slopes and Offsets Report ........................................................... 124<br />

Figure 4-14 Example of aim Analog Input Display ............................................... 125<br />

Figure 4-15 ASPC Backplane (-003 Version Shown) ............................................ 127<br />

Figure 4-16 Test Board Hookup ............................................................................. 128<br />

Figure 4-17 Carriage Assembly .............................................................................. 129<br />

Figure 4-18 Diagnostic Card: Top Power .............................................................. 130<br />

Figure 4-19 Diagnostic Card: Bottom Power ......................................................... 131<br />

Figure 4-20 Diagnostic Card: Top Signal ............................................................. 132<br />

Figure 4-21 Diagnostic Card: Bottom Signal Sensor ............................................ 133<br />

Figure 4-22 Diagnostic Card: Backplane Power ................................................... 134<br />

Figure 4-23 Diagnostic Card: Bottom Auxiliary Power ......................................... 135<br />

Figure 4-24 Detector Module Diagnostics Card .................................................... 136<br />

Figure 4-25 Source Module Diagnostics Card ....................................................... 137<br />

Figure 4-26 Smart Plarform Electronics Cabinet (-003 Backplane) ...................... 143<br />

Figure 4-27 Location of SMI and BRAM Boards .................................................. 144<br />

Figure 4-28 Location of OSPS2 and EC24V (SP1200) ......................................... 145<br />

Figure 4-29 Example of Analog I/O Documentation ............................................. 146<br />

Figure 4-30 Historical Trend for Microcontroller DC Voltages ............................ 153<br />

Figure 5-1 gstore Menu Screen ............................................................................ 162<br />

Figure 5-2 Hierarchical View of the smr Utility .................................................. 169<br />

Figure 5-3 smr Menu Selection Tree .................................................................... 170<br />

Figure 5-4 Analog and Measurement Historical Data Display ............................ 174<br />

Figure 5-5 Digital Historical Data Display ........................................................... 174<br />

Figure 5-6 Statistical Data Display ....................................................................... 175<br />

Figure 5-7 Monitor Command Menu ................................................................... 180<br />

Figure 5-8 Monitor General Time Display ........................................................... 181<br />

Figure 5-9 monitor Resource Activity Display .................................................... 182<br />

Figure 5-10 Example of the Use of derr, bfchk, and dfree ..................................... 183<br />

Figure 5-11 Standardize Report .............................................................................. 187<br />

Figure 5-12 Check Sample Report ......................................................................... 188<br />

Figure 5-13 Check Sample Report ......................................................................... 189<br />

Figure 5-14 Health Overview Page ........................................................................ 191<br />

Figure 5-15 Basis Weight Health Report Showing Sample Check ........................ 193<br />

Figure 5-16 Basis Weight Health Page Showing Calibrate Sample ....................... 194<br />

Figure 6-1 Flow Diagram of Compensation Selection Logic ............................... 200<br />

xii List of Figures 3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Figure 6-2 Basis Weight <strong>Troubleshooting</strong> Flow Chart ........................................ 210<br />

Figure 6-3 Sensor Head Signals ........................................................................... 216<br />

Figure 6-4 <strong>Troubleshooting</strong> Flow Chart 1 ........................................................... 221<br />

Figure 6-5 <strong>Troubleshooting</strong> Flow Chart 2 ........................................................... 222<br />

Figure 6-6 <strong>Troubleshooting</strong> Flow Chart 3 ........................................................... 223<br />

Figure 6-7 <strong>Troubleshooting</strong> Flow Chart 4 ........................................................... 224<br />

Figure 6-8 <strong>Troubleshooting</strong> Flow Chart 5 ........................................................... 225<br />

Figure 6-9 <strong>Troubleshooting</strong> Flow Chart 6 ........................................................... 226<br />

Figure 6-10 <strong>Troubleshooting</strong> Flow Chart 7 ........................................................... 227<br />

Figure 6-11 <strong>Troubleshooting</strong> Flow Chart 8 ........................................................... 228<br />

Figure 6-12 <strong>Troubleshooting</strong> Flow Chart 9 ........................................................... 229<br />

Figure 6-13 <strong>Troubleshooting</strong> Flow Chart 10 ......................................................... 230<br />

Figure 6-14 <strong>Troubleshooting</strong> Flow Chart 11 ......................................................... 231<br />

Figure 6-15 <strong>Troubleshooting</strong> Flow Chart 12 ......................................................... 232<br />

Figure 6-16 <strong>Troubleshooting</strong> Flow Chart 13 ......................................................... 233<br />

Figure 6-17 <strong>Troubleshooting</strong> Flow Chart 14 ......................................................... 234<br />

Figure 6-18 <strong>Troubleshooting</strong> Flow Chart 15 ......................................................... 235<br />

Figure 6-19 <strong>Troubleshooting</strong> Flow Chart 16 ......................................................... 236<br />

Figure 6-20 Ash Sensor <strong>Troubleshooting</strong> Flow Chart ........................................... 239<br />

Figure 6-21 Ash Correlation <strong>Troubleshooting</strong> Flow Chart .................................... 245<br />

3BUS 208 055 R1101<br />

List of Figures<br />

xiii

Blank Page

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

1<br />

Selected Theories of Operation<br />

This section presents an overview of profile and motion theory for both<br />

ABB 1190 and ABB 1180 systems.<br />

This chapter contains the following major sections:<br />

Section ...............................................................................................Page<br />

Positioning System Overview ........................................................................ 2<br />

Head Package Dimensions Setup ................................................................... 3<br />

How Head Position is Determined ................................................................. 5<br />

Motion Theory ............................................................................................... 7<br />

Profile Development for 1190 Systems ......................................................... 19<br />

1190 Measurement Analysis using On-Line Utilities .................................... 27<br />

Profile Development for 1180 Systems ......................................................... 38<br />

Sensor Theory ................................................................................................ 49<br />

3BUS 208 055 R1101<br />

Selected Theories of Operation<br />

1

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

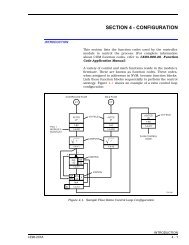

Positioning System Overview<br />

The positioning subsystem is made up of several components encompassing both<br />

software and hardware elements. See Figure 1-1. In simplified terms, scanner01<br />

determines what is to be done, getting needs from other parts of the system and<br />

determining priorities. servo01, upon a request from the scanner01, decides how<br />

to do it by establishing the needed acceleration, cruise, deceleration, and homing<br />

instructions. The ECF portion of the servo software translates these instructions<br />

for the Motor Controller which delivers the required energy to the motor. It is<br />

here that the motor controller slope and offset (MCslope & MCcoffset) are applied<br />

to the voltage being sent to the Motor Controller. The action of the motor rotates<br />

the encoder whose output is interpreted by the ECF who, in turn, converts it into<br />

position complete information. This is sent to the servo01 who determines<br />

completion of the task and notifies the scanner01 that it is done.<br />

MPRC<br />

scanner01<br />

ECF<br />

Micro–controller<br />

(servo execution)<br />

Motor<br />

Controller<br />

motor<br />

trajectory<br />

servo01<br />

(trajectory)<br />

position<br />

complete<br />

encoder<br />

Figure 1-1 Diagram of Positioning Subsystem<br />

2 Selected Theories of Operation<br />

3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Head Package Dimensions Setup<br />

The sensor head package dimensions are used to control the orientation of the<br />

window over the sheet as the head moves through its various sequences. The<br />

variables used for this purpose can be manipulated to accomplish a variety of head<br />

behavior patterns as the head moves from off sheet to a scanning condition. This<br />

section contains information about the locations of these variables and a procedure<br />

for determining their values. The head package dimensional variables are defined<br />

below. Two basic equations deal with bringing the head on sheet, depending on<br />

whether auto edge-of-sheet is turned on or not:<br />

Auto Edge-of-Sheet Turned Off:<br />

Prepare to measure position=homeScanLimit + homeHeadClearance - homeWindowClearance<br />

+ curlDist + positioningSafetyFactor<br />

Auto Edge-of-Sheet Turned On:<br />

Prepare to measure position = homeEOS + homeHeadClearance + curlDist + positioningSafetyFactor<br />

3BUS 208 055 R1101<br />

Selected Theories of Operation<br />

3

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Definition of Head Package Dimensions<br />

homeHeadClearance This variable represents the distance between the home–side<br />

edge of the sensor head package and the measurement center<br />

line. Its value will depend on how far beyond the home edge of<br />

the sheet the head must come before starting the Prepare To<br />

Measure activity. In any event, it must always be larger than the<br />

homeWindowClearance.<br />

farHeadClearance This variable represents the distance between the far–side edge<br />

of the sensor head package and the measurement center line.<br />

This variable only comes into play when the head must enter the<br />

prepare to measure position from the far side of the scanner. In<br />

that case, it will have the same function as the<br />

homeHeadClearance. When it is to be used, it must be larger<br />

than the farWindowClearance.<br />

homeWindowClearance This variable represents the distance, on the home–side of the<br />

head package, from the measurement center line to the edge of<br />

the largest sensor window in the head package. The window<br />

radii will range from approximately 0.3 inches for an STLXR<br />

Ash sensor, to 2.5 inches for a HemiPlus IR sensor.<br />

farWindowClearance This variable represents the distance, on the far–side of the head<br />

package, from the measurement center line to the edge of the<br />

largest sensor window in the head package. The window radii<br />

will range from approximately 0.3 inches for an STLXR Ash<br />

sensor, to 2.5 inches for a HemiPlus IR sensor.<br />

curlDist<br />

This variable represents the additional distance that the heads<br />

will travel when first coming on–sheet to the prepare-tomeasure<br />

position to assure that sheet contacting sensors, such as<br />

caliper, are fully on-sheet before making contact. The head will<br />

then back up to the current homeScanLimit to start scanning. If<br />

desired, the entire prepare-to-measure positioning can be<br />

accomplished with the homeHeadClearance dimension, leaving<br />

the curlDist at its default value of 0.1 units.<br />

positioningSafetyFactor This is a small amount of distance (default of approximately 0.5<br />

inches) which is included in the various positioning algorithms<br />

to assure that errors made in determining the dimensional<br />

characteristics of the head and the sheet positions, will result in<br />

a minimal exposure of the window being off the sheet during a<br />

measure operation.<br />

The locations of these positions on a <strong>Scanning</strong> <strong>Platform</strong> sensor head package are<br />

shown in Figure 1-2 on page 14.<br />

4 Selected Theories of Operation<br />

3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

How Head Position is Determined<br />

This section will trace the operational steps and calculations being made along the<br />

way as head position calibration is established within the <strong>Scanning</strong> <strong>Platform</strong>.<br />

Several components and software programs come into play as calibration takes<br />

place. These are:<br />

Table 1-1 Head Position Calibration Components and Programs<br />

The Digital Encoder<br />

ECF Micro–controller<br />

ft. utility<br />

home limit switch<br />

home mechanical stop<br />

home reference plane<br />

A electro-mechanical device which outputs a<br />

stream of pulses. Based on the gear ratios used,<br />

each pulse represents 0.010 in. of linear motion.<br />

Each rotation of the shaft generates an index pulse<br />

which computes out to once every 20 in.<br />

Contains hardware devices to collect and process<br />

the pulses coming from the encoder. Resident<br />

software then converts the information into<br />

engineering units for the rest of the system to use.<br />

A diagnostic utility which is used to establish the<br />

relationships between the encoder and the physical<br />

dimensions of the frame.<br />

A device which will interrupt the motor drive<br />

power when activated by the head carriage<br />

assembly as it drives toward the home end column.<br />

It serves to prevent a mechanical collision with the<br />

end column as well as identifying a point where the<br />

encoder signals can become synchronized.<br />

A bump block several inches past the limit switch<br />

(about 4 in.), which defines the absolute farthest the<br />

head can go in the home direction.<br />

The point in space where position of the head<br />

package on the frame are referenced to. This is<br />

typically the inside surface of the home end<br />

column. It could be any structural point that has a<br />

fixed positional relationship with the frame as long<br />

as it is past the head carriage position.<br />

With these definitions in mind, the steps to head position calibration can be<br />

explained as follows. In order to perform the head position calibration, the encoder<br />

must be synchronized. This happens when the system is started up and the Frame<br />

Control Panel (FCP) is placed in remote. At this point in time, the head is driven<br />

in search of the home limit switch. When the switch is tripped, the head stops and<br />

immediately the direction of motion is reversed and the head is moved very slowly<br />

until the system senses that the limit switch has disengaged. At this point, the A2D<br />

value becomes arbitrarily defined as 2001. This A2D value has the default engSlope<br />

and engOffset for headPosition01_ai applied to it to establish a default head<br />

position. The ft utility can now be activated to do the head position calibration.<br />

3BUS 208 055 R1101<br />

Selected Theories of Operation<br />

5

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

The ft utility does several things during the course of calibration. First, it modifies<br />

the engSlope and engOffset of headPosition01_ai so that all reported positions<br />

will be relative to the home reference plane. Then it divides up the maximum travel<br />

available (farTravelLimit - homeTravelLimit) into an A2D range of 1000 to 31767<br />

units. It also establishes an a2dConversionSlope and a2dConversionOffset which<br />

is used to convert the reported head positions into pseudo-A2D units for transmittal<br />

to a host. This slope and offset is stored in the pmmFrame01 object.<br />

The sequence of steps is as follows. The operator places the head at the home<br />

mechanical stop as directed by the utility. The distance from the home reference<br />

plane and the head carriage support surface is then measured and the value entered<br />

into the utility. The utility then adds a fixed amount to this value so that the value<br />

becomes the distance from the home reference plane to the measure window center<br />

line. A different add-on dimension is used for SP1200 and SP700 due to slight<br />

differences in their head sizes.<br />

It should be noted here that it really does not matter what the entered value is. It<br />

only becomes important if someone decides to take a tape measure and check the<br />

distance from the measure window centerline to the home reference plane. CMC<br />

does use the value in its setup, however, it does not care what it is in reference to,<br />

only that it be consistent over time.<br />

Here are some of the equations the calibration goes through:<br />

Hpslope = engSlope = 0.0254/units (where units = 1.0 for cm, and 2.54 for in.)<br />

Hpoffset = engOffset = homePosition - (homePosCounts * engSlope)<br />

a2dConversionSlope = (farTravelLimit - homeTravelLimit)/30767<br />

a2dConversionOffset = homeTravelLimit - (1000 * a2dConversionSlope)<br />

Here is a summary of what happens to an actual head position as it gets processed<br />

and sent up to a host. The ECF micro–controller software has kept track of encoder<br />

pulses with respect to the point at which it was synchronized. The current position,<br />

therefore, has a specific count associated with it. This count is converted to customer<br />

units by applying the engSlope and engOffset. Along with being used by other<br />

parts of the <strong>Scanning</strong> <strong>Platform</strong>, the position is also converted to pseudo-a2d units<br />

for availability to the host. This is done by taking the head position in customer<br />

units, and applying the a2dConversionSlope and a2dConversionOffset factors to<br />

it. The exception to this are AccuRay Direct applications which present the host<br />

with data in terms of customer units.<br />

6 Selected Theories of Operation<br />

3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

Motion Theory<br />

Servo Theory of Operation<br />

The scanner sends trajectories to the servo asynchronously and without regard to<br />

the servo’s current duties. The previously requested trajectory may be overridden<br />

at any time by the scanner, even if the servo has not yet responded to that previously<br />

received trajectory.<br />

A trajectory consists of the following information. Refer to Table 1-2.<br />

Type:<br />

FIXED_POINT<br />

STOP_PAST<br />

MOVING<br />

HOLD_POSITION<br />

STOP<br />

POSITION<br />

VELOCITY<br />

MESSAGE<br />

Table 1-2 Trajectory Type and Definition<br />

One of the following:<br />

Go to position and stop (single point, stdz position, etc.)<br />

Go slightly beyond position and stop (scanning)<br />

Go to position and remain moving at speed<br />

Stop and return to current position<br />

Stop and remain at resulting position<br />

Desired final position in units of head position<br />

Desired average velocity to position<br />

Response to the scanner upon satisfaction of this trajectory<br />

Most trajectory requests from the scanner are of the type STOP_PAST; this insures<br />

that the requested positions are attained plus a small dead band. Using STOP_PAST<br />

trajectory requests insures that data is filled in all assigned profile boxes.<br />

Occasionally, the scanner will request a STOP type trajectory in order to guarantee<br />

that it has an unchanging position before making motion decisions. MOVING and<br />

HOLDING_POSITION are rarely used. FIXED_POINT is used to achieve Off–<br />

Sheet, Standardize, and Single Point positions.<br />

The servo attempts to satisfy the requested trajectory by applying four control<br />

phases in sequential order. These phases are defined in Table 1-3.<br />

Table 1-3 Control Phases and Definitions<br />

Control Phase<br />

ACCELERATION<br />

CRUISING<br />

DECELERATION<br />

HOMING<br />

Definition<br />

Increments the velocity from the current output value<br />

Maintains the requested velocity via Direct Digital Control<br />

(DDC)<br />

Decrements the velocity to the final value<br />

Closes on the final position at the minimum velocity<br />

These four phases are unconditionally performed, regardless of the trajectory.<br />

3BUS 208 055 R1101<br />

Selected Theories of Operation<br />

7

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

When the trajectory is first received from the scanner, the servo computes a vector<br />

for each of the first three phases: ACCELERATION, CRUISING, and<br />

DECELERATION based on the tuning parameters provided to it, such as vmin,<br />

vmax, Accel, xdb, vdb, and so forth. These vectors define the predicted endpoint<br />

for each phase in space and time. The fourth phase HOMING, infers its end point<br />

from the original trajectory and therefore does not need a vector to define it, for<br />

example, the final position at zero velocity. The run task of servo will make every<br />

effort to match these predicted end points.<br />

Each of the three vectors contain the following information. Refer to Table 1-4.<br />

Table 1-4 Information Type and Description<br />

Information Type<br />

POSITION<br />

VELOCITY<br />

INCREMENT<br />

DURATION<br />

Description<br />

Predicted final position for this phase<br />

Desired termination velocity for this phase<br />

Per execution VELOCITY or POSITION<br />

increment for this phase<br />

Predicted total time of execution for this phase<br />

The Servo run task determines when each phase is finished by performing the<br />

following comparisons (referred to as the “done check”). Refer to Table 1-5.<br />

Table 1-5 Motion Phases and Descriptions<br />

Comparison<br />

ACCELERATION<br />

CRUISING<br />

DECELERATION<br />

HOMING<br />

Definition<br />

Finished when current output velocity exceeds the<br />

requested speed for this phase or when the requested<br />

acceleration is close to zero.<br />

Finished when the position is close to the estimated<br />

end point<br />

OR<br />

Finished when the elapsed time is greater than the<br />

predicted duration<br />

OR<br />

Finished when the trajectory type is STOP<br />

Finished when the position is close to the predicted end<br />

point<br />

OR<br />

Finished when the elapsed time is greater than the<br />

predicted duration<br />

OR<br />

Finished when the velocity is within vmin of the<br />

desired speed<br />

Finished when the position is close to the trajectory<br />

end point<br />

OR<br />

Finished when the trajectory is STOP<br />

8 Selected Theories of Operation<br />

3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

When the final phase, HOMING, is complete, the required message is returned to<br />

the scanner object to indicate that this trajectory has been achieved.<br />

The following phase logic is executed by the Servo’s run task every 200<br />

milliseconds. Each phase executes its “done check” prior to continuing. When the<br />

“done check” is complete, then the next phase begins.<br />

ACCELERATION Phase Operation<br />

During the ACCELERATION phase, Servo increments its velocity output by adding<br />

the predicted velocity increments during each sampleInterval. The predicted<br />

velocity increment is derived from the following equation:<br />

inc [this phase] = Accel * sampleInterval<br />

CRUISING Phase Operation<br />

During the HOMING phase, the positioning is handled in two different ways. One<br />

way is used when the trajectory mode is scanning and the other is used for all other<br />

trajectory modes.<br />

For the normal scanning mode (called STOP_PAST in the program), the head is<br />

driven toward the target until it reaches a location close to the target and then the<br />

output to the motor controller is set to zero and the head comes to a stop slightly<br />

past the target. The servo logic monitors the distance the head travels after<br />

outputting the zero output (the stopping distance) in order to determine how far in<br />

advance of the target to start stopping the head. A separate distance is kept<br />

depending on the direction the head is moving. Initially, the servo logic has no<br />

history of the stopping distance so it defaults to using the actual target for when to<br />

start stopping. But after scanning in both directions the operation of the servo will<br />

get much better. This is a key point to keep in mind, because after every restart the<br />

system must go through this learning process. That means that the initial scans<br />

after a restart will not be as accurate in terms of achieving the correct EOS position<br />

as will later scans. The learning curve is, however, fairly short with only two to<br />

four scans needed to establish reasonable results.<br />

The other trajectory modes; i.e., single point, standardize, etc., are handled in the<br />

traditional positioning (called NON_STOP_PAST in the program) way. The head<br />

is driven toward the target until it gets to a location close to the target and then the<br />

output to the motor controller is set to zero and the head should come to a stop<br />

slightly past the target. The determination of how far in advance of the target to<br />

start stopping is the same as for the scanning mode. After once trying to stop, the<br />

logic reverts back to keeping the head inside the deadband of xdb around the target.<br />

The stopping distance is not monitored for the positioning cases. In this way, the<br />

stopping distance is more accurately kept for the scanning logic (scanning is the<br />

mode desired to optimize).<br />

During the CRUISING phase, Servo performs a DDC-PI (proportional and integral<br />

direct digital control) algorithm on the desired scan position which insures that the<br />

position error is kept to a minimum.<br />

3BUS 208 055 R1101<br />

Selected Theories of Operation<br />

9

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

A motion restriction detector has been built into this phase which senses the<br />

increased effort required to overcome an obstacle. Its sensitivity may be adjusted<br />

infinitely from zero. If an obstacle has been detected, then the head is immediately<br />

stopped and the platform is put in local. To recover, the platform must be cycled<br />

through local using the pushbuttons at the platform control panel. A console<br />

message notes this local condition.<br />

The algorithm used for the obstacle detection is:<br />

IF: ddc speed is more than ddcExcessiveErrorPercent greater than<br />

requested speed<br />

AND IF: measured motion is less than ddcRestrictedMotionPercent of<br />

expected motion<br />

OR IF: measured motion is close to zero<br />

THEN: motion is restricted.<br />

DECELERATION Phase Operation<br />

During the DECELERATION phase, Servo decrements the velocity output by<br />

subtracting the predicted velocity increment each sampleInterval. The predicted<br />

velocity increment is derived from the following equation:<br />

inc [ACCELERATION] = Accel * sampleInterval<br />

The terminal velocity for this phase is assumed to be vmin for most trajectories<br />

since the HOMING phase is next and will zero the output immediately if the position<br />

dead band, xdb, has been satisfied. This velocity assures that “stiction” (an<br />

impedance to free movement either by friction or stickiness) does not occur between<br />

deceleration and homing.<br />

10 Selected Theories of Operation<br />

3BUS 208 055 R1101

PROPRIETARY DATA: This document contains proprietary data of ABB Inc. No disclosure, distribution (electronic or otherwise),<br />

reproduction, or other means of dissemination may be made without written permission.<br />

HOMING Phase Operation<br />

For both modes of HOMING when trying to drive the head (non-zero output to the<br />

motor controller), the initial output to the motor controller will be the activeVmin<br />

speed. If the head stalls (no movement when trying to drive the head), the output<br />

is increased by a small amount velInc (velInc = vminFilterFactor * activeVmin).<br />

After two time iterations, the movement is checked again. If there is still no<br />

movement, the output is again increased by velInc. This procedure is repeated until<br />

the head shows movement.<br />